TooJung2Die

Master member

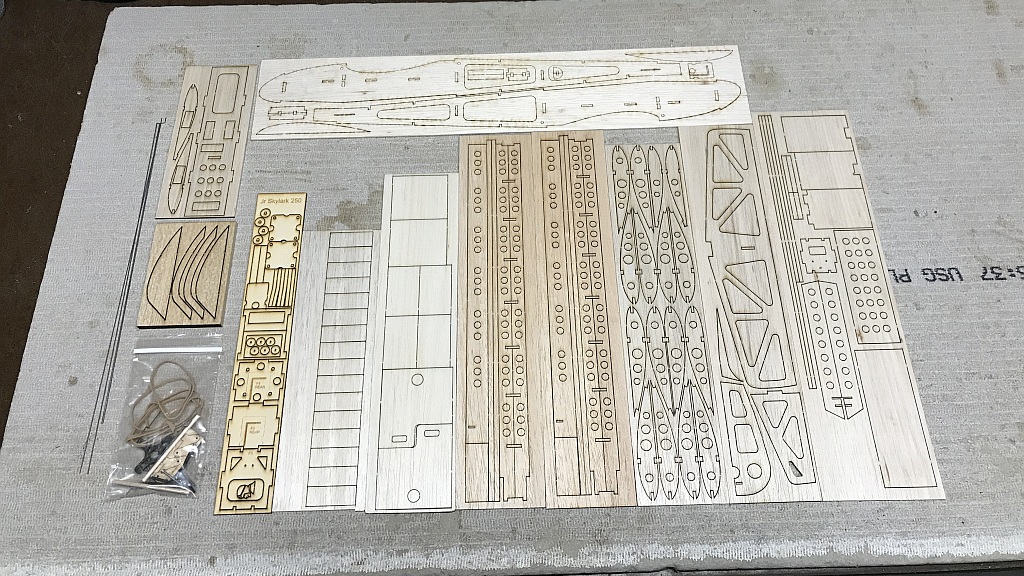

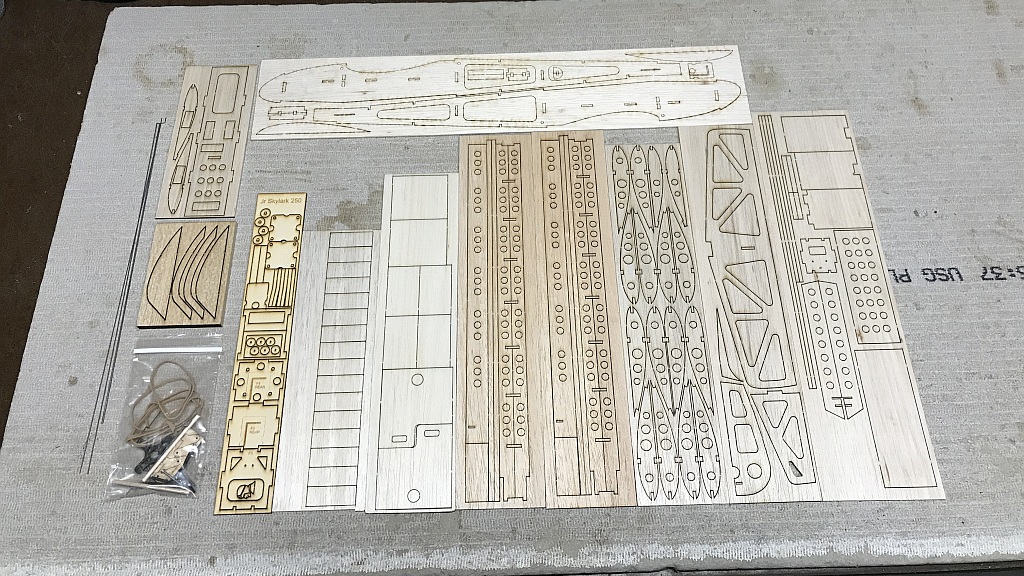

I'm a big fan of delayed gratification so I'm starting to build the Jr. Skylark 250 kit I got last winter. Everyone else says I'm a procrastinator. 🙂 Since this is a Beta kit I'll point out some things I think should be fixed. Not because I like to complain but it's a Beta kit and Doug did ask for constructive criticism. Here are the kit contents.

I'll start with the fuselage. I've sorted out everything I think I'll need to build the fuselage for electric motor. I probably won't use the balsa canopy so I didn't separate those pieces.

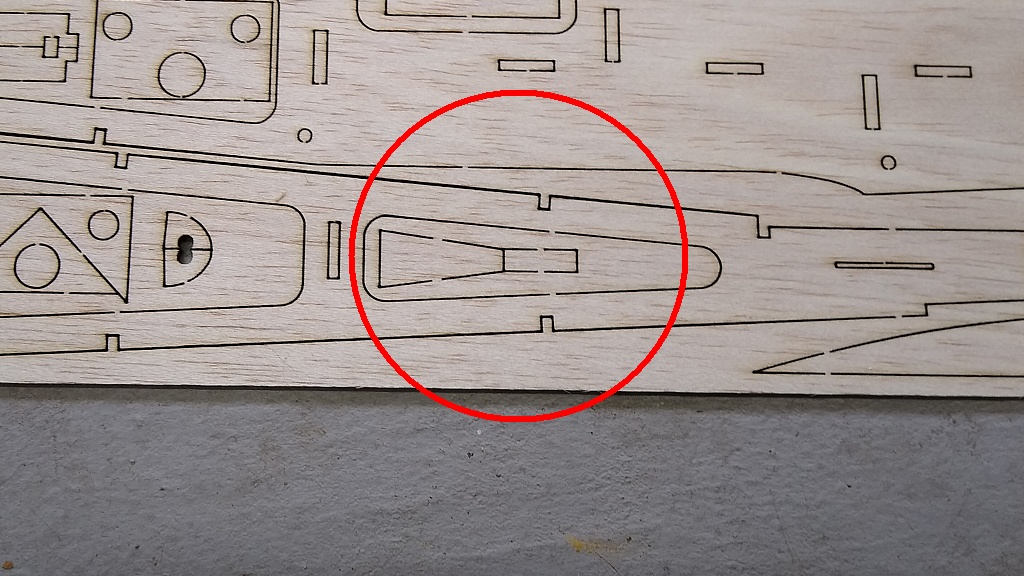

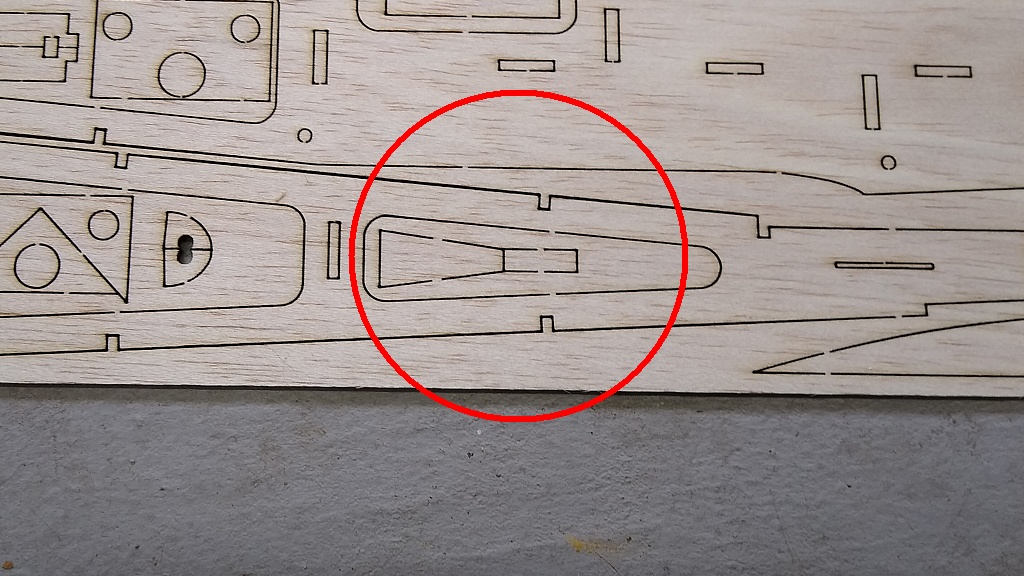

I noticed right away the little triangular piece that goes on the bottom of the tip of the tail is missing. Search the first photo and you won't find it. It's supposed to be here:

No problem, I'll make one from scrap later. I know from building the Eaglet 250 the first step is making the landing gear from 0.055" wire included in the kit. There is supposed to be enough wire to make the elevator joiner too but when I was done there was only about 1" of wire left. Again, no problem, I have lots of piano wire.

When I dry fit the fuselage bulkheads and servo/battery tray I found I couldn't put the firewall with landing gear in place. I think there should be a cut-out here. That's a real easy fix.

There is one short shear web in the sheet. Same thing I found with the Eaglet 250 Beta kit. All the shear webs are 0.625" in height except for this one that is only 0.585".

That's all I got done tonight. If I had to find something serious to complain about it would be that Willy Nillies kits are too easy and build too fast. This gonna be fun! 😁😁😁

Jon

I'll start with the fuselage. I've sorted out everything I think I'll need to build the fuselage for electric motor. I probably won't use the balsa canopy so I didn't separate those pieces.

I noticed right away the little triangular piece that goes on the bottom of the tip of the tail is missing. Search the first photo and you won't find it. It's supposed to be here:

No problem, I'll make one from scrap later. I know from building the Eaglet 250 the first step is making the landing gear from 0.055" wire included in the kit. There is supposed to be enough wire to make the elevator joiner too but when I was done there was only about 1" of wire left. Again, no problem, I have lots of piano wire.

When I dry fit the fuselage bulkheads and servo/battery tray I found I couldn't put the firewall with landing gear in place. I think there should be a cut-out here. That's a real easy fix.

There is one short shear web in the sheet. Same thing I found with the Eaglet 250 Beta kit. All the shear webs are 0.625" in height except for this one that is only 0.585".

That's all I got done tonight. If I had to find something serious to complain about it would be that Willy Nillies kits are too easy and build too fast. This gonna be fun! 😁😁😁

Jon

Last edited: