You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VISTA v2 - a slippery pitcheron

- Thread starter bracesport

- Start date

bracesport

Legendary member

I think the Simulator has been helping with the downwind turns rather than just figure eights, and the landing is improving (sadly we will not know for sure until flying again)!

bracesport

Legendary member

Well it has been awhile, but I have been thinking about what to do next on this project - there are two main steps required - the first is to epoxy the fuse which is ready and waiting, and then to build the wings.

The fuse is pretty straightforward with the CF braid in place I just need to add the epoxy and wrap it with cling wrap to smooth the surface while curing - this is a technique used to wrap fishing rods.

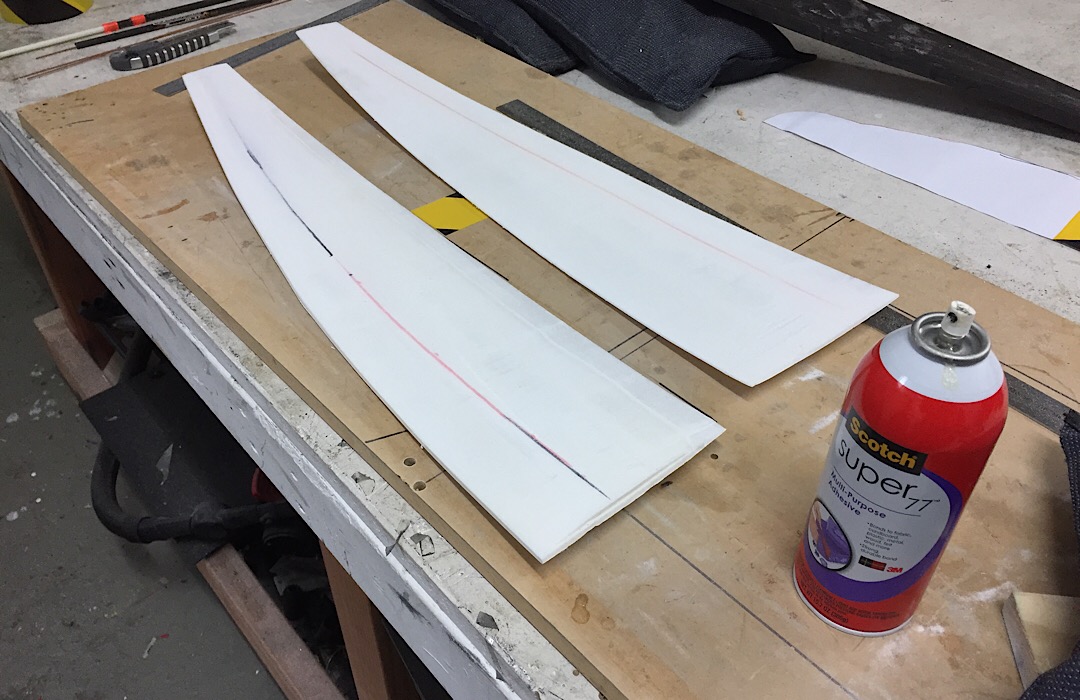

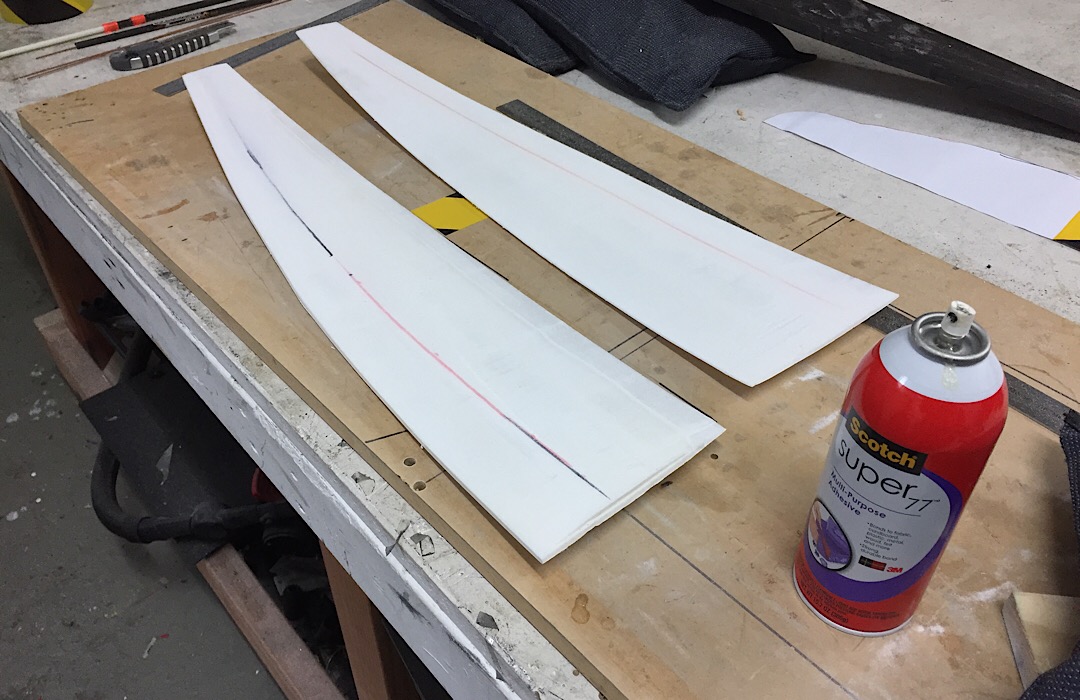

The wing will be a bit trickier and will need to be built in stages as the tips are symmetrical and the root is semi symmetrical - the spar will be a sine wave (more on that soon) - today I made the 2D templates and will start to prepare the blanks.

The fuse is pretty straightforward with the CF braid in place I just need to add the epoxy and wrap it with cling wrap to smooth the surface while curing - this is a technique used to wrap fishing rods.

The wing will be a bit trickier and will need to be built in stages as the tips are symmetrical and the root is semi symmetrical - the spar will be a sine wave (more on that soon) - today I made the 2D templates and will start to prepare the blanks.

Attachments

Wildthing

Legendary member

Well it has been awhile, but I have been thinking about what to do next on this project - there are two main steps required - the first is to epoxy the fuse which is ready and waiting, and then to build the wings.

The fuse is pretty straightforward with the CF braid in place I just need to add the epoxy and wrap it with cling wrap to smooth the surface while curing - this is a technique used to wrap fishing rods.

The wing will be a bit trickier and will need to be built in stages as the tips are symmetrical and the root is semi symmetrical - the spar will be a sine wave (more on that soon) - today I made the 2D templates and will start to prepare the blanks.

Make sure to take pictures

bracesport

Legendary member

I re-printed my tail feathers with added internal ribs - printing went really well - both tailpieces are joined with a connecting rib front and rear - the purpose is to prevent any movement during printing - works well.

bracesport

Legendary member

Started prepping my foam for the main wings - the chord is 15mm thick so there will be three pieces of foam used to construct the wings - I will use my handheld hot wire cutter to rough out the chords and then sand and laminate together - the bottom half will be two layers of foam (already glued together) and taper from root to tip down to one thickness - the top lamination will be one layer of foam - sound intriguing - we will see!

The wiggly line will be a vertical spar from CF formed in a wave pattern.

The wiggly line will be a vertical spar from CF formed in a wave pattern.

Last edited:

Wildthing

Legendary member

Definitely heavy duty supportsI re-printed my tail feathers with added internal ribs - printing went really well - both tailpieces are joined with a connecting rib front and rear - the purpose is to prevent any movement during printing - works well.

View attachment 172686 View attachment 172687

Boberticus

Active member

the wavey spar, are you planning on custom forming some carbon fiber roving with a mold of some sort?

maybe some layup on some polished and release wax covered 3d printed molds?

this is an awesome build.

maybe some layup on some polished and release wax covered 3d printed molds?

this is an awesome build.

bracesport

Legendary member

@Boberticus - my loose plan with the wave spar is to make a wave template and hot-wire the wave through the wing - then I will sandwich some paper in the wave to determine the total length - from there I plan to cut two tapered strips of CF and 3M77 each one to the wave halves - after that I will epoxy the front and rear of the wing back together - the two strips of spar will bond together.

Given this is a Pitcheron I also need to add a wing rod tube after the spar is in - then I will sheet the wing with CF - I have some really fine CF sheet (0.8K) - the process will be to 3M77 the CF onto the wings, epoxy and bag (using domestic food bagger).

Given this is a Pitcheron I also need to add a wing rod tube after the spar is in - then I will sheet the wing with CF - I have some really fine CF sheet (0.8K) - the process will be to 3M77 the CF onto the wings, epoxy and bag (using domestic food bagger).

Wildthing

Legendary member

@Boberticus - my loose plan with the wave spar is to make a wave template and hot-wire the wave through the wing - then I will sandwich some paper in the wave to determine the total length - from there I plan to cut two tapered strips of CF and 3M77 each one to the wave halves - after that I will epoxy the front and rear of the wing back together - the two strips of spar will bond together.

Given this is a Pitcheron I also need to add a wing rod tube after the spar is in - then I will sheet the wing with CF - I have some really fine CF sheet (0.8K) - the process will be to 3M77 the CF onto the wings, epoxy and bag (using domestic food bagger).

Make sure you post pictures on the method, sounds really interesting.

bracesport

Legendary member

I roughed out the blanks this morning using the hand hotwire - I use metal guides to run the wire across and a height gauge for the foam thickness to keep the foam flat on the bench as I feed the foam through - the hotwire stays stationary against the height gauge - the great thing about this technique is that it can follow curves.

next stage some sanding.

next stage some sanding.

bracesport

Legendary member

I just realised with this method I could rig up the hot wire to be a fixed system that would free up one hand to focus on feeding the foam through with more accuracy (less post sanding) - I will think on it!

Wildthing

Legendary member

But then both guide wires would have to be fixed to the foam somehow and you would need a rigid backing.I just realised with this method I could rig up the hot wire to be a fixed system that would free up one hand to focus on feeding the foam through with more accuracy (less post sanding) - I will think on it!

bracesport

Legendary member

I was thinking the hot-wire would hinge from the front edge - when it hinges over the wire would make contact with the two guides (taped on) - as the hot-wire has some spring tension it would stay in contact with the two guide wires even as they change in distance around the curves - currently I have to hold the hot-wire in one hand and feed the foam with the other (it works, but improvements are always welcomed)!

Wildthing

Legendary member

ok, I didn't know you were feeding the foam through. I had the guide wires and foam all taped down and just ran the hot wire over it.I was thinking the hot-wire would hinge from the front edge - when it hinges over the wire would make contact with the two guides (taped on) - as the hot-wire has some spring tension it would stay in contact with the two guide wires even as they change in distance around the curves - currently I have to hold the hot-wire in one hand and feed the foam with the other (it works, but improvements are always welcomed)!

bracesport

Legendary member

This morning I tapered the middle to the tips to thin the overall wing thickness (15mm @root and 8mm @tip) - the sanding all went pretty well.

Next, I laminated the tops and bottoms with 3M77 and applied some sandbags - I then taped the two wings back to back while the glue cures over the weekend.

I also made a wide template to cut the wave for the spar - the paper will come off before I add the spar - I also left some TE thickness for some final sanding before the skins go on (insurance against damage).

Next, I laminated the tops and bottoms with 3M77 and applied some sandbags - I then taped the two wings back to back while the glue cures over the weekend.

I also made a wide template to cut the wave for the spar - the paper will come off before I add the spar - I also left some TE thickness for some final sanding before the skins go on (insurance against damage).

bracesport

Legendary member

this morning I had a hankering for sausages, so I mixed up some epoxy and wrapped the fuse with packaging cellophane - it was impossible to wrap the cellophane without wrinkles, but I think it looks worse in the pictures than the first layers of wrapping (which was not too bad) - I always expected to have to do some sanding - you can also see the canopy edge former in place between two layers of the wrap, it should form the joggled edge.

Wildthing

Legendary member

I was thinking zucchinithis morning I had a hankering for sausages, so I mixed up some epoxy and wrapped the fuse with packaging cellophane - it was impossible to wrap the cellophane without wrinkles, but I think it looks worse in the pictures than the first layers of wrapping (which was not too bad) - I always expected to have to do some sanding - you can also see the canopy edge former in place between two layers of the wrap, it should form the joggled edge.

View attachment 173185 View attachment 173186

bracesport

Legendary member

@Wildthing - I use Wests’ epoxy - short set epoxy does not go hard enough for sanding etc.

Wildthing

Legendary member

Hmmm, I maybe have to look into it, is it fairly thin?@Wildthing - I use Wests’ epoxy - short set epoxy does not go hard enough for sanding etc.