Duffusmonkey

Junior Member

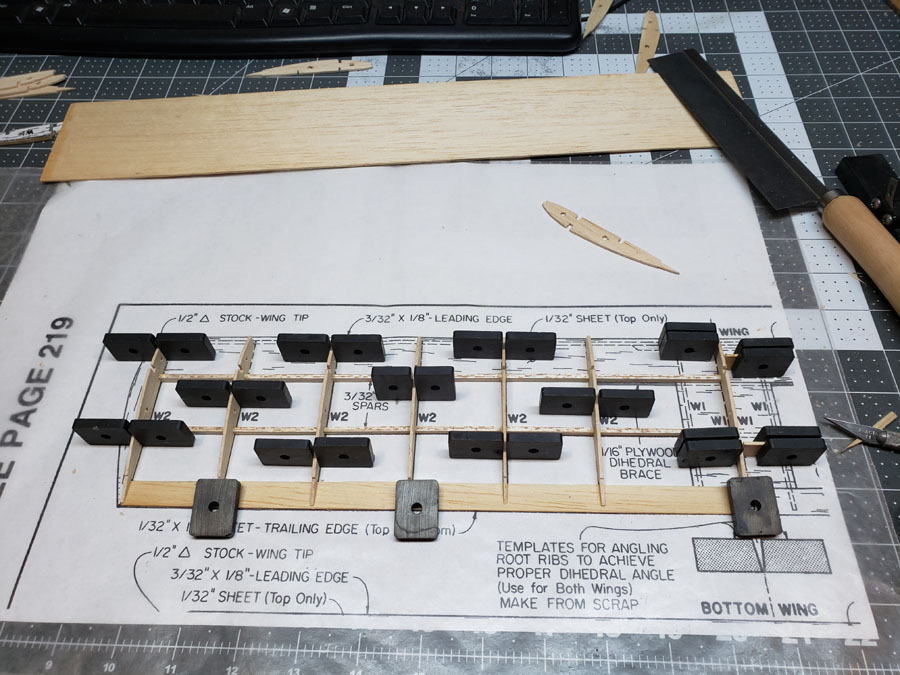

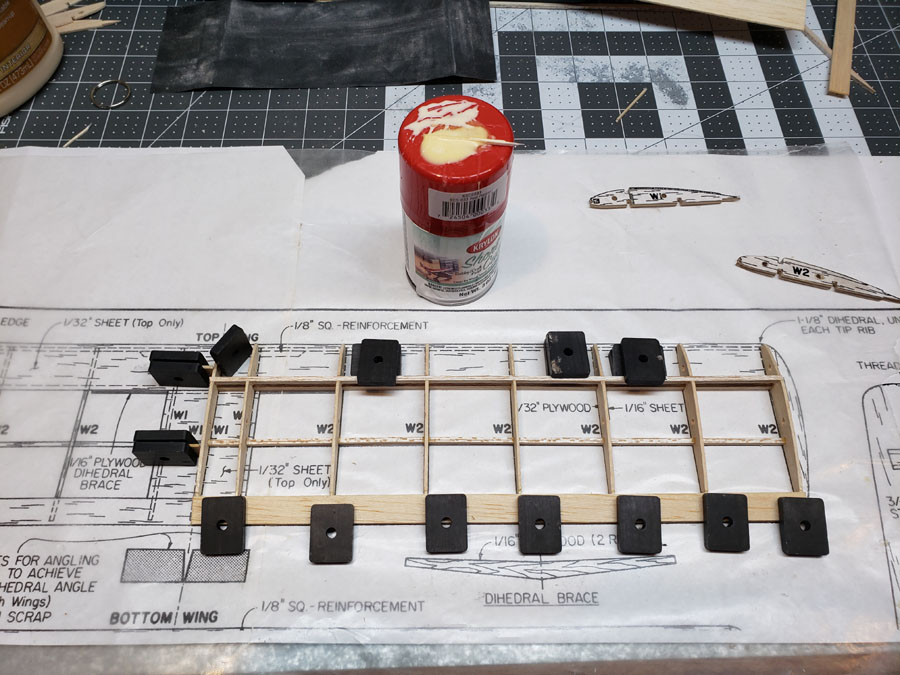

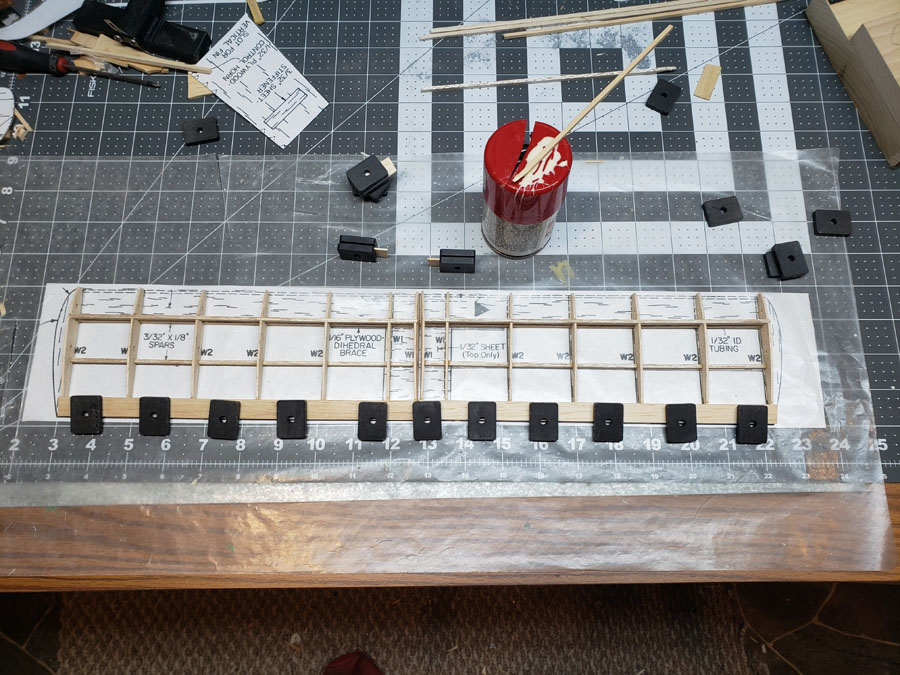

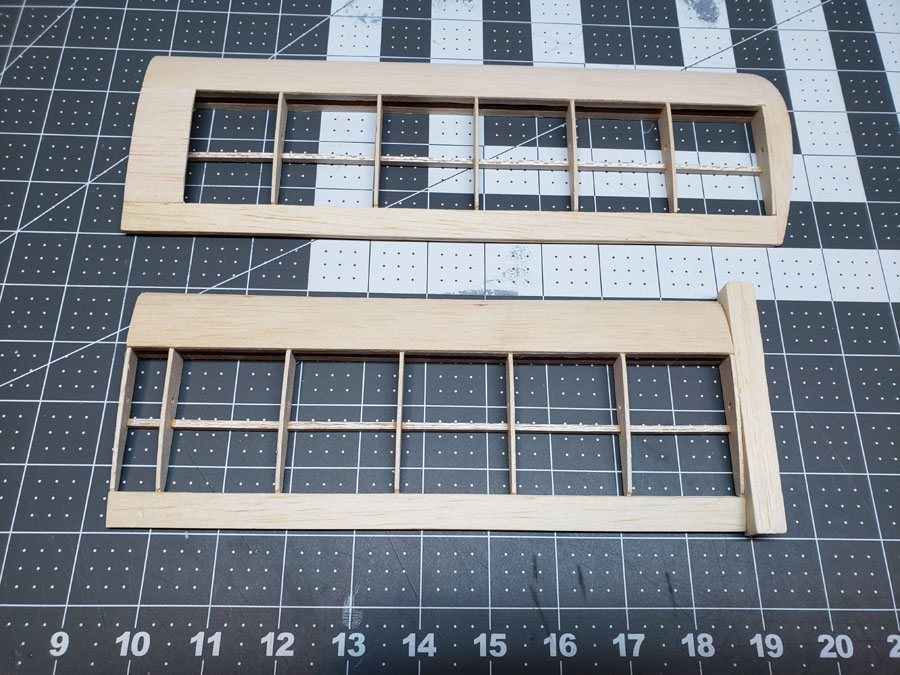

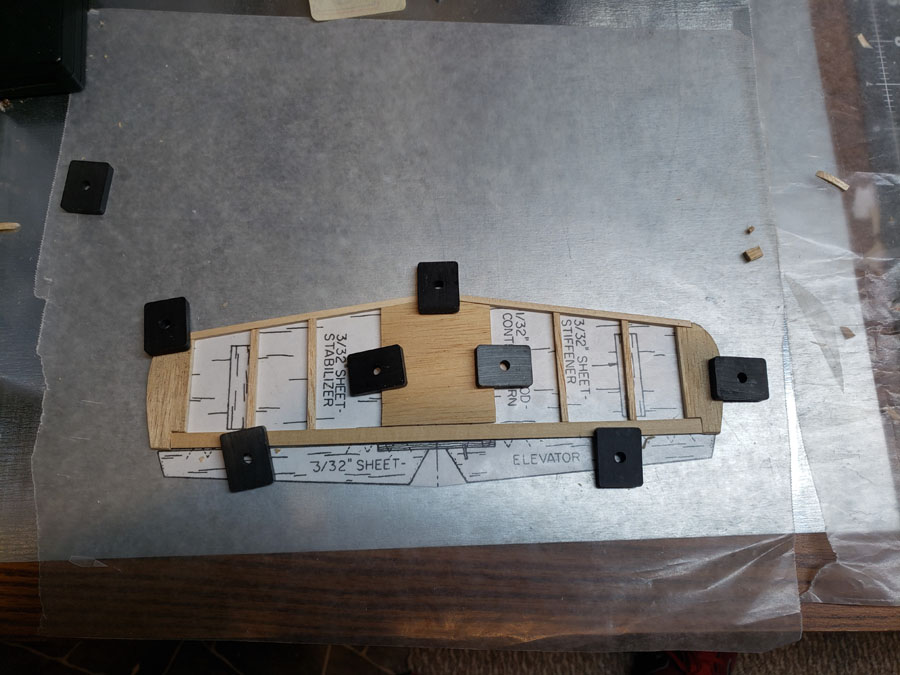

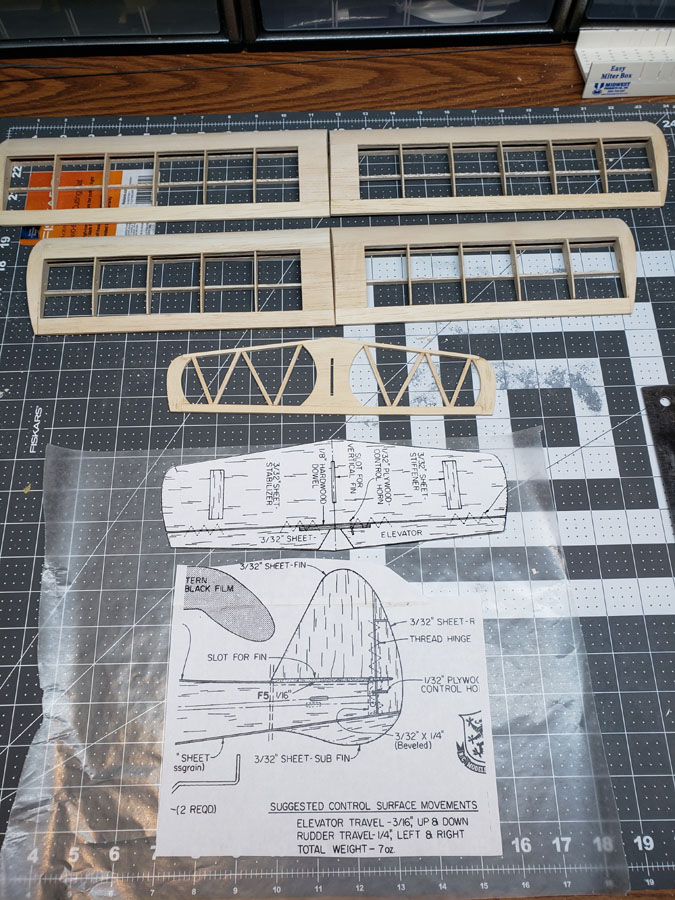

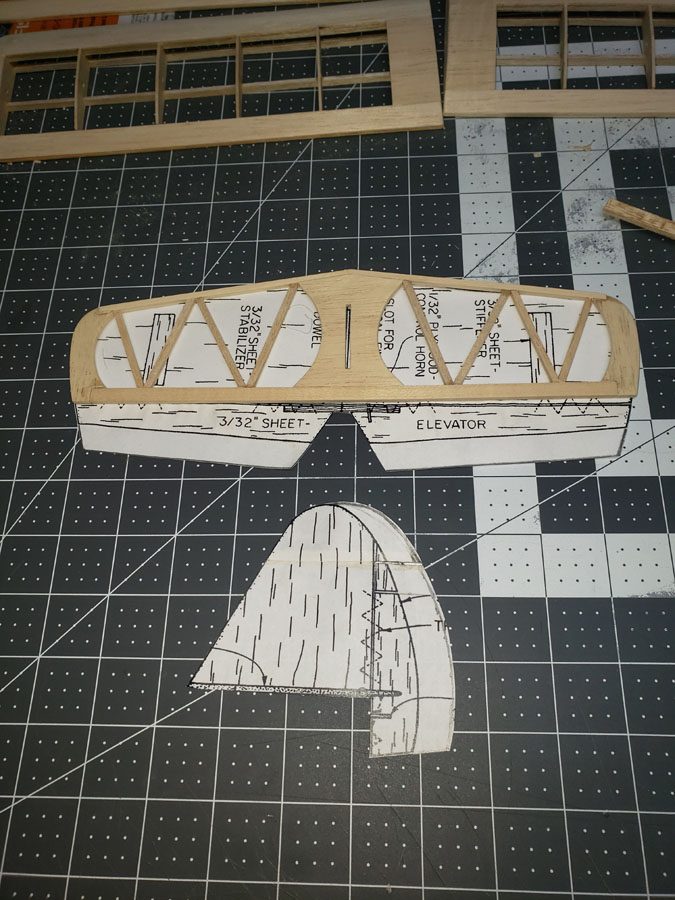

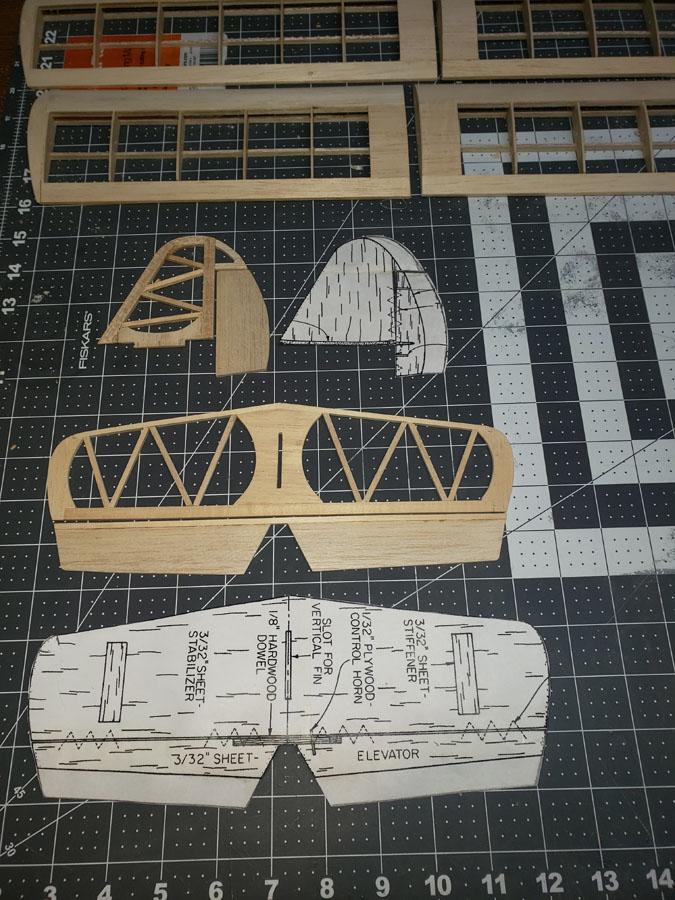

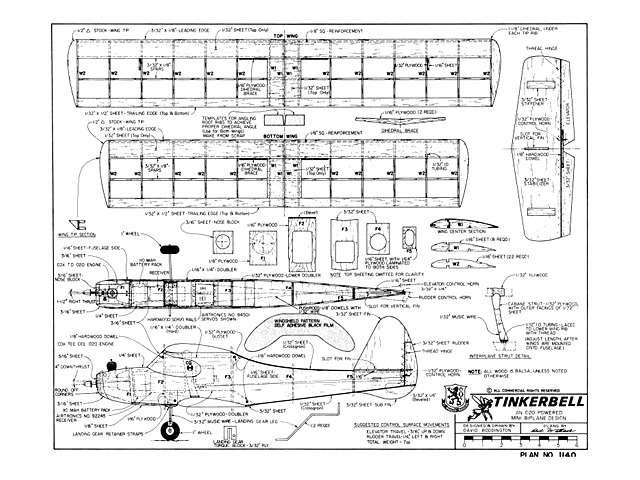

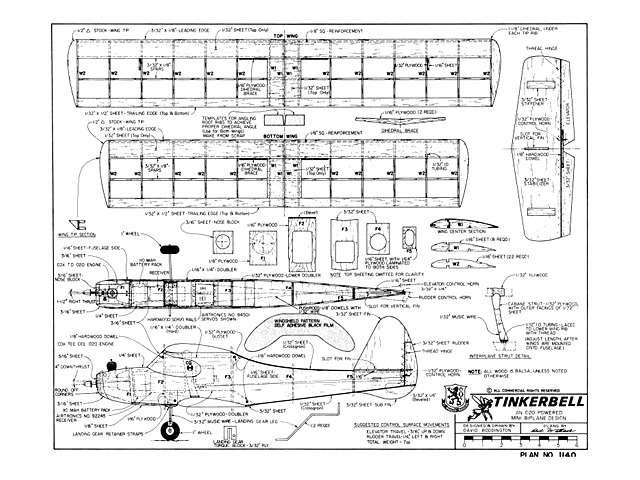

I decided to scratch build a balsa model... because I had a lot of balsa just collecting dust in my basement. There are so many plans for RC planes on the internet that actually spent a few days looking for candidates. I kind of gave up because they were too many options. I decided to build one of the first plans that caught my attention. The Tinkerbell designed by David Boddington , The plans were published in RCModeler magazine in 1993.

https://outerzone.co.uk/plan_details.asp?ID=6306

I picked this plan because I wanted a small biplane and I already have a powertrain that I THINK will work in it. To be honest I have never built a model completely from scratch and it has been a LONG time since I built anything balsa. But I am having fun so I decided to document it.

