Easy to Build - Swappable DTF Floats & Skis

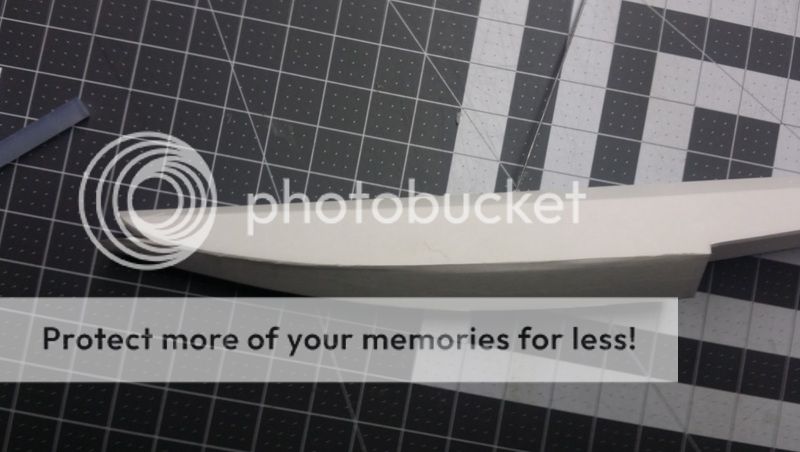

Due to all the snow we've been having in my area I was forced to come up with some ski's if I wanted to fly my 42" Zero Swappable design. After using some crummy ski's that only worked half the time, and discovering that there were actual wartime Zeros with floats, I went all out and built a scale set for my plane.

They're simply Dollar Tree foam, packing tape, and hot glue. Waterproof and incredibly strong with the simple internal supports. Light weight too.

While doing the design work I though it would be cool to adapt the design and come up with some swappable floats and ski's that could be used for the various FT planes out there. I know that planes like the Storch and the Bushwacker would be excellent candidates for floats.

Just about any of the larger planes could benefit from ski's, and planes like the Spitfire, Mustang, Sportster, or even the Cruiser and Guinea Pig could also be a lot of fun on Floats.

*******************************************************

So here's the Beta Plans as they stand now:

Scale Triple Floats for 42" Zero Beta v.4 - Tiled

These are suitable for my 42" Zero design or any other warbird or equivalent sized plane you'd like to stick tri floats on.

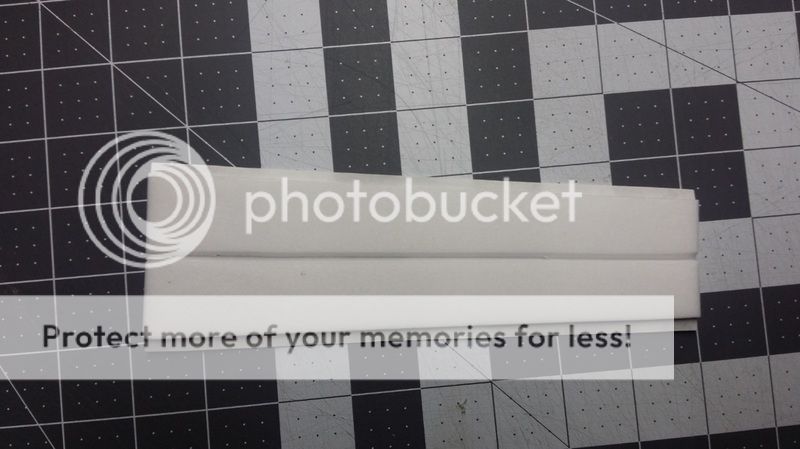

Swappable Ski's - 7.7" Version - Tiled

Suitable for just about any FT Plane that takes the standard size power pod. Think they would even work fine for the smaller swappable stuff like the FT Flyer etc...

21" Dual Swappable Floats for ~30" Wingspan Planes - Full - Tiled

These should work great on the smaller swappable series planes like the Baby Blender, Duster, or Bloody Wonder/Baron.

27" Dual Swappable Floats for the Bushwacker - Tiled - Full

Increased the step, and went a bit shorter, and made the rear section one piece instead of two. Mostly just to see what would happen. Turns out these work great and I'll probably replace the 29" version with these.

29" Dual Swappable Floats for > 40" Wingspan Planes - Full - Tiled

Suitable for any FT plane with a greater than 40" Wingspan. Should be excellent for planes like the Storch, Bushwacker, or Spitfire.

Due to all the snow we've been having in my area I was forced to come up with some ski's if I wanted to fly my 42" Zero Swappable design. After using some crummy ski's that only worked half the time, and discovering that there were actual wartime Zeros with floats, I went all out and built a scale set for my plane.

They're simply Dollar Tree foam, packing tape, and hot glue. Waterproof and incredibly strong with the simple internal supports. Light weight too.

While doing the design work I though it would be cool to adapt the design and come up with some swappable floats and ski's that could be used for the various FT planes out there. I know that planes like the Storch and the Bushwacker would be excellent candidates for floats.

Just about any of the larger planes could benefit from ski's, and planes like the Spitfire, Mustang, Sportster, or even the Cruiser and Guinea Pig could also be a lot of fun on Floats.

*******************************************************

So here's the Beta Plans as they stand now:

Scale Triple Floats for 42" Zero Beta v.4 - Tiled

These are suitable for my 42" Zero design or any other warbird or equivalent sized plane you'd like to stick tri floats on.

Swappable Ski's - 7.7" Version - Tiled

Suitable for just about any FT Plane that takes the standard size power pod. Think they would even work fine for the smaller swappable stuff like the FT Flyer etc...

21" Dual Swappable Floats for ~30" Wingspan Planes - Full - Tiled

These should work great on the smaller swappable series planes like the Baby Blender, Duster, or Bloody Wonder/Baron.

27" Dual Swappable Floats for the Bushwacker - Tiled - Full

Increased the step, and went a bit shorter, and made the rear section one piece instead of two. Mostly just to see what would happen. Turns out these work great and I'll probably replace the 29" version with these.

29" Dual Swappable Floats for > 40" Wingspan Planes - Full - Tiled

Suitable for any FT plane with a greater than 40" Wingspan. Should be excellent for planes like the Storch, Bushwacker, or Spitfire.

Last edited: