StatiK RC

Member

Have a scratch-build you need to put tricycle landing gear on? Here is a quick and easy solution! If you follow this step by step guide, you will end up with a landing gear setup below:

____________________________________________________

What you need:

First, trace your 5-9 gram servo out on a piece of foam board

Cut out your trace

It should look similar to this:

Next, trace your coffee straw in the middle of the foam board.

Your foam board piece should now look like this:

Put a 50% score cut along the lines you just traced.

Your piece of foam board should look like this now:

Bend the piece of foam along the score cut lines and remove the middle strip of foam:

Put a section of the straw where the strip of foam was before.

Take it out then put glue in the slot....

Put the straw back into the glue while it is still hot and let it cool.

Put the section of coat hanger through the straw.

Bend the end of the hanger at a 90 degree angle in any direction

Bend the wire another 90 degrees. The vertical length of wire is the same as a pair of needle nose pliers. Your wire should now look like this:

Thread the bent end into the servo horn. Your project should now look like this:

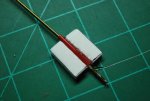

Bend the wire at a 90 degree angle down the backside of the servo like these pictures show:

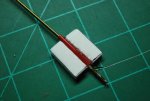

Glue the foam board piece/straw to the backside of the servo. The straw should be centered with the control horn.

Hold the foam piece in place firmly until the glue dries.

Your landing gear should now look like this:

All landing gears are different: they have different wheel sizes and angles. I used scrap pieces of foam to keep the wheel in line. Here is a picture of how I completed the project:

Congratulations, your done! Sorry about formatting.... I'm still getting used to the format of this forum! If it didnt show up for you, I also have it up on my blog here: http://rcappetite.blogspot.com/p/diy-tricycle-landing-gear.html

thankyou for reading this long post. Feedback is always appreciated!

____________________________________________________

What you need:

First, trace your 5-9 gram servo out on a piece of foam board

Cut out your trace

It should look similar to this:

Next, trace your coffee straw in the middle of the foam board.

Your foam board piece should now look like this:

Put a 50% score cut along the lines you just traced.

Your piece of foam board should look like this now:

Bend the piece of foam along the score cut lines and remove the middle strip of foam:

Put a section of the straw where the strip of foam was before.

Take it out then put glue in the slot....

Put the straw back into the glue while it is still hot and let it cool.

Put the section of coat hanger through the straw.

Bend the end of the hanger at a 90 degree angle in any direction

Bend the wire another 90 degrees. The vertical length of wire is the same as a pair of needle nose pliers. Your wire should now look like this:

Thread the bent end into the servo horn. Your project should now look like this:

Bend the wire at a 90 degree angle down the backside of the servo like these pictures show:

Glue the foam board piece/straw to the backside of the servo. The straw should be centered with the control horn.

Hold the foam piece in place firmly until the glue dries.

Your landing gear should now look like this:

All landing gears are different: they have different wheel sizes and angles. I used scrap pieces of foam to keep the wheel in line. Here is a picture of how I completed the project:

Congratulations, your done! Sorry about formatting.... I'm still getting used to the format of this forum! If it didnt show up for you, I also have it up on my blog here: http://rcappetite.blogspot.com/p/diy-tricycle-landing-gear.html

thankyou for reading this long post. Feedback is always appreciated!