I was super happy to find a new kit cutter starting up this year - https://willynillies.com/ - and with very reasonable priced kits sized for 1806 quad motors too! Lots of options, but my eye was caught by the Barnstormer 250 - in a shoulder mounted wing configuration it looks like a mini Ugly Stick

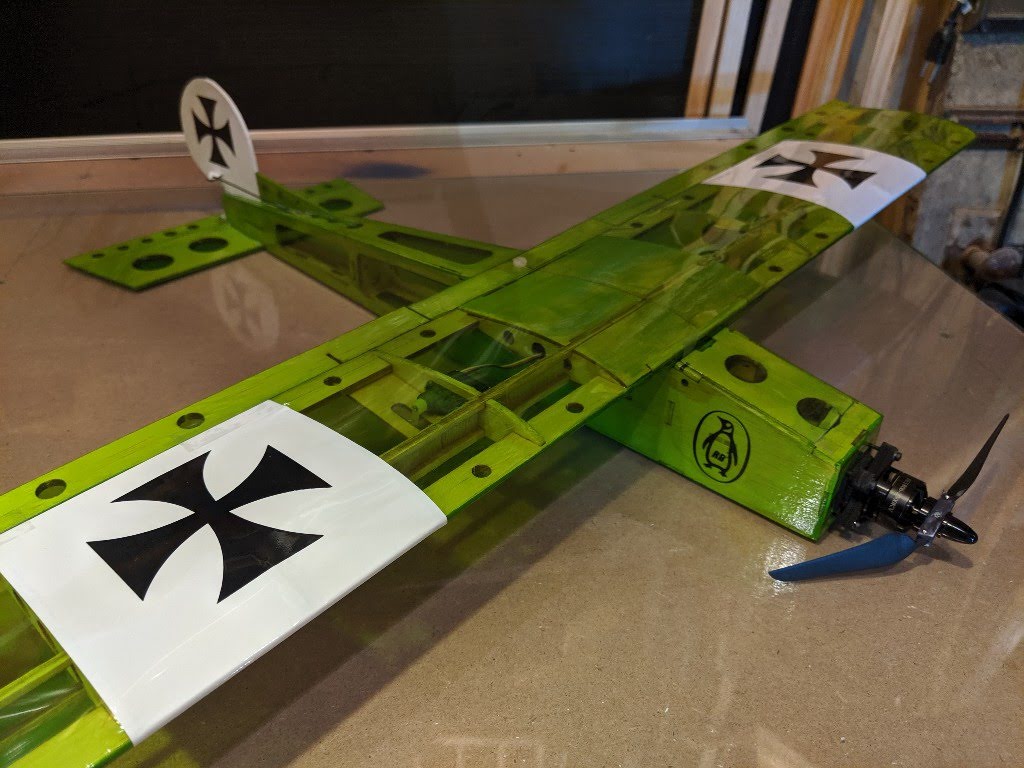

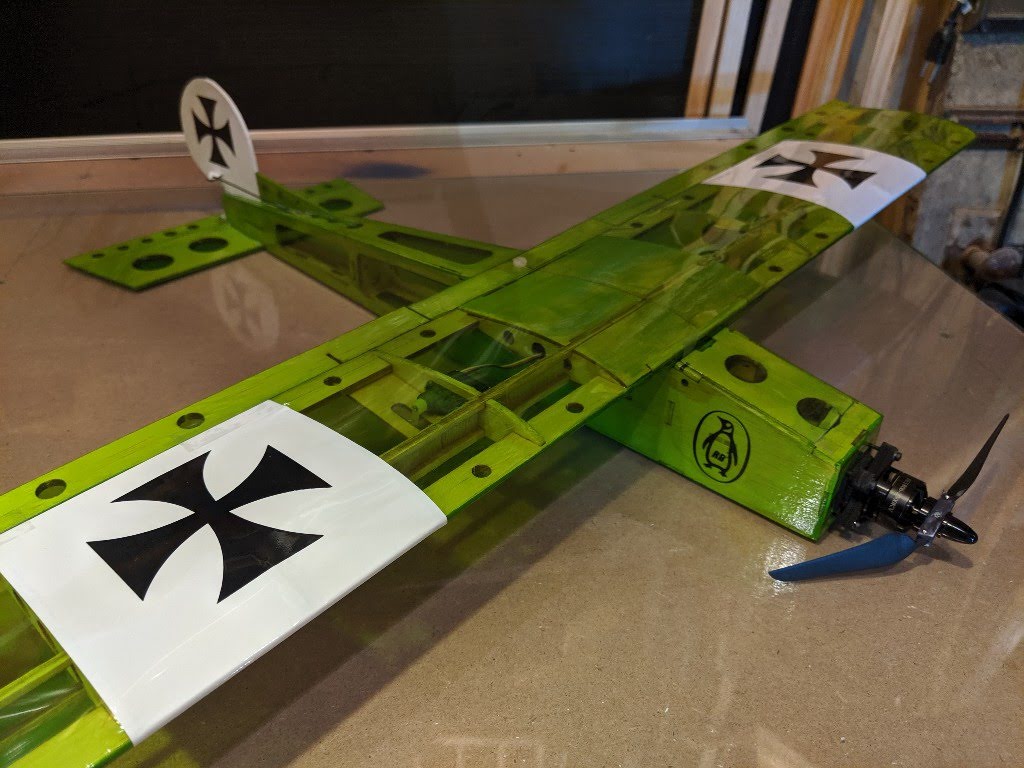

Here's a picture from their website so you can see what the end products can look like. [Oh yeah, that's a picture of my build from this thread right here too!]

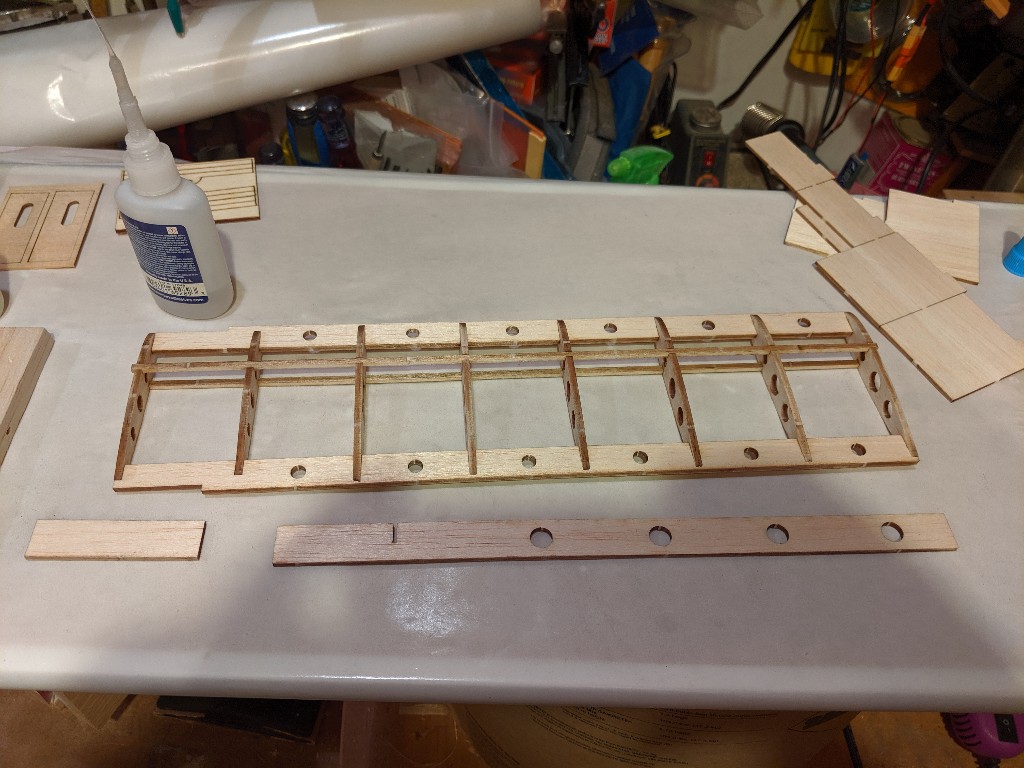

Order was placed and received in a little less than a week, and after a couple weeks of finishing up my last project to clear a space on the bench, it's time to start the build!

First, for anyone who is thinking about one of these kits, they follow the Flite Test model for instructions. I.E. there aren't any paper instructions in the kits - you follow along to the video of the build instead! And here are the three videos that show the whole assembly process (except covering & electronics installation)

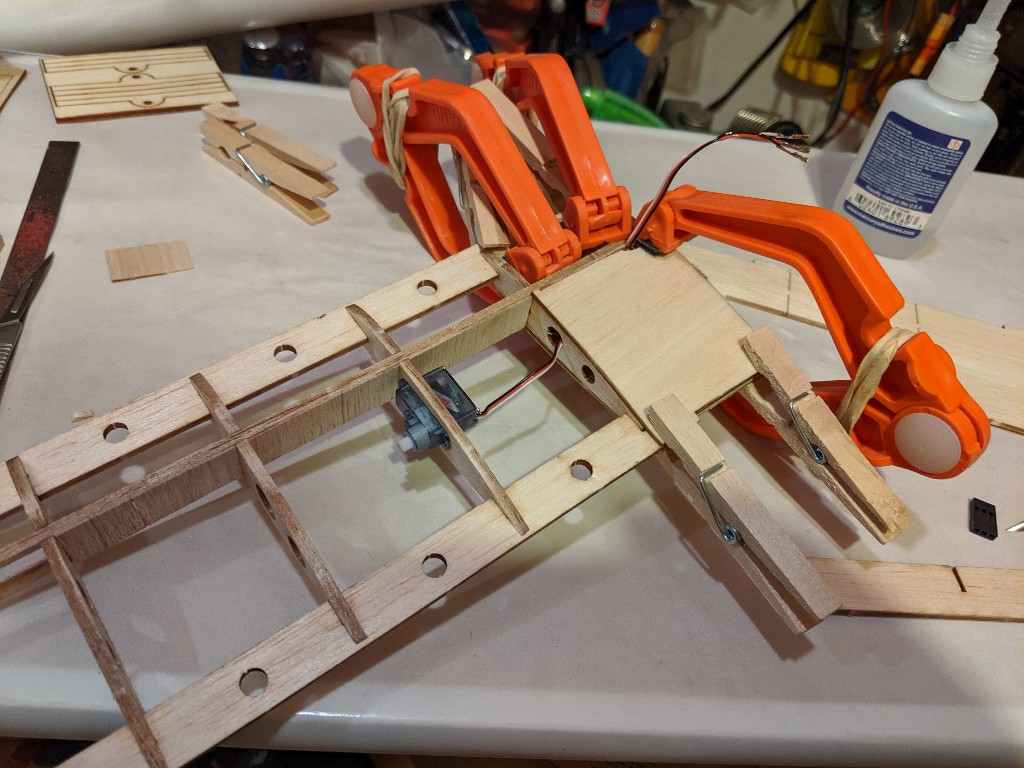

Building the motor mount - do this first!

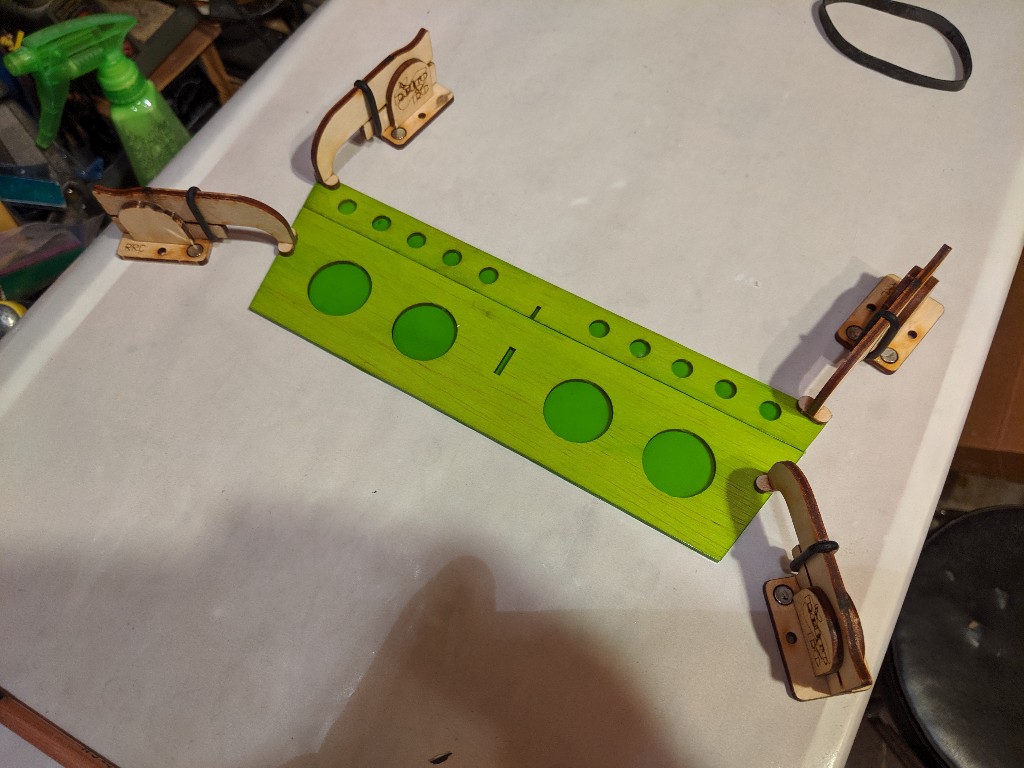

Building the fuselage...

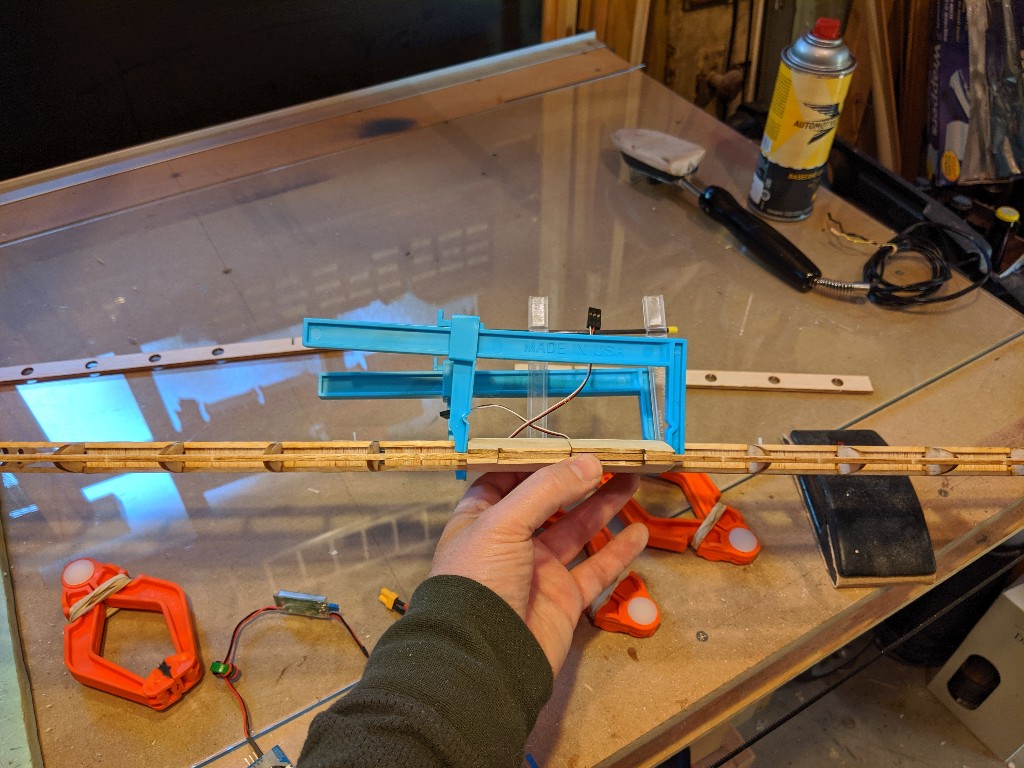

Building the wing....

Stay tuned for some build pictures coming up!

Here's a picture from their website so you can see what the end products can look like. [Oh yeah, that's a picture of my build from this thread right here too!]

Order was placed and received in a little less than a week, and after a couple weeks of finishing up my last project to clear a space on the bench, it's time to start the build!

First, for anyone who is thinking about one of these kits, they follow the Flite Test model for instructions. I.E. there aren't any paper instructions in the kits - you follow along to the video of the build instead! And here are the three videos that show the whole assembly process (except covering & electronics installation)

Building the motor mount - do this first!

Building the fuselage...

Building the wing....

Stay tuned for some build pictures coming up!

Last edited: