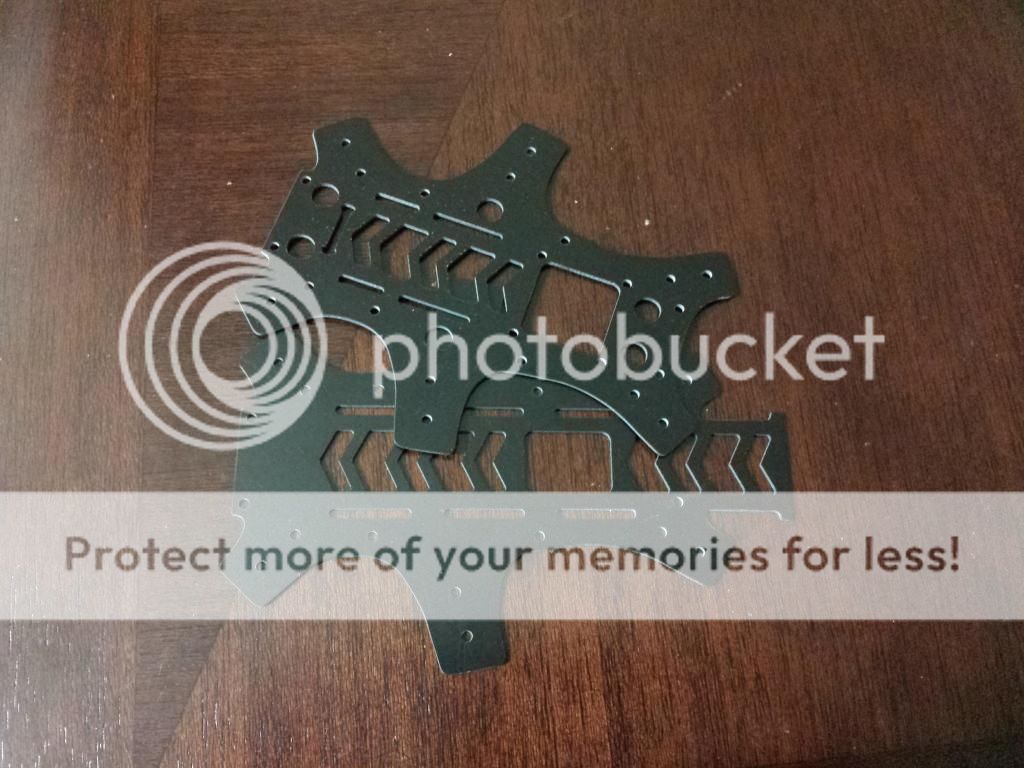

FinalGlide is correct, the extension on the bottom frame is so you can mount a battery so the CG is correct.

I was worried that the anti-vibration balls wouldn't provide much vibration reduction with these little high KV motors, but I had hoped that with the weight of the battery and FPV gear on the top cage they would reduce what little vibration might be there. This is a feature that will be in the next version of the frame, but can be bypassed if wanted.

When I put the hole in the arms to lighten it up a little bit, I was worried it would cause a weak point in a crash so I'll remove it for the next design. I have seem Soma's videos on his Warp Quad build and I did notice the arms were thicker next to the mounting holes. I will edit my design to do the same

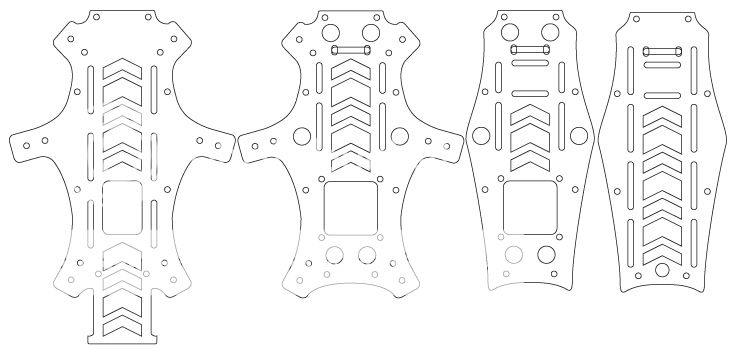

Also, while we're on the topic, should I increase the distance between the two mounting holes? As you can see in the picture above, the holes are fairly close together. I can extend the frame a little bit and move the outer mounting hole further away.

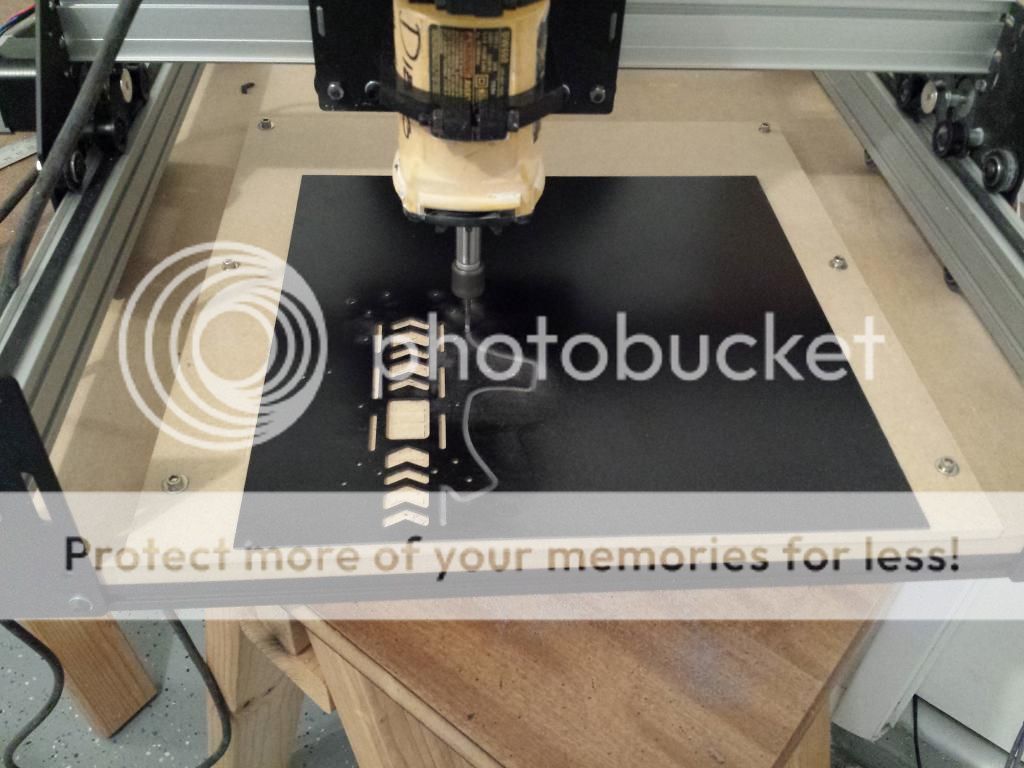

The arms are 1/8" (3.175mm) G10. Once I get a design finalized, I would like to start making them out of 1mm and 3mm carbon fiber if there is a demand for it.

FinalGlide, if you're truly interested in this frame, shoot me a PM and we'll see if we can work anything out. I could use another tester, and you're an infinitely better pilot than myself.