varg

Build cheap, crash cheap

Taranis Q X7 died on me, inspection reveals many bad solder joints! Check yours!

It could have been a lot worse, my transmitter cut out right after launching my flying wing today, and it proceeded to go nose-first into the ground from 50ft or so at moderate speed. The damage; crushed my power pod, ripped the balance connector off of my brand new battery and dented it, shot my battery alarm off into the grass somewhere, and crumpled the nose of the plane. Luckily I didn't lose the plane and all of my electronics. I'm lucky it cut out right after launch and not while the plane was facing towards the lake west of my field, the trees north of it, or the people south of it.

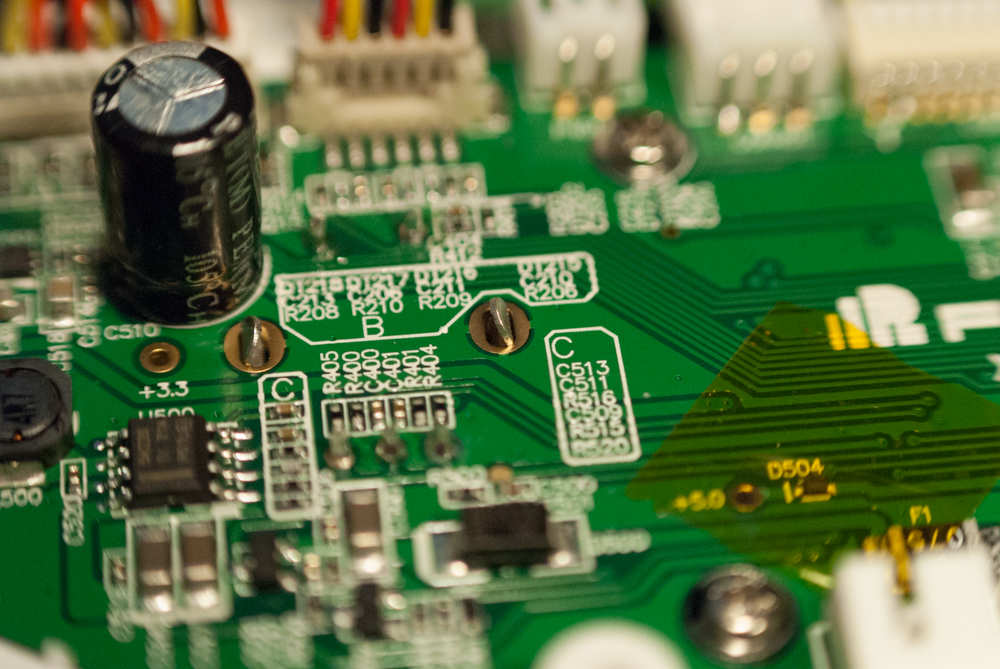

After the walk of shame I couldn't turn the transmitter on so I checked the batteries and they had plenty of voltage, I pulled the battery tray out and saw a nearly solder-less joint on the battery connector. Took the back of the case off of the transmitter and shot these photos; bad solder joints all over the place. It's an intermittent contact issue and the transmitter turns on and works fine now.

Please take the back plate off and check your Q X7's boards guys, it might be just my transmitter, but I doubt it, and I'd hate to see an easily discovered defect to cost someone much hard earned cash.

