Twitchity

Senior Member

Having sold my previous tricopter (pic below), I decided it was time to make another one since Cranial wouldn't sell me his :black_eyed:. After seeing the quality of Armattan's cutting service on mpbiv's SCX-200 quad http://forum.flitetest.com/showthread.php?25620-SCX-200-Race-Quad-Build-Log I decided to give Armattan a shot and created a new tricopter design similar to the original since the hard drive I had my files on got fried and couldn't recover the files.

So I'll go over my initial impressions of the kit provided by Armattan. Overall I'm extremely happy with the quality and service they offer, and this tri will be on their store once I finish my build to ensure everything fits how it was intended. For the price of the kit I would have to give the quality an A, but disregarding the price and looking at the CF strictly from an aesthetic view I would give it a B-, and that may be a little on the conservative side. The cuts are nice and smooth, and the edges aren't sharp.

This brings me to my first (somewhat) complaint. It looks like they sanded the edges of all the pieces which is great as the edges aren't sharp and won't slice your wires. The bad part (for my OCD at least) is the edges aren't consistent. Some parts you can visibly see where the edge was sanded down more to give it a more rounded edge, while others are closer to being square. There are also some light surface scratches/scuffs that you can see when the light hits the CF just right. I expected this but not in the amount that's on the pieces. It's going to get beat up anyways, but again my OCD doesn't like it.

The last complaint is there are some tiny chips in the cuts, not many, but there are some. It almost appears that the tooling used was dull and needed to be changed so chances are this isn't always going to be an issue. But like I said earlier, for the price Armattan can cut you a custom frame, all of these issues aren't anything that would keep me from buying another frame from them again. All of the parts fit together perfectly and I didn't have to sand anything to make the pieces work.

So now onto the new frame. This is designed to run any 16x19 motors with 5" props; the MTM distance is 175. The camera bracket is designed to work with the h1177 camera, and mounting for any standard 30.5mm x 30.5mm FC. I originally made the top plate for a TS5823 VTX but I've recently switched to a Hawkeye VTX so I'll have to cut a new top plate. Once I finish my build I'll have a link to the kit on Armattan and upload the 3D parts to Thingiverse.

Now time for pictures. Here's the frame assembled when I got in from Armattan. The antenna will mount in the back right of the top plate, and there is a clamp for the battery wires in the back left.

All the CF pieces included in the kit

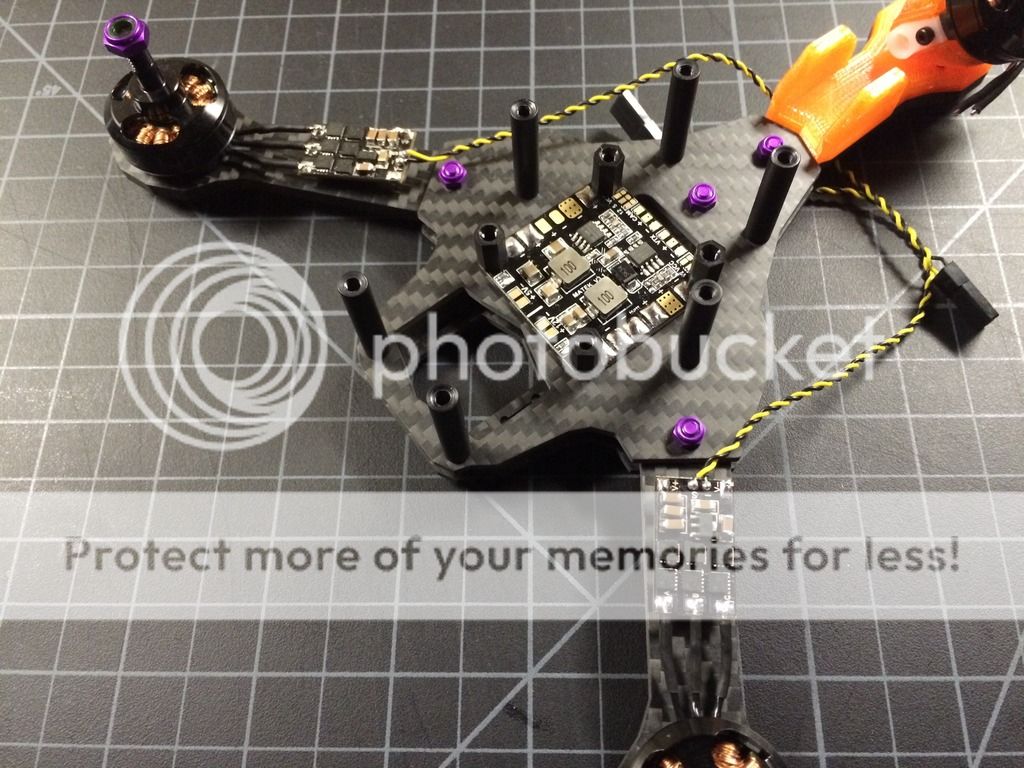

Now time for the build. First I assembled the frame. You can see in the picture where all three arms come together and meet in the center. The cutout isn't necessary in the top plate for my current build, but I originally was going to mount the FC close to the frame and wanted the little extra space for clearance. All of the 25mm standoffs are held in place by 16mm bolts, the 10mm standoffs and bolts with locknuts got 12mm bolts. Everything was tightened up at this point.

Next I fitted the motors and tilt mechanism

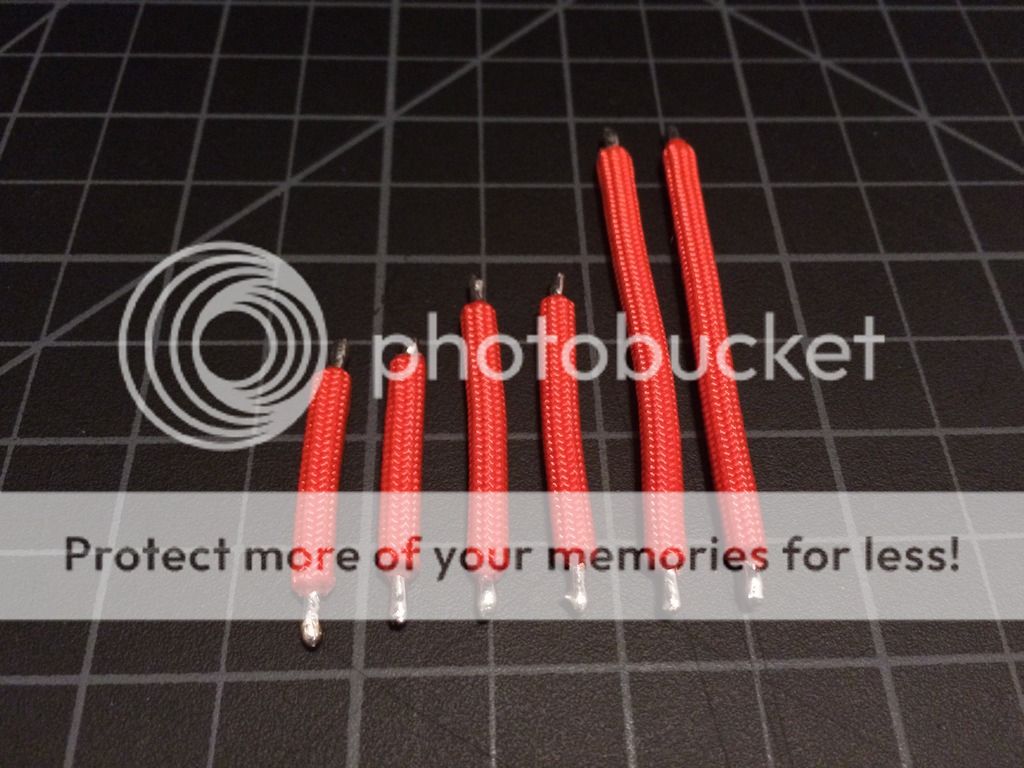

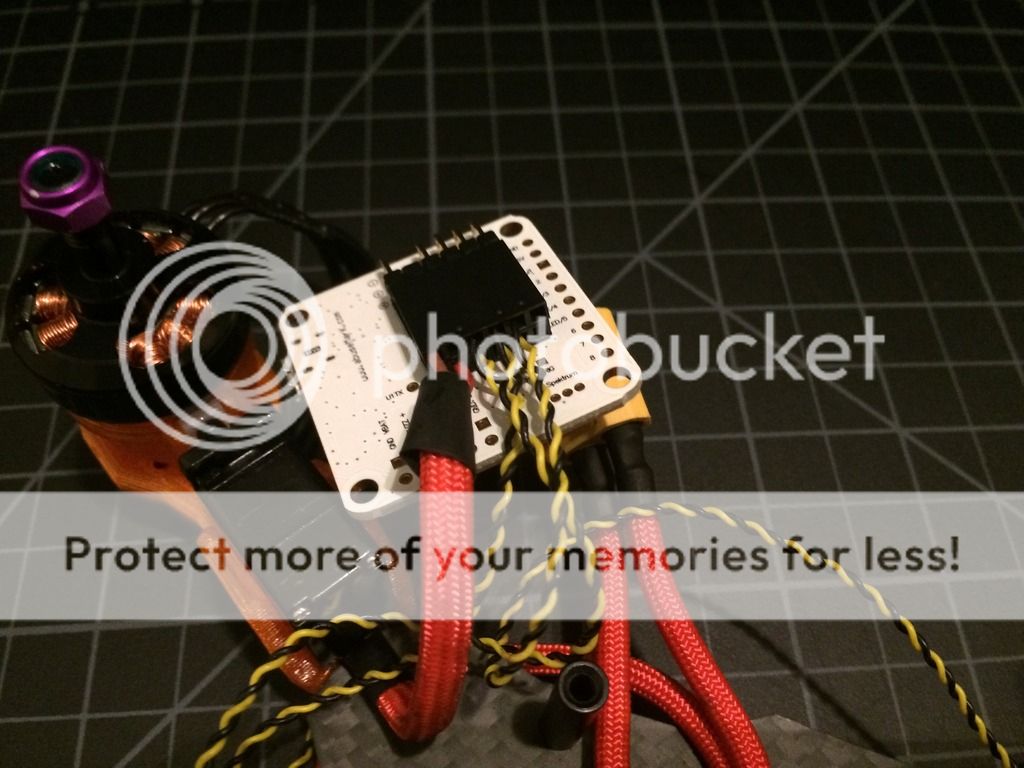

With the motors mounted it came time to solder the wires to the ESCs. I'm going with DYS XM20A ESCs for this build as they were on sale at the time I purchased them, and the LittleBee ESCs were all sold out. Once I got the ESCs I instantly regretted that decision as the soldering on them was horrible, hopefully this isn't an indication as to their quality. Anyways, motor wires were cut to size and soldered to the ESCs.

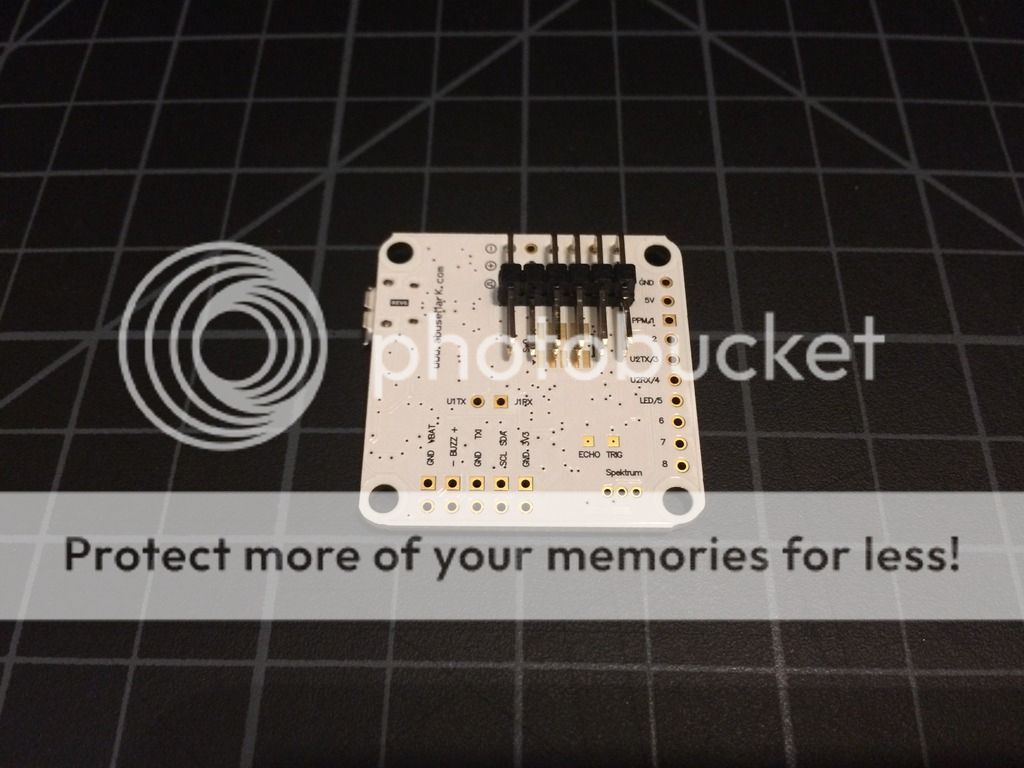

The pads on the Matek PDB were tinned and the PDB was mounted directly to the frame. There is a layer of kapton tape on the bottom of the PDB to insulate it from the frame. I may raise it up with some 4mm spacers before I finish the build, but I think the kapton tape will be just file.

And that's as far as I got for the night. Hopefully more build progress will happen tomorrow.

So I'll go over my initial impressions of the kit provided by Armattan. Overall I'm extremely happy with the quality and service they offer, and this tri will be on their store once I finish my build to ensure everything fits how it was intended. For the price of the kit I would have to give the quality an A, but disregarding the price and looking at the CF strictly from an aesthetic view I would give it a B-, and that may be a little on the conservative side. The cuts are nice and smooth, and the edges aren't sharp.

This brings me to my first (somewhat) complaint. It looks like they sanded the edges of all the pieces which is great as the edges aren't sharp and won't slice your wires. The bad part (for my OCD at least) is the edges aren't consistent. Some parts you can visibly see where the edge was sanded down more to give it a more rounded edge, while others are closer to being square. There are also some light surface scratches/scuffs that you can see when the light hits the CF just right. I expected this but not in the amount that's on the pieces. It's going to get beat up anyways, but again my OCD doesn't like it.

The last complaint is there are some tiny chips in the cuts, not many, but there are some. It almost appears that the tooling used was dull and needed to be changed so chances are this isn't always going to be an issue. But like I said earlier, for the price Armattan can cut you a custom frame, all of these issues aren't anything that would keep me from buying another frame from them again. All of the parts fit together perfectly and I didn't have to sand anything to make the pieces work.

So now onto the new frame. This is designed to run any 16x19 motors with 5" props; the MTM distance is 175. The camera bracket is designed to work with the h1177 camera, and mounting for any standard 30.5mm x 30.5mm FC. I originally made the top plate for a TS5823 VTX but I've recently switched to a Hawkeye VTX so I'll have to cut a new top plate. Once I finish my build I'll have a link to the kit on Armattan and upload the 3D parts to Thingiverse.

