quorneng

Master member

The JB2 "Loon" was an almost exact copy of the Fieseler Fi 103 (better known as the V-1).

40,000 were ordered to assist with the proposed invasion of Japan in 1945/6 but with the surrender after the atomic bombs the order was cancelled. Republic only headed the design team. The air frame was made by Willys and the pulse jet by Ford. About 1000 had been completed. Many were used experimentally in the years after the war.

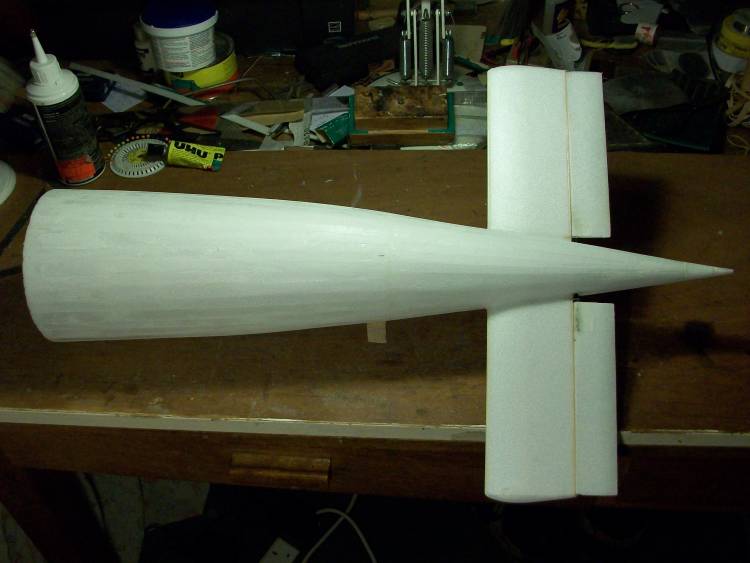

It actually makes quite a good EDF. The air frame is simple but has low drag aerodynamics and the duct is both simple and completely external.

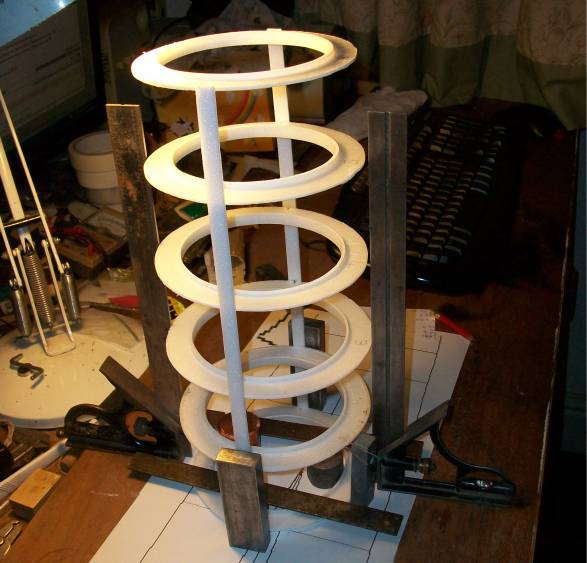

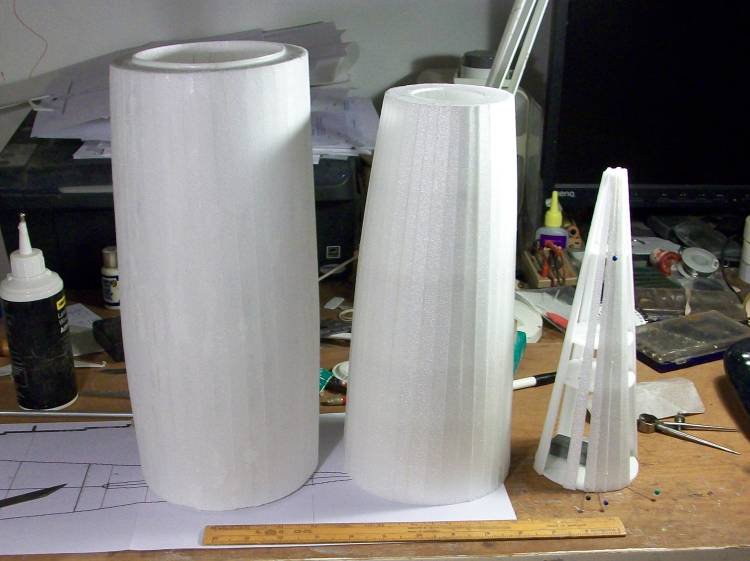

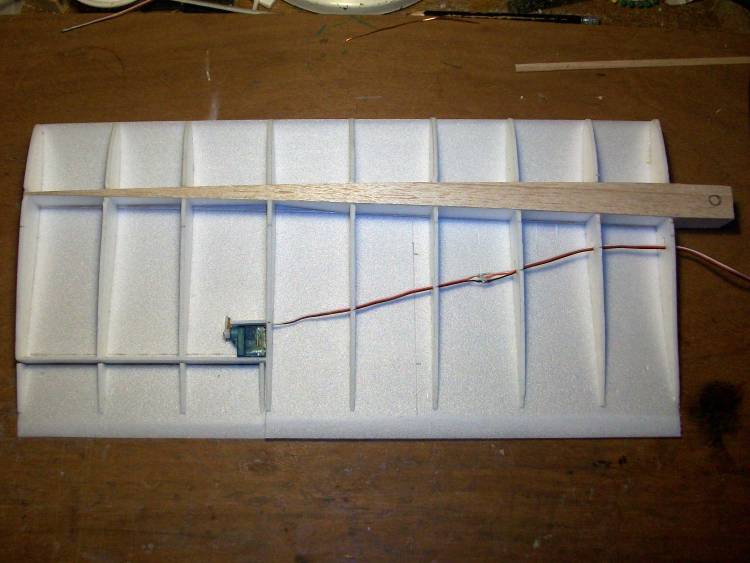

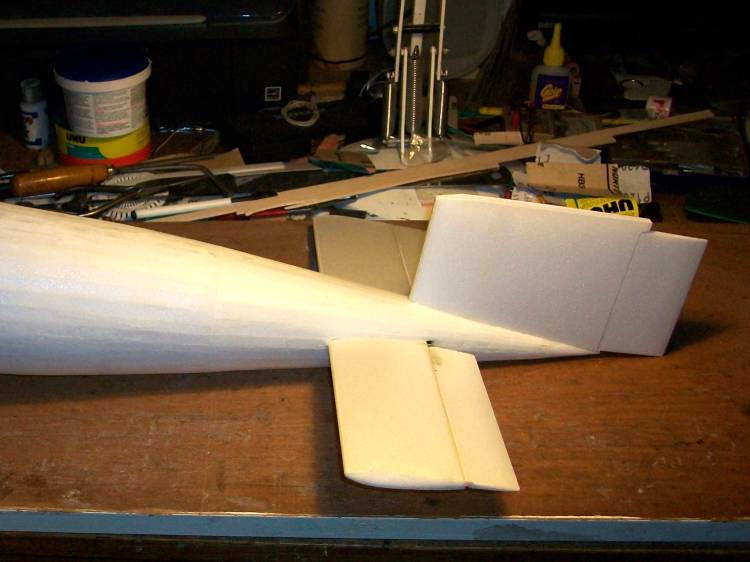

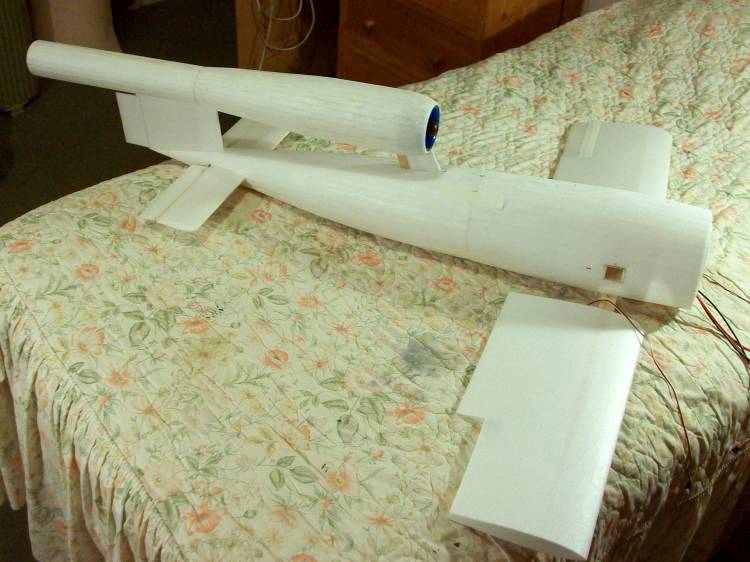

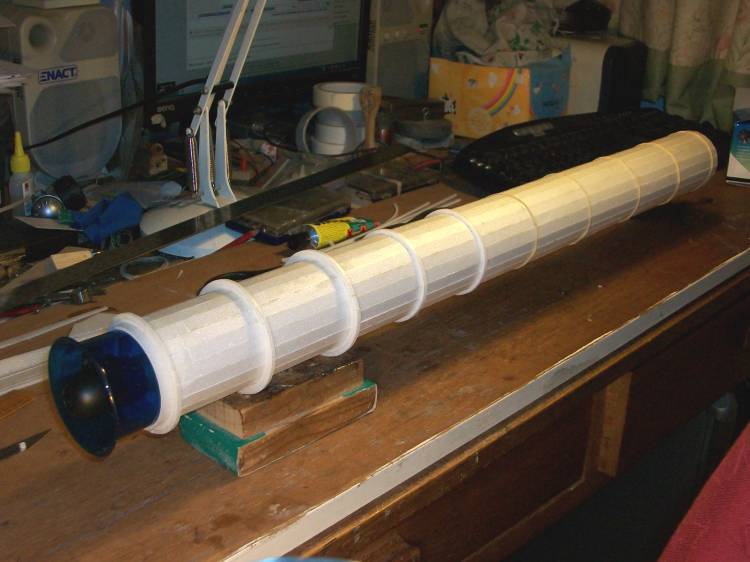

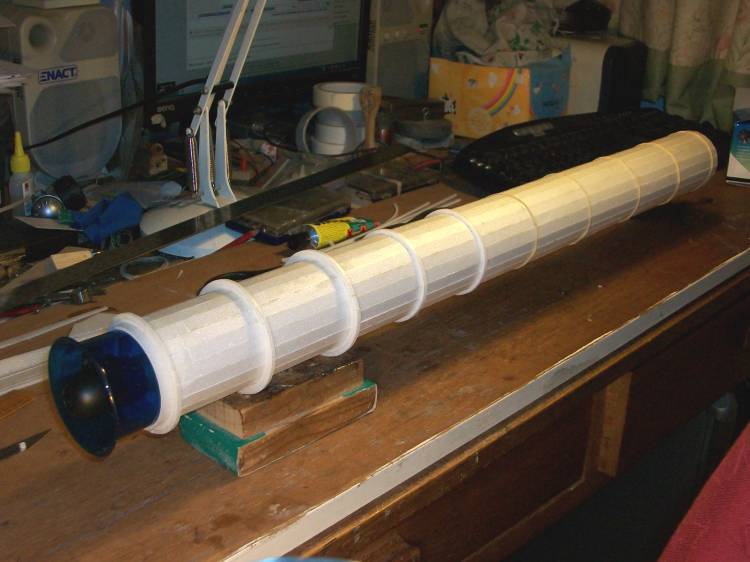

I decided on a 40" (1000 mm) span and to made almost entirely in 3 mm Depron with just a small amount of balsa in the wing, tail and fin which also supports the duct. A cheap AEO 55 mm EDF is positioned at the front of the pulse jet duct. A length of plastic gutter down pipe was used as "former" to build the duct around.

Done like this means the exhaust portion of the duct is very long so was left a constant diameter to keep down the duct losses. I hoped that by retaining the EDF bell mouth a good static thrust figure could be achieved for what was hopefully going to be a fairly slow flying plane, for an EDF!

With a completely separate duct meant the final thrust could be determined before even starting on the rest of the air frame.

It developed a bit over 16 oz thrust on a 3s. The aim was to keep the complete plane under 2 lbs all up.

To be continued.

40,000 were ordered to assist with the proposed invasion of Japan in 1945/6 but with the surrender after the atomic bombs the order was cancelled. Republic only headed the design team. The air frame was made by Willys and the pulse jet by Ford. About 1000 had been completed. Many were used experimentally in the years after the war.

It actually makes quite a good EDF. The air frame is simple but has low drag aerodynamics and the duct is both simple and completely external.

I decided on a 40" (1000 mm) span and to made almost entirely in 3 mm Depron with just a small amount of balsa in the wing, tail and fin which also supports the duct. A cheap AEO 55 mm EDF is positioned at the front of the pulse jet duct. A length of plastic gutter down pipe was used as "former" to build the duct around.

Done like this means the exhaust portion of the duct is very long so was left a constant diameter to keep down the duct losses. I hoped that by retaining the EDF bell mouth a good static thrust figure could be achieved for what was hopefully going to be a fairly slow flying plane, for an EDF!

With a completely separate duct meant the final thrust could be determined before even starting on the rest of the air frame.

It developed a bit over 16 oz thrust on a 3s. The aim was to keep the complete plane under 2 lbs all up.

To be continued.