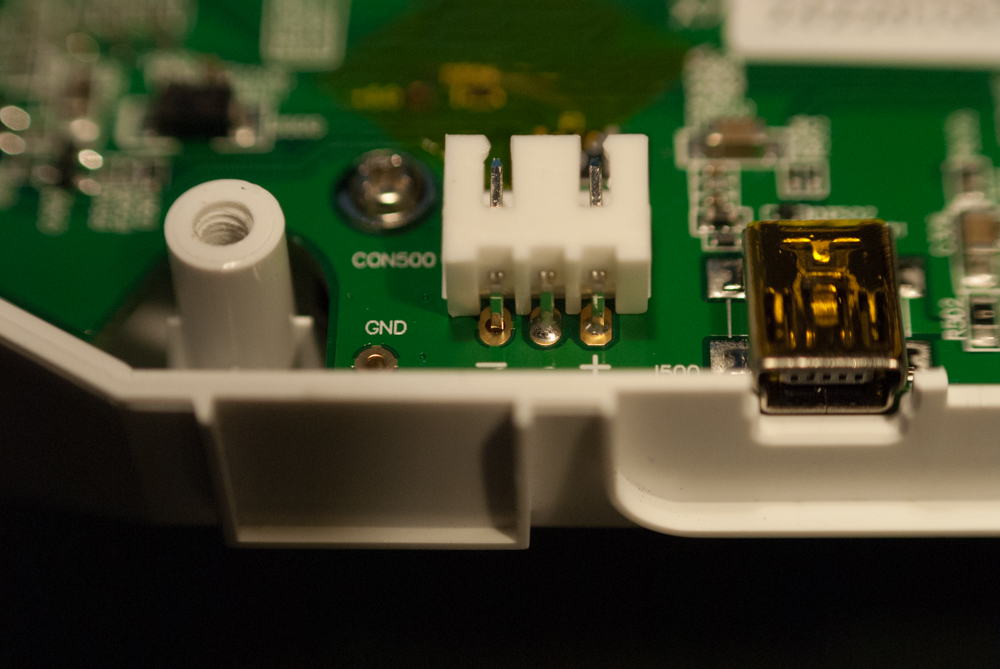

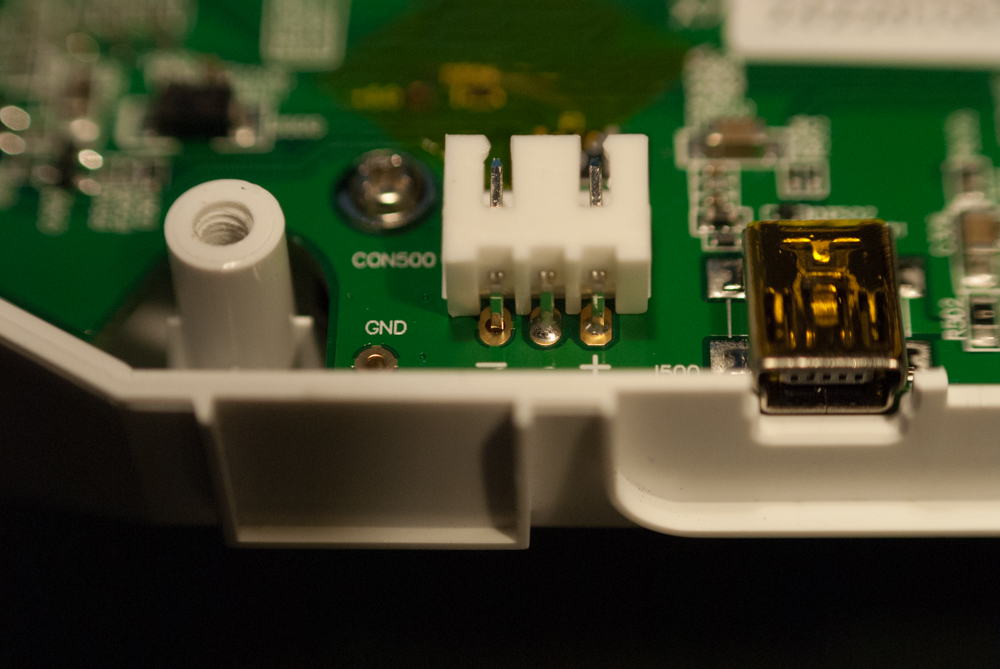

Here's the battery connector:

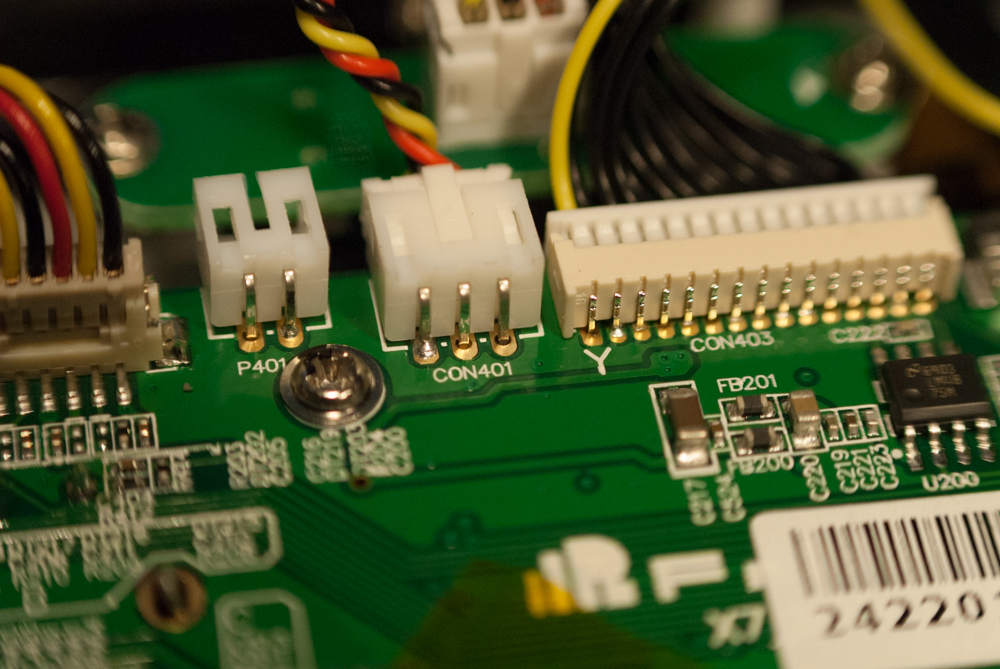

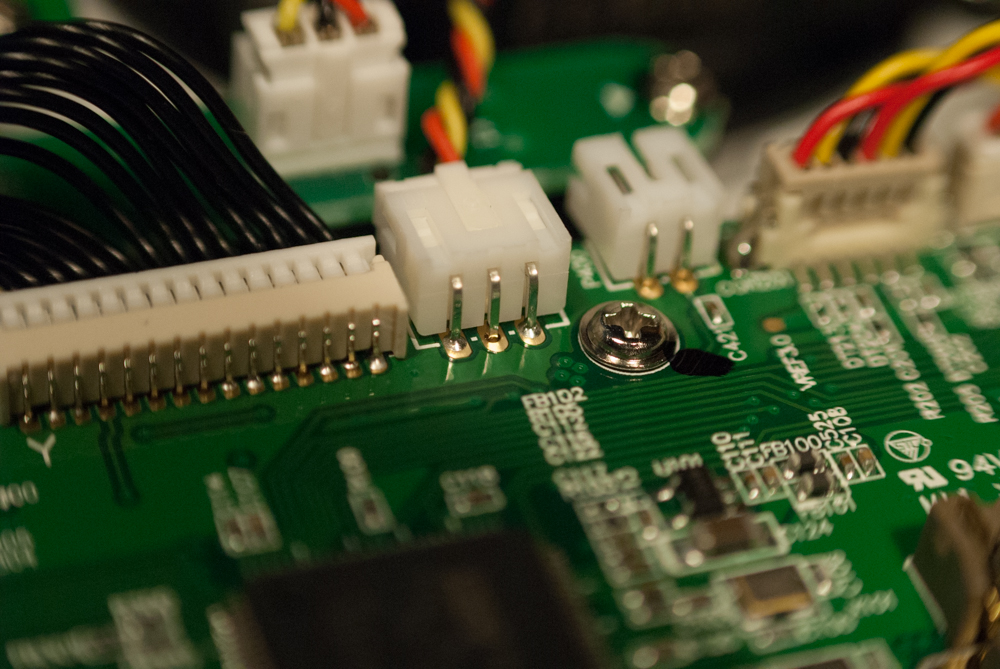

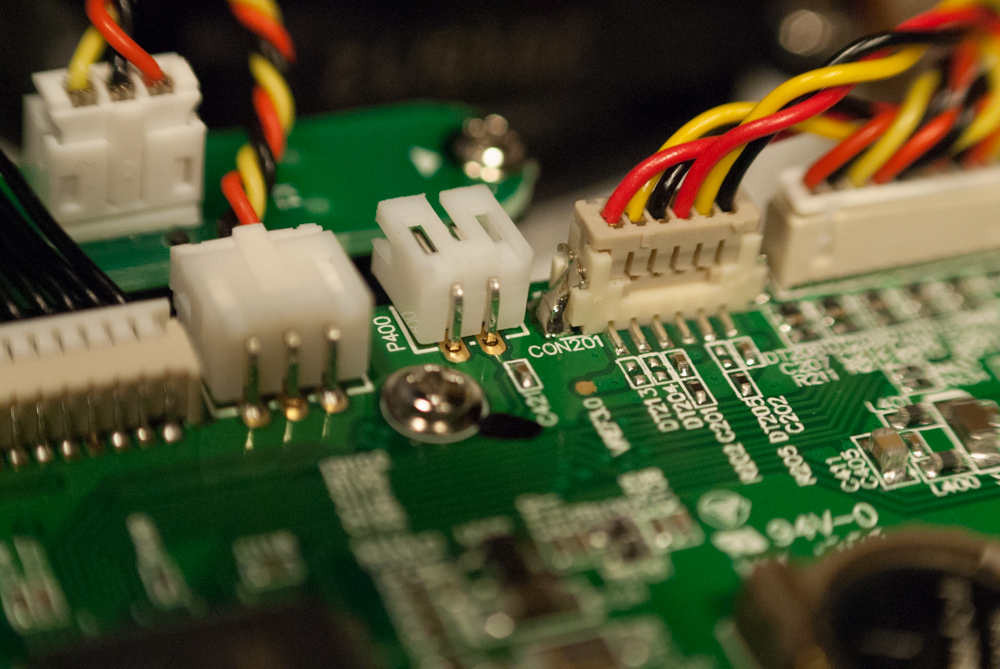

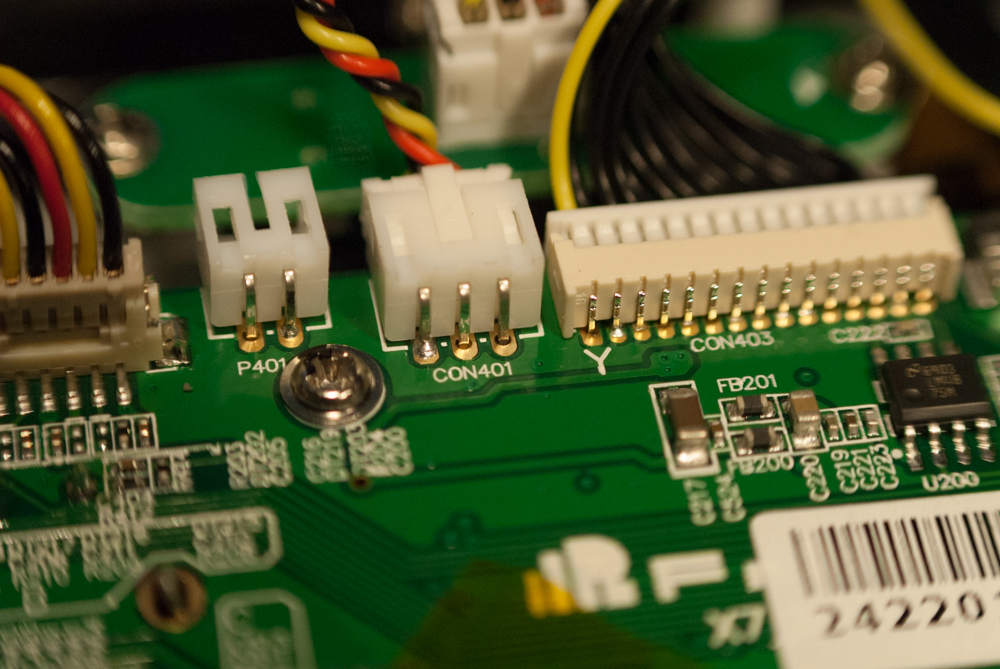

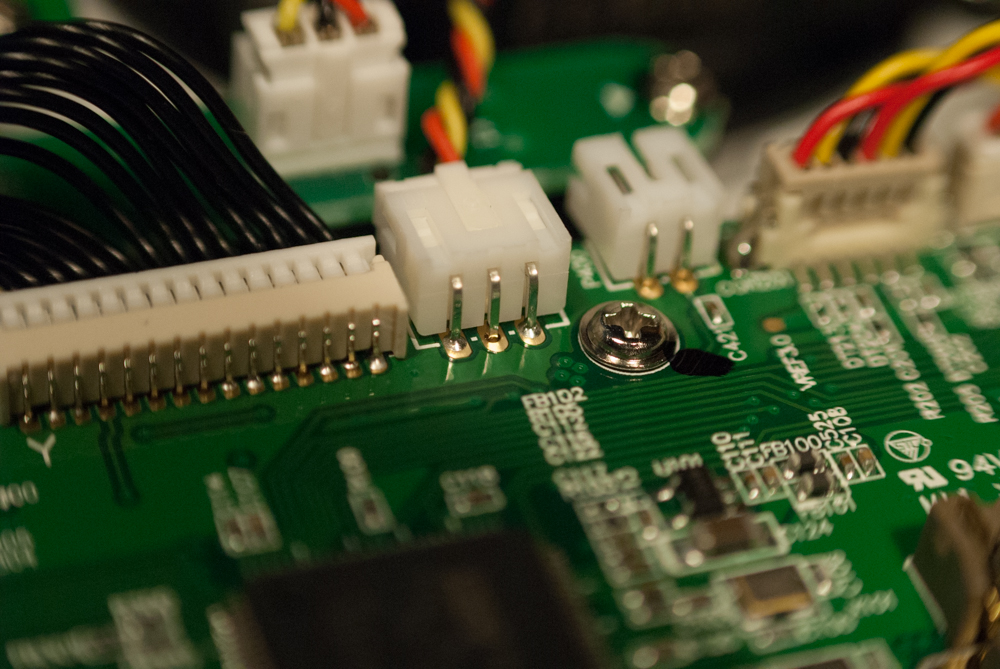

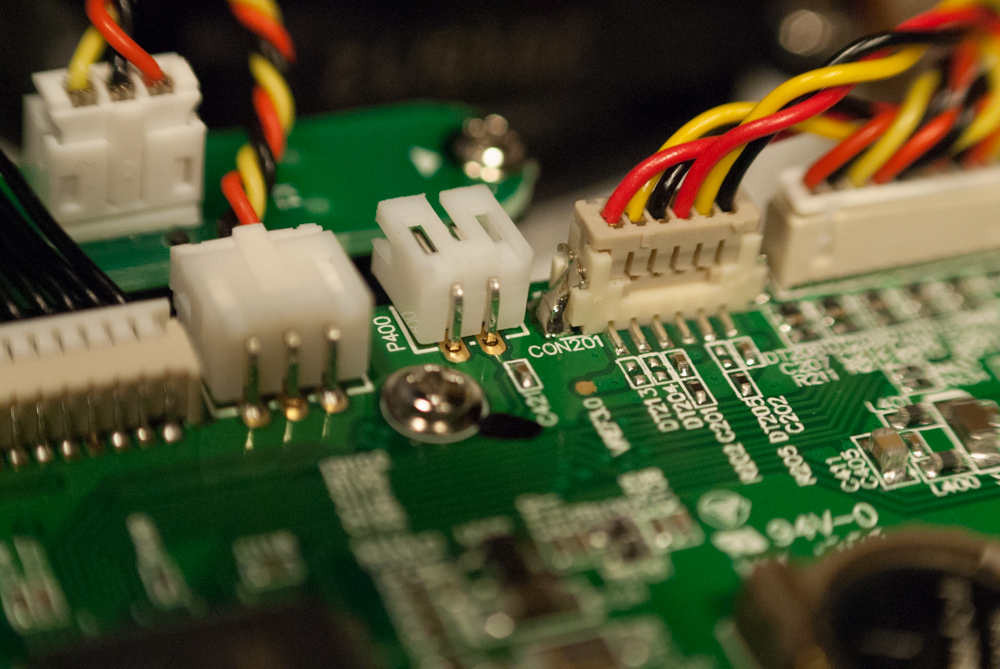

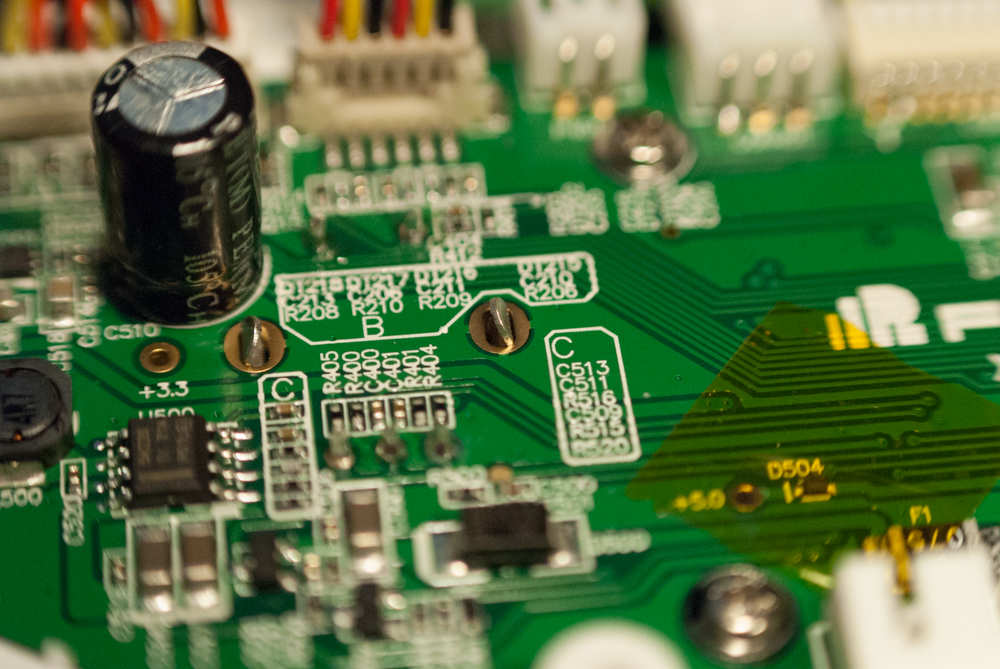

Other connectors with bad solder joints:

I'm torn on how to proceed on this, I am more than capable of fixing this myself with better quality solder joints than the factory will make, and then I'd not have to wait ages and pay shipping while I try to get a replacement under warranty, but I'd hate to fix it and void my warranty then have a bigger problem which I can't fix down the road and no warranty. The thought of waiting and going back and forth trying to resolve this is what bothers me, I can fix it today and fly this week, or wait what might be weeks or months to resolve the issue under warranty. I'm not even sure how long the warranty is on these, there's no info in the manual and my googling didn't reveal anything, the transmitter was purchased for me from flitetest as a gift in May.

It could have been a lot worse, my transmitter cut out right after launching my flying wing today, and it proceeded to go nose-first into the ground from 50ft or so at moderate speed. The damage; crushed my power pod, ripped the balance connector off of my brand new battery and dented it, shot my battery alarm off into the grass somewhere, and crumpled the nose of the plane. Luckily I didn't lose the plane and all of my electronics. I'm lucky it cut out right after launch and not while the plane was facing towards the lake west of my field, the trees north of it, or the people south of it.

After the walk of shame I couldn't turn the transmitter on so I checked the batteries and they had plenty of voltage, I pulled the battery tray out and saw a nearly solder-less joint on the battery connector. Took the back of the case off of the transmitter and shot these photos; bad solder joints all over the place. It's an intermittent contact issue and the transmitter turns on and works fine now.

Please take the back plate off and check your Q X7's boards guys, it might be just my transmitter, but I doubt it, and I'd hate to see an easily discovered defect to cost someone much hard earned cash.

Here's the battery connector:

Other connectors with bad solder joints:

I'm torn on how to proceed on this, I am more than capable of fixing this myself with better quality solder joints than the factory will make, and then I'd not have to wait ages and pay shipping while I try to get a replacement under warranty, but I'd hate to fix it and void my warranty then have a bigger problem which I can't fix down the road and no warranty. The thought of waiting and going back and forth trying to resolve this is what bothers me, I can fix it today and fly this week, or wait what might be weeks or months to resolve the issue under warranty. I'm not even sure how long the warranty is on these, there's no info in the manual and my googling didn't reveal anything, the transmitter was purchased for me from flitetest as a gift in May.

Last edited: