Mustang7302

Senior Member

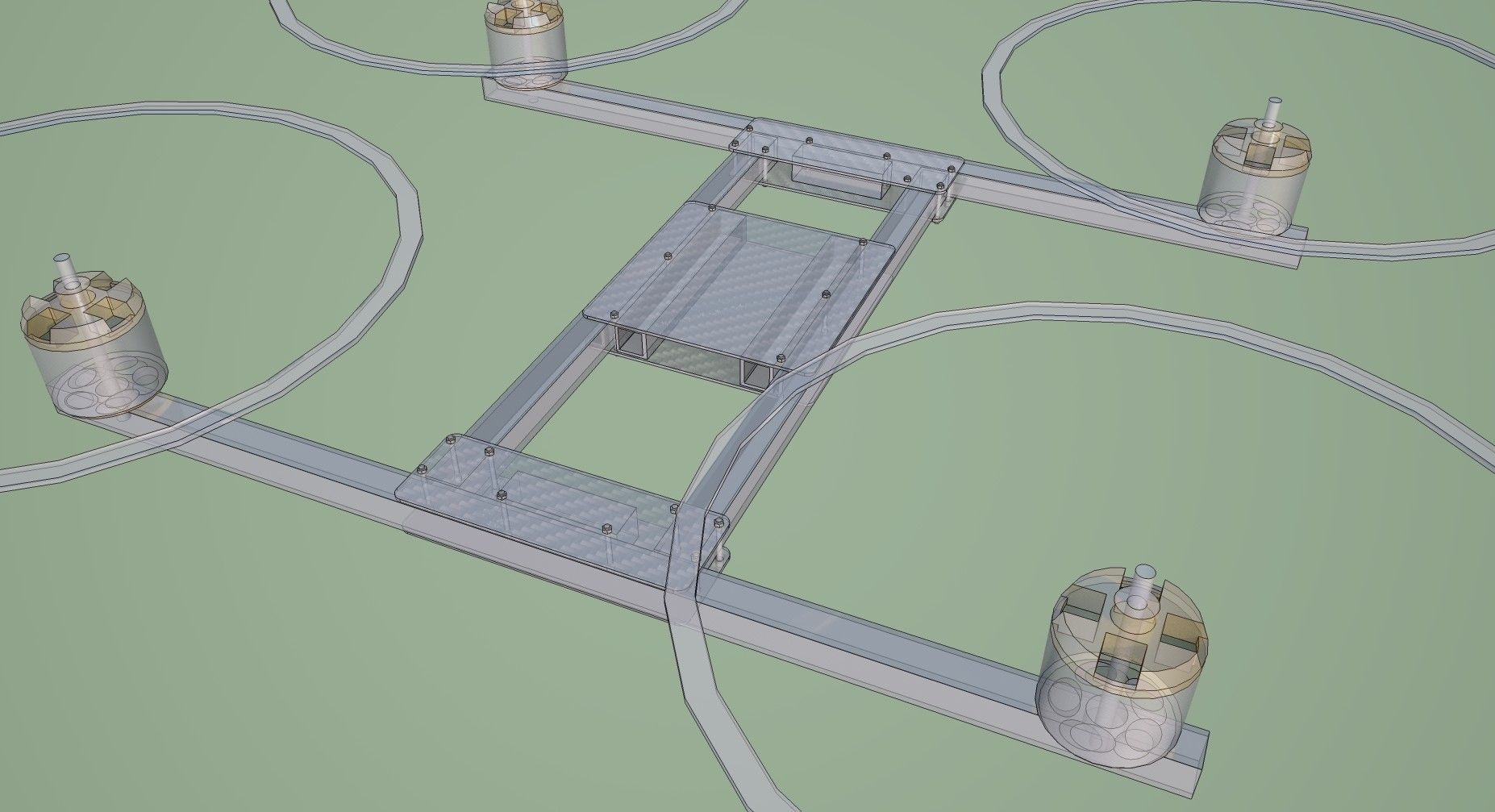

Got the new frame for the iQuad finished being painted today. Masked off half of the support booms with blue painters tape and laid down two costs of blue paint on all surfaces.

I just happened to have a piece of Carbon Fiber sheet laying around which was the same size of the new support plates and used it to get a look at how it would look together.

Even though I've taken all of the hardware off of my last version of a iQuad for 10" props, I still had its frame in one piece and put the two next to each other for comparison. As you can see they're within an inch of each other in size, that's because I decided on the spacing out the rotors on the new build further than ~1/2" apart to not have the center plate in the thrust column.

Finally, I ran to Radio Shack to get some 7" female/female jumper prototyping wires for micro-controllers to make the wire harness that will connect the receiver to the KK2.1. Took seven wires and used red, blue, and white heat shrink to "label" the ends of each wire with different color combinations and then secured them together with some wire mesh.

I just happened to have a piece of Carbon Fiber sheet laying around which was the same size of the new support plates and used it to get a look at how it would look together.

Even though I've taken all of the hardware off of my last version of a iQuad for 10" props, I still had its frame in one piece and put the two next to each other for comparison. As you can see they're within an inch of each other in size, that's because I decided on the spacing out the rotors on the new build further than ~1/2" apart to not have the center plate in the thrust column.

Finally, I ran to Radio Shack to get some 7" female/female jumper prototyping wires for micro-controllers to make the wire harness that will connect the receiver to the KK2.1. Took seven wires and used red, blue, and white heat shrink to "label" the ends of each wire with different color combinations and then secured them together with some wire mesh.