Now time for pictures. Here's the frame assembled when I got in from Armattan. The antenna will mount in the back right of the top plate, and there is a clamp for the battery wires in the back left.

All the CF pieces included in the kit

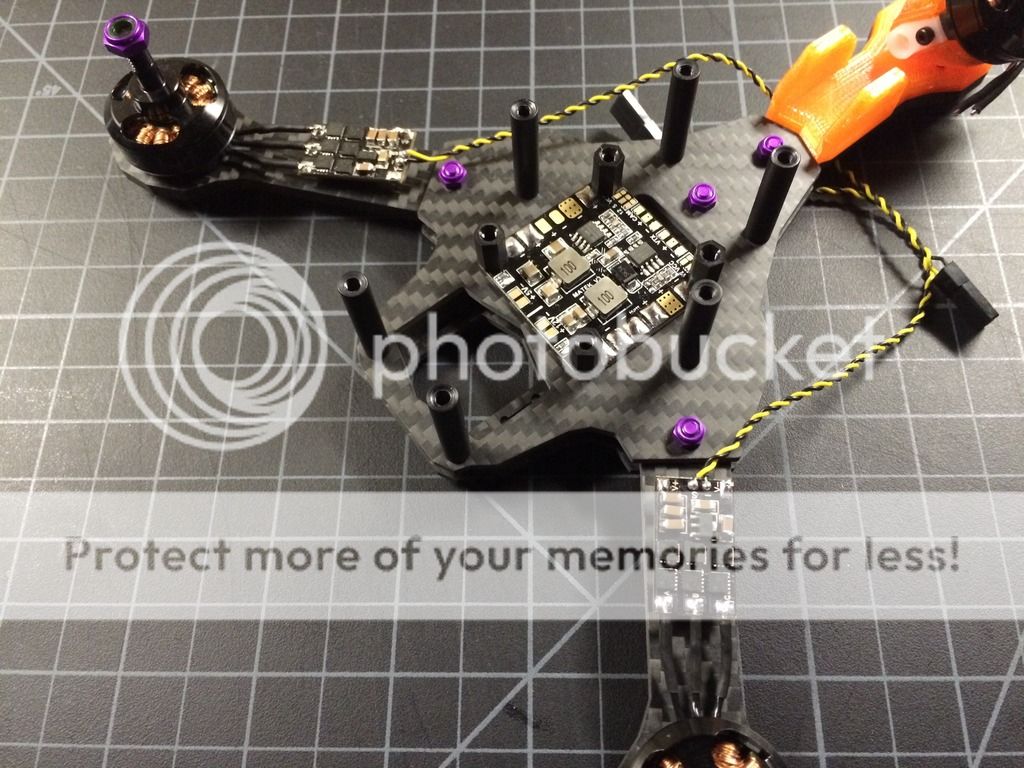

Now time for the build. First I assembled the frame. You can see in the picture where all three arms come together and meet in the center. The cutout isn't necessary in the top plate for my current build, but I originally was going to mount the FC close to the frame and wanted the little extra space for clearance. All of the 25mm standoffs are held in place by 16mm bolts, the 10mm standoffs and bolts with locknuts got 12mm bolts. Everything was tightened up at this point.

Next I fitted the motors and tilt mechanism

With the motors mounted it came time to solder the wires to the ESCs. I'm going with DYS XM20A ESCs for this build as they were on sale at the time I purchased them, and the LittleBee ESCs were all sold out. Once I got the ESCs I instantly regretted that decision as the soldering on them was horrible, hopefully this isn't an indication as to their quality. Anyways, motor wires were cut to size and soldered to the ESCs.

The pads on the Matek PDB were tinned and the PDB was mounted directly to the frame. There is a layer of kapton tape on the bottom of the PDB to insulate it from the frame. I may raise it up with some 4mm spacers before I finish the build, but I think the kapton tape will be just file.

And that's as far as I got for the night. Hopefully more build progress will happen tomorrow.