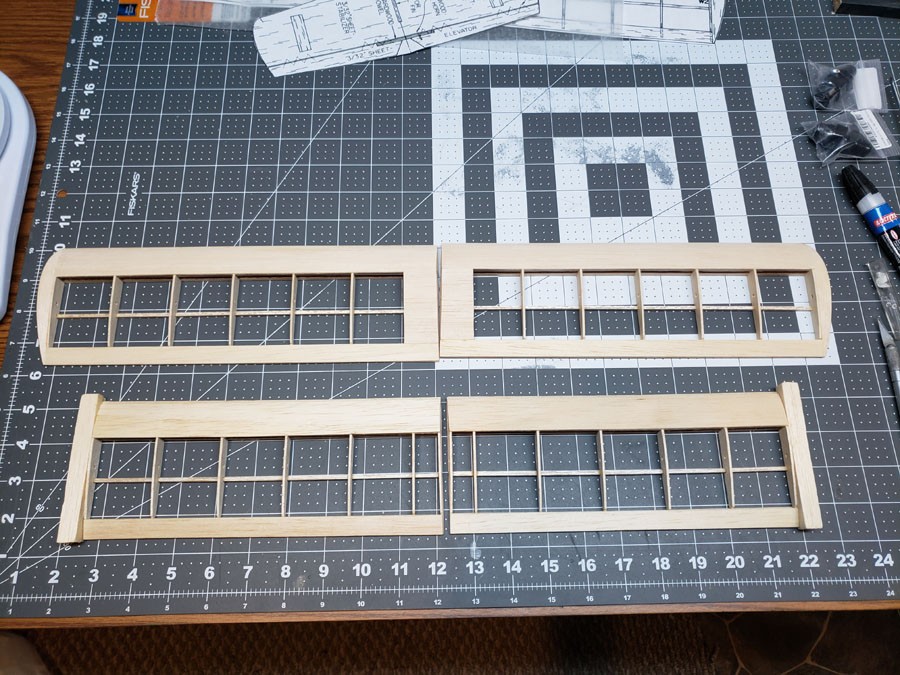

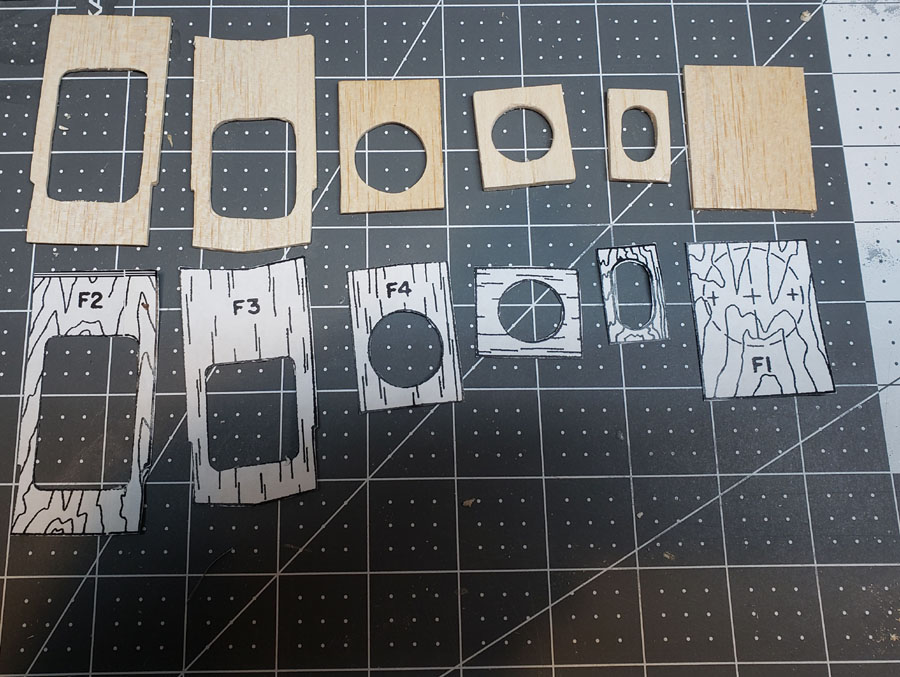

One of the reasons I picked this model to scratch build is because all of the wing ribs were the same size. I just made a template out of plywood then used that to guide my knife while cutting out all of the ribs.

https://outerzone.co.uk/plan_details.asp?ID=6306

I picked this plan because I wanted a small biplane and I already have a powertrain that I THINK will work in it. To be honest I have never built a model completely from scratch and it has been a LONG time since I built anything balsa. But I am having fun so I decided to document it.

One of the reasons I picked this model to scratch build is because all of the wing ribs were the same size. I just made a template out of plywood then used that to guide my knife while cutting out all of the ribs.

Last edited: