Uncle Manuel said:

Hi! (*the-Josh-Bixler-Hi!*

)

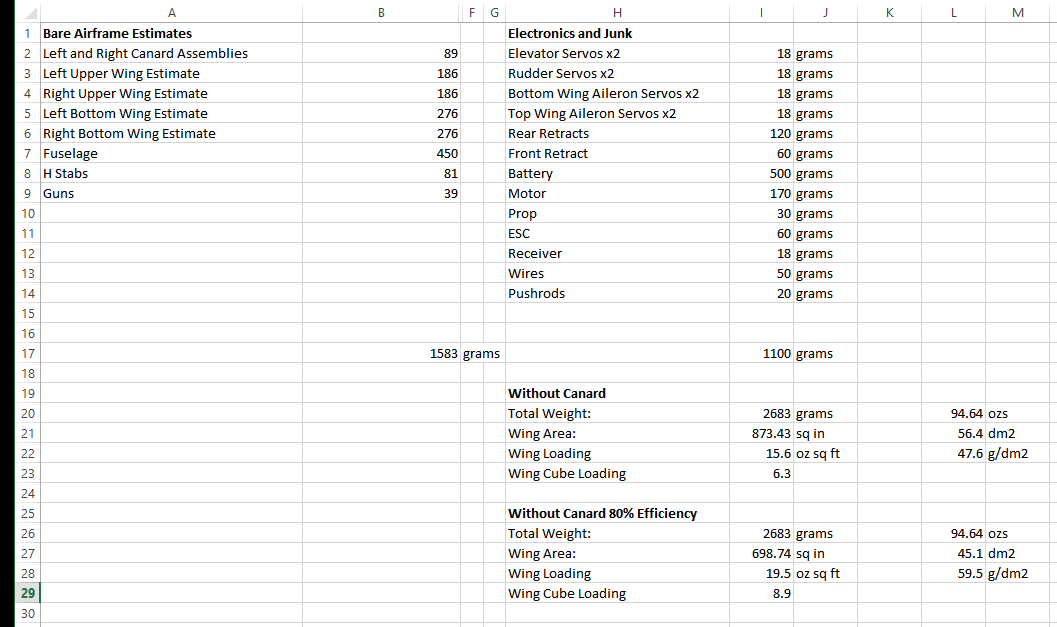

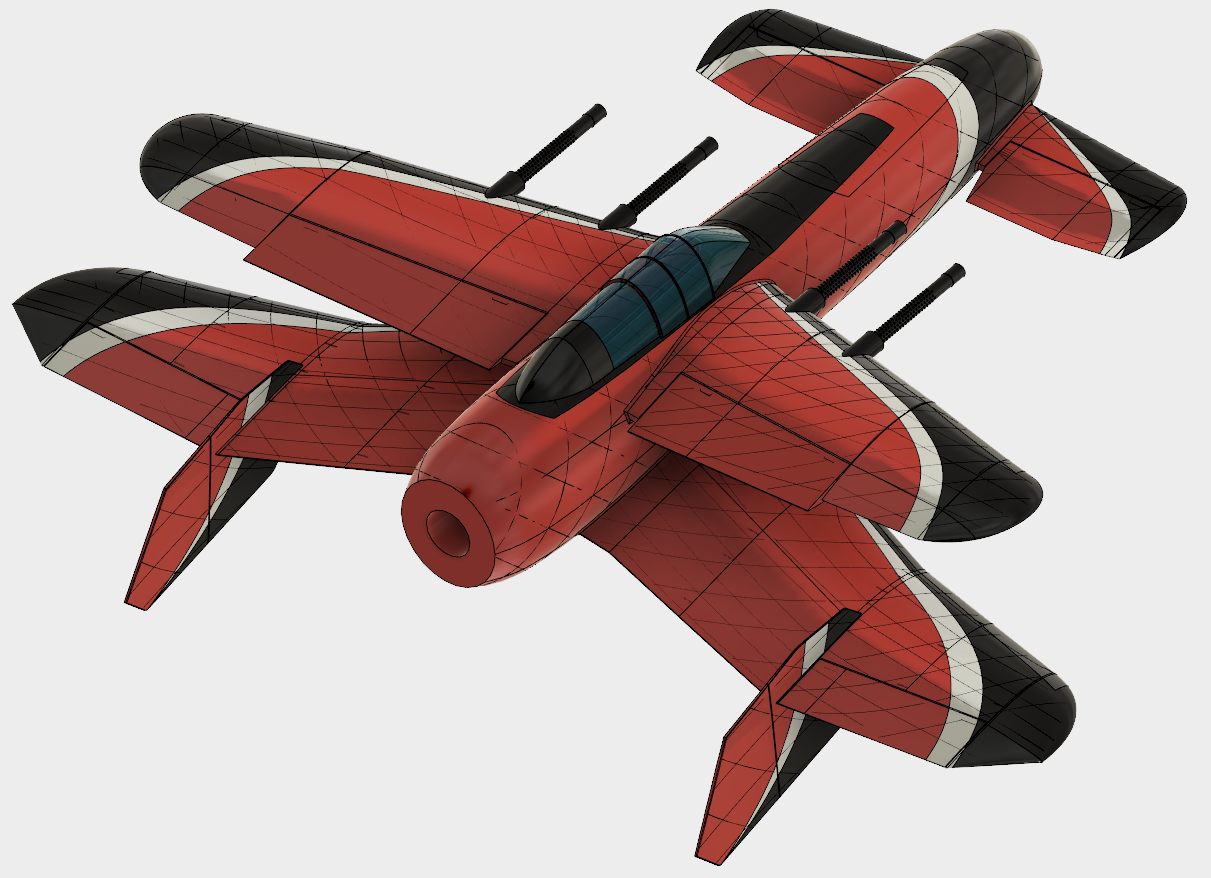

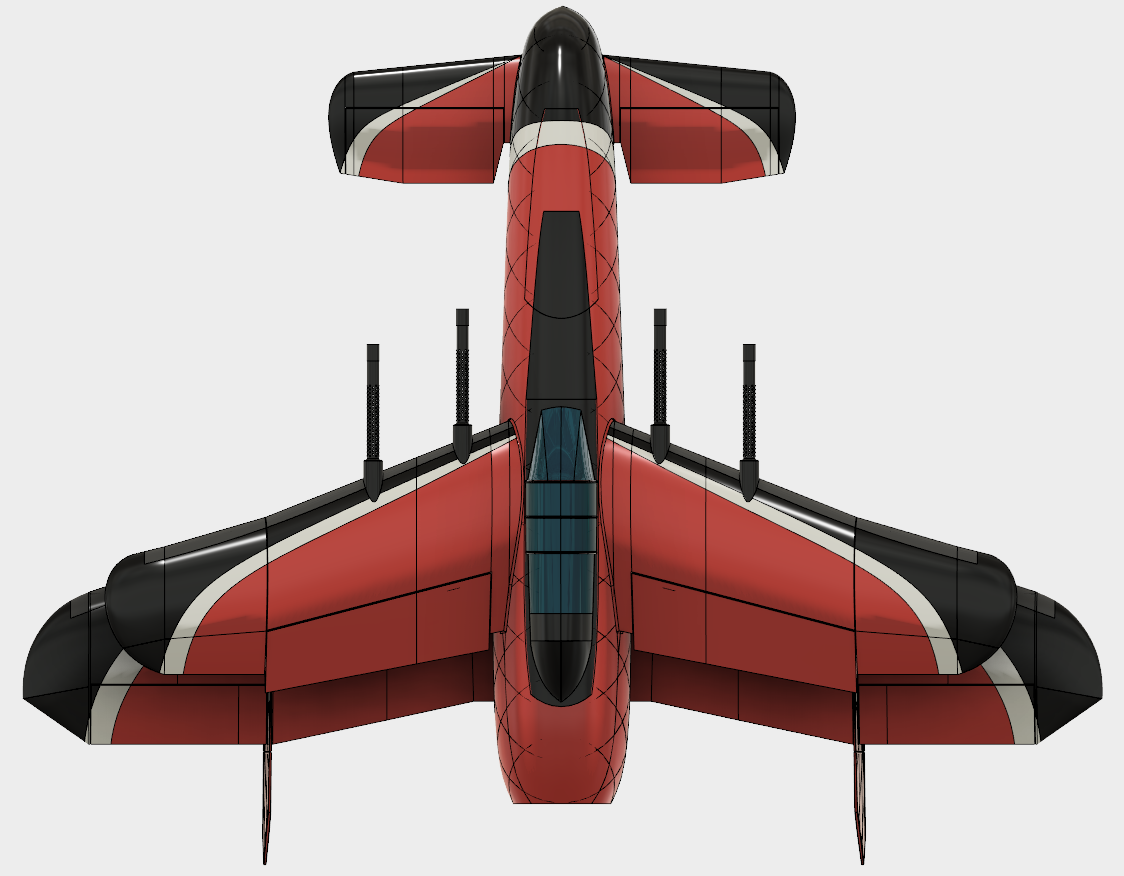

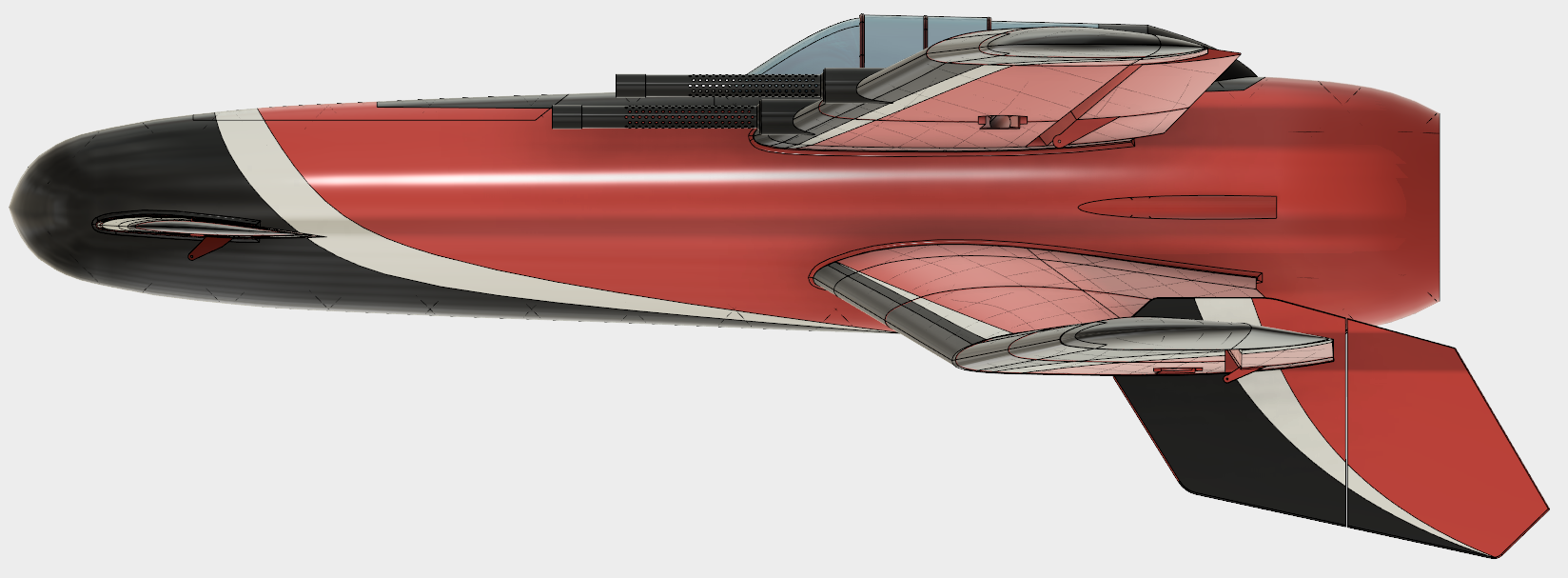

I stumbled upon your amazing Hughes Devastator build and I'm thinking about getting into 3D printing myself. I'm pretty much sold on a Creality3D CR-10S model, maybe the 4S (400 x 400 x 400 mm) or even the 5S (500 x 500 x 500 mm) for large wing sections or whole fuselage sections. Right now I'm having a twin-motor box-wing tailsitter VTOL with around 1 meter wingspan in mind. Ambitious goals, I know. But I'm basically sold on the whole 3D print idea and that you can make everything what you can draw in CAD...

That brings me right to some questions:

1) what filament do you use and what's the structural limit in an airplane environment?

2) can you design integrated hinges for ailerons & flaps or does this not work with PLA? (tolerances/fitment, smoothness, wear,...)

3) what's the weight penalty over EPP or foamboard?

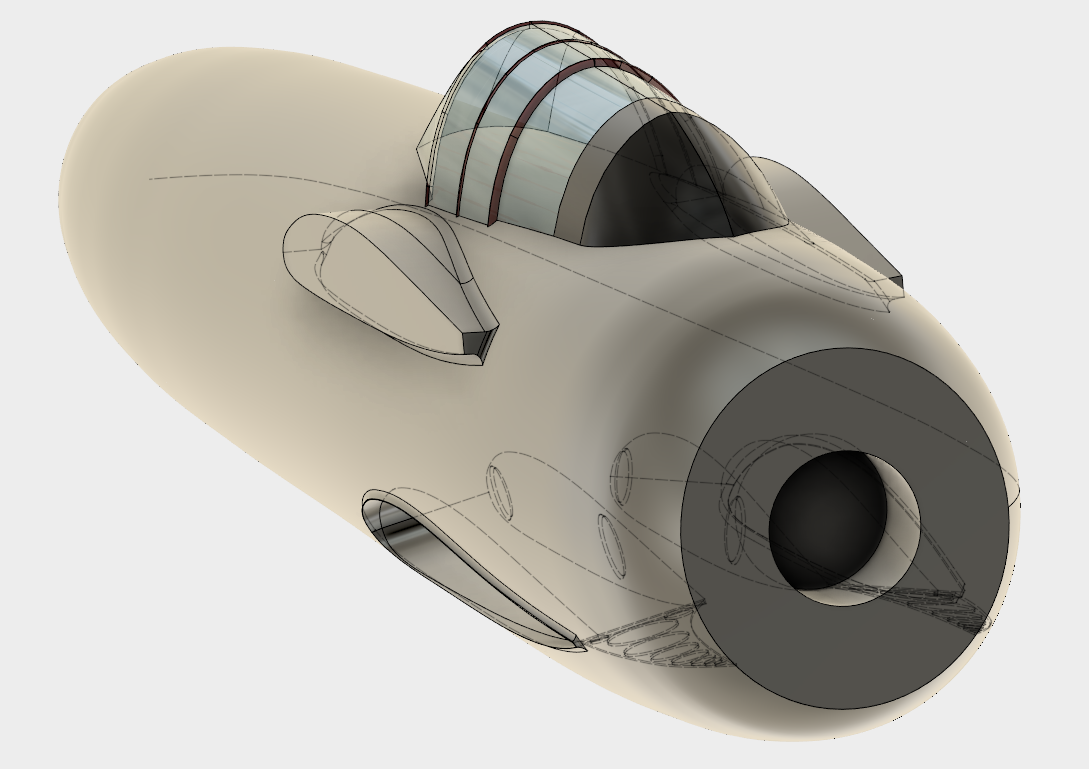

4) what nozzle size and feed rates do you run on large sections like for the Devastator?

5) what parameters do you run to archive a good print quality (temperatures, feed, return, jerk,...)

6) is the wing surface just made out of one layer PLA or do you run more material there?

7) do you need carbon fiber spars or are integrated ones (PLA) sufficient?

8) what's your workflow from the idea for a part to the finished print?

Sorry for asking so much questions but I wanna know the practical strength for usage in a R/C model, especially with the wings and the high G-forces during hard pulls. I don't wanna baby the airplane around in fear of it breaking apart...

Software-wise: I guess you have to construct the part/section in a CAD program, create printable files from there and then setup the print in a slicer? I'm pretty much set on BLENDER and CURA, I guess. What do you use?

Many thanks in advance

Manuel

Uncle Manuel sent me a bunch of questions in a PM, and I asked him if I could answer them in the thread. Helps get the information out there for others that might also have the same questions. If people have questions in the future, don't worry about asking them in one of my threads, it's what they're there for.

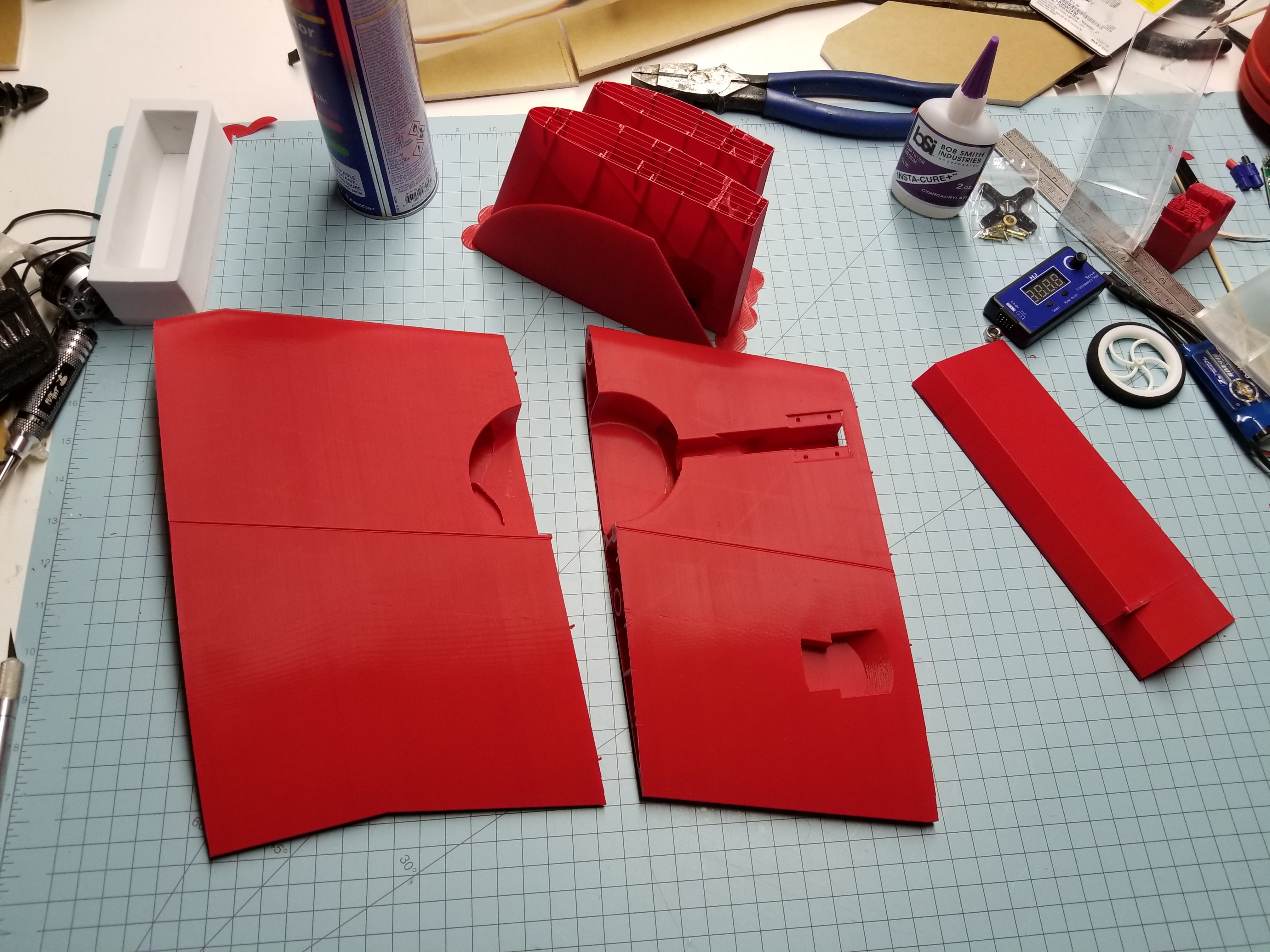

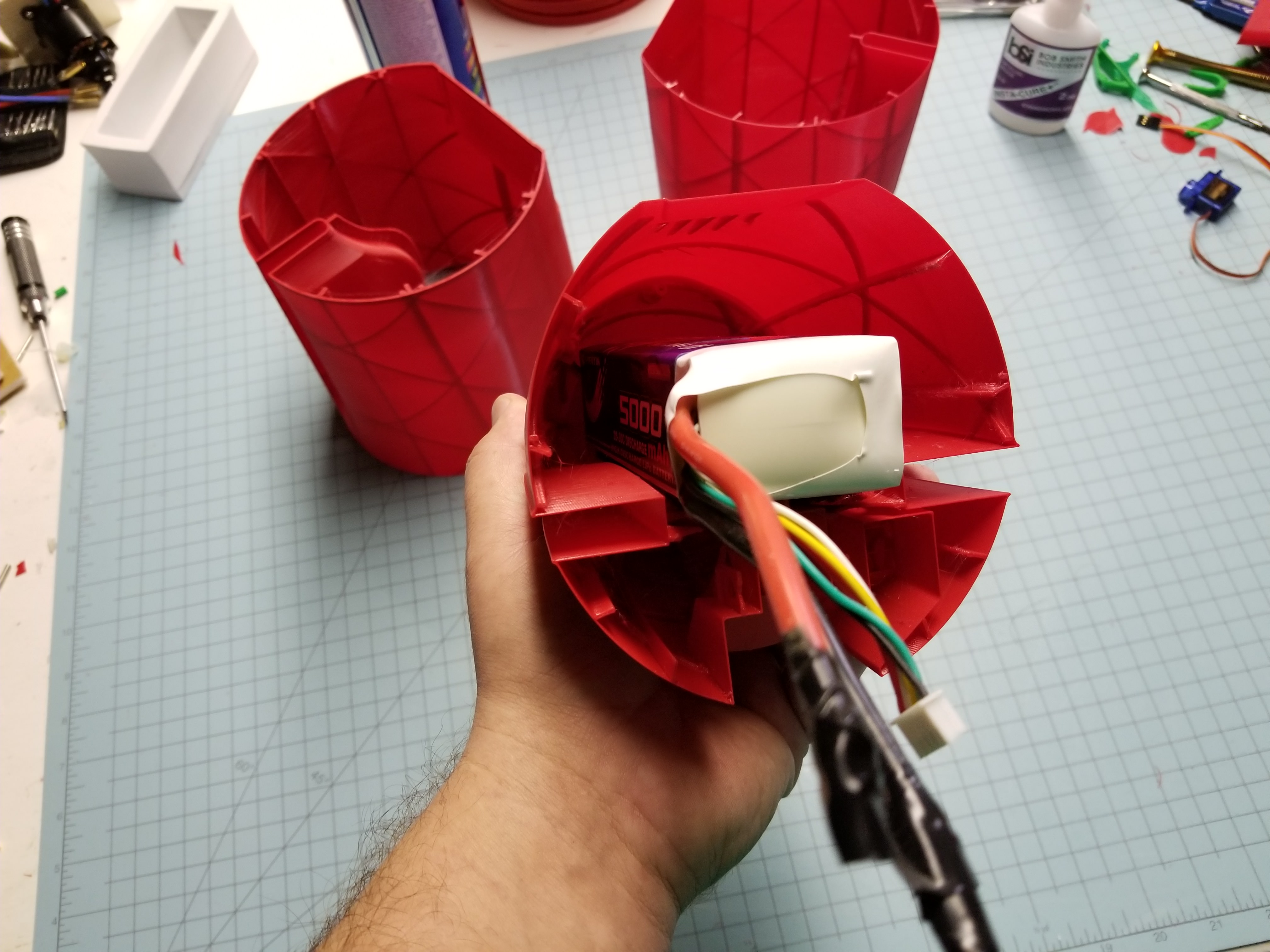

1.) I'm playing with several different filament types. PLA of course is the standard, but I'm also working on PETG and Polycarbonate filaments. PETG is more flexible, and will require stiffeners like carbon fiber rod. Polycarbonate is very strong, and I'm testing some lower warp stuff. A print chamber will probably be required (foamboard box lol).

2.) You can do integrated hinges. I'm using CA hinges on the Devastator, cause it's simple. Maybe I'll add some integrated ones later after I know it flies.

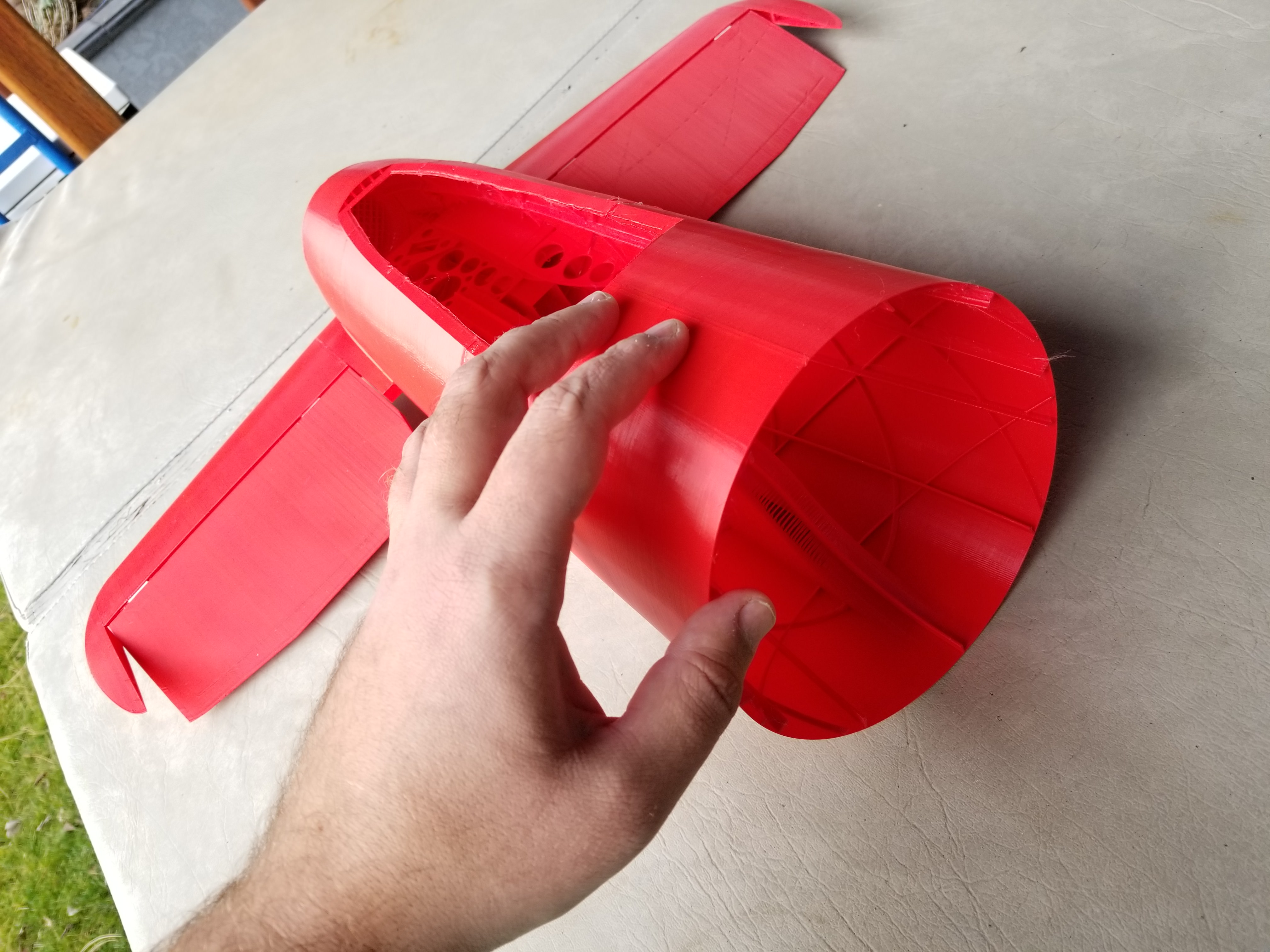

3.) It's quite a bit heavier, at least with the way I design foamboard planes. Of course, a lot of EPP ARF planes are heavier than foamboard, and end up closer in weight to 3D printed models. Basically you want your planes to have around 40in/1000mm of wingspan. Too much smaller than that, and your wing loading is pretty high.

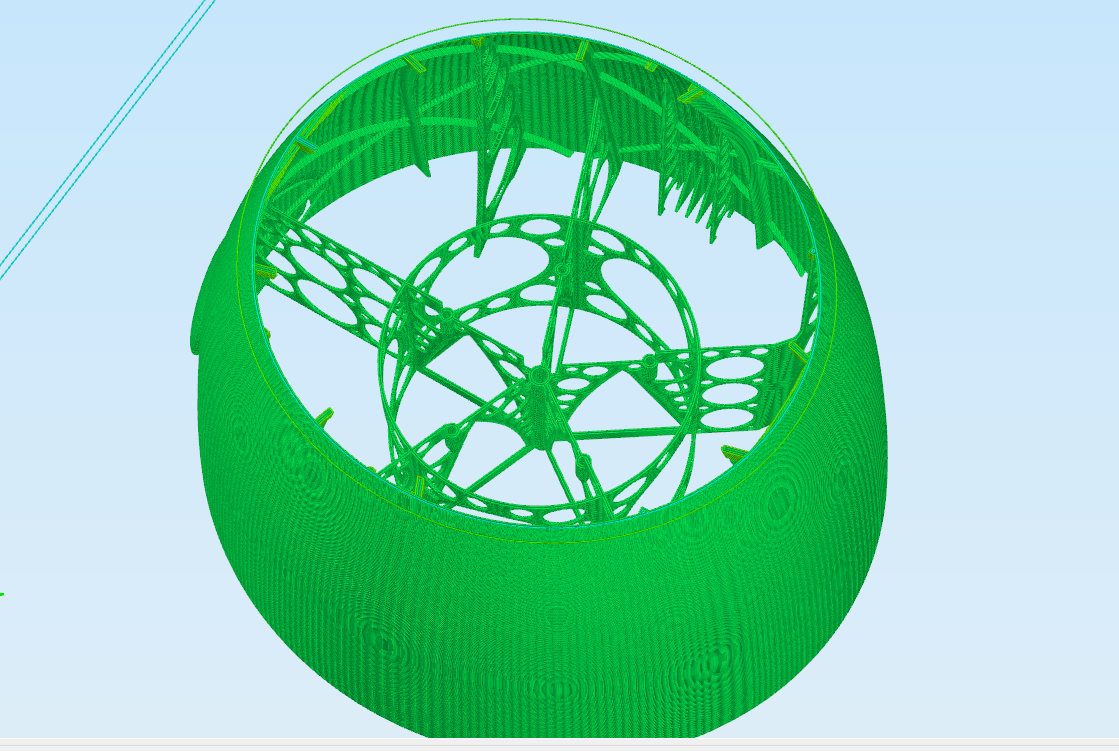

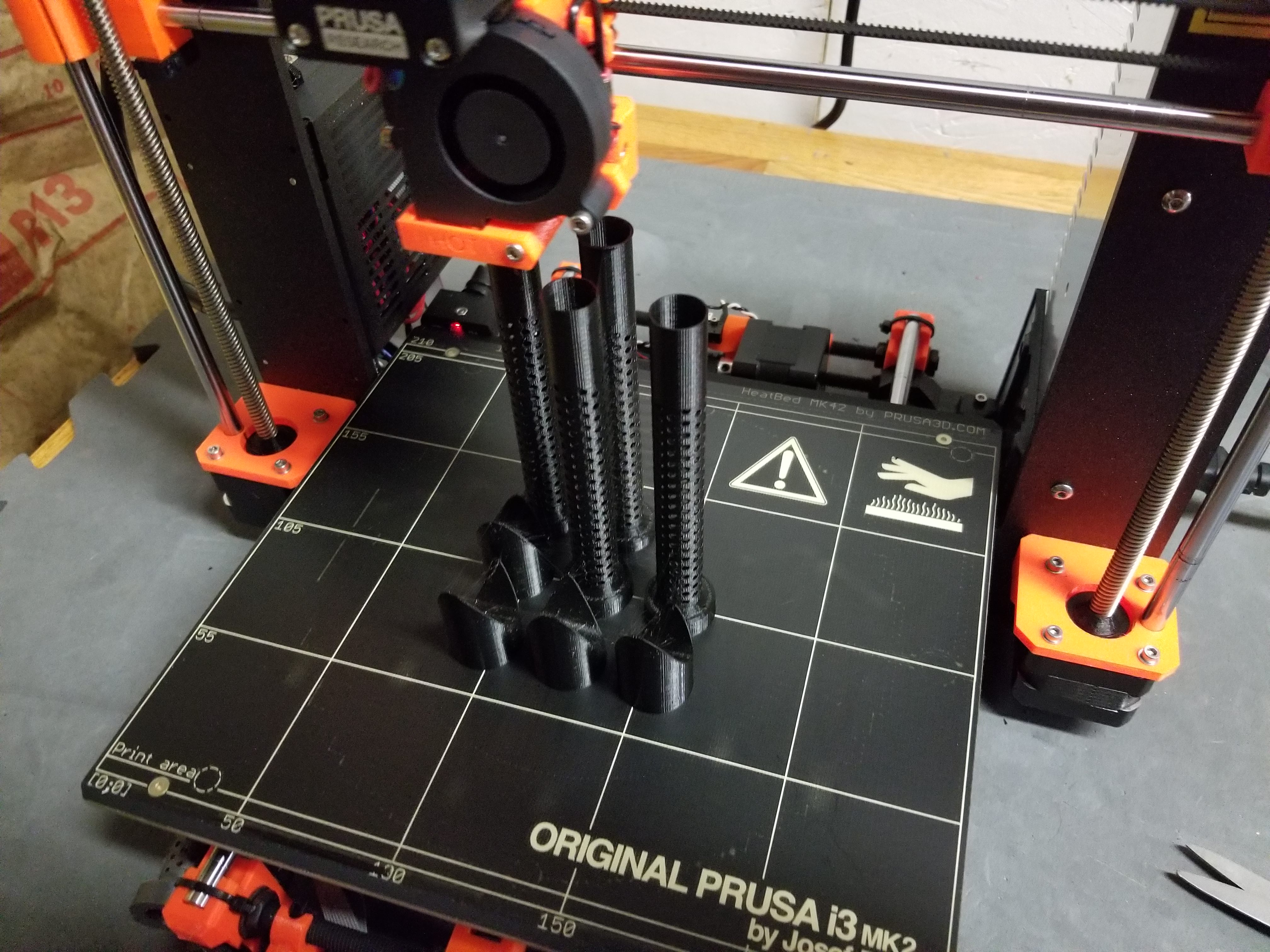

4.) I'm using a standard .4mm nozzle, .25mm layer heights, and 60mm/s print speeds.

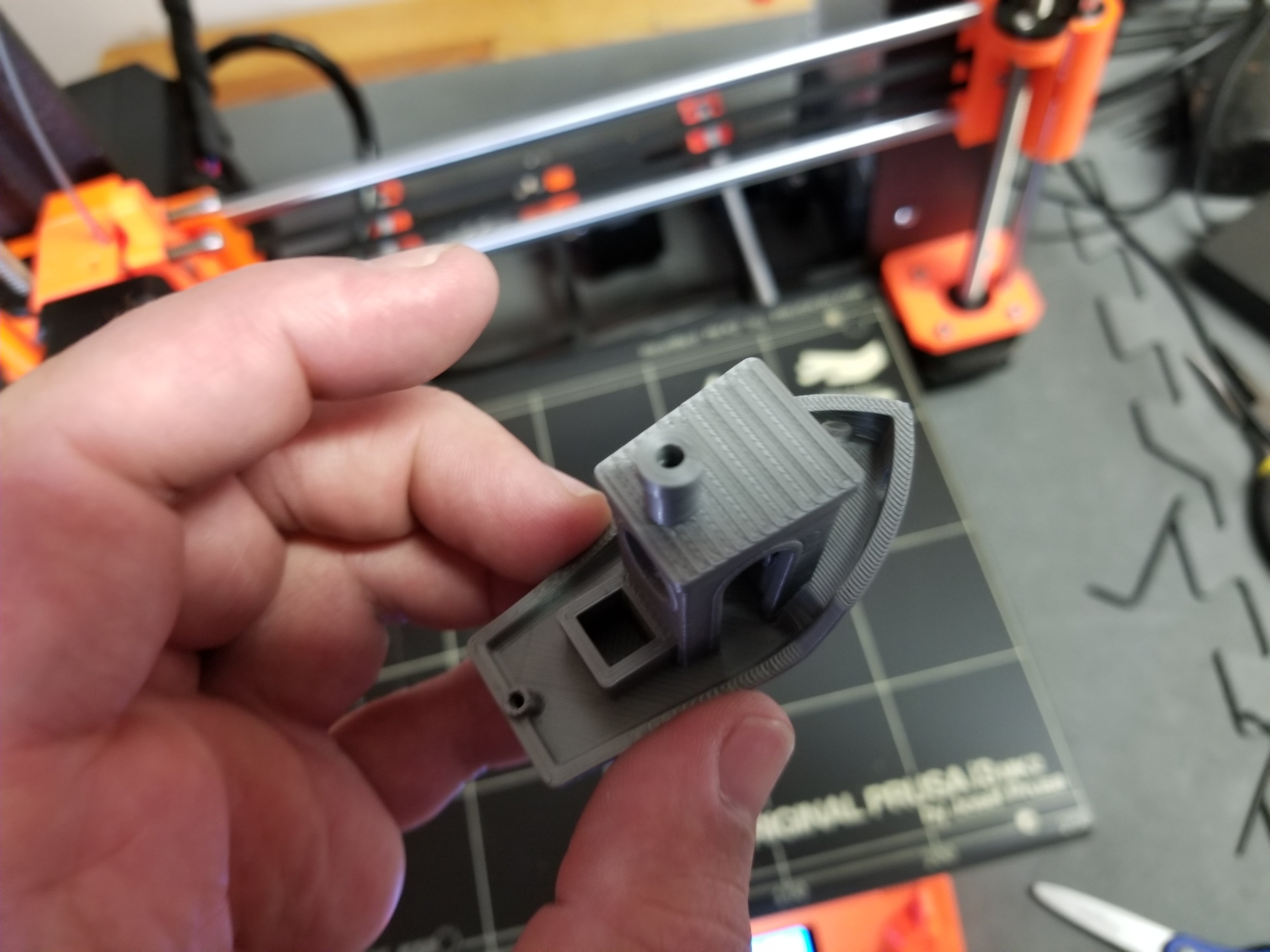

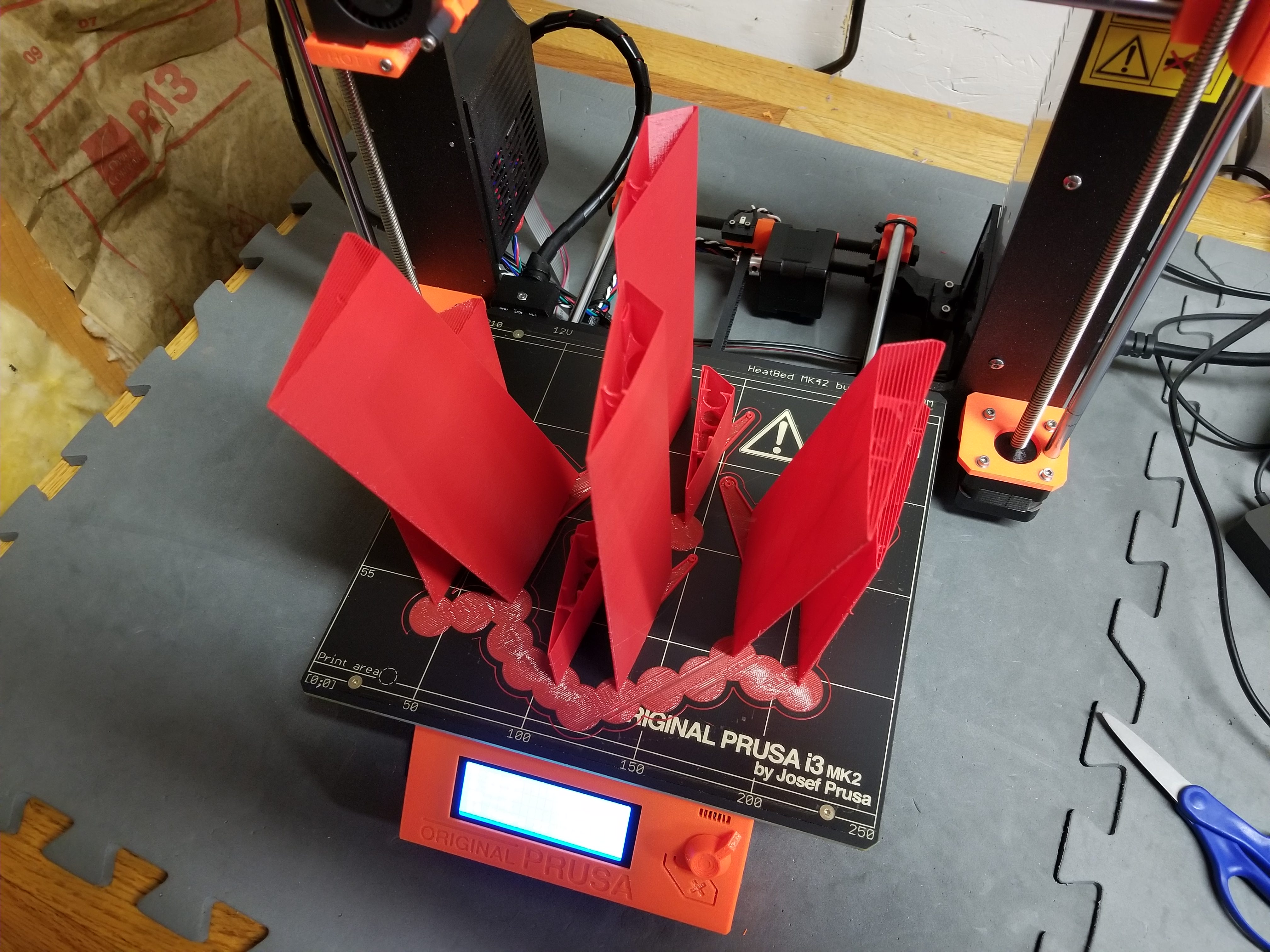

5.) I'm using a Prusa i3 mk2, so never needed to adjust return or jerk settings. On some cheaper kits, or if you compile you may be required to do that. Most 3D printers now are all setup for acceleration, and you don't have to do tuning on them like a CNC machine.

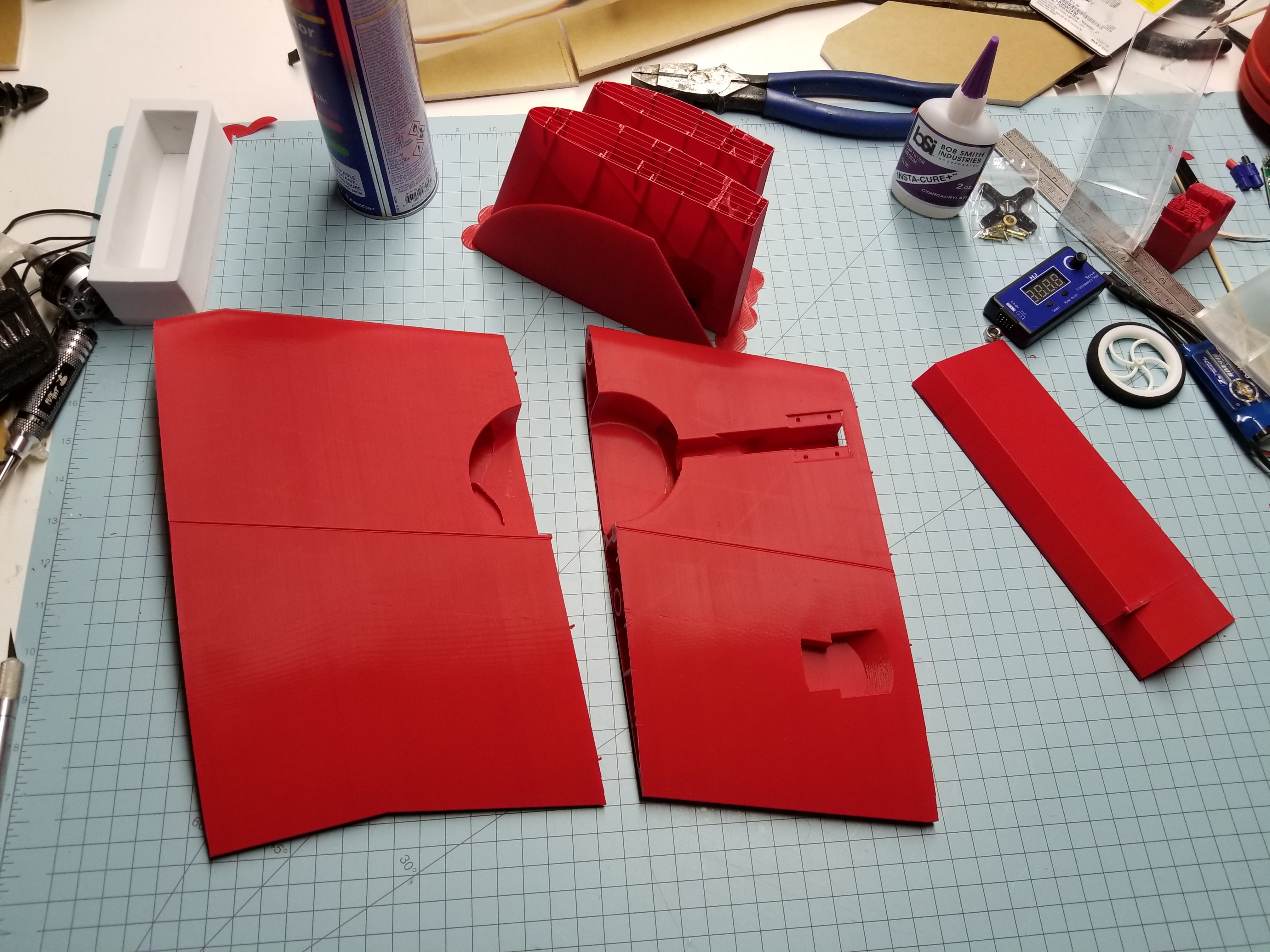

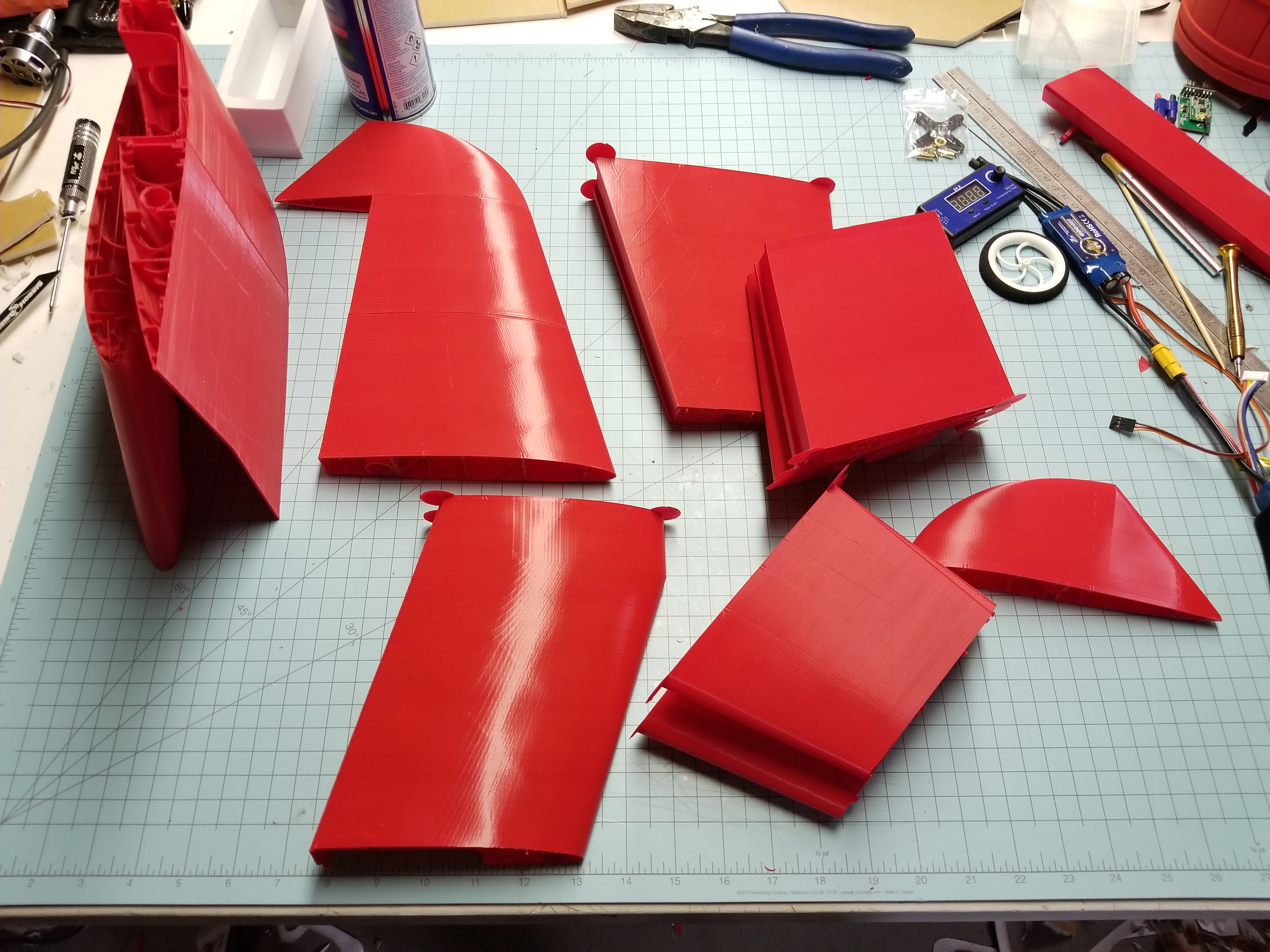

6.) For the size of the devastator, the outer wall is just one perimeter of PLA. More than that would be very heavy.

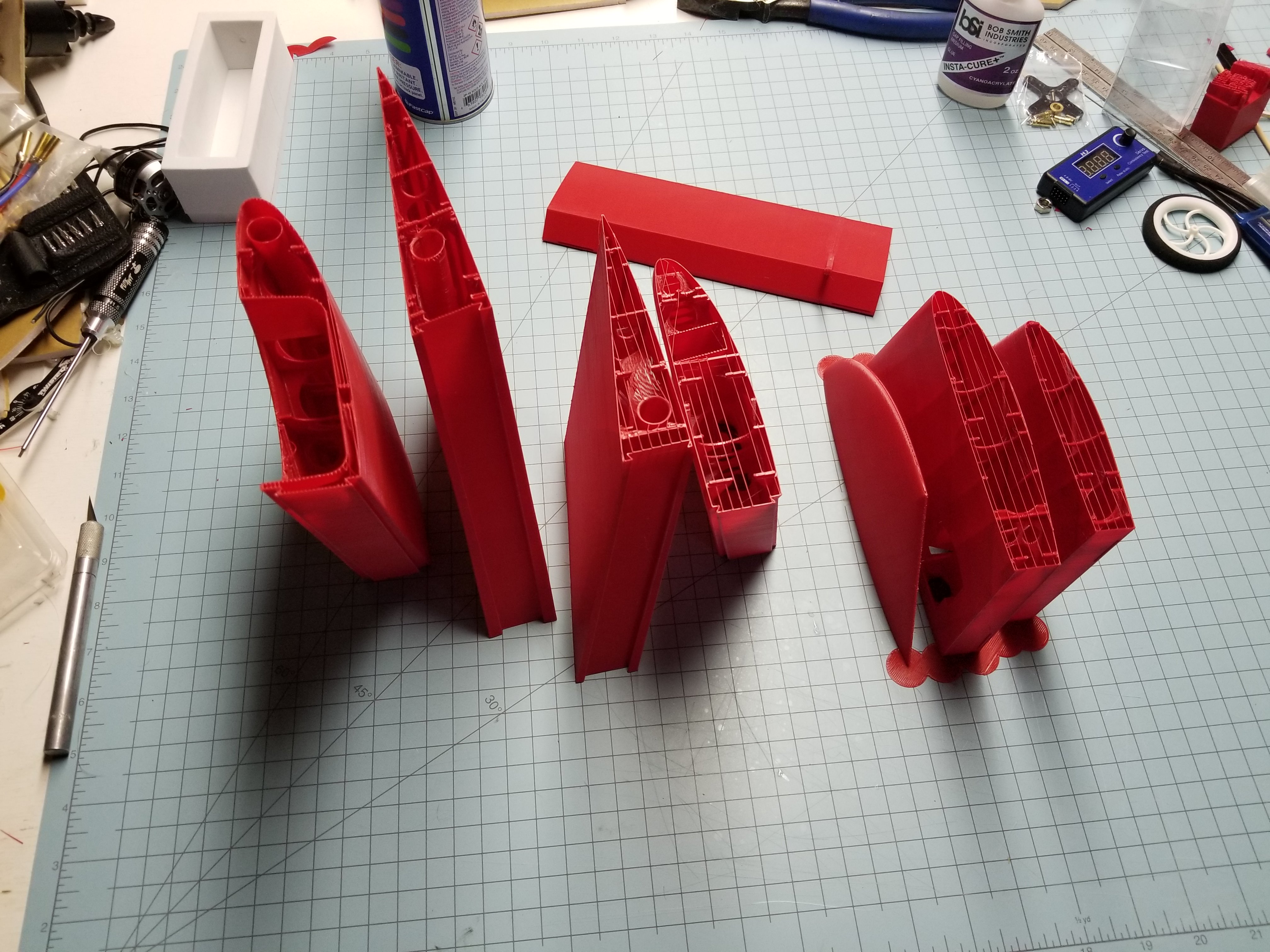

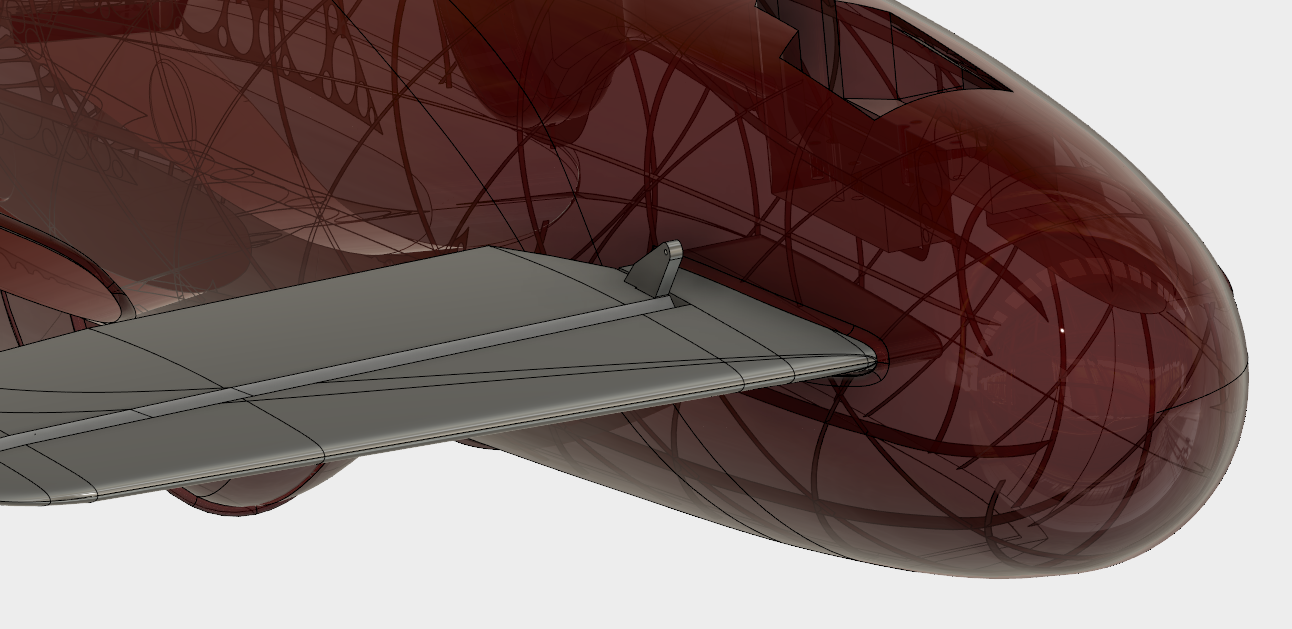

7.) PLA is fine as far as stiffness goes, and I think my wings will be strong enough. I bent a test over my knee and applied more force to it than a foamboard wing can handle and it didn't break. Guess we will find out if I have enough internal supports.

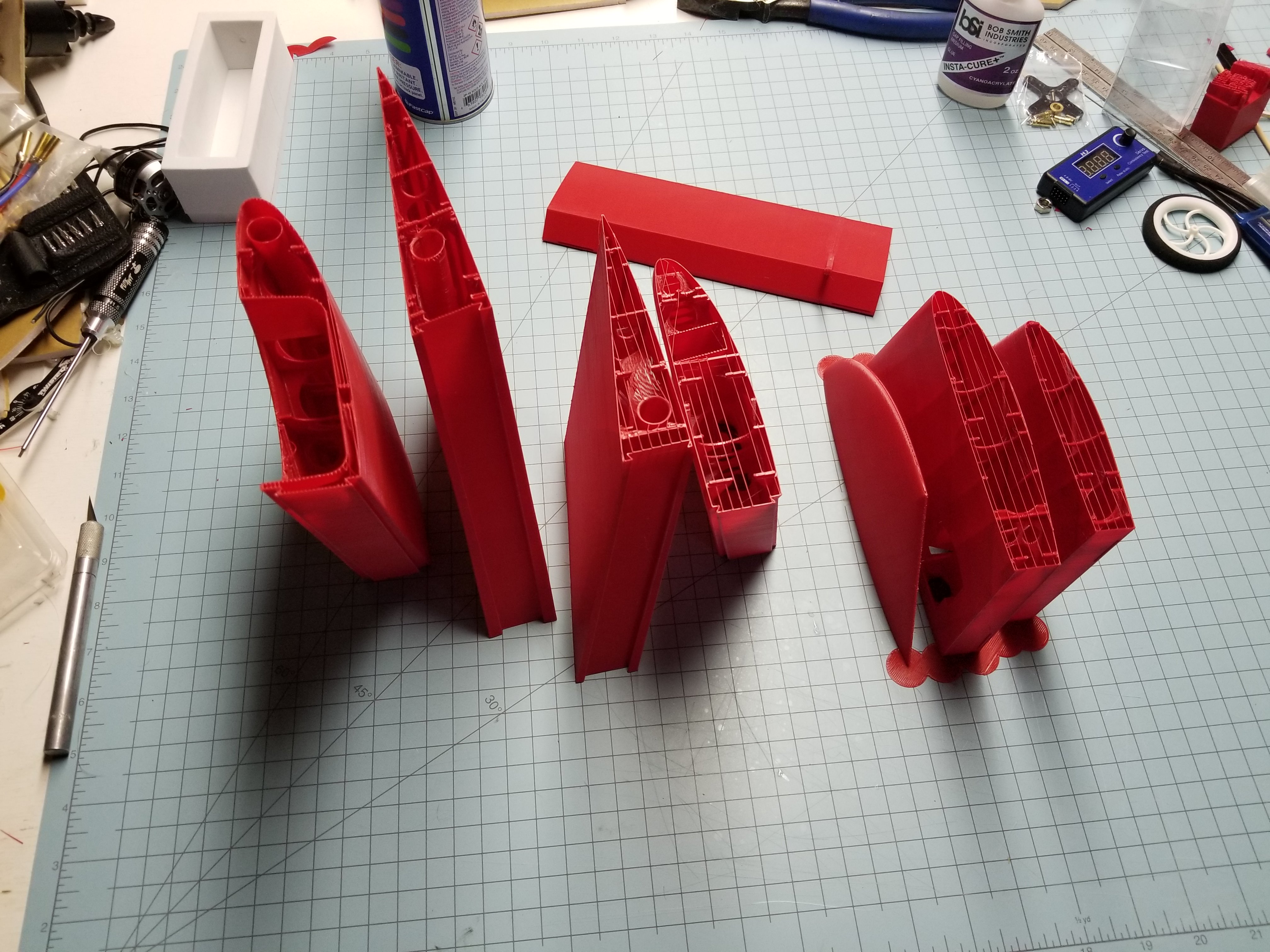

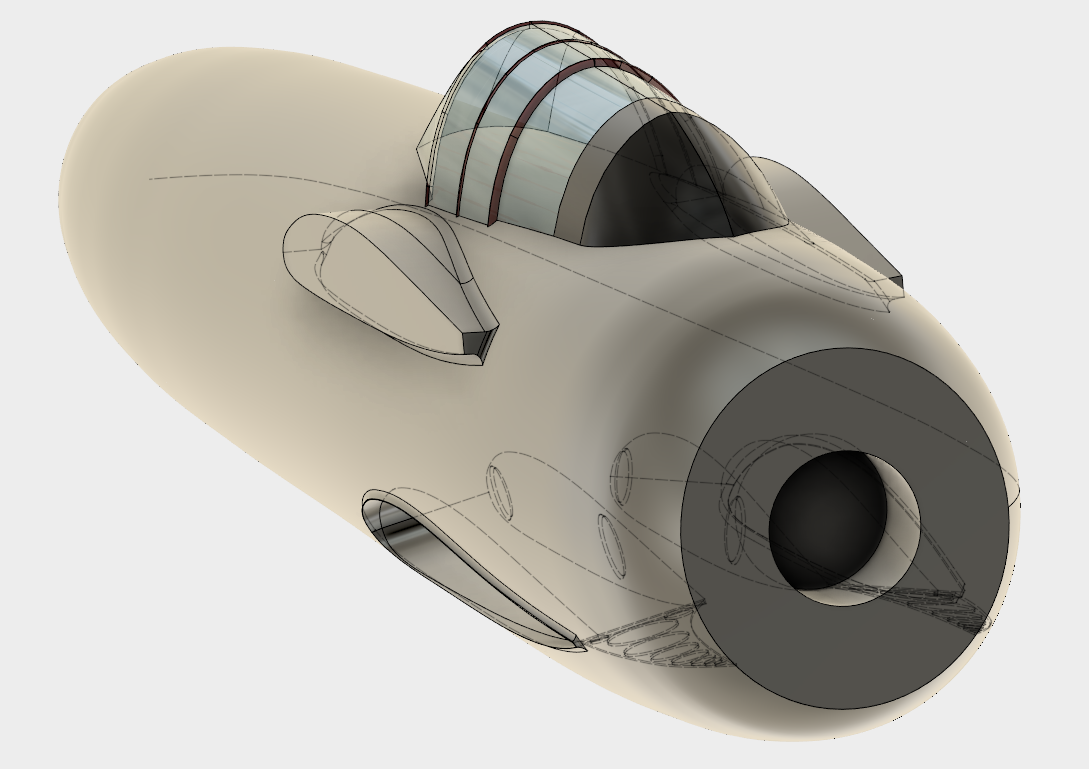

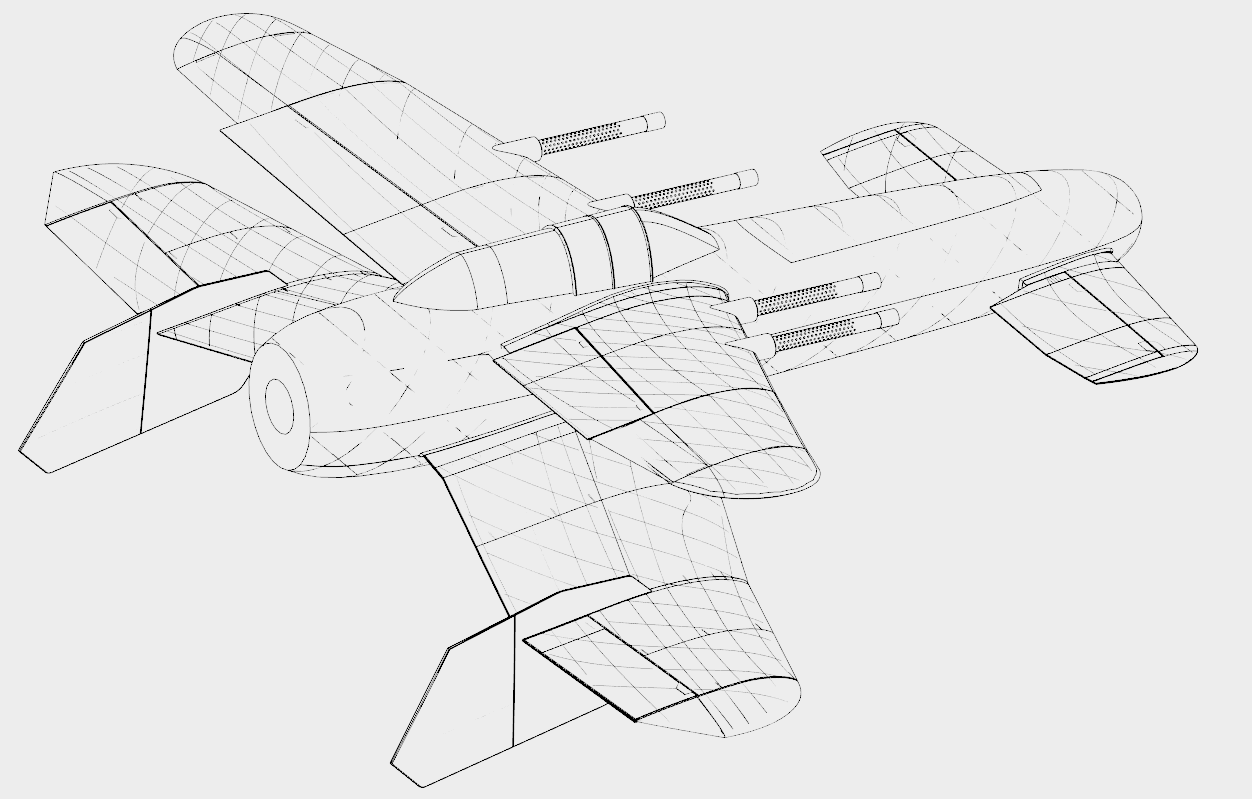

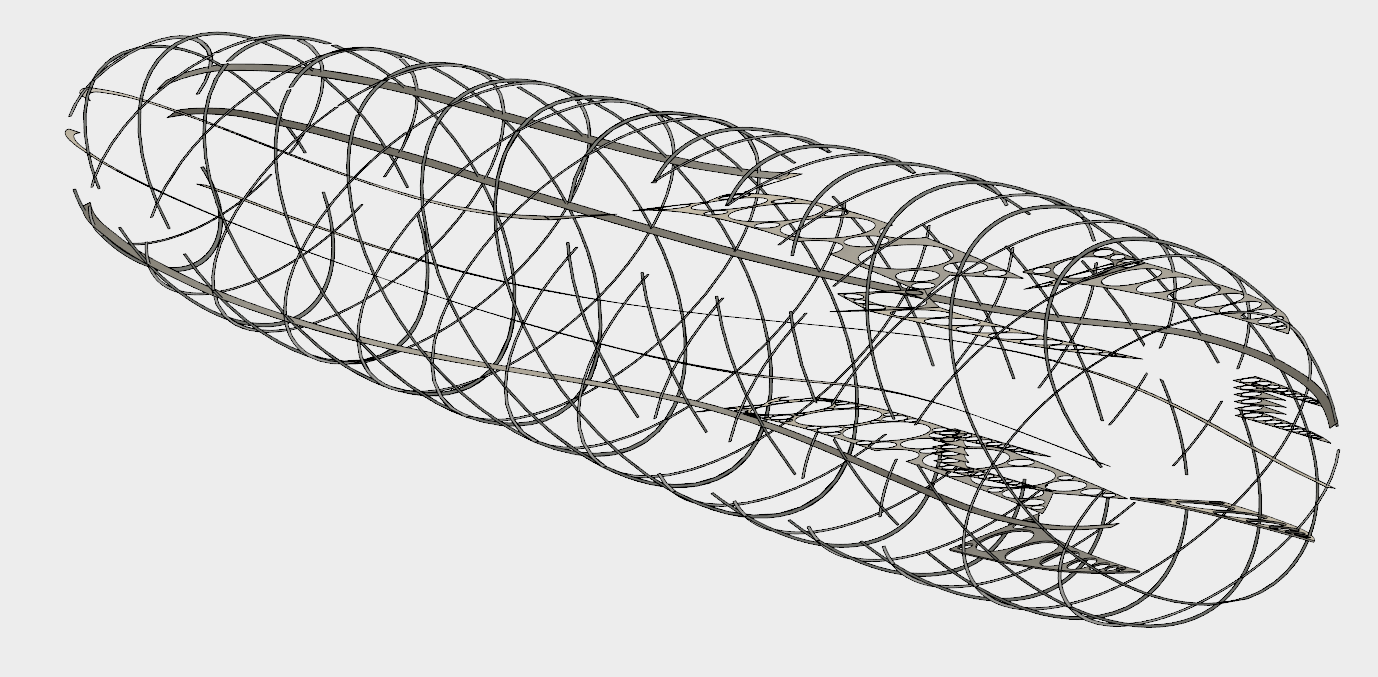

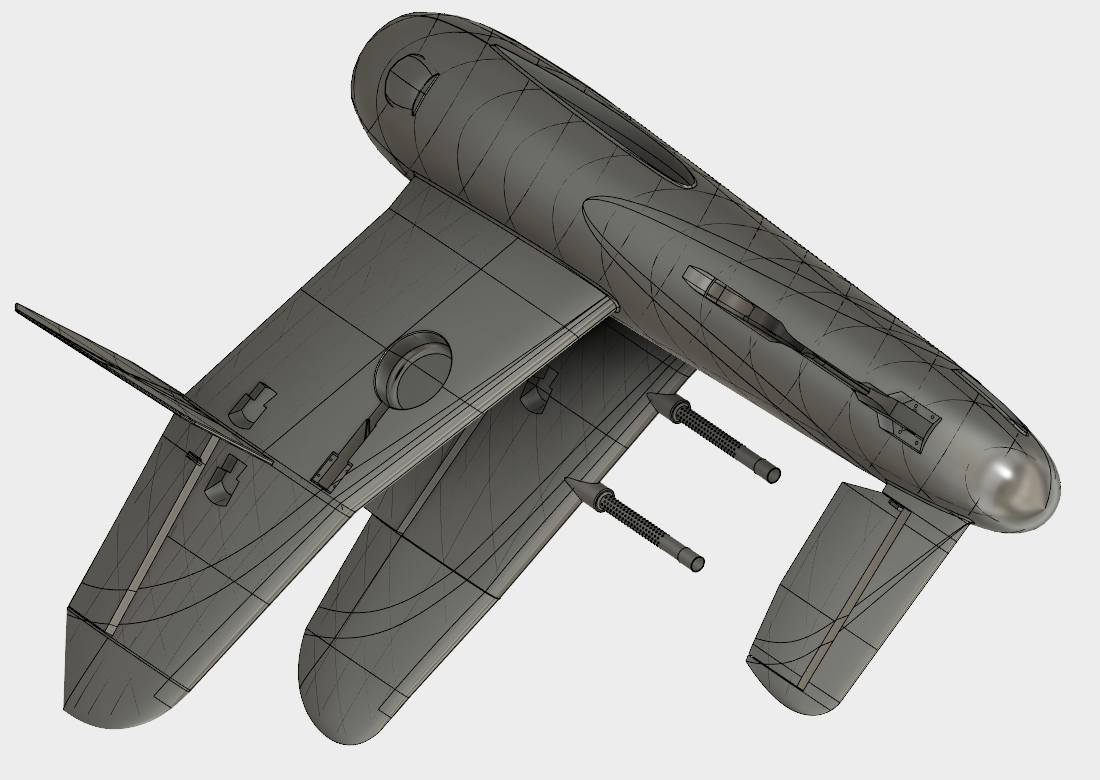

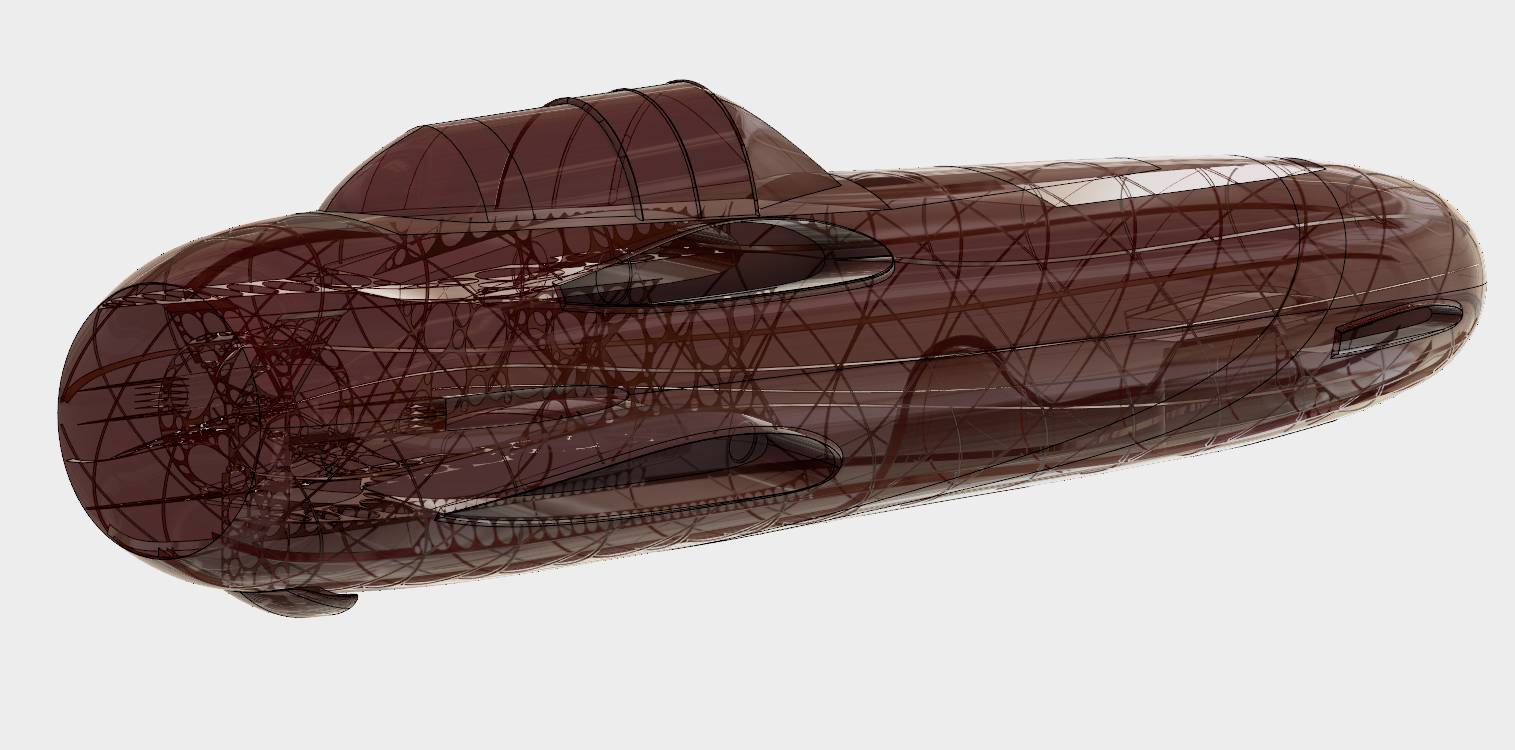

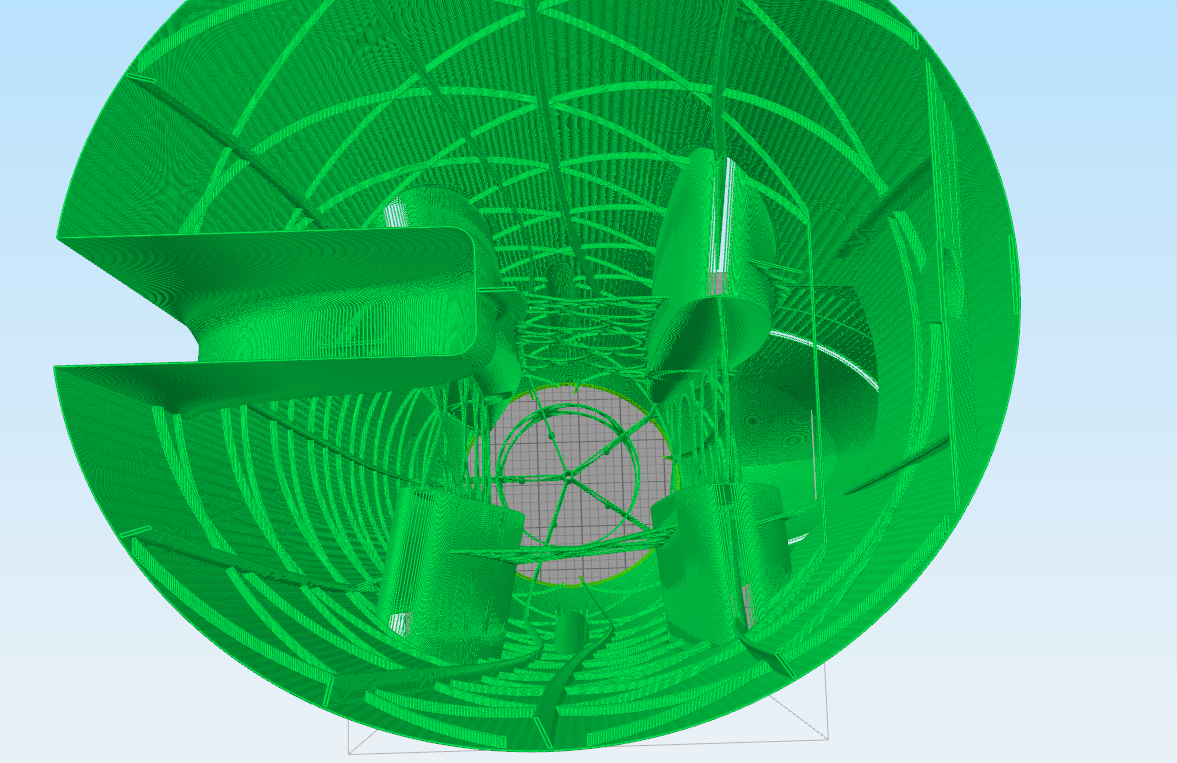

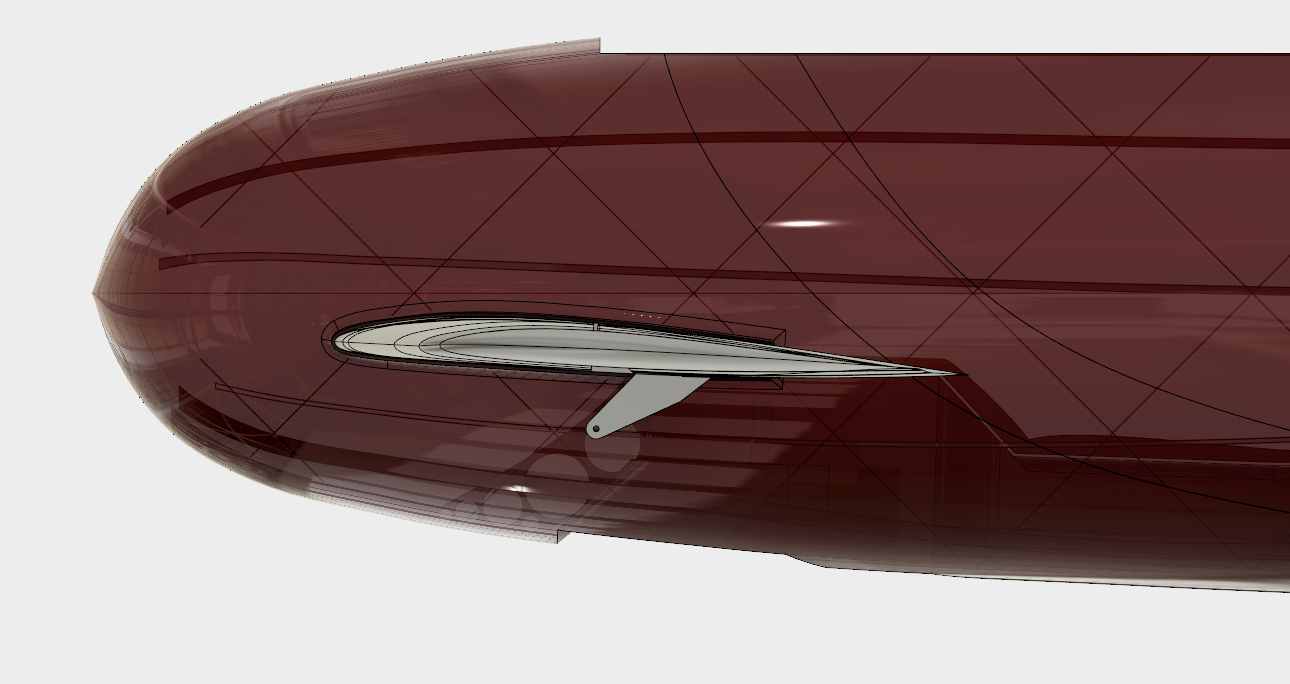

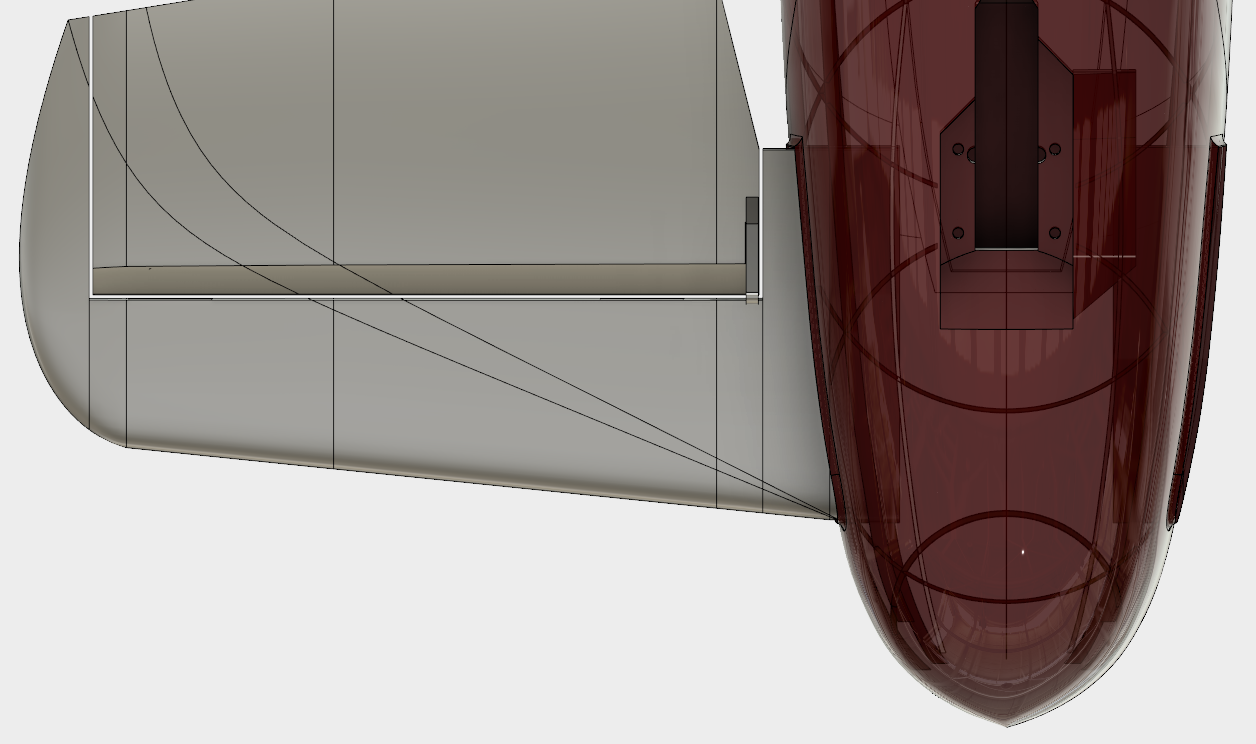

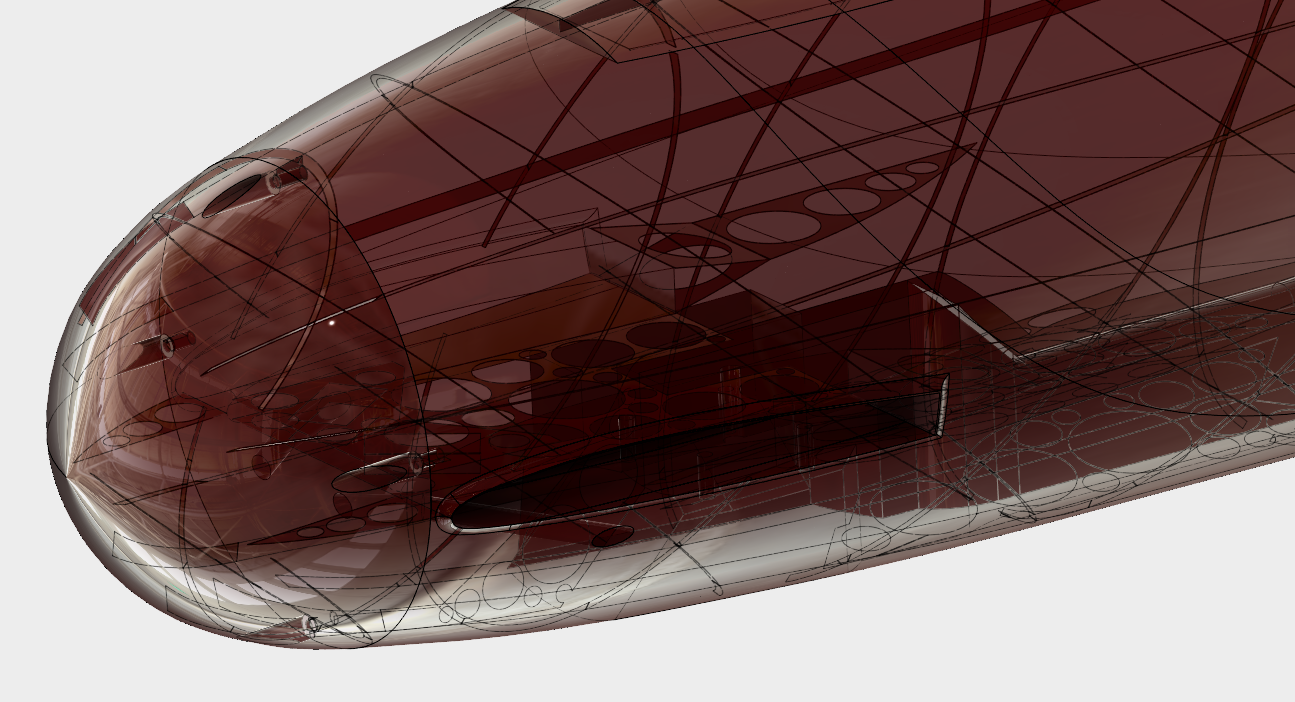

8.) Workflow is complex I've discovered. But essentially, what seems to work best is modeling the outer shape, and all the tools needed to offset the internal structure from the outer skin first. Once that's all done, you can cut out things like control surfaces, and start putting in internal structure. Once spars, servo wire runs, retracts etc are in place you can start slicing stuff up for printing. Once the model is in printable chunks you can add addition supports and mating surface aids.

I'm primarily using Fusion 360 for all my 3D parts. I use DoubleCAD XT for two dimensional work. Simplify3D is my slicer software of choice. It's far more powerful that a lot of others on the market, and has features that are needed if you want to get the best thin wall airplane prints.

I've been tempted to get a printer with massive build volume, but didn't do it from the start because my goal was to be able to share what I make with others. Not a lot of other people have big giant printers.

I'm also discovering that bigger sized planes require a lot more supports, so printing in smaller pieces and using dovetails or other methods of attachment can add a ton of strength, so a small printer doesn't matter much. For my purposes, I'd be better off with multiple smaller printers rather than one big one.

Of course, the cool thing you could do with a larger printer, is scale up the size of airplane parts designed using my or 3D labprints methods by 33% and use a .6mm nozzle. I have a feeling that the additional plastic from that might be strong enough for a plane to survive at the larger size.