Wildthing

Legendary member

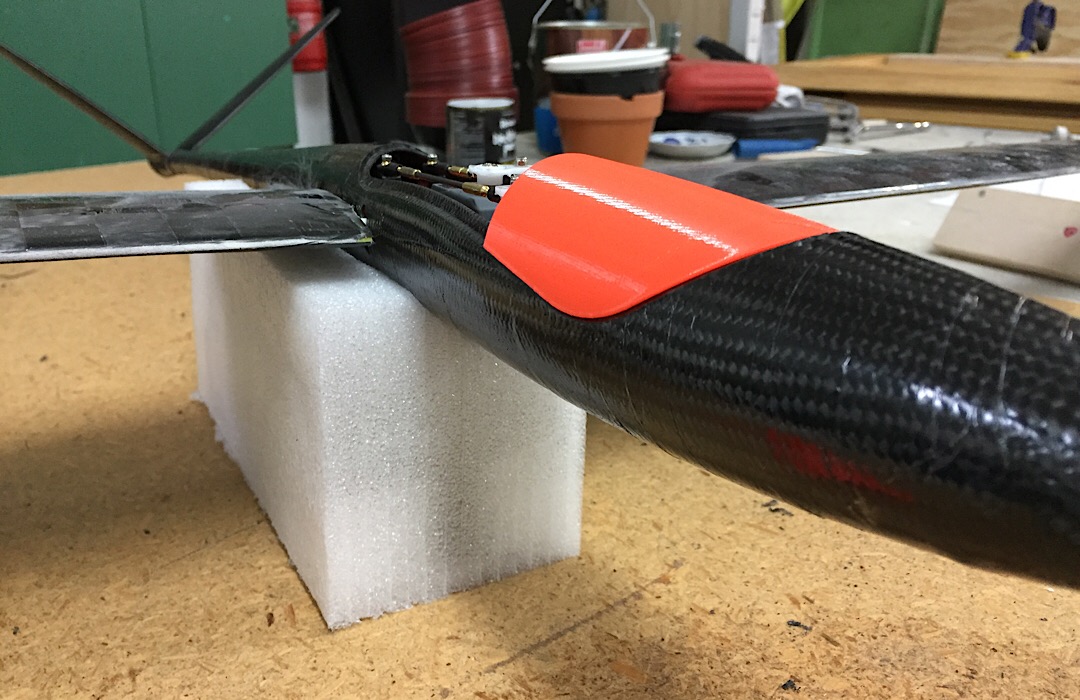

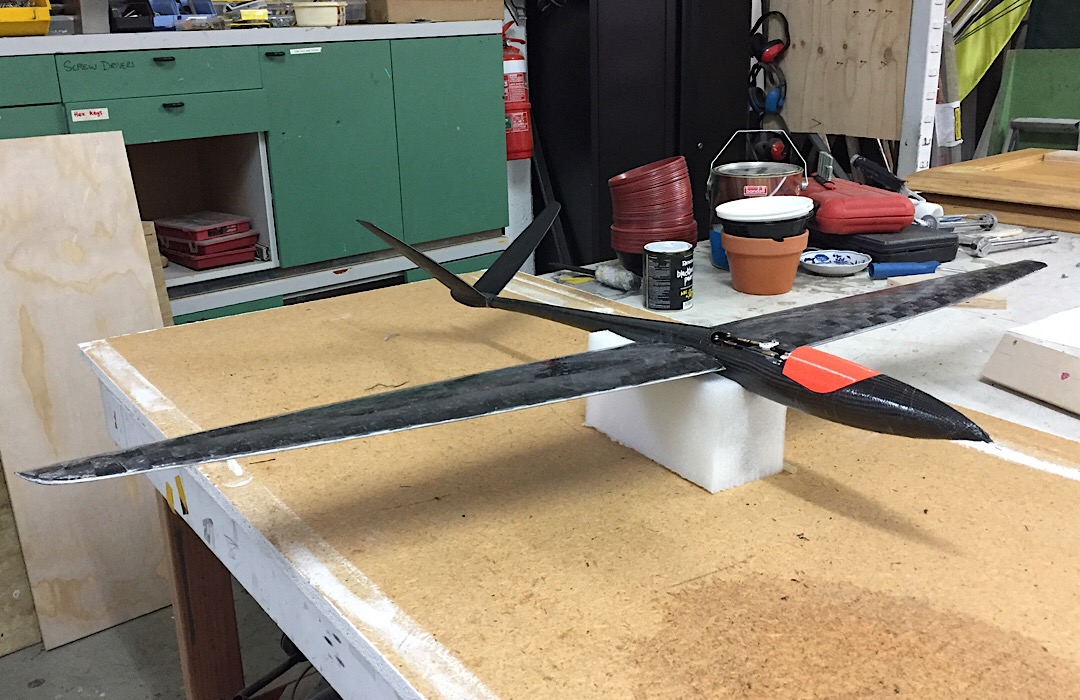

For the fuse I used a 50mm braided CF tube as the wrap - this allowed me to get around the thickest part of the fuse an almost to the end of the tail - the tail diameter was just a tad to small to the braided tube to reduce down to - I opted to add a smaller 15mm braided tube to finish the job - there is some overlap which will require a bit of sanding.

View attachment 174405 View attachment 174406

I think I should apply some of your technics to my combat planes, they just look bullet proof.