So this is getting a little out of hand I have to admit

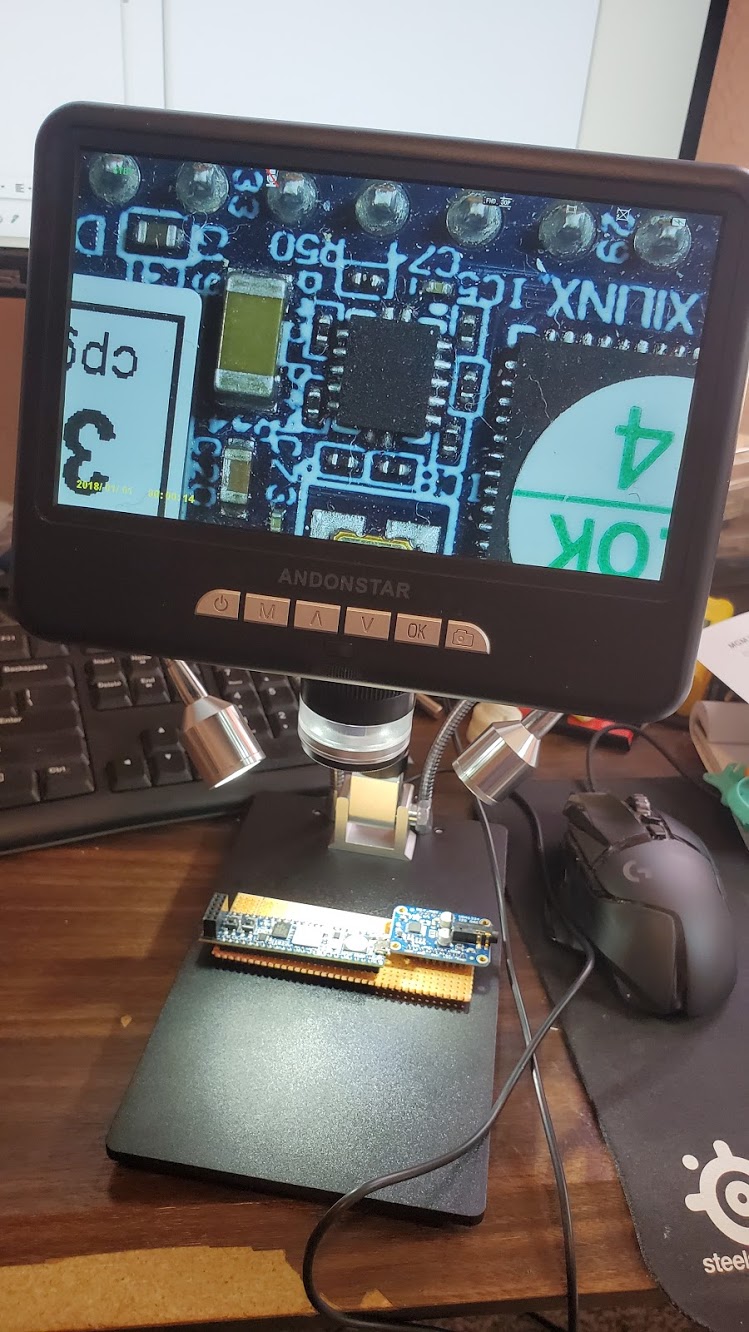

New addition to the resin madness today. No, not another printer! I got one of the new Elegoo Mercury wash and cure stations:

There are basically 3 wash and cure stations out there right now. (Ok, formlabs has some but they're priced out of this discussion and are really designed to work with the ultra expensive form labs printers.)

Prusa CW1 - $700. (Only $600 if bought in conjunction with their SLA printer!) Ouch...that's more than I paid for both of my printers! And it's wash container doesn't even have a way to seal to store your wash liquid. It is a stainless tank though which is nice...but...have to say much like Prusa's SLA it's just too expensive to be competitive with no major benefits over much more affordable options.

Anycubic Wash and Cure - $250 I've mentioned this before and the rave reviews it gets. It uses a plastic tank that can seal and is way more affordable. I was seriously considering one when I ordered the Sonic Mini. They've even gone on sale for $180 which really had me tempted. (They're on sale again right now for $180...probably because of the Mercury being more available.)

Elegoo Mercury Plus - $120. Yeah, cheapest out there by far. And it's got a nicer display than the anycubic. But...it's brand new and hard to get because it sells out almost immediately when stock is available. I lucked out and happened to check Amazon just when a new batch went up for sale. It wasn't supposed to be here until Friday but Amazon decided to surprise me and shipped it early!

Note - there is a cheaper Elegoo Mercury without the plus. It's basically just a UV lamp in a box. It doesn't do washing as well as curing.

It's a little smaller than the Mars Pro and has the same styling. The two machines next to each other would look like a good pair. I had to cheat and put it around the corner because my little cart is full with the two printers. And since both printers and this require the top to be lifted off to put things in and out I can't put any of them on a lower shelf.

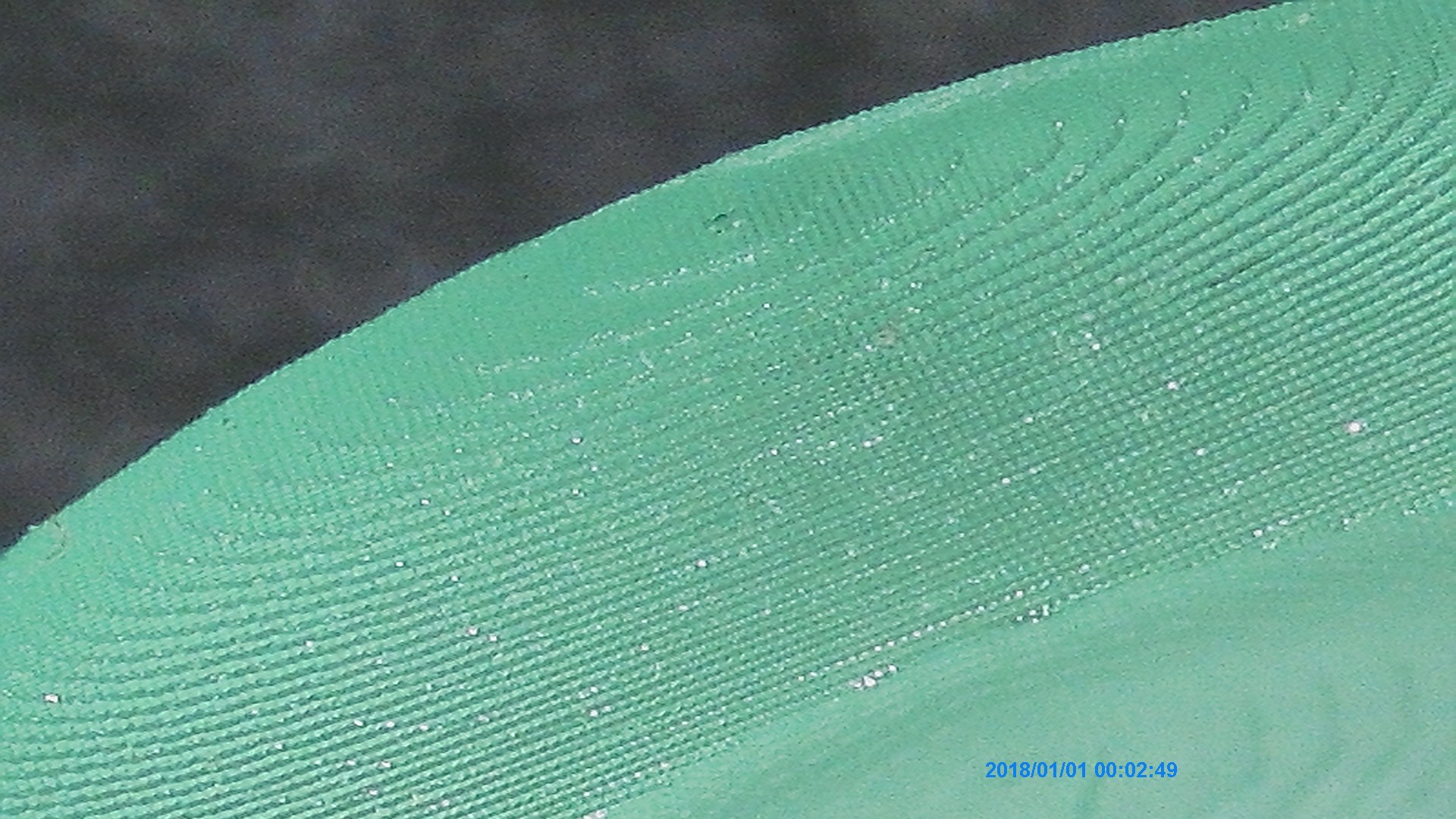

Note it does have a lid for the tank so you can safely store your alcohol in it without worrying about evaporation. It comes with a couple of parts to make it flexible to use. There's an acrylic plate with a smaller metal plate attached which attaches magnetically to the base for the curing operation:

A special hook designed so the Mars/Mars Pro build plate can be attached and the parts/plate can be washed before being removed from the plate:

And a basket that can be used for parts already removed from the plate - making it usable with any printer.

It seems pretty well made, and the controls are very simple and easy to use. Just push some buttons to set how long to wash...then hit go. Half way through the wash it switches directions. Then pull out the tank, put in the plate and let your part cure - again pushing the buttons to set the time and then letting it go.

It has a light sensor that detects the presence of the lid and won't operate without the lid on. At first I thought there was something wrong since any button I pushed just beeped but other than the time changing they wouldn't do anything. I couldn't even get it to change from wash to cure mode or cure to wash mode. Then I put the lid on and it all worked. I had to investigate how it sensed the lid since I saw no switches or magnets and found the little IR sensor on the back that appears to work as a proximity sensor since my hand was equally good at triggering it.

Hard to say how effective it is...I only did one part in it so far. I gave the part an initial rinse in my normal "Dirty" denatured alcohol bath so I won't gunk up the alcohol in this as quick then gave it a 3 minute wash cycle. Not sure if this was long enough or not. Then gave it a 5 minute cure.

It's worth noting that it was a lot more UV led's than the anycubic...not sure how much more UV it actually puts out...but it looks like a better setup overall.

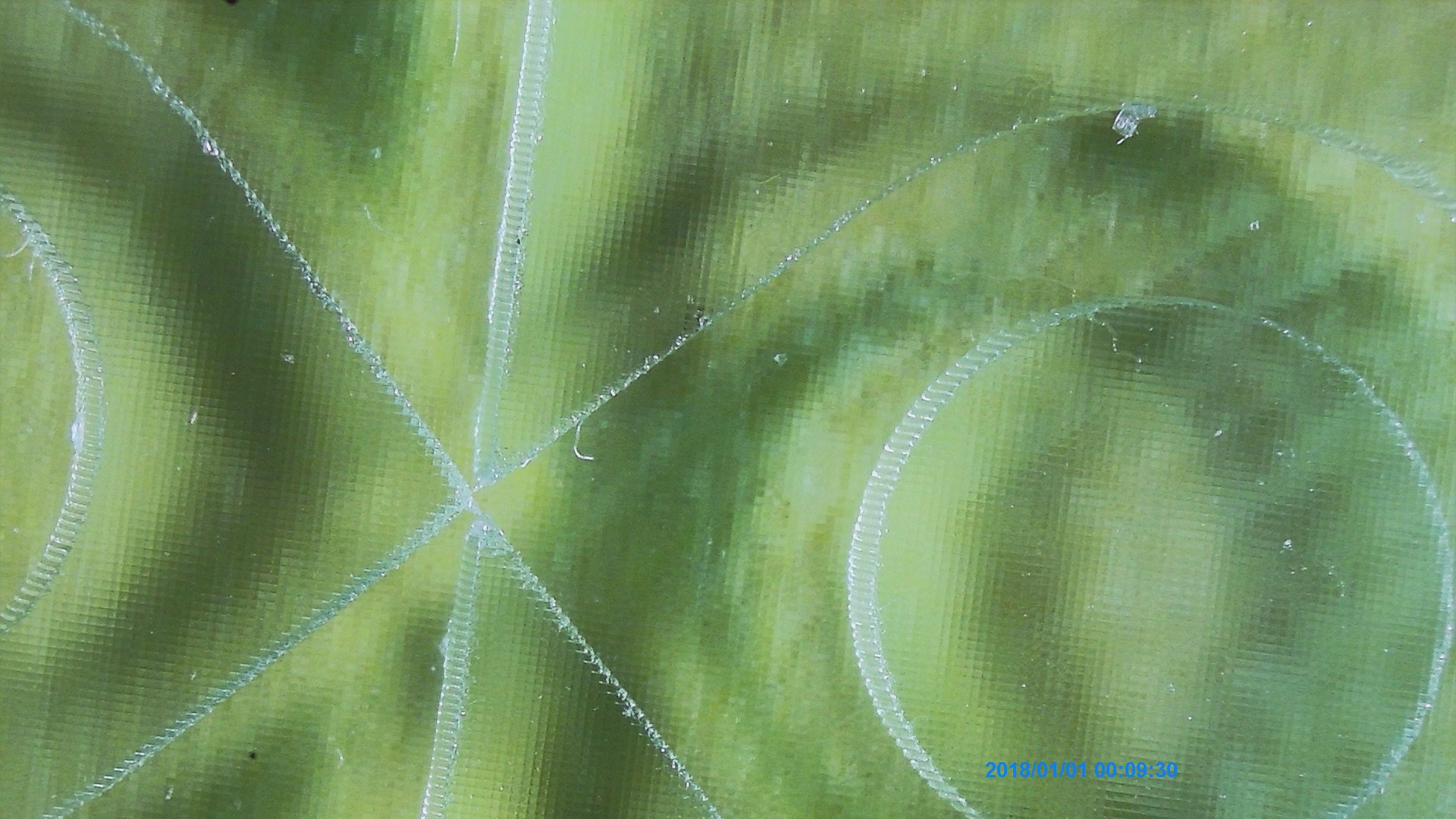

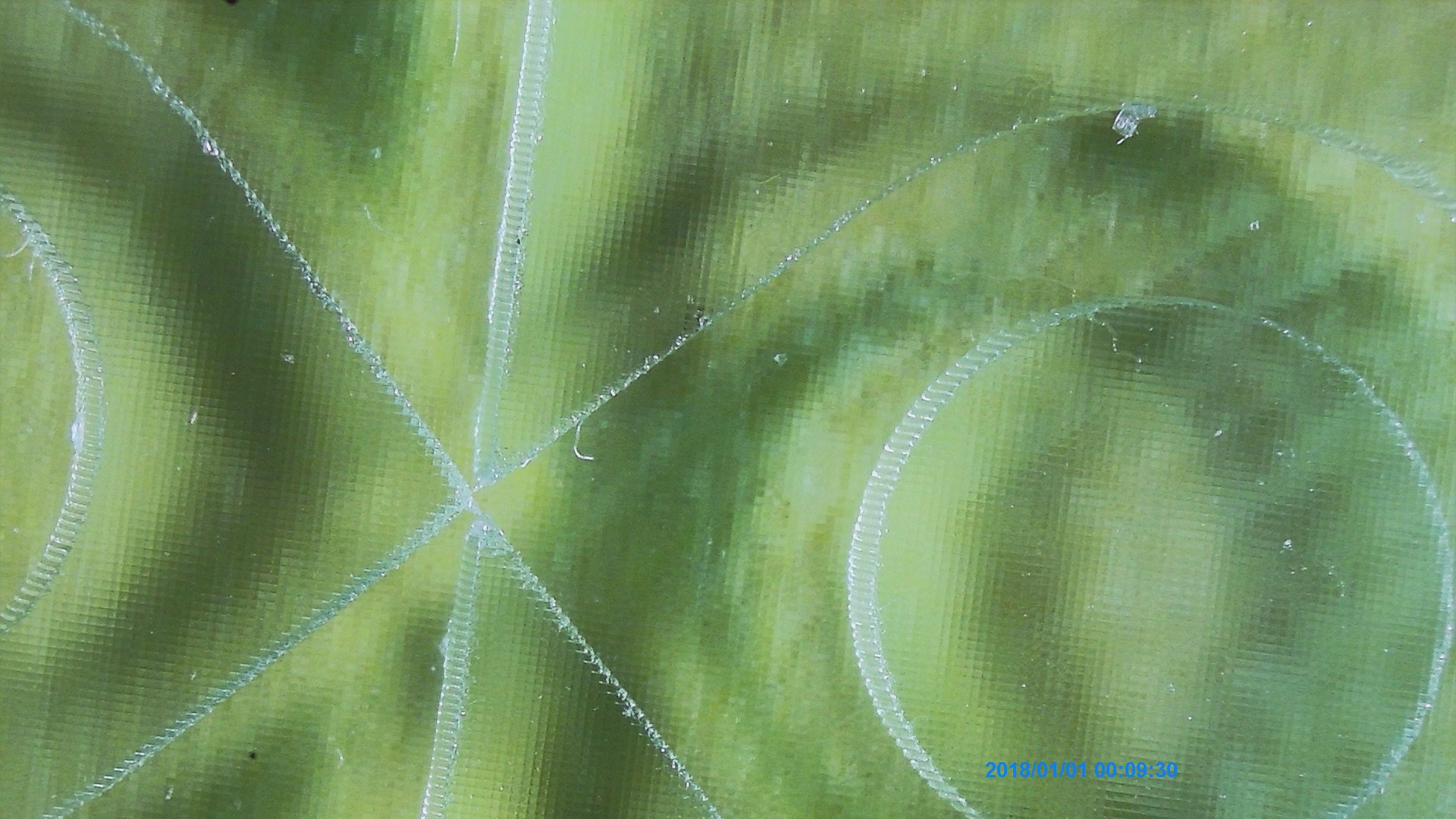

The part is ok...but...I rushed and didn't let the alcohol dry fully before starting the cure and I'm not sure if the wash was long enough...so there are some shiny spots on the print. Both poor washing and not letting it dry can cause that...but...it may also be because this was a mix of fast and tenacious that's been sitting in the vat for two days so maybe they weren't well mixed and some areas got more of one type of resin than another. Further experimentation is required.

This part BTW is a chute I designed for my coffee grinder. It's a $1,200 commercial grinder I got used for $70 from a guy who used to run an espresso trailer and was retiring. His wife listed it for sale cheap because the base was broken and doesn't fully attach to the machine anymore. The stock setup on it wastes more coffee each time I used it than I would use in a day. So I designed this to replace it and help guide the grounds as they came out. It's not perfect...but it works ok.

Oh, and that color shift part way up? (I printed it upside down...with the bottom against the build plate no supports) That's where I worried that the resin in the tank was getting a little low and topped it up with more Siraya fast grey. So the mix of tenacious suddenly got much lower.

I may try giving it a bit more cure time...but I actually want it in black anyway so I may print in that first and give the wash/cure another go with longer settings.

I've been using a PLA version of this on the grinder for almost 2 years, it replaced one I had carved out of wood. I don't really need to replace it but it's getting a bit grungy from the oily coffee grounds running over it and I figured a SLA one would look a bit nicer so I gave it a try on here.

So far I like the wash and cure...wish I had been able to get it when I got the printers...would have saved me some tupperware containers. I'm a bit concerned about how this print came out...but I think it was a combo of the resin and me being rushed...so I'll probably run this in black overnight and see how the wash/cure does on that tomorrow.