Well... where should I start.. This was a fun build.

A few weeks back I asked a few questions on this forum about the parts I bought for this build. I quickly came to the conclusion that I had no idea what I got myself into it... But thankfully two members(cranialrectosis and jhitesma) stepped in and gave me a lot of tips and suggestions.

So... let's begin with the build I used the following :

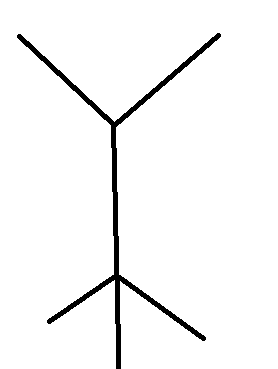

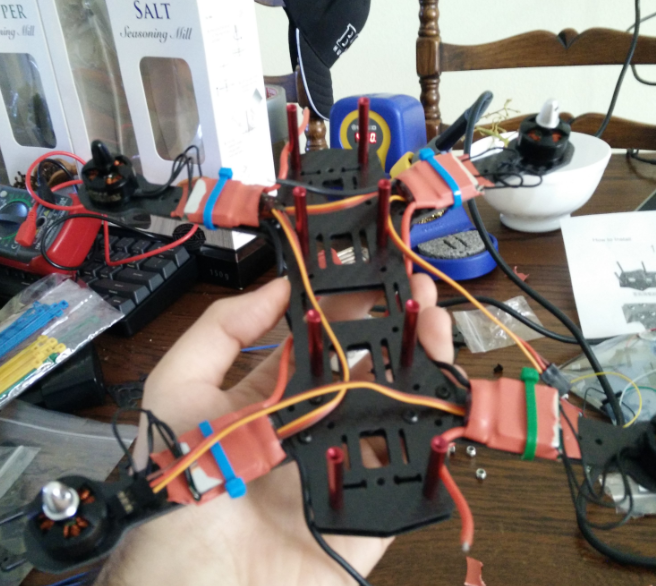

I started with building the frame, this part was probably the easiest part in the build.

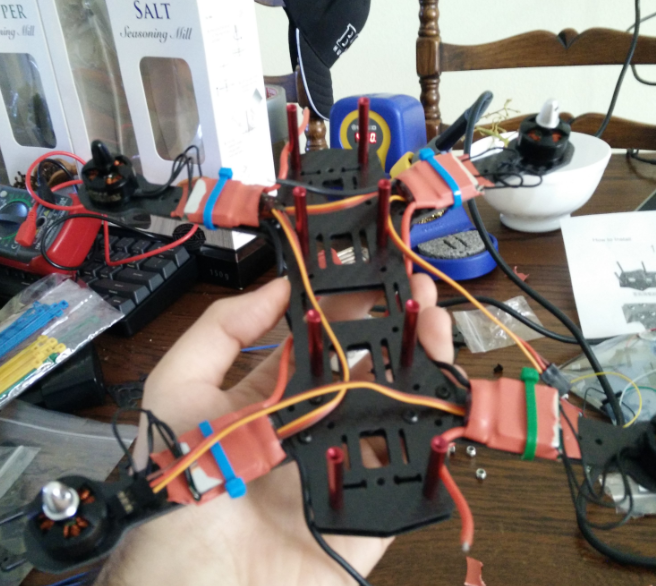

After that I hooked up the motors and ESCs(I watched some videos on how to do this properly)

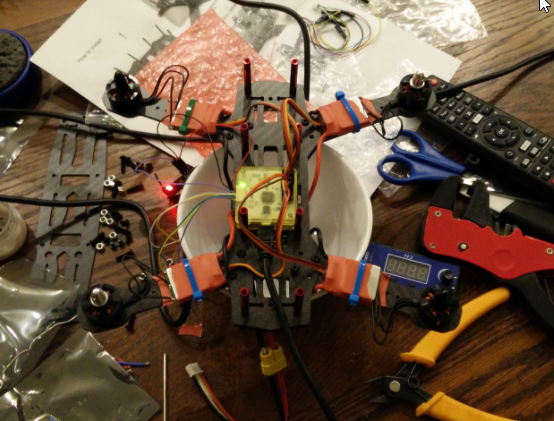

At this part I had some struggles, I had to solder all the ESCs together, I got a power board that would make it easy for me to solder it in and make it work but I have seen some people wire it all together on the wire that goes to the battery, since I had no idea on how safe it was I just used the powerboard.

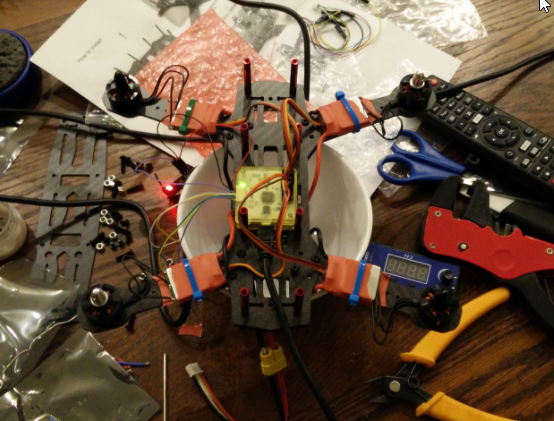

Hookinh up the flightcontroller was a nightmare..... I tried using my Orange RX for it but the cheap reseller didn't include the wires with the servo leads they were not labeled it was just a big mess. I ended up using my Lemon RX PPM receiver.

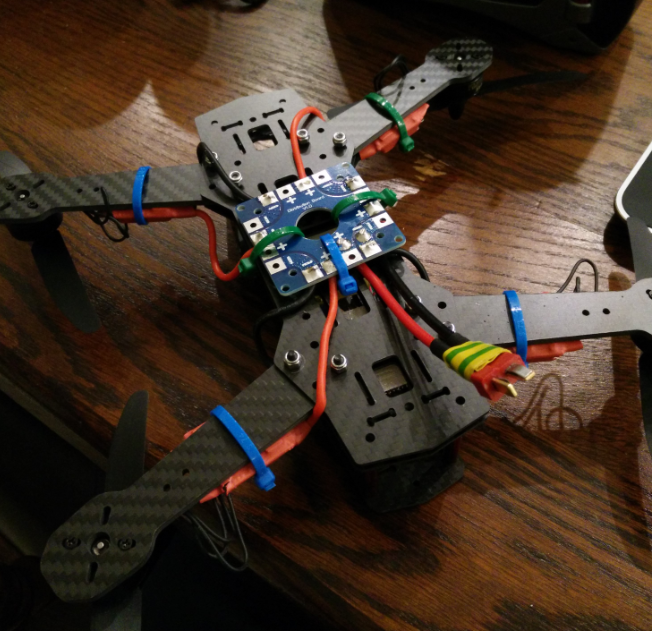

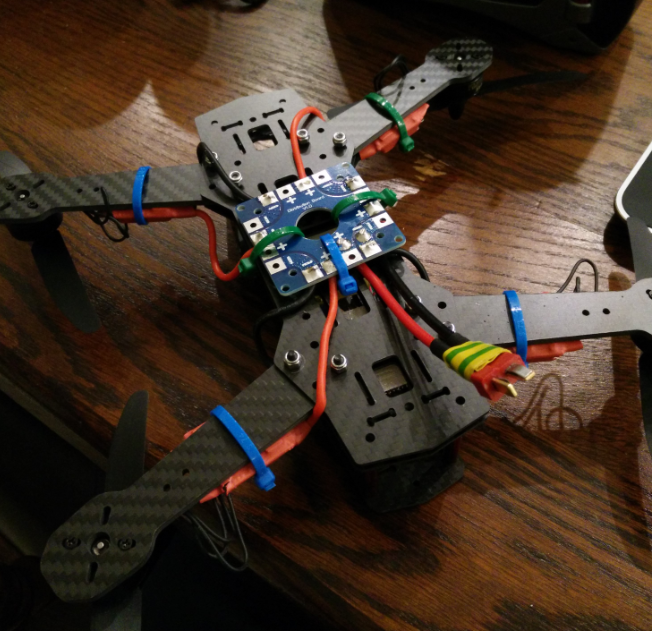

The finished quad:

So the quad went together pretty good considering I only got mad twice and I burned myself once with the soldering iron... I still have to wait for hobbyking to deliverer my props and Lipos.

Do you guys have any suggestions on how I could place the powerboard better? I don't like the way it's placed right now. Also I have read online that the Naza flight controllers are perfect for racing quads, what do you guys recommend?

(If I posted this in the wrong section please forgive me)

A few weeks back I asked a few questions on this forum about the parts I bought for this build. I quickly came to the conclusion that I had no idea what I got myself into it... But thankfully two members(cranialrectosis and jhitesma) stepped in and gave me a lot of tips and suggestions.

So... let's begin with the build I used the following :

- MT1806 2280kv Brushless Motor (EMax)

- 12A Simonk ESC (Unknown brand)

- CC3D Flight Controller

- Props are still in order

- And a cheap 250 frame

I started with building the frame, this part was probably the easiest part in the build.

After that I hooked up the motors and ESCs(I watched some videos on how to do this properly)

At this part I had some struggles, I had to solder all the ESCs together, I got a power board that would make it easy for me to solder it in and make it work but I have seen some people wire it all together on the wire that goes to the battery, since I had no idea on how safe it was I just used the powerboard.

Hookinh up the flightcontroller was a nightmare..... I tried using my Orange RX for it but the cheap reseller didn't include the wires with the servo leads they were not labeled it was just a big mess. I ended up using my Lemon RX PPM receiver.

The finished quad:

So the quad went together pretty good considering I only got mad twice and I burned myself once with the soldering iron... I still have to wait for hobbyking to deliverer my props and Lipos.

Do you guys have any suggestions on how I could place the powerboard better? I don't like the way it's placed right now. Also I have read online that the Naza flight controllers are perfect for racing quads, what do you guys recommend?

(If I posted this in the wrong section please forgive me)