joelspangler

Active member

I just wanted to share how I've been using carbon fiber strips to strengthen my builds. The specific product I'm talking about is 1x6x750mm carbon strips from hobbyking Carbon Strip 1x6x750mm (5pcs/set) (hobbyking.com)

One of the best places to use them is in the leading edge of the wing inside the paper. Pictured, I'm showing foam where I removed paper and added colored "wing tape" to contrast where the paper is. First, the finished product. The bottom of the wing is almost flat, and the top is rounded over on the leading edge. The wing is stiffened significantly and leading edge is much more durable taking tree hits and crashes much better.

This is accomplished by slightly modifying the wing plans. Instead of doing a double bevel, you remove the width of foam one one side (like with an a/b fold) and bevel the other side. Picture below. I find it easiest to glue the spar on the bottom first, then finish bending the wing.

Here's a picture of one of the planes I used this technique on, which is inspired by the Funder and Lightning http://funderandlightning.com/

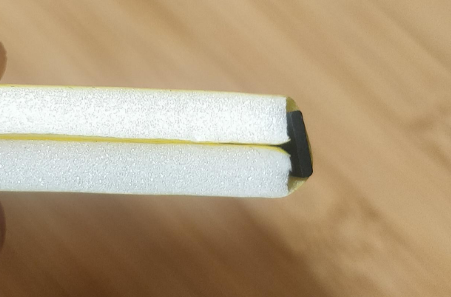

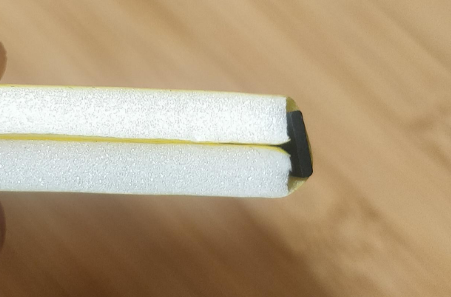

The other way I use these spars is inside of the doubled over foam spars common to many builds. I simply place the carbon fiber strip on the inside of the paper fold. Once glued in, the spars feel twice as strong, and I haven't broken one yet.

These strips only re-enforce things in one direction, but in both of these scenarios, it's the only direction the joint is weak in. Using these over rods or square tubes, significantly saves weight.

I've also used 1x3x750 carbon strips Carbon Strip 1x3x750mm (5pcs/set) (hobbyking.com) however these have fewer scenarios where they are useful. I've embedded these in a single layer of foam (cut slit, add superglue, push down in slot, cover with tape)

One of the best places to use them is in the leading edge of the wing inside the paper. Pictured, I'm showing foam where I removed paper and added colored "wing tape" to contrast where the paper is. First, the finished product. The bottom of the wing is almost flat, and the top is rounded over on the leading edge. The wing is stiffened significantly and leading edge is much more durable taking tree hits and crashes much better.

This is accomplished by slightly modifying the wing plans. Instead of doing a double bevel, you remove the width of foam one one side (like with an a/b fold) and bevel the other side. Picture below. I find it easiest to glue the spar on the bottom first, then finish bending the wing.

Here's a picture of one of the planes I used this technique on, which is inspired by the Funder and Lightning http://funderandlightning.com/

The other way I use these spars is inside of the doubled over foam spars common to many builds. I simply place the carbon fiber strip on the inside of the paper fold. Once glued in, the spars feel twice as strong, and I haven't broken one yet.

These strips only re-enforce things in one direction, but in both of these scenarios, it's the only direction the joint is weak in. Using these over rods or square tubes, significantly saves weight.

I've also used 1x3x750 carbon strips Carbon Strip 1x3x750mm (5pcs/set) (hobbyking.com) however these have fewer scenarios where they are useful. I've embedded these in a single layer of foam (cut slit, add superglue, push down in slot, cover with tape)

Last edited: