WHAT IS A SERVO?

A servo (or servomotor) in the R/C industry is a small mechinism that turns the radio waves from your transmitter into kenetic energy to control your craft.

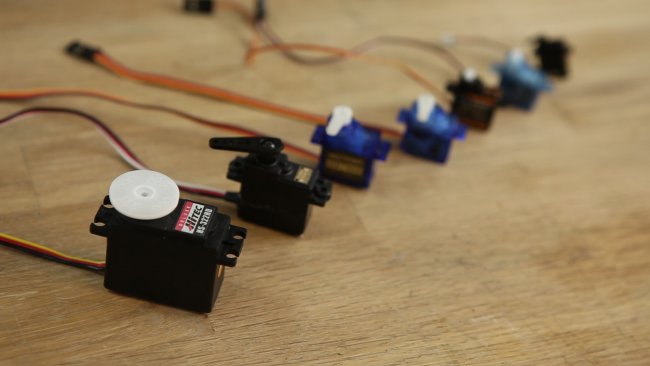

They come in all shapes, sizes, brands, weights, types, and prices. We hope that by the end of this episode, you'll have the confidence to know exactly what kind of servo you need for your project.

SIZES

When shoping for classes of servos you'll notice them labeled by grams. But what does that gram measure?

The gram is the weight of the servo itself (minus the wire) Here is a typical everyday 9-gram servo on a scale. We got a reading of 8 grams (probably rounded down).

This applies to 5-gram, 2.7-gram, and so on.

TYPES

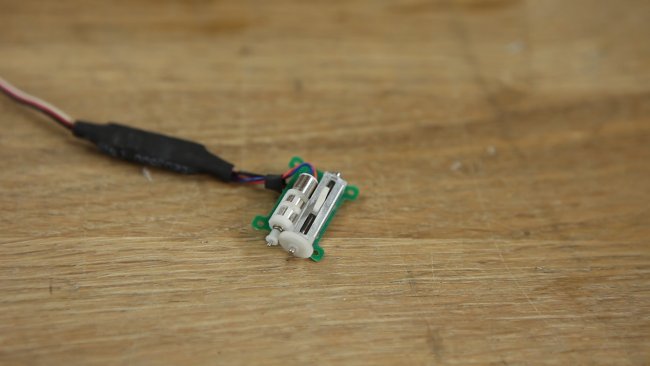

Above you will see a liner actuator servo. Instead of applying rotational motion these only move in a linear fashion.

The reason you'll find these on a lot of smaller models is because they weigh significantly less than a standard servo.

Blow that up a bit and you'll find something like this! This is another style of liner servo that trades speed for power.

If you took look inside you would find a threaded screw that is turned by a motor. Depending on the rotation, the rod either extends or retracts.

THE GUTS

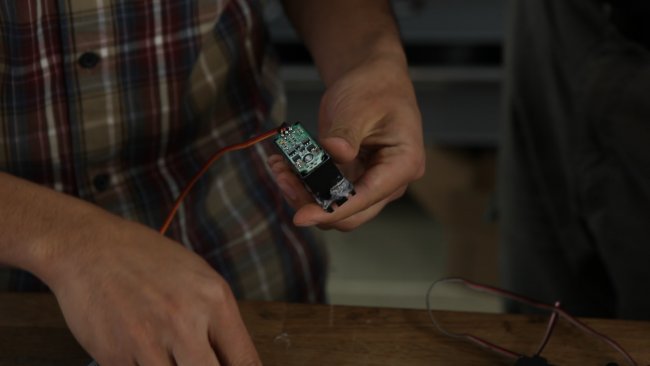

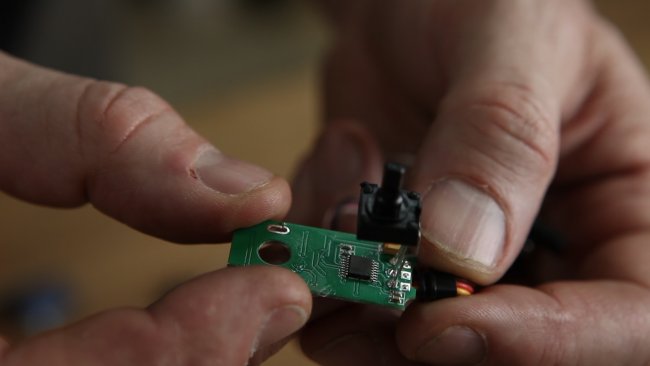

If you remove the bottom plate on a servo you'll see the control board.

This is the brain of your servo. The little black knob looking thing is a potentiometer (or pot). A potentiometer measures the variable resistance in voltage. A more common example of a pot would be the volume knob on your car stereo.

This measurement information is send back to the board which then tells the servo which direction to turn, how fast to turn, where to center, etc.

Remove the top...

...and you'll see the gear set. This is where the lack of torque is compensated by gearing up that energy. The motor can still rotate quickly and the gears do all the heavy lifting.

On some models, underneath the top plate you'll see a bearing. This smooths out the rotation just like you would imagine.

If you ever see 'dual bearing' servos, that means exactly what it sounds like. There is the addition of another bearing underneath the gear shaft.

The gears on most servos are made of nylon. Nylon has some self lubricating properties (although most companies still add a bit more just for insurance).

Because it is still a synthetic polymer it will never be as strong as titanium or metal gear servos, but will never be as expensive.

If you're trying to decide on wether to buy metal gear or not, it all depends on the project. If you are building a precision 3D plane or a tail mechinism for a tricopter, a metal gear is going to hold up to the pressure required for those designs.

For our foamies on the other hand, nylon gears work wonderfully and are dirt cheap!

STANDARDIZATION

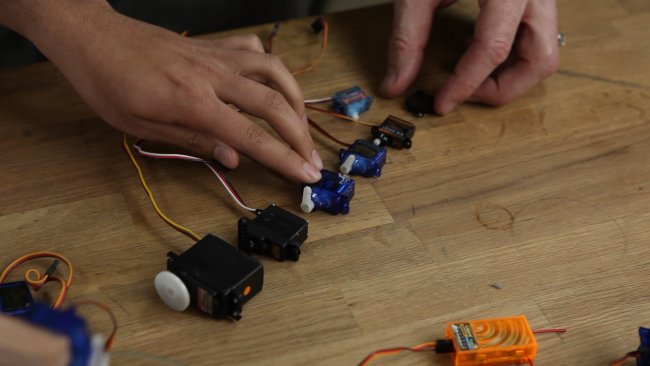

By now you would assume that all brands of servos have the same rules. This is ALMOST true. There are a few things that are unique to certain models and not all are created equal.

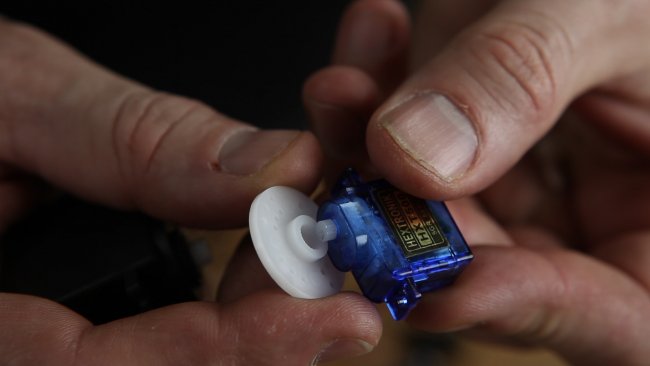

As you see above, the splines are different sizes depending on which company you buy from. This servo arm does not line up with the horn. As a rule if you stick with the same company, all should fit perfectly.

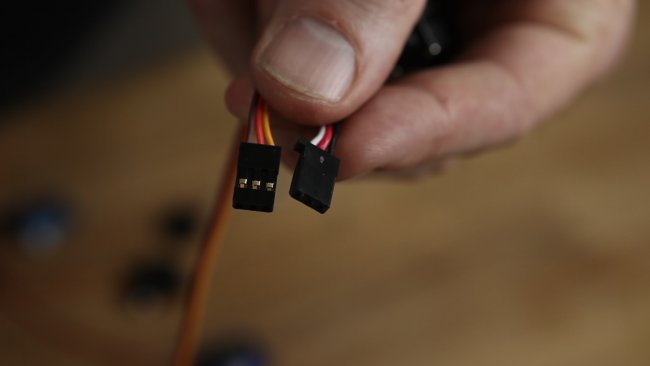

The same applys to servo wires. All models should have a signal wire, a positive, and a ground. If you look a bit closer the connector on the right has a little tooth sticking out on the side.

This is commonly known as a Futaba style connector while the left is known as universal. To be honest there is no difference other than that little tab. If you decided to sand it off the connectors would be identical.

SERVO MOTORS

Servo motors usually come in two flavors. Coreless and cored. These terms are pretty self explanitory, but what does that mean for performance?

The smaller motor is coreless. It has much less mass which give it the ability to react faster and weigh less. If you looked down the copper tube you would see that its hollow.

This does not mean that coreless is better! This falls into the category of your projects needs. If you need razor sharp precision a coreless will give it to you. If you want more torque and power a cored will do the job.

PULSE WIDTH MODULATION

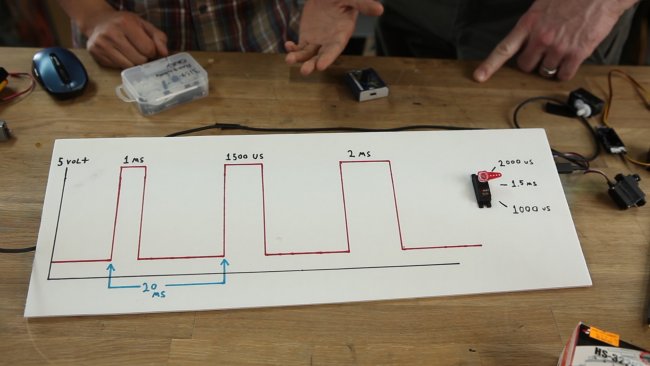

How does a servo know how to do what you tell it? Well a servo knows how to speak electronic signal. The only way to really make sentences with an electronic signal is to use pulses. Think Morse code!

The amount of pulses being sent to the servo tell it what position to be in.

If the pulses are coming in around 1 millisecond (or 1000 microseconds) it knows to rotate X degrees to the 1000us position.

When you modulate that signal to something else it recognizes the change in pulse and knows to move to whatever position it hears.

The direction in which it rotates depends on who you buy from! Rotation in not standardized between brands.

TORQUE

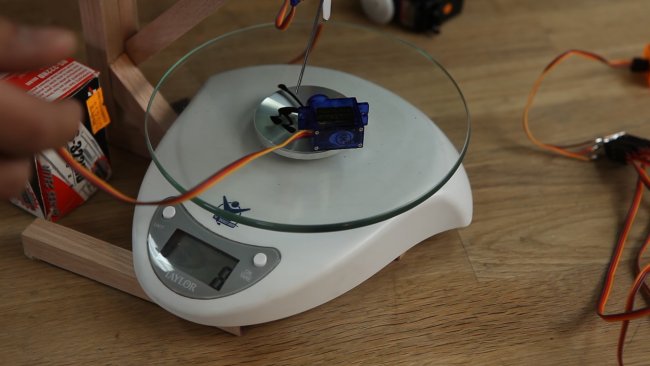

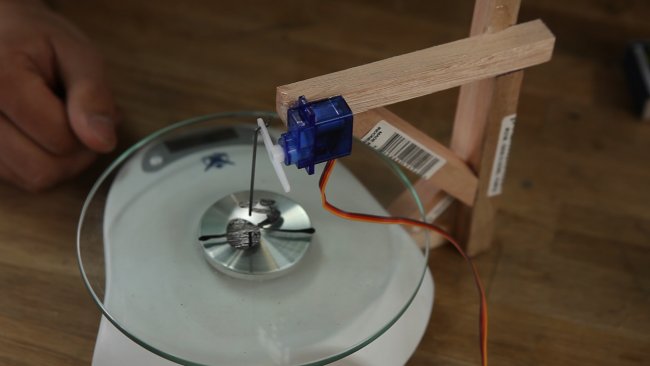

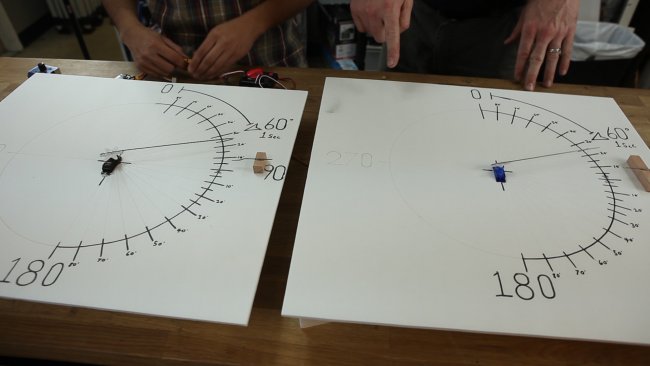

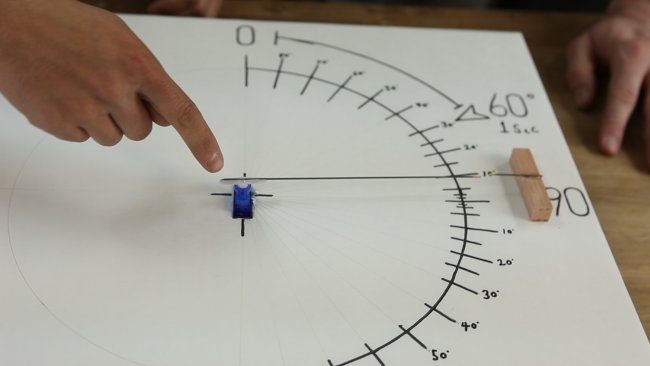

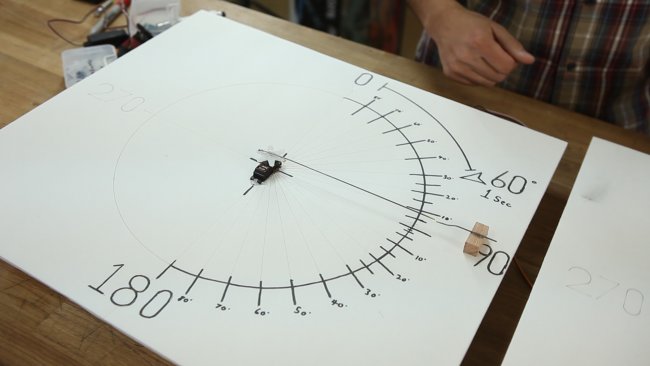

If you look up the specs for servos you'll see torque measured in ounces per inch (oz-in). What does that mean?

This is one thing that IS somewhat standard between brands. To find the oz-in you measure out one inch from the center of the servo. However much pressure is applied from this point, in ounces, gives you your measurement.

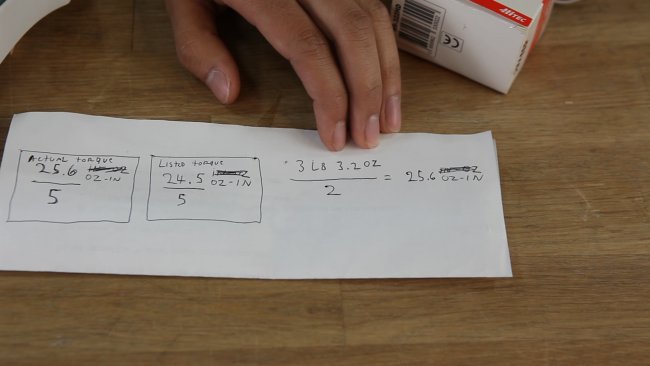

Here we see that the servo is applying 3lb 4.7oz from a HALF inch.

The mean weight applied between a few different servos of the same brand came out to 3lb 3.2oz. Divided by 2 to make up for that half inch from center, you'll find 25.6 oz-in.

The listed oz-in from this particular brand was 24.5 oz-in so it actually performs better than advertised!

BROWN OUT

Have you ever been flying your plane a little too hard and had a loss of signal? The go-to excuse usually is, "It's my radios fault!"

We say before you blame your radio we suggest you investigate into how much power you're drawing from your servos.

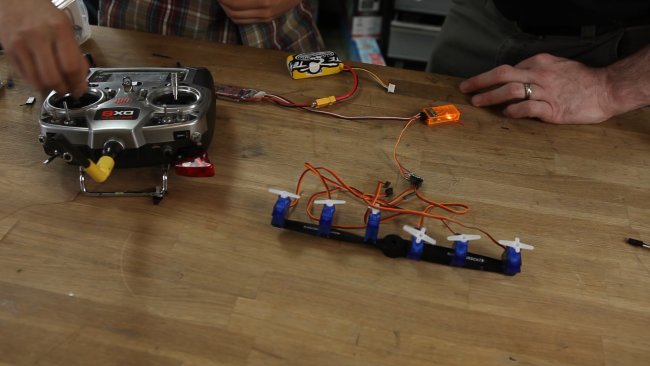

If you've never experienced a brown out, this is when the total milliamps being drawn from the servos is too much for your ESC's BEC to handle. The BEC then shuts down and will try and reboot, which effectively turns your plane off.

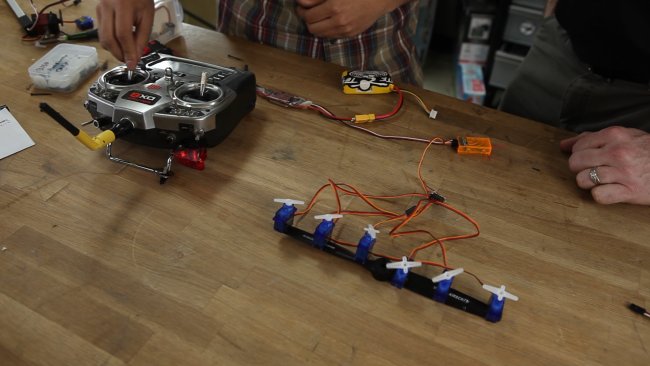

As an example, we hooked up way too many servos into this orange receiver. Keep an eye on the LED inside the receiver.

Lights out! No light means no signal.

This can be avoided with some simple arithmetic. Find out how many milliamps your servos need and how much your reciever is rated for. This way you'll never overwork your gear.

ANALOG VS. DIGITAL

By now you know how a servo works, how it talks to your radio, how they are measured; so the last decision you'll probably make is between digital and analog. What's the difference?

The ONLY difference between an analog and digital servo is the brain inside of it. Sans control board, they are identical.

The control board inside will determine how fast it is able to think and how it can control the servo's motor.

An analong servo for example can make adjustments at around 50 cycles a second.

A digital servo can make adjustments around 400 cycles a second! They react quicker and are far more accurate.

THIS DOES NOT MEAN DIGITAL IS BETTER! We can't stress enough that your decisions should be based around what you are building.

You can absolutlely put digital servos onto one of our foamies and it will fly just as well as if it had analog servos. That extra cash you spent really only shows when you are putting it into projects that will truly benefit from the extra performance.

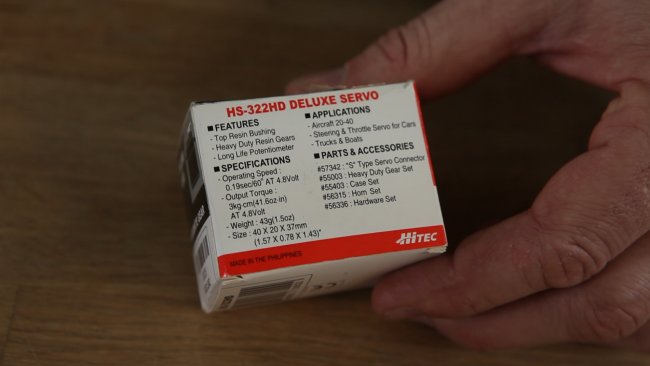

We hope we helped you understand what all that silly math on the side of the box means!

At the end of the day if you are torn between a few brands, take a step back and ask what your plane really needs.

Don't bother spending a small fortune on the best-of-the-best if you are making a simple design.

On the flip side, don't go cheap if your craft is asking for precision and stability.

We want to thank Little Bits for sponsoring this episode of Flite Test!

Little Bits are a modular electronic building kit that allows young minds to learn how electronics work and old minds to prototype ideas instantly with no waste!

They were so kind to not only sponsor this episode but provide a discount for our viewers! If you go to littlebits.com/flitetest they are offering $20 off your first kit!

If you do end up integrating Little Bits into your planes we want to see! Take a picture and upload to social media with the tag #flitetest.