TooJung2Die

Master member

First a little back story. I thought flying a 3D airplane was way beyond my abilities. I'm a slow-fly and glider type of pilot. A couple of weeks ago one of the guys at the RC field has a EPP foamy profile 3D Extra. He's no 3D pilot either. He tells me I have to fly his new airplane. I think he's out of his mind. I'll destroy it. So I fly it anyway.  I was amazed at how easy it was to fly. So slow and floaty. It wasn't twitchy at all. It felt slow and smooth. I was doing my short repertoire of stunts with ease. A tight loop looks like a backflip. It rolls like a drill. Flying two mistakes high is only 30 feet up. I gotta have one!

I was amazed at how easy it was to fly. So slow and floaty. It wasn't twitchy at all. It felt slow and smooth. I was doing my short repertoire of stunts with ease. A tight loop looks like a backflip. It rolls like a drill. Flying two mistakes high is only 30 feet up. I gotta have one!

I searched for plans and find one of the most popular and most copied 3D out there is Leadfeather's Yak-55. Plans galore. 32" wingspan; downloaded it. For the first time ever I make templates from the plans. I know for sure I will be making more than one. The retail foamy I flew was made from 9mm EPP foam. I don't have any EPP but I have lots of Adams foam board from Dollar Tree. When you peel off the paper and glue two sheets together you have 10mm sheet foam. Close enough.

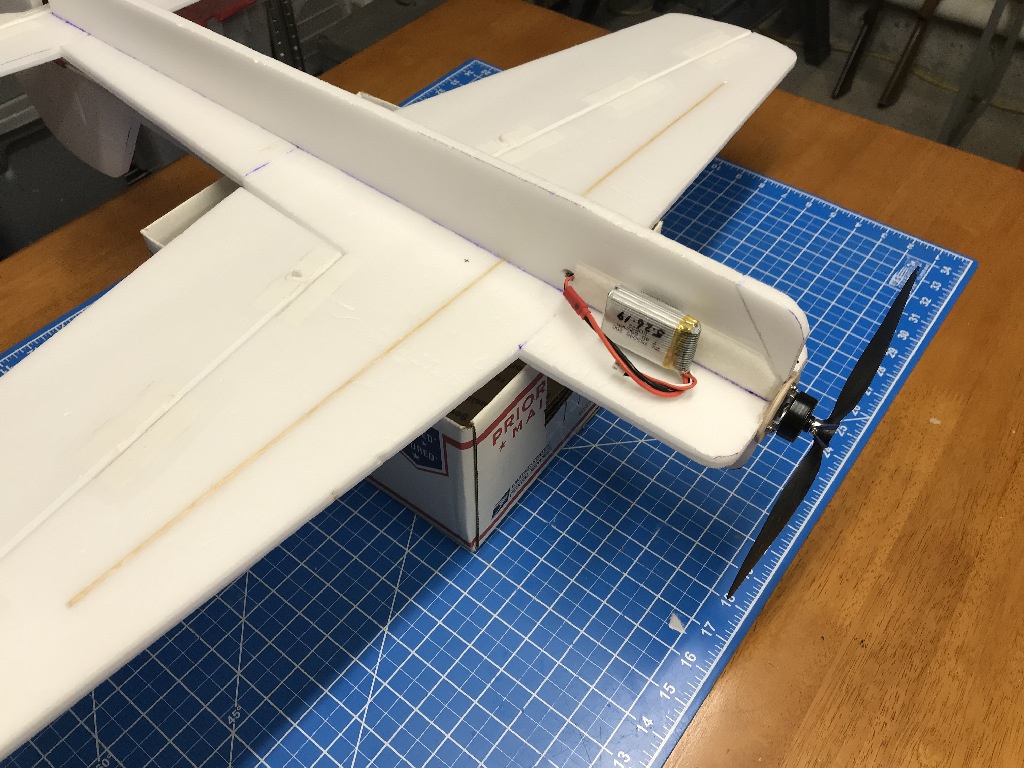

Here's the first shot at making a 3D airplane.

Two sheets of DTFB, no paper, glued together with spray adhesive.

Templates arranged on one sheet of foam. The other half of the wing goes on a second sheet.

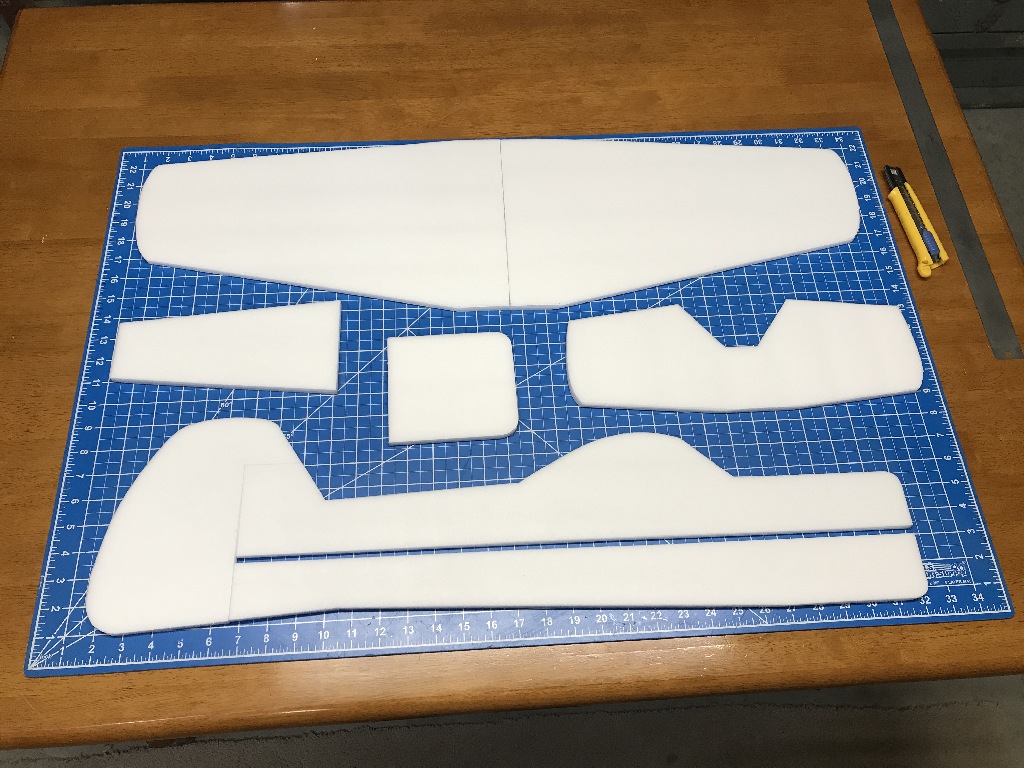

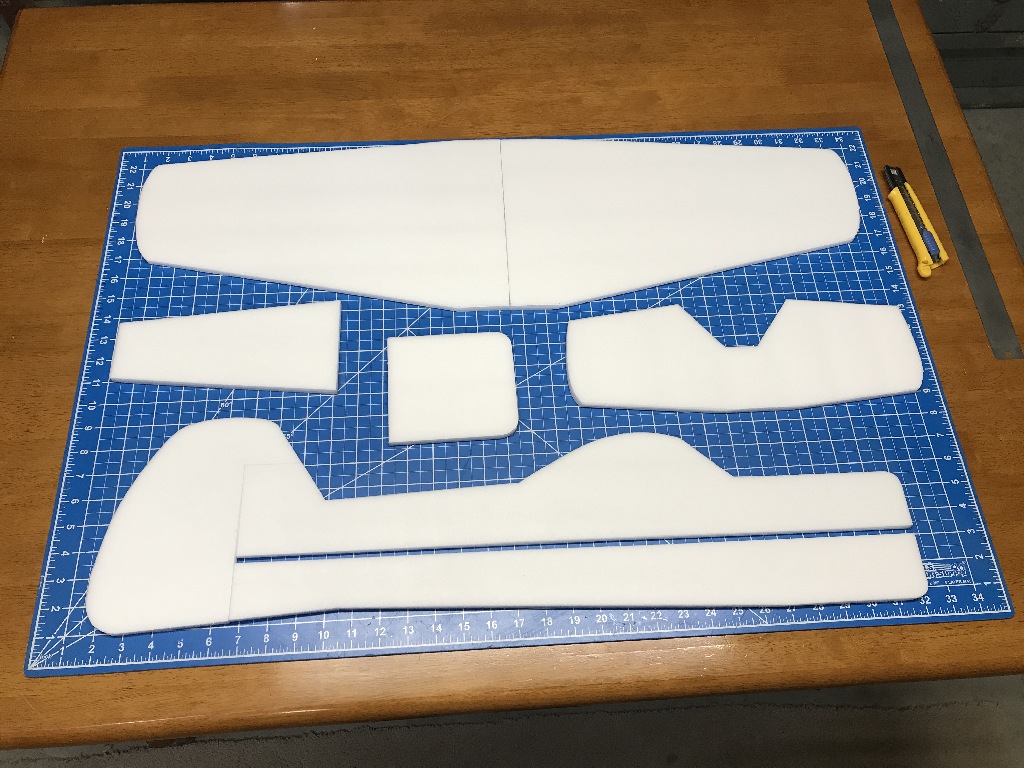

These are all the parts cut out. I don't think I've made an airplane with this few number of pieces. If you had a big enough sheet of foam it could be even less parts by combining the horizontal parts before cutting it out.

It's late so I'll continue the build thread later. Stay tuned...

<edit> Plans and build instructions attached.

Jon

I searched for plans and find one of the most popular and most copied 3D out there is Leadfeather's Yak-55. Plans galore. 32" wingspan; downloaded it. For the first time ever I make templates from the plans. I know for sure I will be making more than one. The retail foamy I flew was made from 9mm EPP foam. I don't have any EPP but I have lots of Adams foam board from Dollar Tree. When you peel off the paper and glue two sheets together you have 10mm sheet foam. Close enough.

Here's the first shot at making a 3D airplane.

Two sheets of DTFB, no paper, glued together with spray adhesive.

Templates arranged on one sheet of foam. The other half of the wing goes on a second sheet.

These are all the parts cut out. I don't think I've made an airplane with this few number of pieces. If you had a big enough sheet of foam it could be even less parts by combining the horizontal parts before cutting it out.

It's late so I'll continue the build thread later. Stay tuned...

<edit> Plans and build instructions attached.

Jon

Attachments

Last edited: