Duffusmonkey

Junior Member

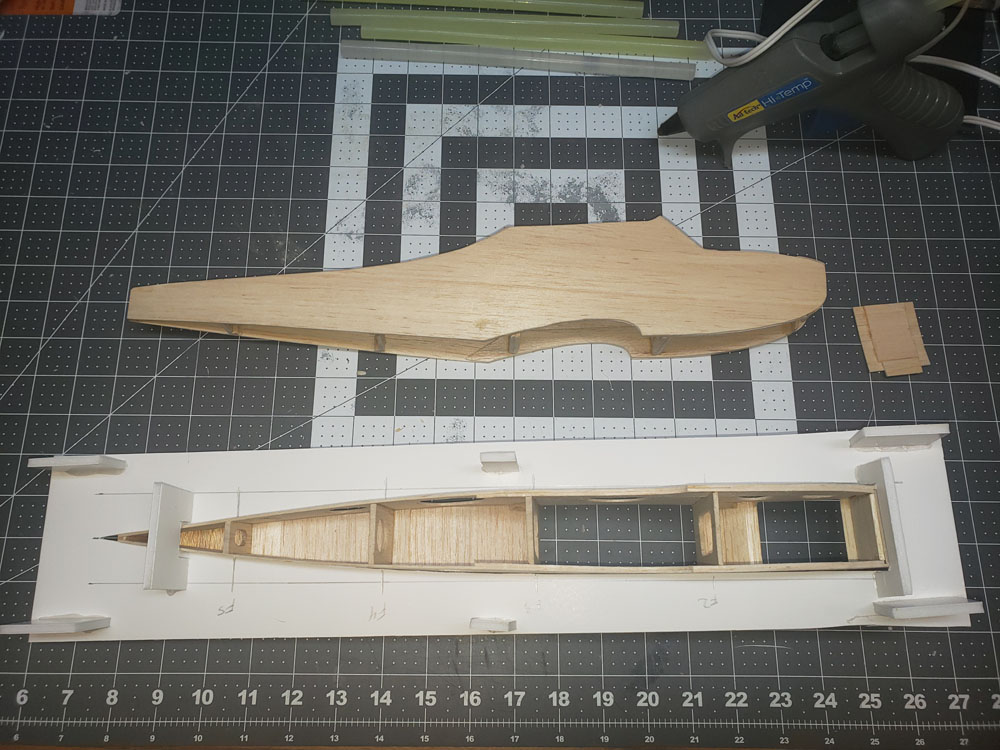

I am going to use 1.5mil clear lamination film. I did a little experimenting and it doesn't seem to shrink as much as monokote but it's lighter.Is there still someone making shrink wrap covering like monokote or is all that stuff long gone too?

I was shrinking it using just an iron, I read that I need a heat gun to get it hot enough to completely shrink so I am going to give that try in a few days.

Last edited: