You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody else scratch building tonight?

- Thread starter K3V0

- Start date

akimbo

Active member

I only had that problem when I put too much at one time. I just do 3 super light coats and fill in any light spots at the end.I'm scared to death when it comes to painting dtfb I painted my Su-30 and absolutely ruined it so I'm really hesitant

tomlogan1

Elite member

Very ambitious plans but a beautiful model. I hope yours turns out as well and would be interested to follow your progress. Good luck.Tdugar. I really liked this model made by Julius Perdan. I printed out the drawing yesterday and cut it out today. I decided to make this model , but in the process of construction I will do my own , based on previous experience . My goal is to make this model lighter without losing strength. I ask for advice: post a photo of model manufacturing in this topic or create a separate topic on the construction of the F-22 from Julius Peredan.Link to the website : https://paper-replika.com/index.php/rc-foam-project/f-22-raptor-rc-plane-plans . I will order the engine and servomechanisms during the construction process on aliexpress . Sheets of foam with a thickness of 5mm should arrive this week in the parcel.

Shurik-1960

Elite member

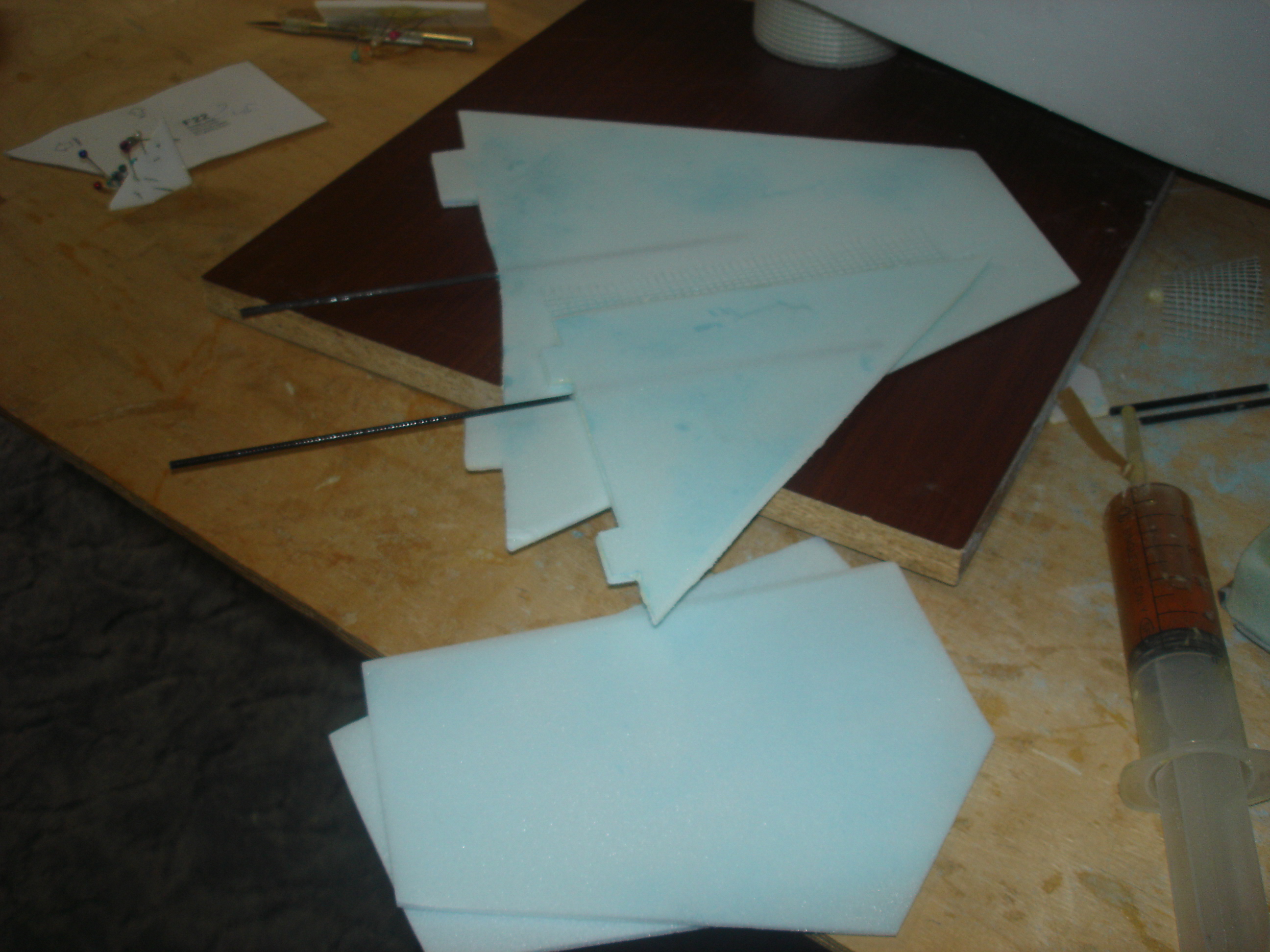

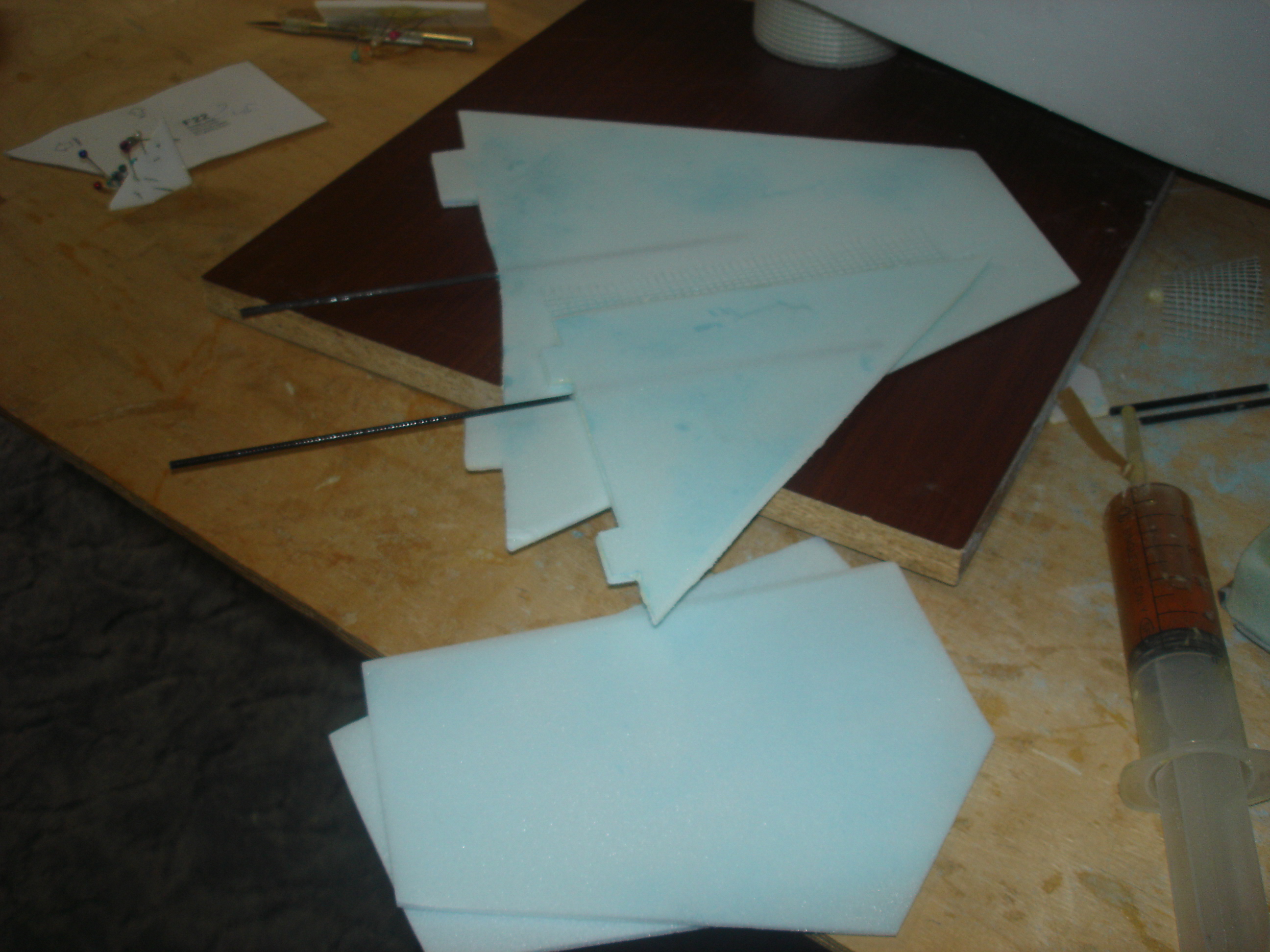

I printed out the drawings. Thanks to Julius Perdana, I cut out all the details and checked for docking. I bought 2 fishing rods for $ 1 at the Angler store. I put the tops of the rods in the keels. Two layers of foam with a thickness of 3 mm are sanded to a thickness of 4 mm. I will make the stabilizer of the model one - piece . The ailerons will be increased .I ordered two packages of foam with a thickness of 5 mm for $ 20 with delivery. : https://alnado.ru/product-category/penolist-dlya-modelirovaniya/ . The store sells interesting kits for those who do not have time to print and cut. The cost of $ is just ridiculous. If I were in the management of Flitetest, I would buy such kits in bulk for the modelers of the site. Beautiful models and all models really fly after assembly. I have collected about 8 sets for my friends' children. For me, collecting is a pleasure, for children - the joy of flying.

Attachments

Last edited:

Brian B

Elite member

I think I've got my next project lined up. 60" long x 40" WS, XB-70 belly-lander twin pusher with KVm2 wing. Time to lay out plans so I can start cutting. Based more on prototype #2 which added 5 degree dihedral compared to the more commonly seen #1 which was almost flat. Haven't finalized tip angle yet, but probably a little more than this. Maybe I'll try and work out servo adjustment.

Shurik-1960

Elite member

KFM2 profile - loses a lot in aerodynamics and strength properties of a wing with a flat-convex profile. I made more than 10 models with a KFM profile (according to the drawings of the authors) and then converted to a flat-convex profile, the models flew like heaven and earth. Make a wing for this model from 3mm foam with a plano-convex profile: the appearance of the model will become more replica and the rigidity of the wing will appear without adding weight. If a high speed is desirable for the model, make the plano-convex profile thinner. I tried the FM2. 3 profile for models flying in a non-motorized form from the slopes - they almost barely flew in the wind from 8m/sec. When modified to a flat convex profile, but thin, it was possible to fly without landing for several hours in a wind of 5 m/sec.A striking example is a Shark with a KFM4 profile : it really did not fly from any modeler. With a thin profile, this model flew...barely.

Brian B

Elite member

Thanks for the feedback. This would have been my first KFM wing. With all the hype I figured I might try something different.KFM2 profile - loses a lot in aerodynamics and strength properties of a wing with a flat-convex profile. I made more than 10 models with a KFM profile (according to the drawings of the authors) and then converted to a flat-convex profile, the models flew like heaven and earth. Make a wing for this model from 3mm foam with a plano-convex profile: the appearance of the model will become more replica and the rigidity of the wing will appear without adding weight. If a high speed is desirable for the model, make the plano-convex profile thinner. I tried the FM2. 3 profile for models flying in a non-motorized form from the slopes - they almost barely flew in the wind from 8m/sec. When modified to a flat convex profile, but thin, it was possible to fly without landing for several hours in a wind of 5 m/sec.A striking example is a Shark with a KFM4 profile : it really did not fly from any modeler. With a thin profile, this model flew...barely.

So you are suggesting a shape like this smaller Balsa profile F/F model? This one had a lot of reflex. Should I consider Ribs on the undercamber side with no spar?

Matthewdupreez

Legendary member

kfm aerofoils fly really well,Thanks for the feedback. This would have been my first KFM wing. With all the hype I figured I might try something different.

So you are suggesting a shape like this smaller Balsa profile F/F model? This one had a lot of reflex. Should I consider Ribs on the undercamber side with no spar?

View attachment 240081

i've done 5 custom designs now with kfm aeroils all of which flew fast, smoothly and well

defiantly a winner aerofoil for foamboard

COOL! It seems that the foam board sheets sold in Europe are heavier, but perhaps also stronger. As an example, I built a FT Edge with these 5mm (2/10 in) thick plates, purchased in Belgium, and the total weight in flight order is close to 1kg (2 lbs). Do you confirm a noticeable weight difference?Big Stick is just about done. 1.7m wingspan from heavy UK foamboard. A big 5055 motor (580kv) turning a 15x10 prop on 6s (from two 3s 2200’s in parallel). Weight is I think around 2.5kg rtf - I’ll weigh it tomorrow before the maiden.

View attachment 239937

L Edge

Master member

Thanks for the feedback. This would have been my first KFM wing. With all the hype I figured I might try something different.

So you are suggesting a shape like this smaller Balsa profile F/F model? This one had a lot of reflex. Should I consider Ribs on the undercamber side with no spar?

View attachment 240081

Since the battery will most likely be in the overhang section, make sure it is re-enforced stiff enough that a heavy landing doesn't snap off or bend the front section. I use balsa plank epoxied to material. It also works real well if you have to locate nose gear in overhang section.

Brian B

Elite member

Forewarned is forearmed. Thanks. It will be a belly lander, enhanced with a curved wire "skid" at the front of the intakes. Hopefully the battery will be just above that point, with just a canard servo in the main fuse. I'll first make the wing tips fixed, with the ability to expand to actuation later if it flys nice.Since the battery will most likely be in the overhang section, make sure it is re-enforced stiff enough that a heavy landing doesn't snap off or bend the front section. I use balsa plank epoxied to material. It also works real well if you have to locate nose gear in overhang section.

Shurik-1960

Elite member

I continue to assemble the model for 1-2 hours a day. The glue is light, foams and dries for a long time. I check every detail on the spot.There are inconsistencies. I will make the wing with a symmetrical profile made of foam with a thickness of 3mm . In the center of the fuselage there will be a spar from the tip of the fishing rod, In my opinion - the author's design is not rigid enough. The wife, seeing the model, asked : Is this going to be a flying trough? . Now this model will be referred to as the flying trough-22.

Attachments

The Fopster

Master member

The foamboard I can get is double the weight of the FT stuff, but also much stronger. I don’t try making FT planes out of it, but in this larger size category (wingspan 1.7m) it works well.COOL! It seems that the foam board sheets sold in Europe are heavier, but perhaps also stronger. As an example, I built a FT Edge with these 5mm (2/10 in) thick plates, purchased in Belgium, and the total weight in flight order is close to 1kg (2 lbs). Do you confirm a noticeable weight difference?

The Fopster

Master member

Here’s a 1.7m wingspan made from the heavy stuff (in process of being painted, plus it’s had one heavy crash already!). Built pretty much the same as a normal FT plane but bigger. Seems to work just fine but needs bigger motor, batteries etc.The foamboard I can get is double the weight of the FT stuff, but also much stronger. I don’t try making FT planes out of it, but in this larger size category (wingspan 1.7m) it works well.

Timmy

Legendary member

Jeez look at those jets in the background wowie!Next project on the build table is looking gorgeous already

last edition to complete my V bomber fleet 😍

powered by twin FMS 64’s running 4s

View attachment 240088

I remember you posting build images of that vulcan like it was yesterday

Shurik-1960

Elite member

I continue the assembly.The keel and elevator were glued together from two layers of foam 3mm thick, then ground with a skin to a thickness of 3-4mm. While the total weight of the fuselage is 160 grams.

Tdugar

Well-known member

I made his SU-30 I love it.Tdugar. I really liked this model made by Julius Perdan. I printed out the drawing yesterday and cut it out today. I decided to make this model , but in the process of construction I will do my own , based on previous experience . My goal is to make this model lighter without losing strength. I ask for advice: post a photo of model manufacturing in this topic or create a separate topic on the construction of the F-22 from Julius Peredan.Link to the website : https://paper-replika.com/index.php/rc-foam-project/f-22-raptor-rc-plane-plans . I will order the engine and servomechanisms during the construction process on aliexpress . Sheets of foam with a thickness of 5mm should arrive this week in the parcel.

Attachments

Tdugar

Well-known member

You gonna love it.I continue to assemble the model for 1-2 hours a day. The glue is light, foams and dries for a long time. I check every detail on the spot.There are inconsistencies. I will make the wing with a symmetrical profile made of foam with a thickness of 3mm . In the center of the fuselage there will be a spar from the tip of the fishing rod, In my opinion - the author's design is not rigid enough. The wife, seeing the model, asked : Is this going to be a flying trough? . Now this model will be referred to as the flying trough-22.

Attachments

Tdugar

Well-known member

Yessssss I appreciate it DC4LLove the F-22! Love the Dallas Cowboys even more!!!!!!!!!!!

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 8

- Views

- 288

- Replies

- 10

- Views

- 2K