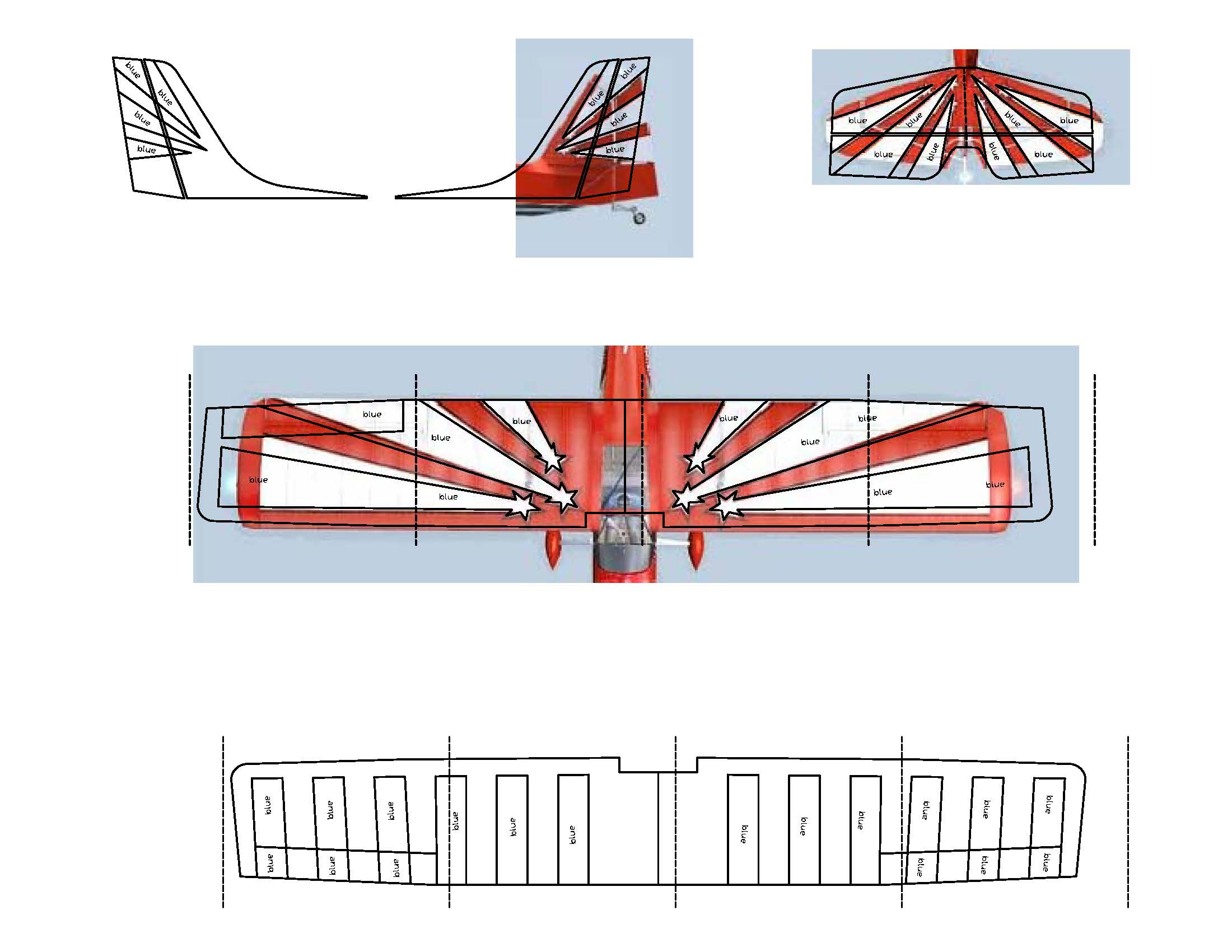

update

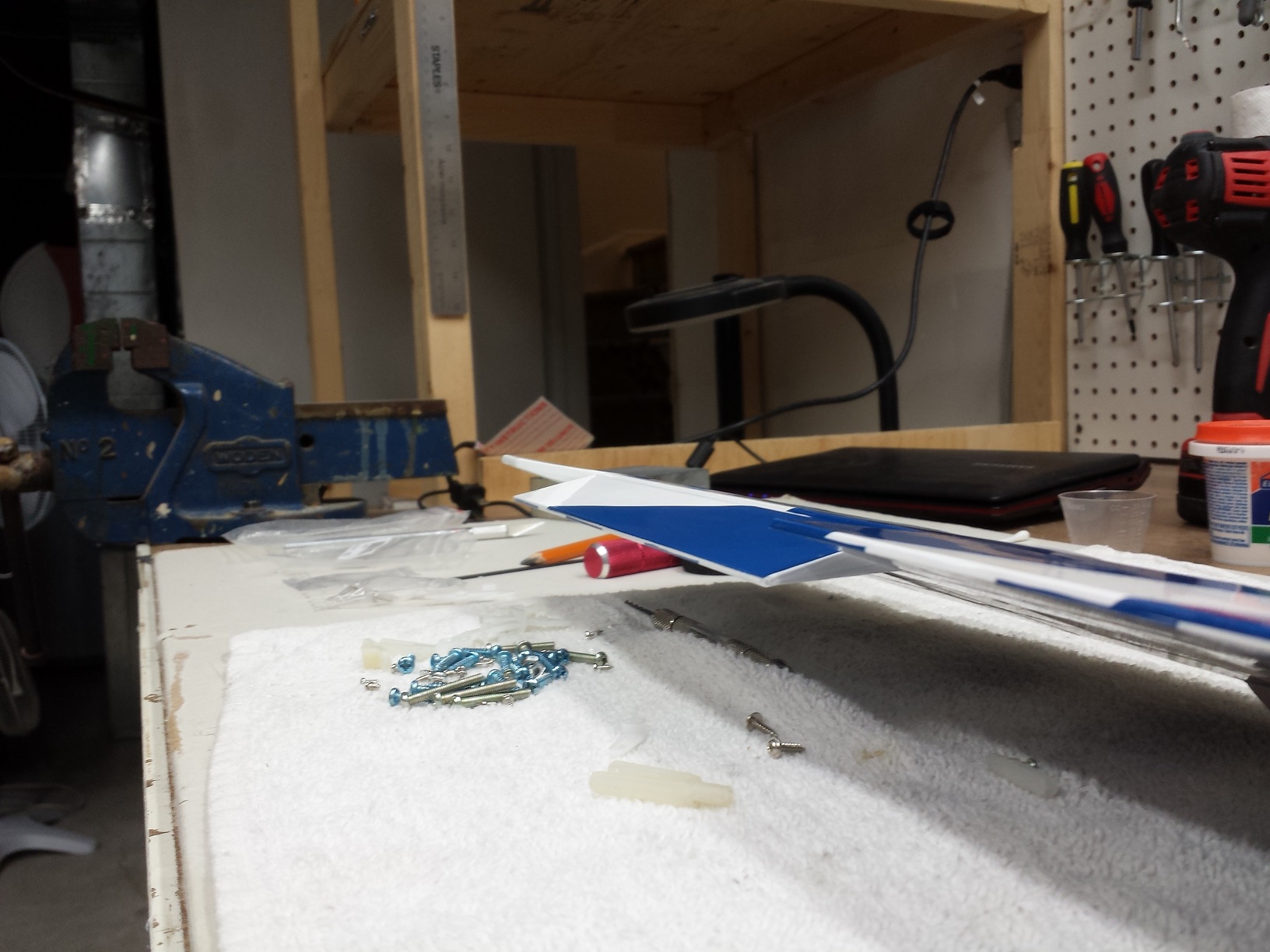

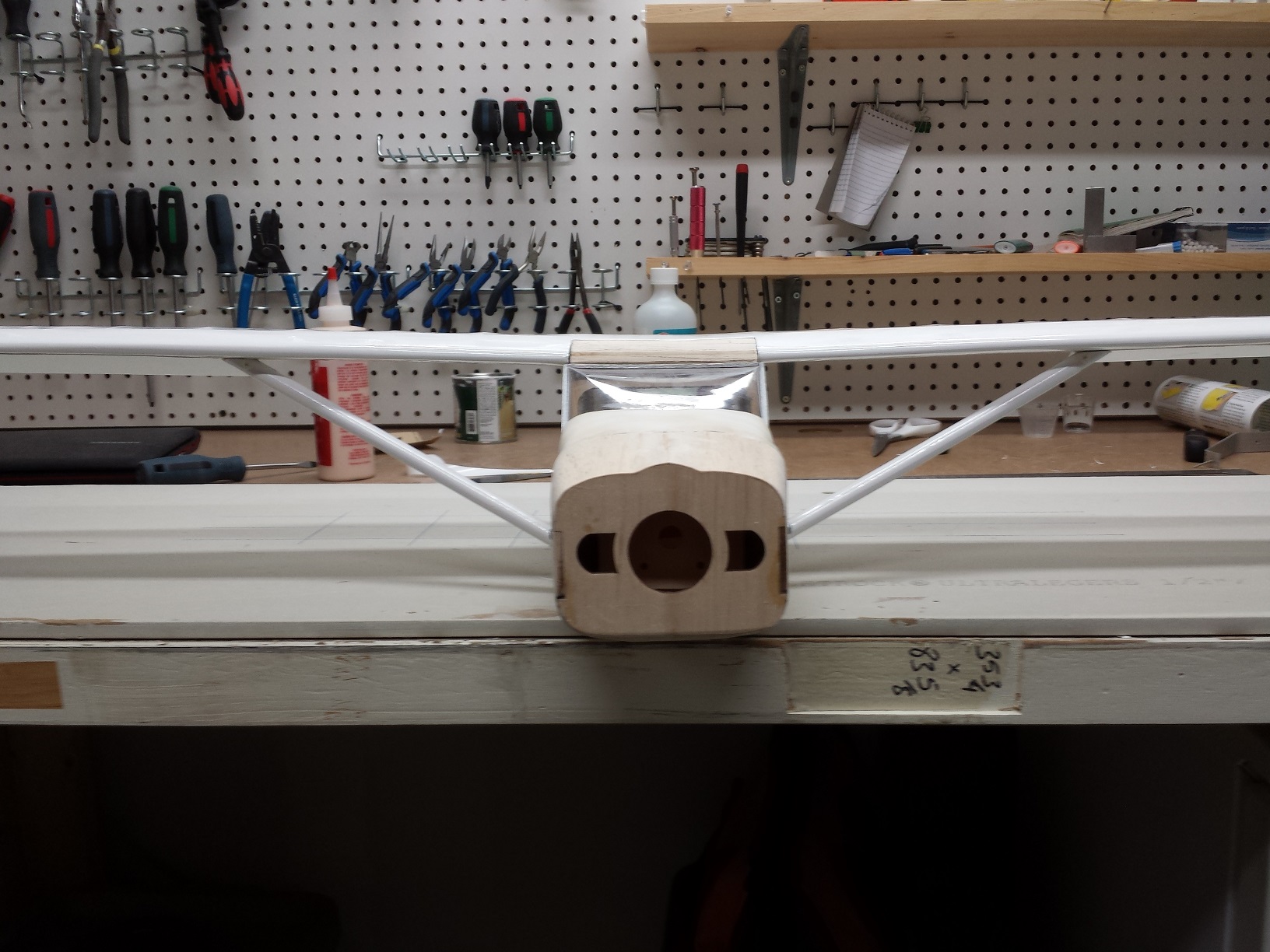

here is an update, I am almost finished with covering and then it is on to pushrods/electronics.

I decided to do the wing struts as well.

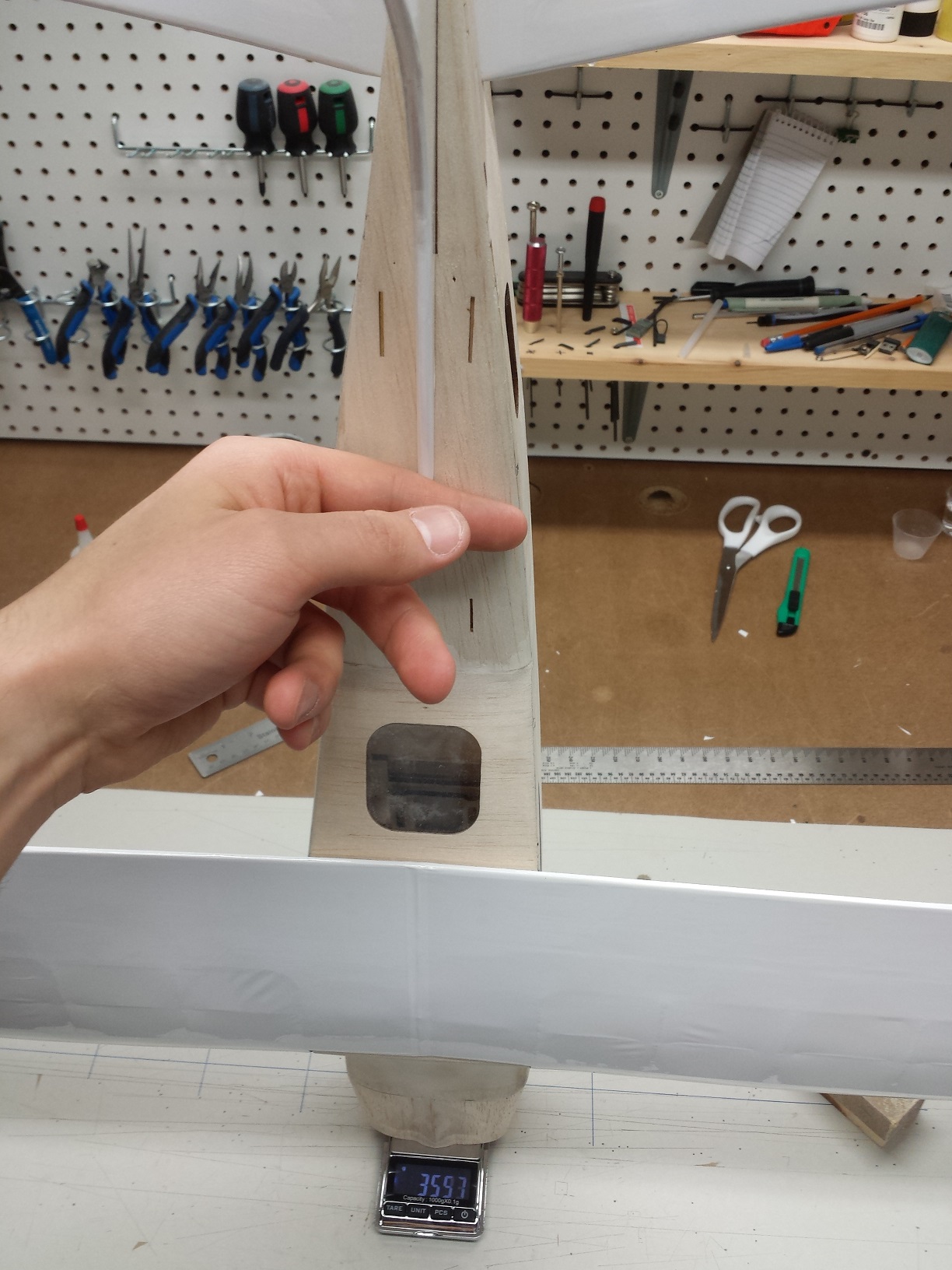

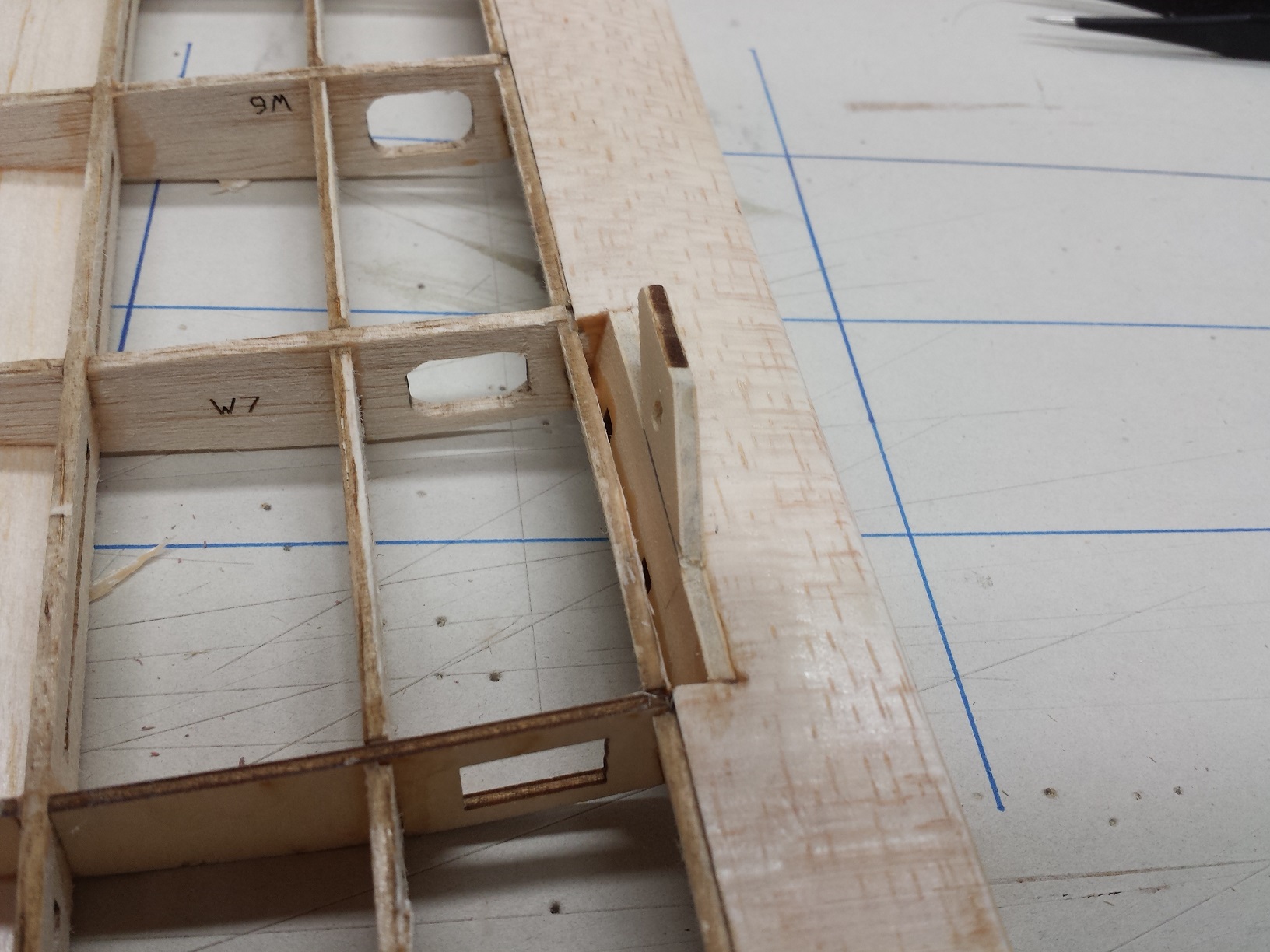

here is the lite ply brace I installed between the 2 ribs inboard of the ailerons. they are angled such a way so the struts end up at the fuselage just ahead of the door pillar.

it is a 3/8" hardwood dowel covered with monokote.

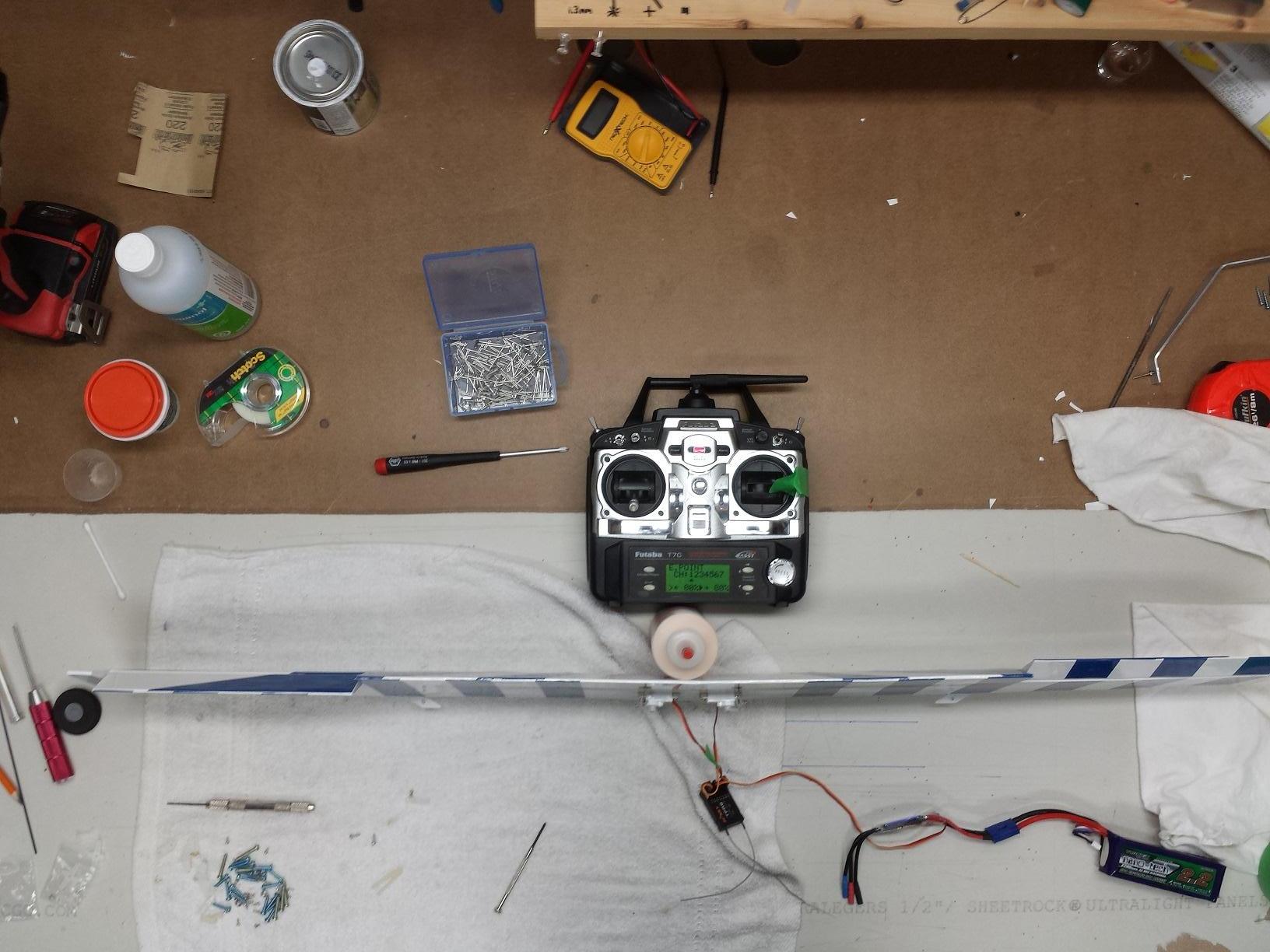

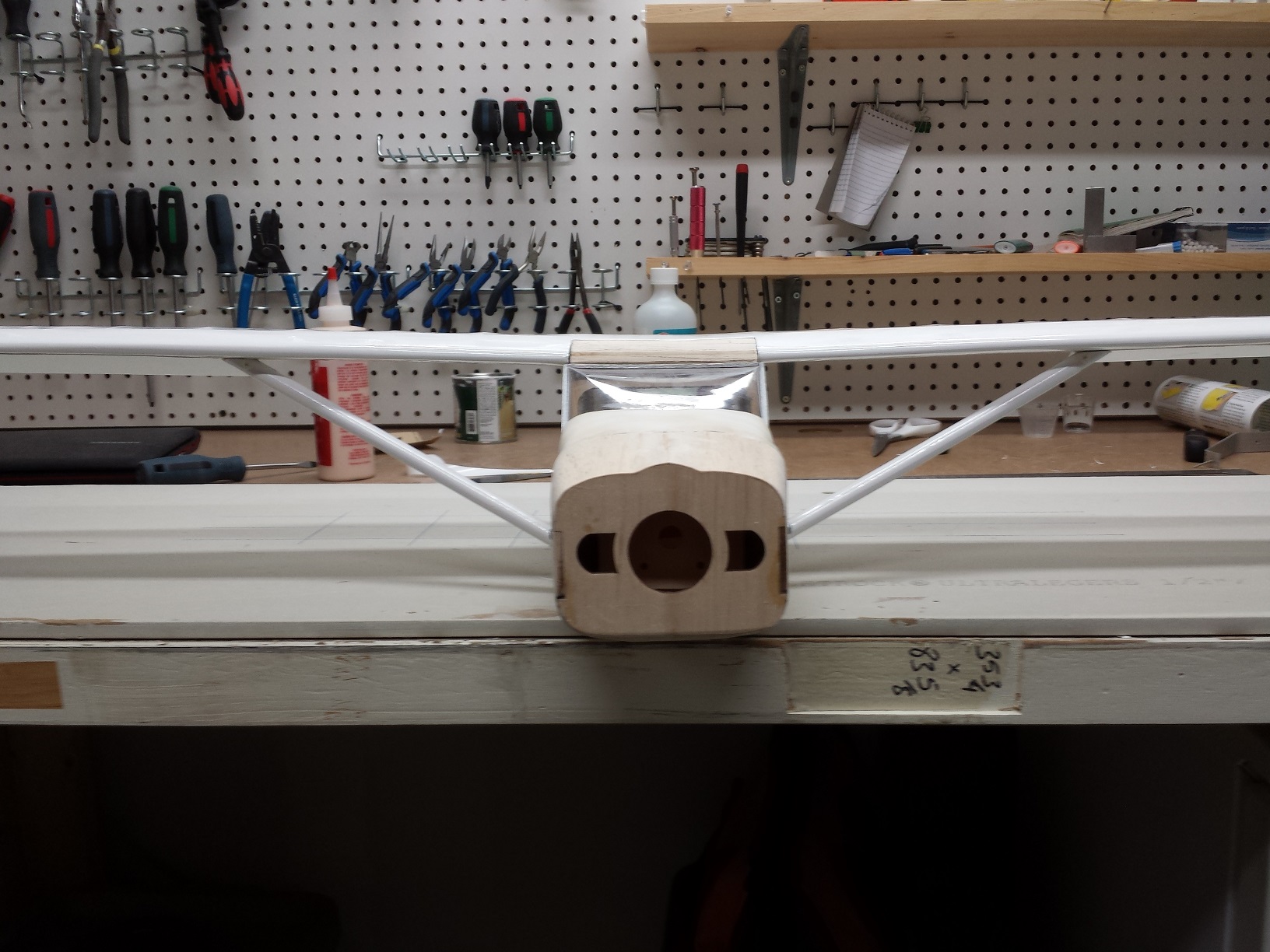

it is starting to look like an airplane!

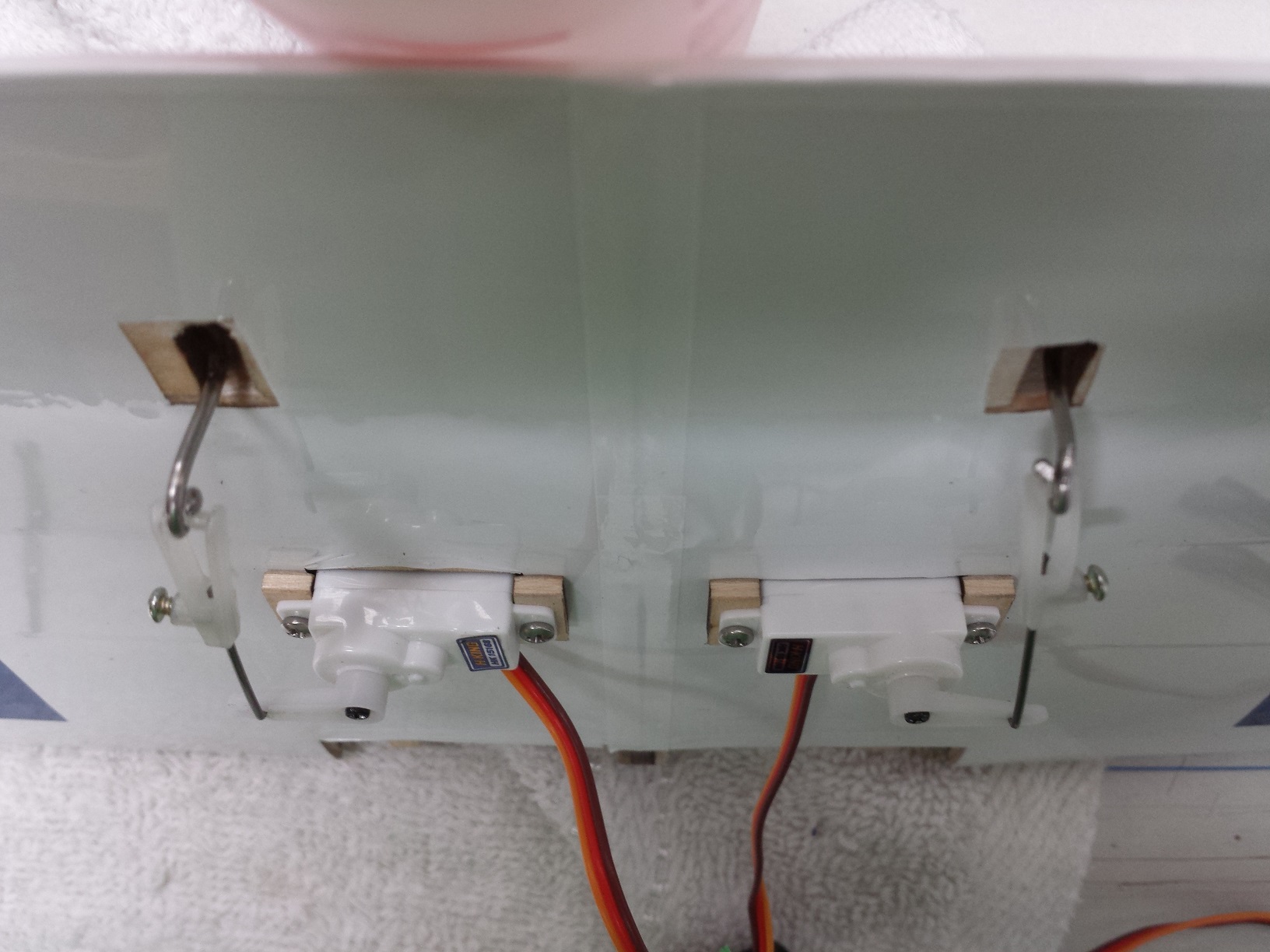

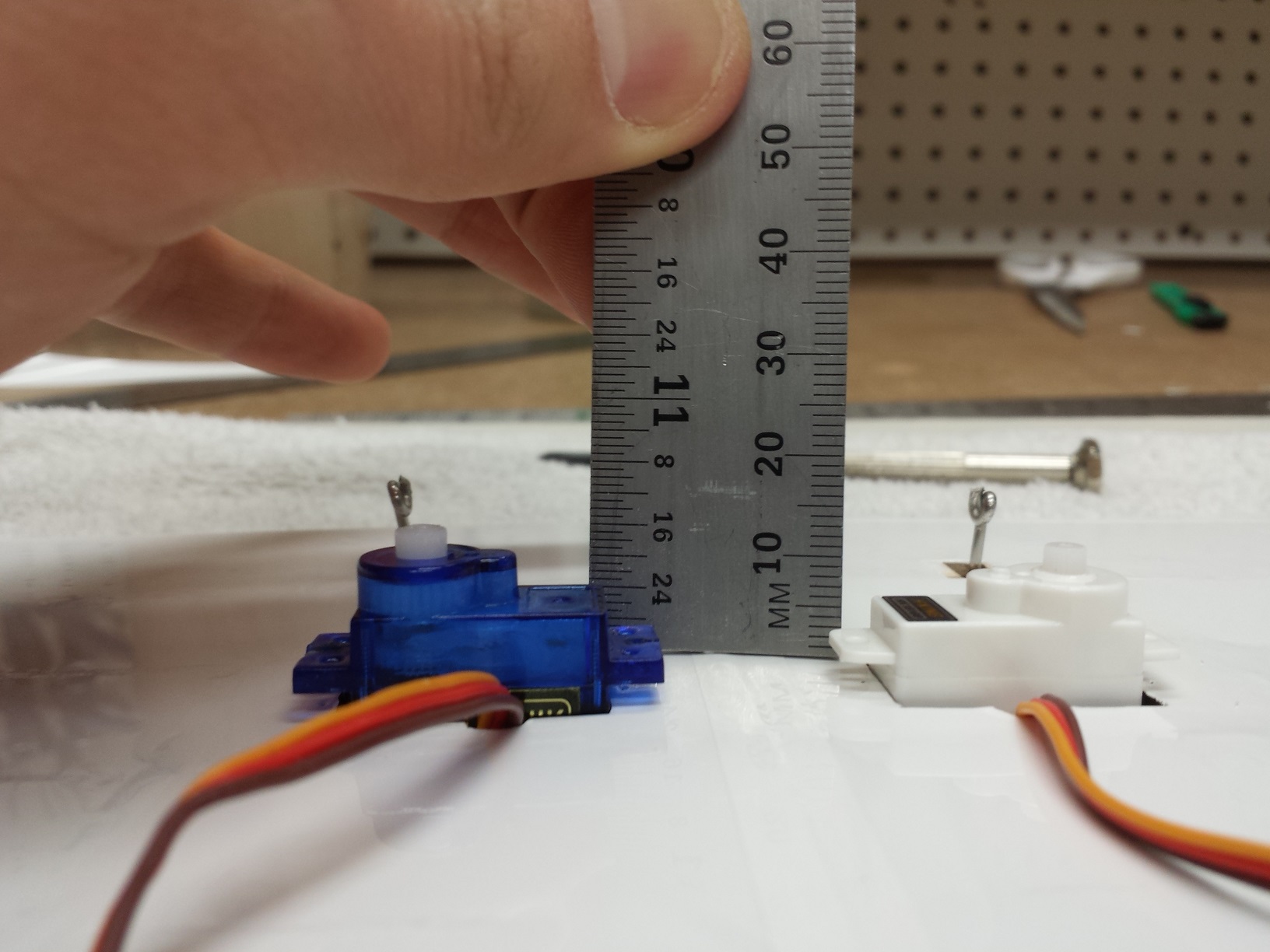

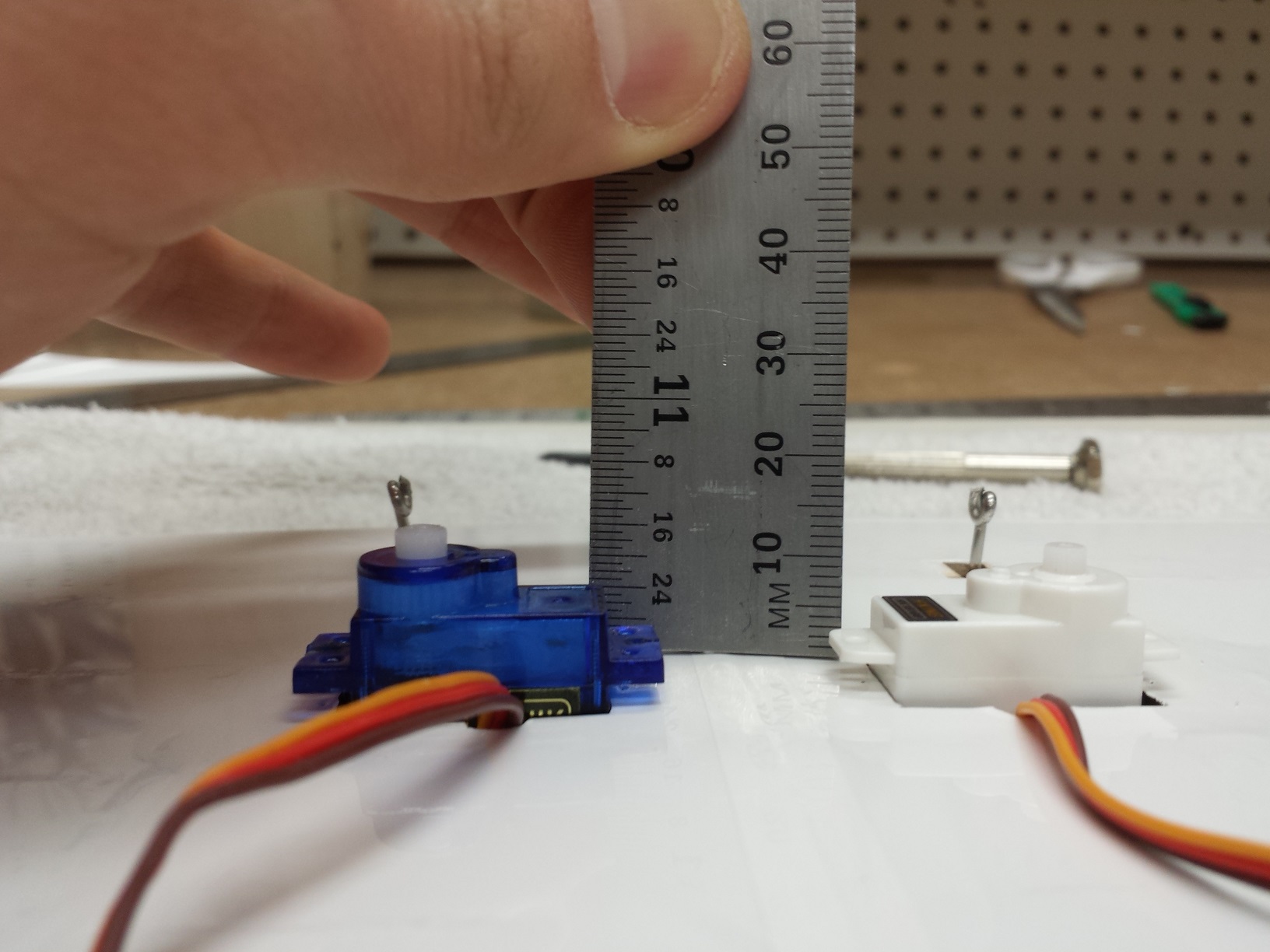

the next step was figuring out the aileron servos.

both an HXT900 and the HK 15168's stick up too far, about 3mm too high.

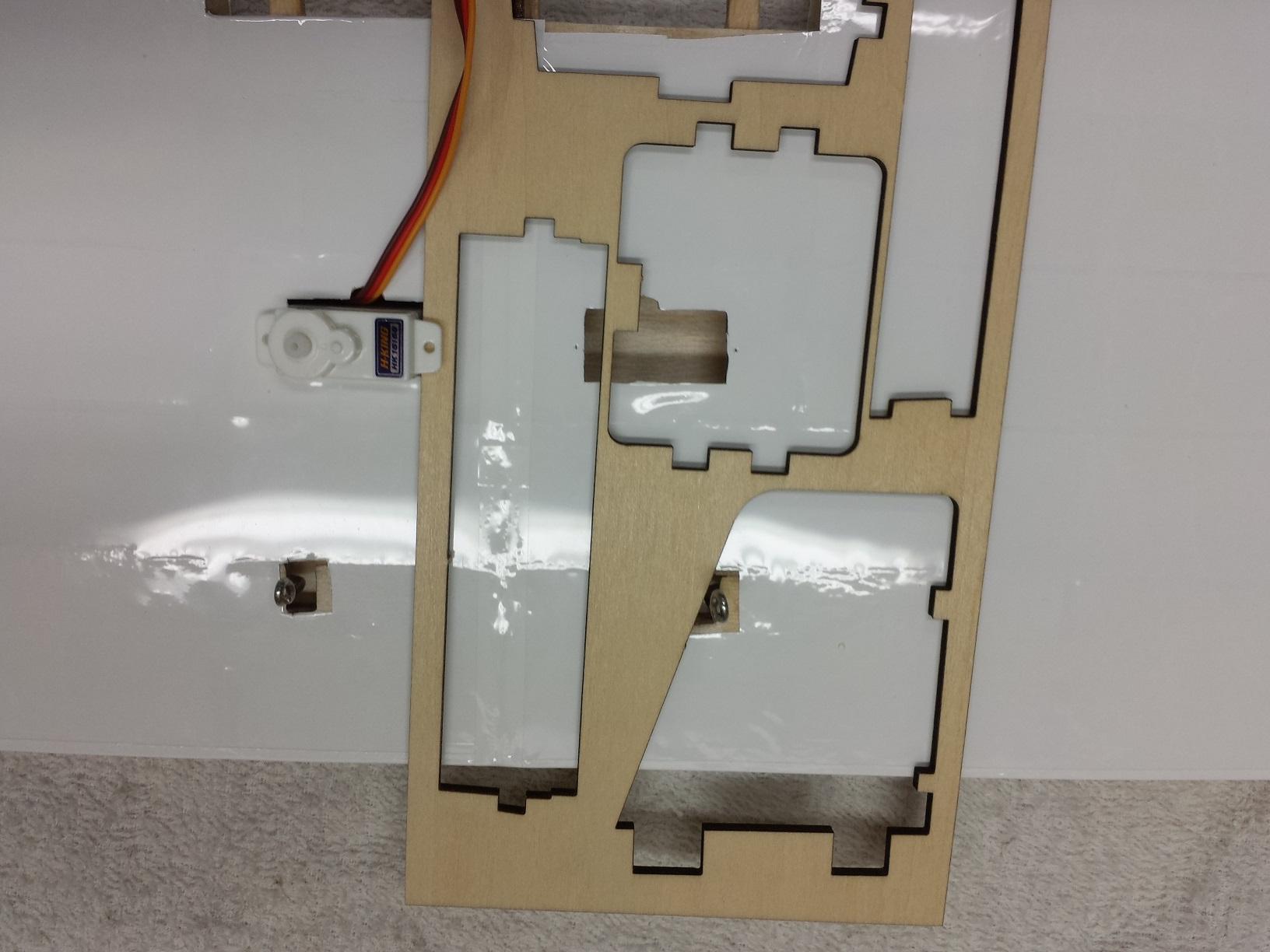

some left over lite ply from the motor mount sheet fit perfectly.

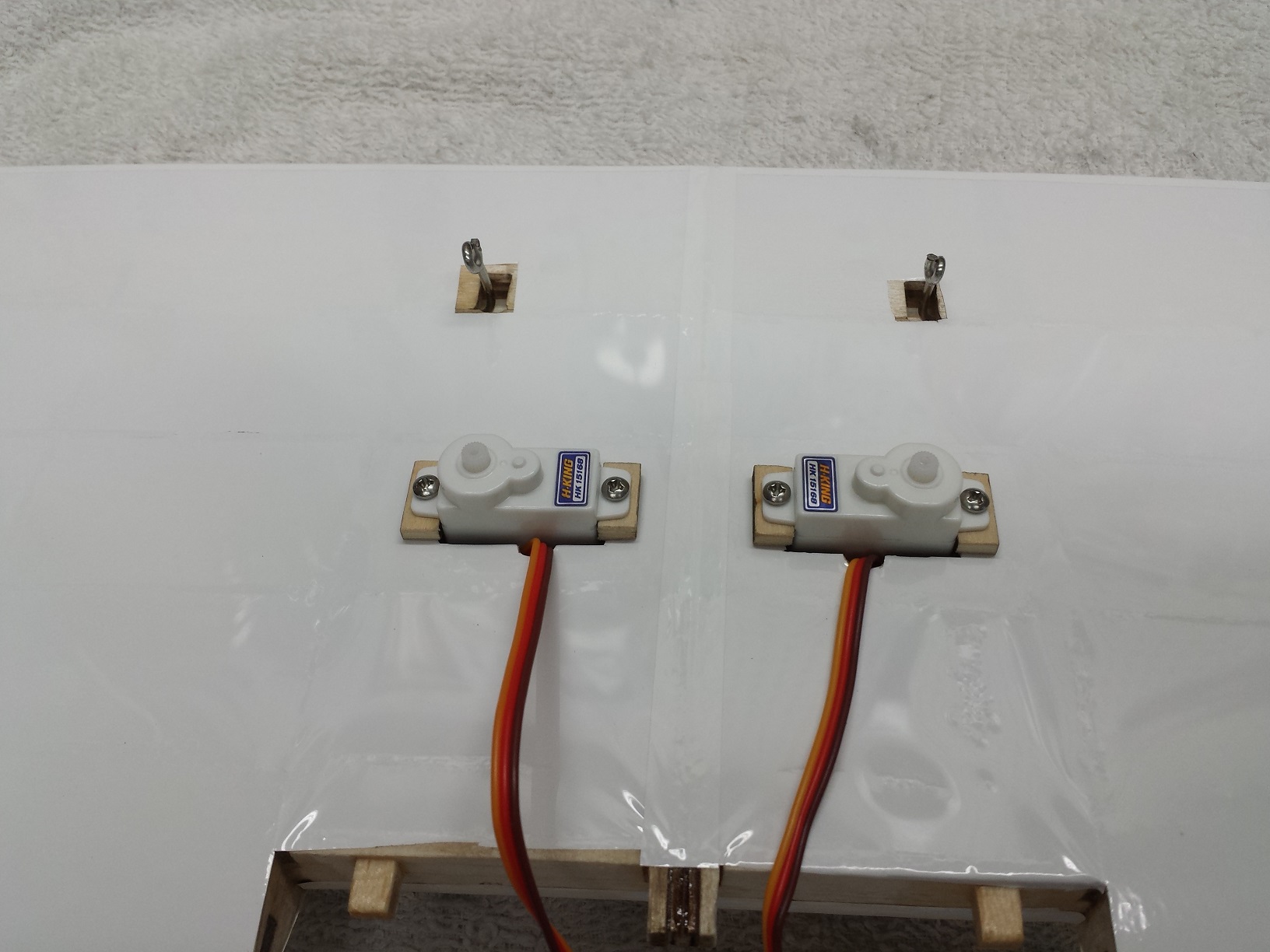

Here are the servos installed with their plywood spacers.

time for a weight check.

it is about 360 grams with the wing covered, ailerons and their servos installed, no pushrods. Tail surfaces covered. No other servos/pushrods/motor/electronics/landing gear.

here is an update, I am almost finished with covering and then it is on to pushrods/electronics.

I decided to do the wing struts as well.

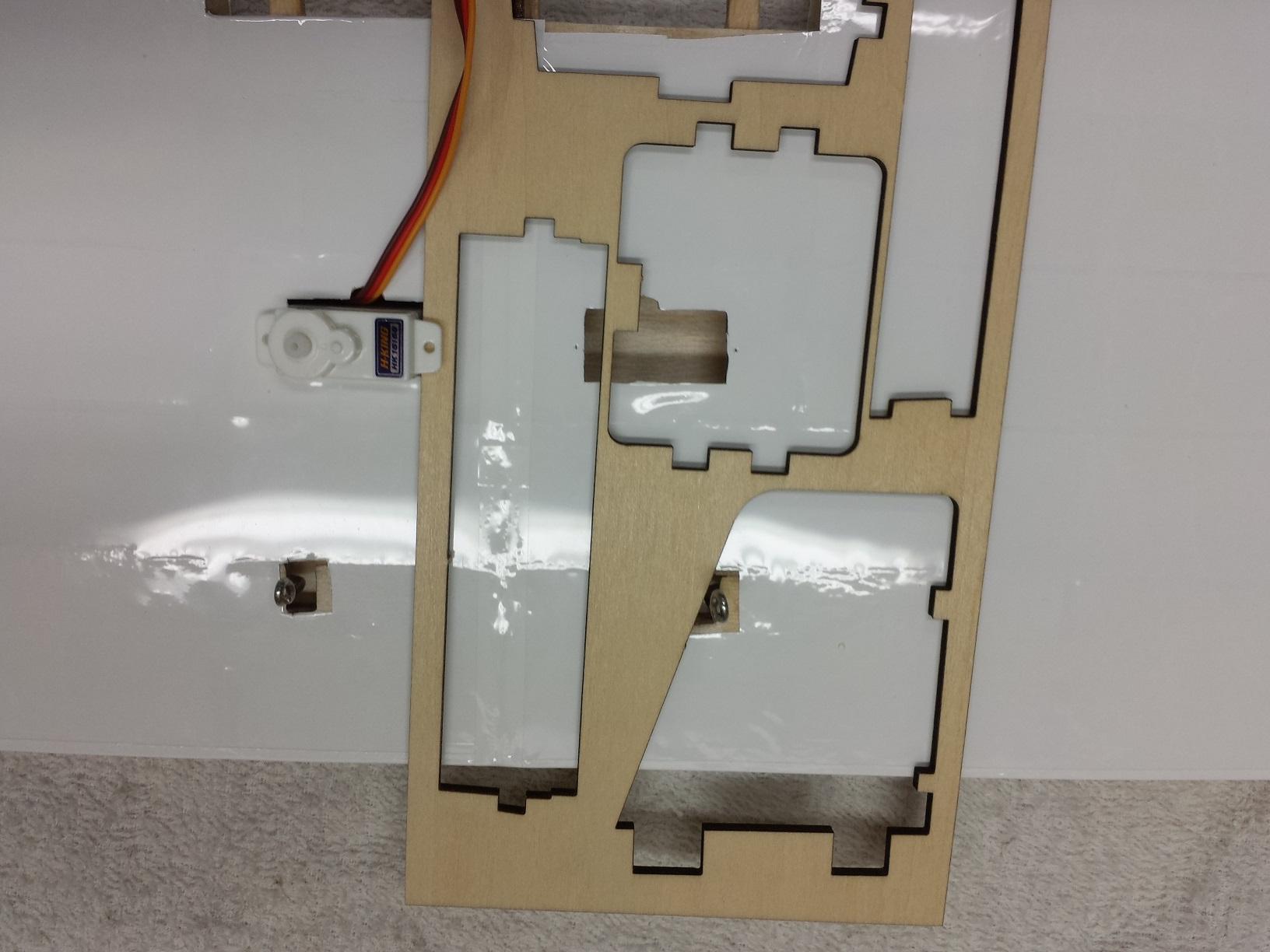

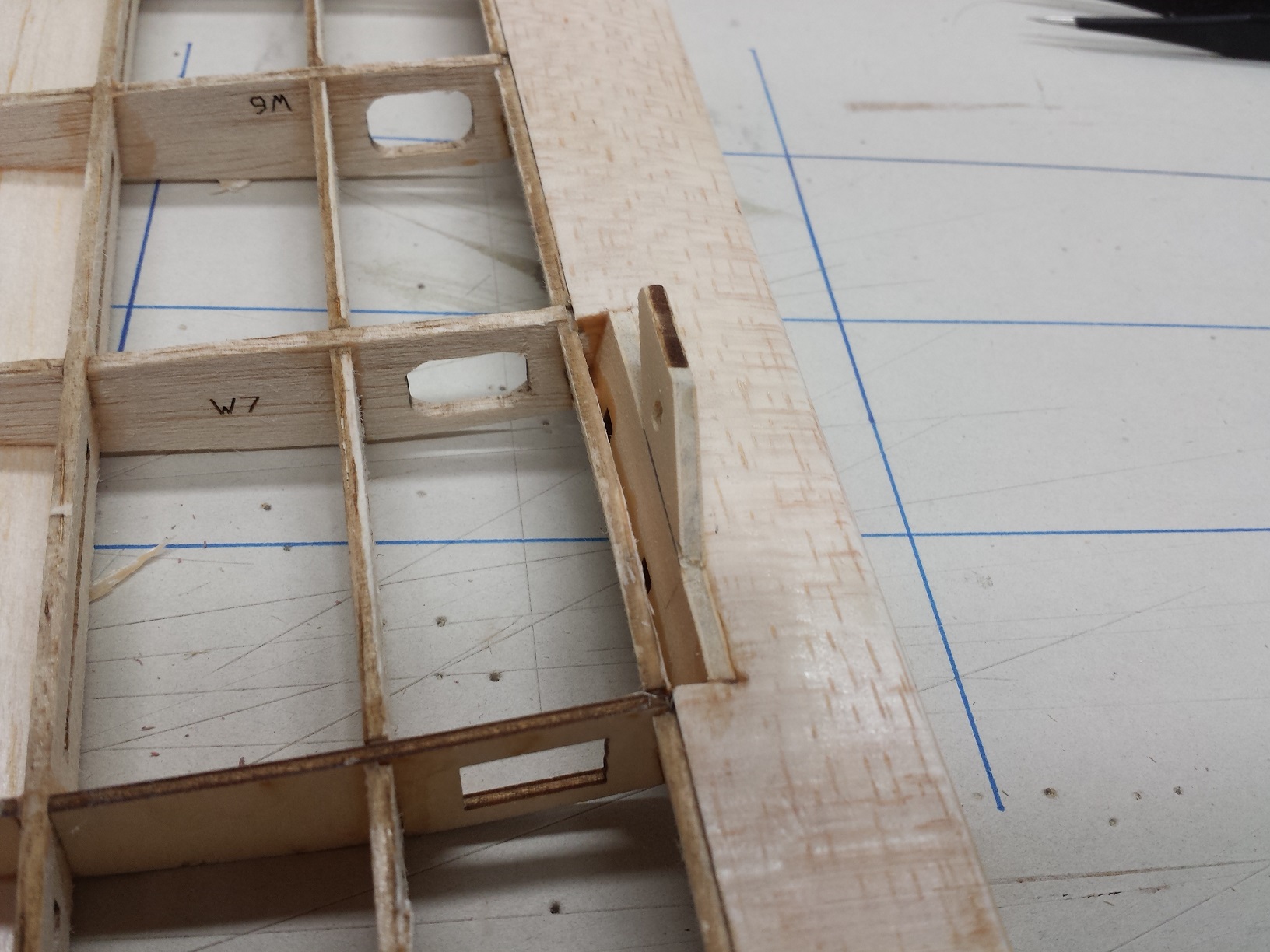

here is the lite ply brace I installed between the 2 ribs inboard of the ailerons. they are angled such a way so the struts end up at the fuselage just ahead of the door pillar.

it is a 3/8" hardwood dowel covered with monokote.

it is starting to look like an airplane!

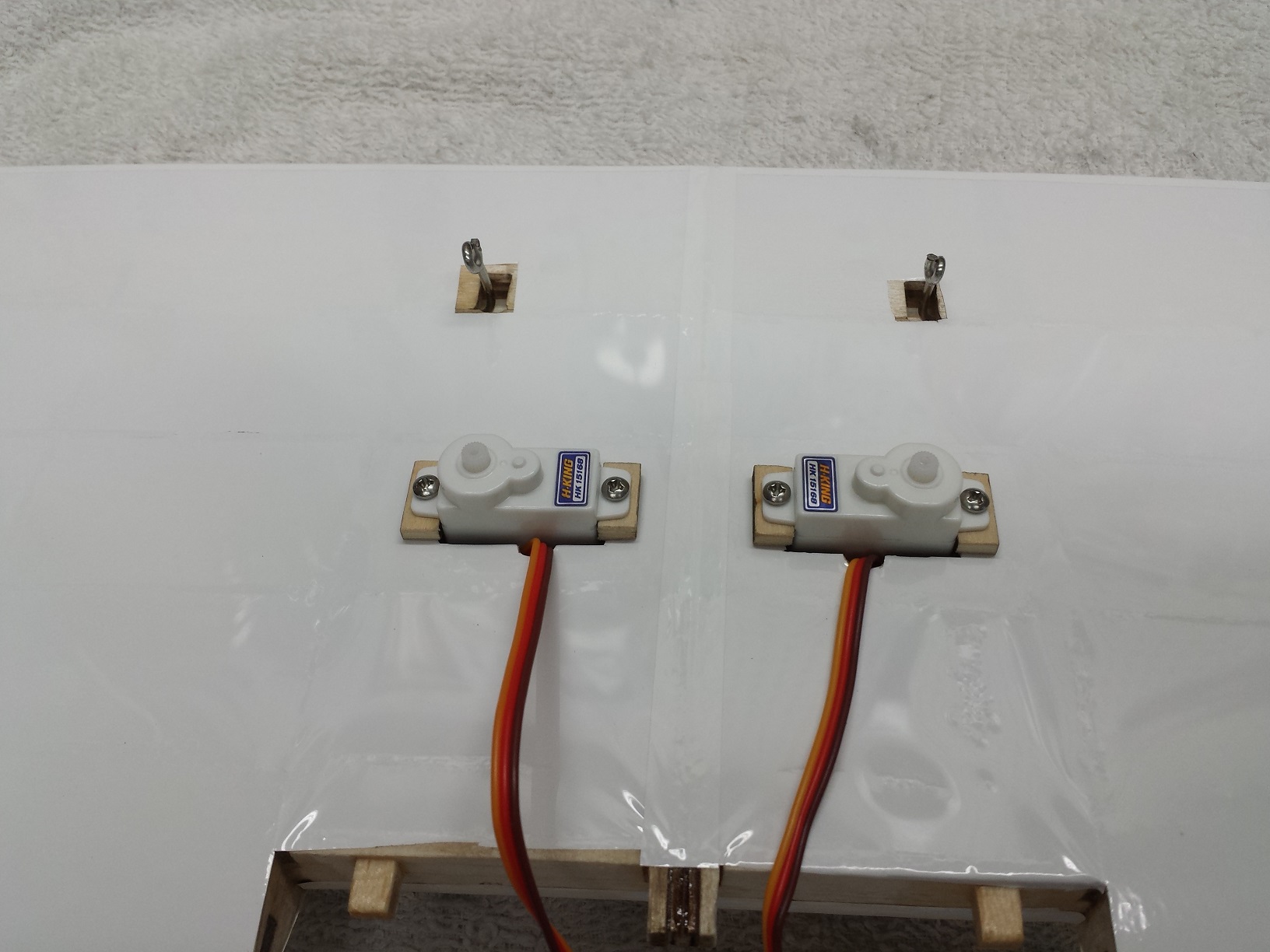

the next step was figuring out the aileron servos.

both an HXT900 and the HK 15168's stick up too far, about 3mm too high.

some left over lite ply from the motor mount sheet fit perfectly.

Here are the servos installed with their plywood spacers.

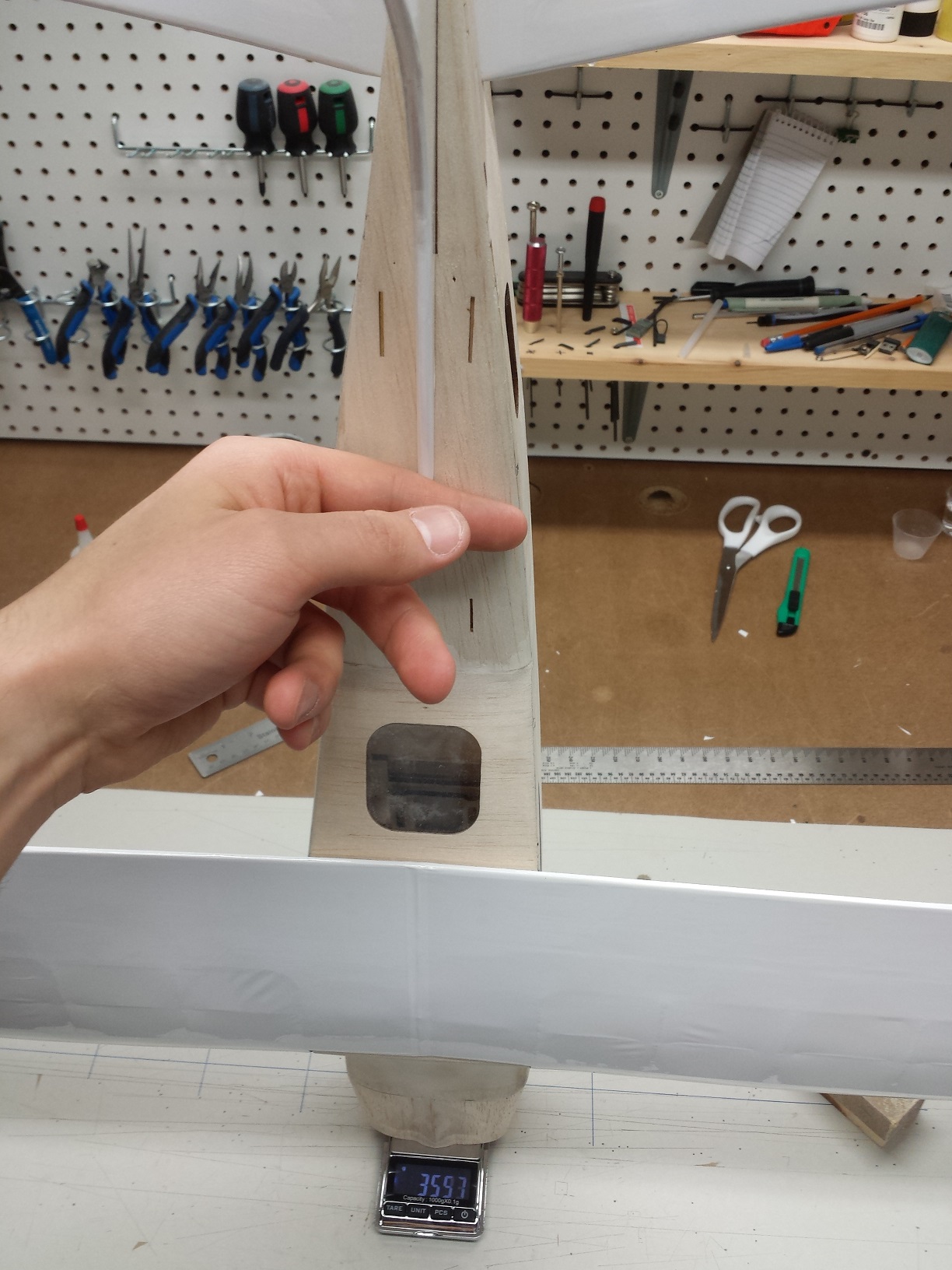

time for a weight check.

it is about 360 grams with the wing covered, ailerons and their servos installed, no pushrods. Tail surfaces covered. No other servos/pushrods/motor/electronics/landing gear.