Inq

Elite member

I'd like to understand the fundamentals of these cheap 30A ESC that come with the "kits" below. I think I understand the three leads going from the ESC to the motor are the different phases and each has a sine wave signal going across it to drive the motor. Does the ESC have circuitry that "senses" the motor's position or something back through the same wires? I've heard the term EMF feedback, but don't really know what it is or if that has anything to do with this or not.

I guess what is driving my Inquisitiveness, is how is the same ESC able to work on these 2212 motors that come in different flavors of 1000, 1400 and 2200KV. How does the ESC know what's hooked up? How does it know what rate to send the sine wave frequency depending on how the prop is loaded climbing and diving or even what prop is attached?

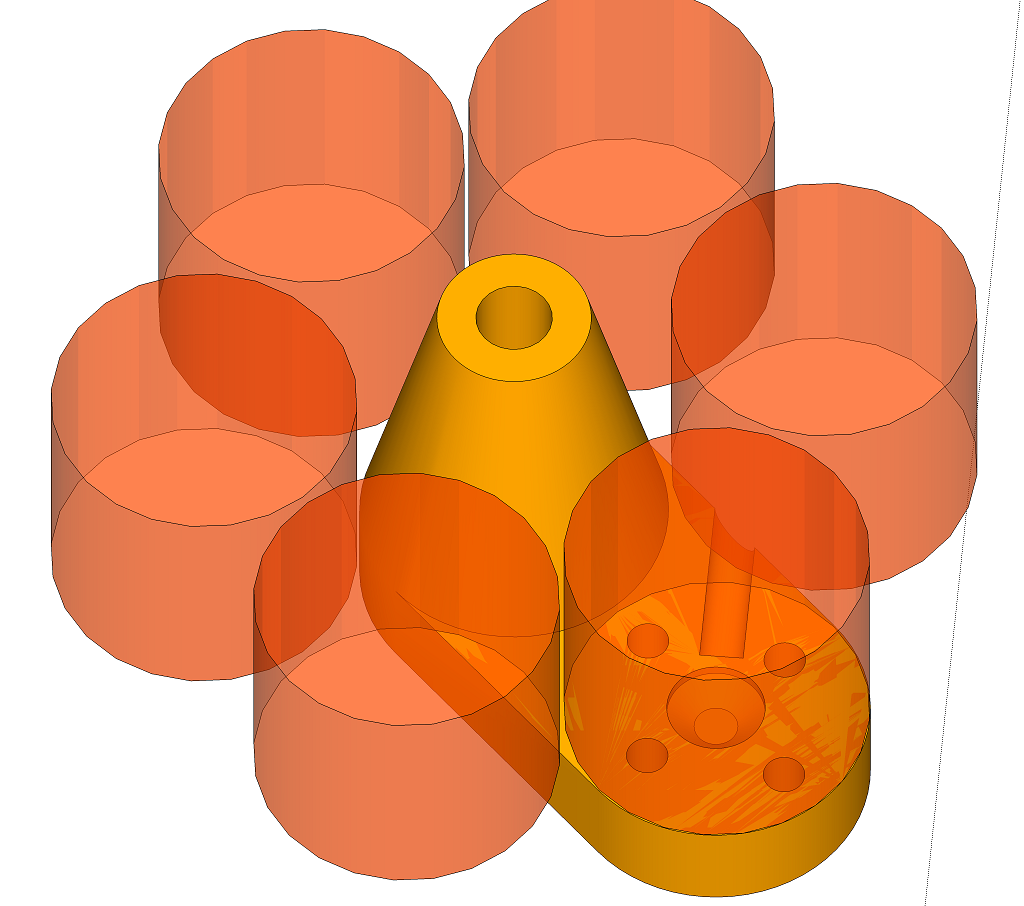

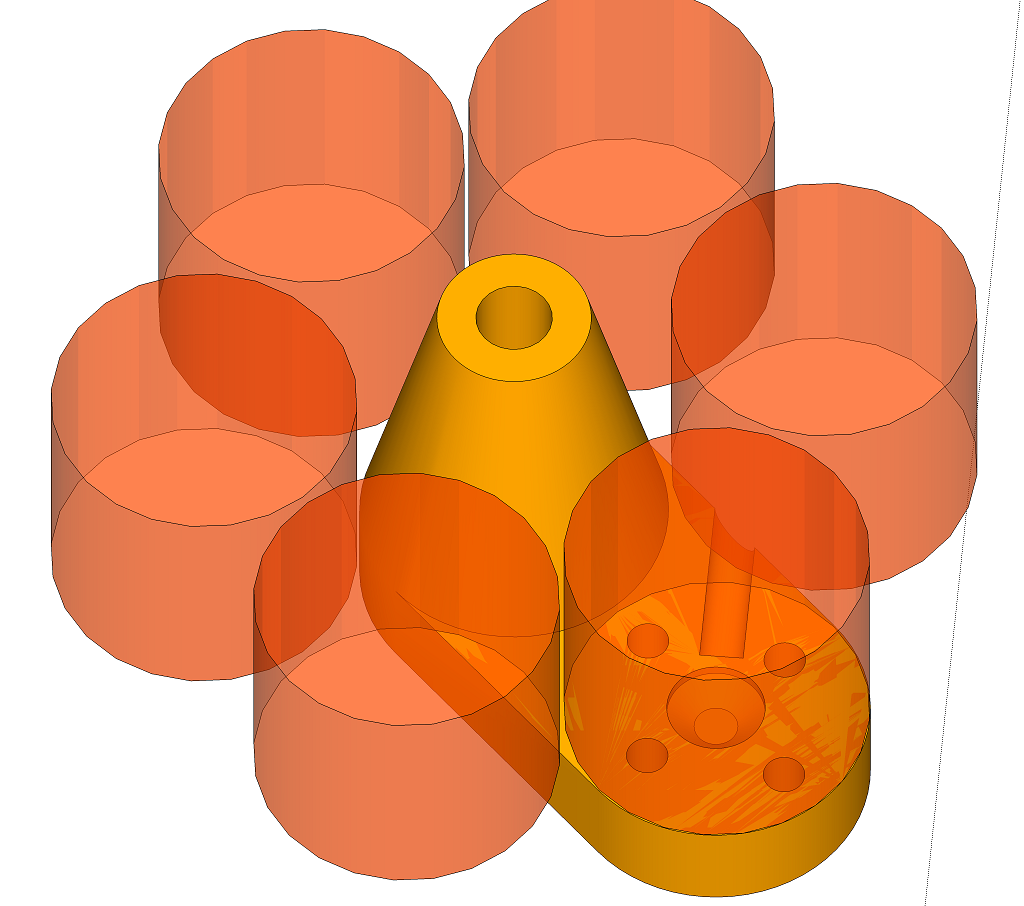

Now... for where I was heading with the title... I'm thrashing something around in my head about making a gearbox so I can swing scale WW2 type propellers. Big gear on the propeller shaft, small one on motor shaft - easy-peasy. As I sketched it up, I realized, there was nothing mechanically limiting me to the number of motors I attach...

Not that I would do this, but could I... say, I'm using 2, 3... 6 of the same 2200KV motor. They'd all be geared at the same ratio, so they would always be turning at the same speed. If I had enough amp capability, could I use one ESC on multiple motors running in parallel off the same 3 output wires?

If you need to throw out the big EE terms, I can do the research and I have a couple of EE's in the family who would be glad to use small terms to explain it to me.

I guess what is driving my Inquisitiveness, is how is the same ESC able to work on these 2212 motors that come in different flavors of 1000, 1400 and 2200KV. How does the ESC know what's hooked up? How does it know what rate to send the sine wave frequency depending on how the prop is loaded climbing and diving or even what prop is attached?

Now... for where I was heading with the title... I'm thrashing something around in my head about making a gearbox so I can swing scale WW2 type propellers. Big gear on the propeller shaft, small one on motor shaft - easy-peasy. As I sketched it up, I realized, there was nothing mechanically limiting me to the number of motors I attach...

Not that I would do this, but could I... say, I'm using 2, 3... 6 of the same 2200KV motor. They'd all be geared at the same ratio, so they would always be turning at the same speed. If I had enough amp capability, could I use one ESC on multiple motors running in parallel off the same 3 output wires?

If you need to throw out the big EE terms, I can do the research and I have a couple of EE's in the family who would be glad to use small terms to explain it to me.