stereodreieck86

Active member

Hello fellow modelers,

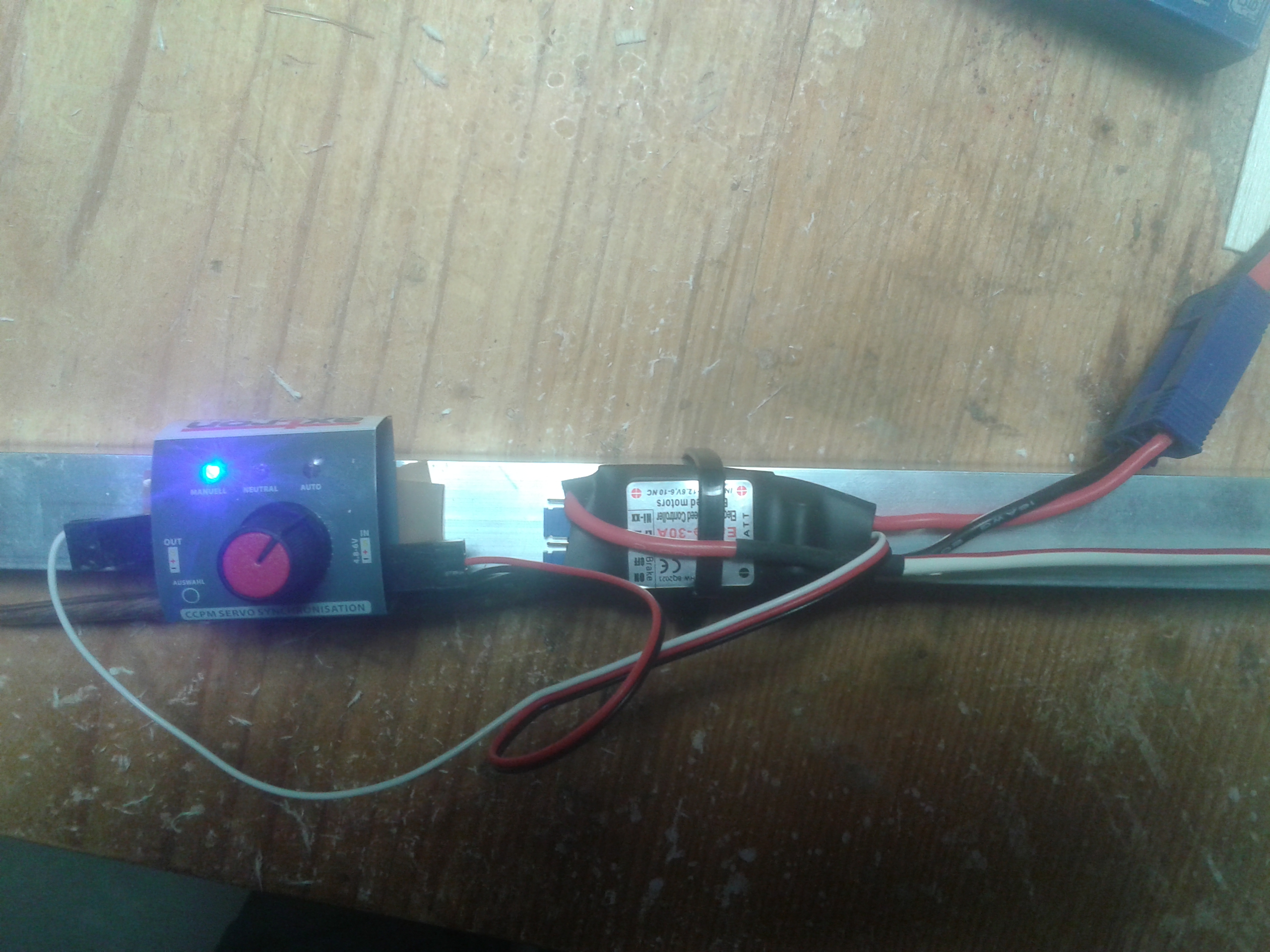

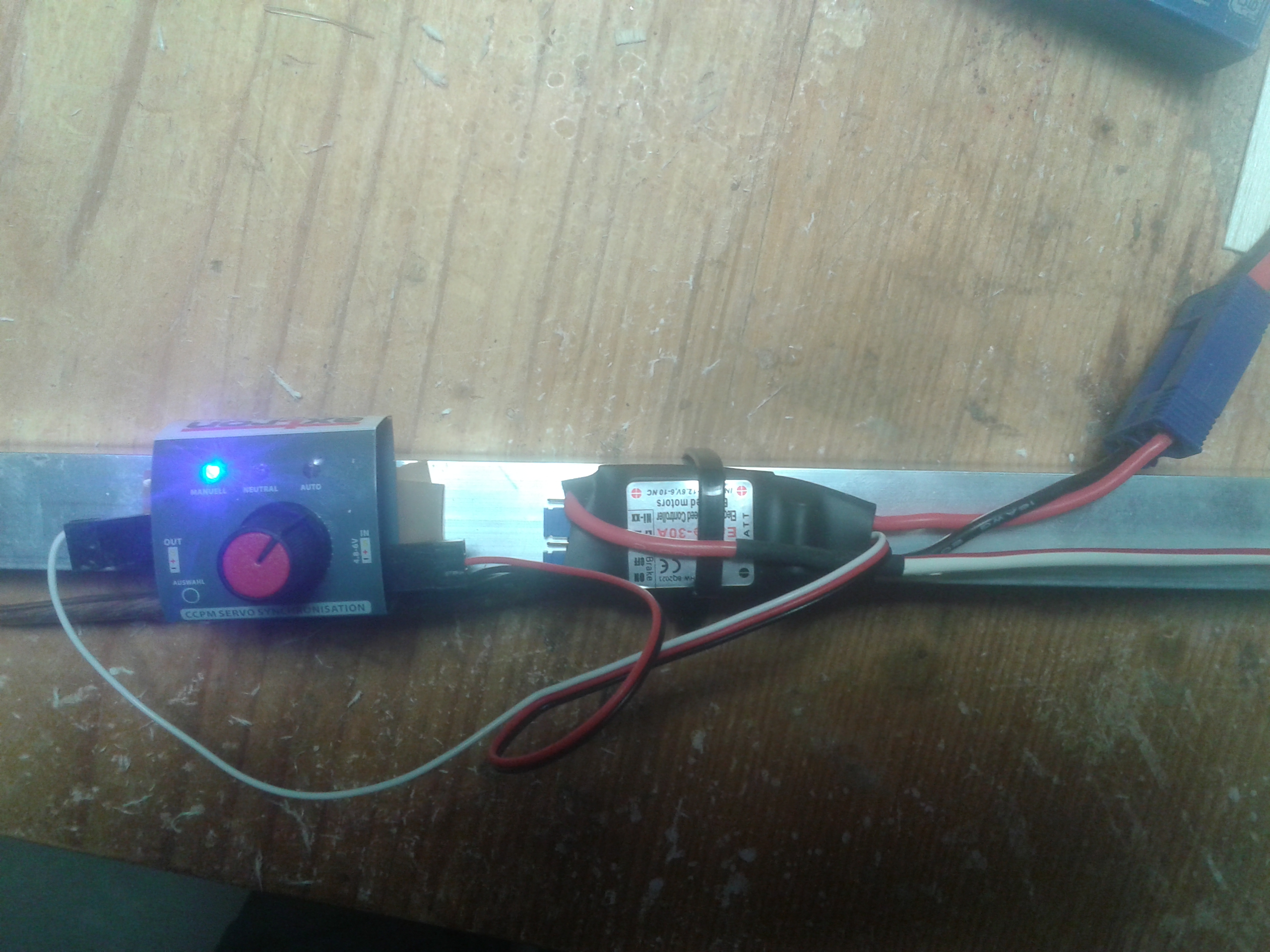

I have bought a Styrofoam cutter on Ebay (https://www.ebay.de/itm/133189036346?ViewItem=&item=133189036346) and assembled. The entire construction is powered by a 3S battery controlled by a brush regulator and servo tester. The bow is over a meter wide but the maximum current is only measly 0.9Ampere in the result, the cutting speed is not sufficient and the heat barely enough to cut the foam.

If I move a clamp on the wire and thus shorten the arc, I get a higher current (1.2Ampere) but then I have less cutting width available to increase the voltage would certainly also be a possibility but then I would have another ( expensive) regulator (6S capable) buy.

Have I overlooked something or is the higher voltage the only solution?

I have bought a Styrofoam cutter on Ebay (https://www.ebay.de/itm/133189036346?ViewItem=&item=133189036346) and assembled. The entire construction is powered by a 3S battery controlled by a brush regulator and servo tester. The bow is over a meter wide but the maximum current is only measly 0.9Ampere in the result, the cutting speed is not sufficient and the heat barely enough to cut the foam.

If I move a clamp on the wire and thus shorten the arc, I get a higher current (1.2Ampere) but then I have less cutting width available to increase the voltage would certainly also be a possibility but then I would have another ( expensive) regulator (6S capable) buy.

Have I overlooked something or is the higher voltage the only solution?