As usual, whenever any flitefest footage comes out i get excited and start imagining epic builds the next time it comes to our area. After seeing Lains pink paper airplane and all the cool Rumbuilder profile stuff it got me thinking about how big can you go with rigid insulation.

The main point i took away from both build styles is that big builds do not need to take a ton of time. I mean that in a good way, more in reference to my previous large builds that took months to accomplish (200% ft-guinea pig and ft22).

So with that in mind i started thinking about going really big with 2x sheets of pink foam on edge, like the FT style of 60" builds from 2x 30"x20" foam sheets, but in this case they would be 8 foot by 4 foot sheets!

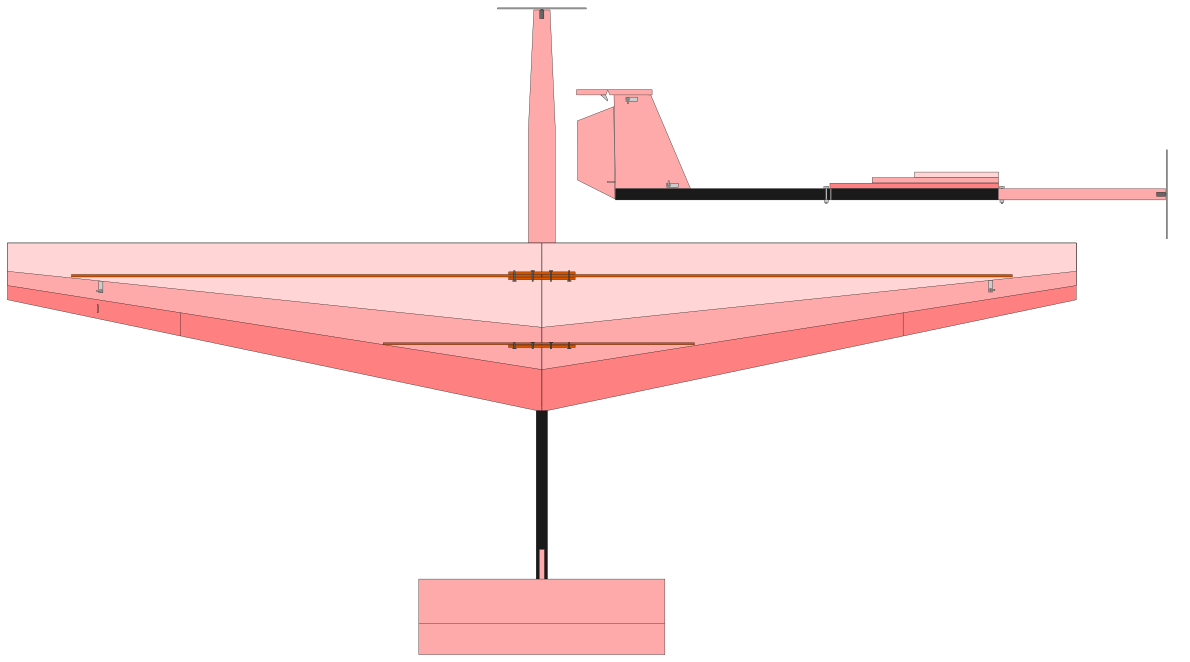

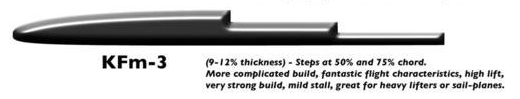

For the airfoil shape i am going to use a kfm3 airfoil. The reason i am leaning towards this is that it will make a much more solid shape, the steps will assist with keeping the foam more rigid. Since i am going to use 1" thick sheets, the front 50" of the wing will be 3" thick which will allow me to have a 3" deep plywood "stringer" (more on that later). From the 50% mark back to the 75% mark it will be 2" thick. And the back 25% will be 1" thick.

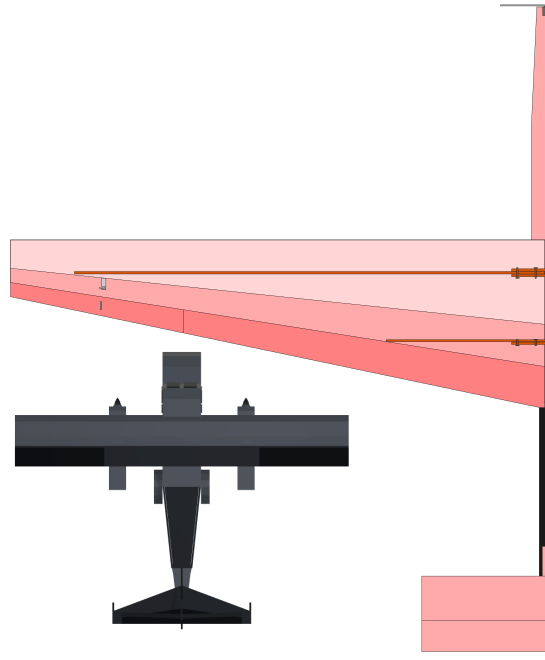

In surfboard building there is a wooden stringer often installed that is in the very center of the build from the tail to the nose and as thick as the board. My first thought was to put an 8 foot stringer right on CG in the center of the wing with a shorter one towards the back. The stringer would be made from half inch plywood (as seen from above), would go all the way thru the wing top/bottom, 3 inches deep, and be 8 feet long from wing tip to wing tip, glued into the foam. But another issue related to this large wing is how to transport it. Even just one 8' section is going to be "fun" to transport, let alone 16'. So than i thought about cutting out the slot for the stringer but gluing it in place on site. The concern there is will the glue be set enough to fly it. So currently my thought is to insert a 7'ish foot stringer in each side of the wing and connect on site with pieces of wood screwed thru connecting each stringer together, as you can see in the picture above.

The next issue i was trying to think of was how to make such a long fuselage stay rigid. I had originally thought to make the entire plane out of pink foam. I could do a profile style tail boom with maybe some reinforcements here and there. But the more i thought about it i just didnt have confidence in the strength of this foam in this configuration. Its going to be almost 9 feet long nose to tail, but its going to be a lot narrower than the wing. It seemed much simpler to design it using carbon fiber tubes that interlock into each other. The picture above has these in black. The size is not to scale as i dont have the carbon in front of me, but i have some wound mandrel carbon tubes around 22mm OD and some perfectly matching tubes that slide right into them. I was going to use them for a large wing to split into pieces but ended up not using them. So there will be a center section that connects to the wings and a tail and nose section that slot in with this.

The tail section I will probably do a very light fiberglass job on the foam, mainly so i can epoxy in some carbon tow in areas to make the large surfaces a little stronger. The Tail boom itself will be bare carbon.

The nose section i will need to make a fuselage that attaches to the carbon tube so there is a place to carry the battery and electronics. The Motor mount will probably be a wooden block fiberglassed to the end of the carbon tube. Possibly the battery and electronics could just "hang" on the carbon tube. I will have to wait to see what it looks like. This is more about trying to get a 16' wingspan flying than a super pretty plane.

The prop pictured is a 16" prop on a 4020 emax motor. It puts out about 5kg/11lbs of thrust. The servos pictured are standard 51g servos. All parts pictured, including the stringer, are the real world dimensions.

Posting here for ideas. While i have built several large builds in the past im sure there are many things i am not thinking of.

Here is a comparison in size between a 60" wingspan guinea pig and 16 foot wingspan.

ps. It may initially seem crazy to put 100g of servos at the tail, but my personal experience with these large builds is that electronics weight does NOT scale up with the size of your plane. IE the parts weight SIGNIFICANTLY less than you think they will. I think it will be fine.