CapnBry

Elite member

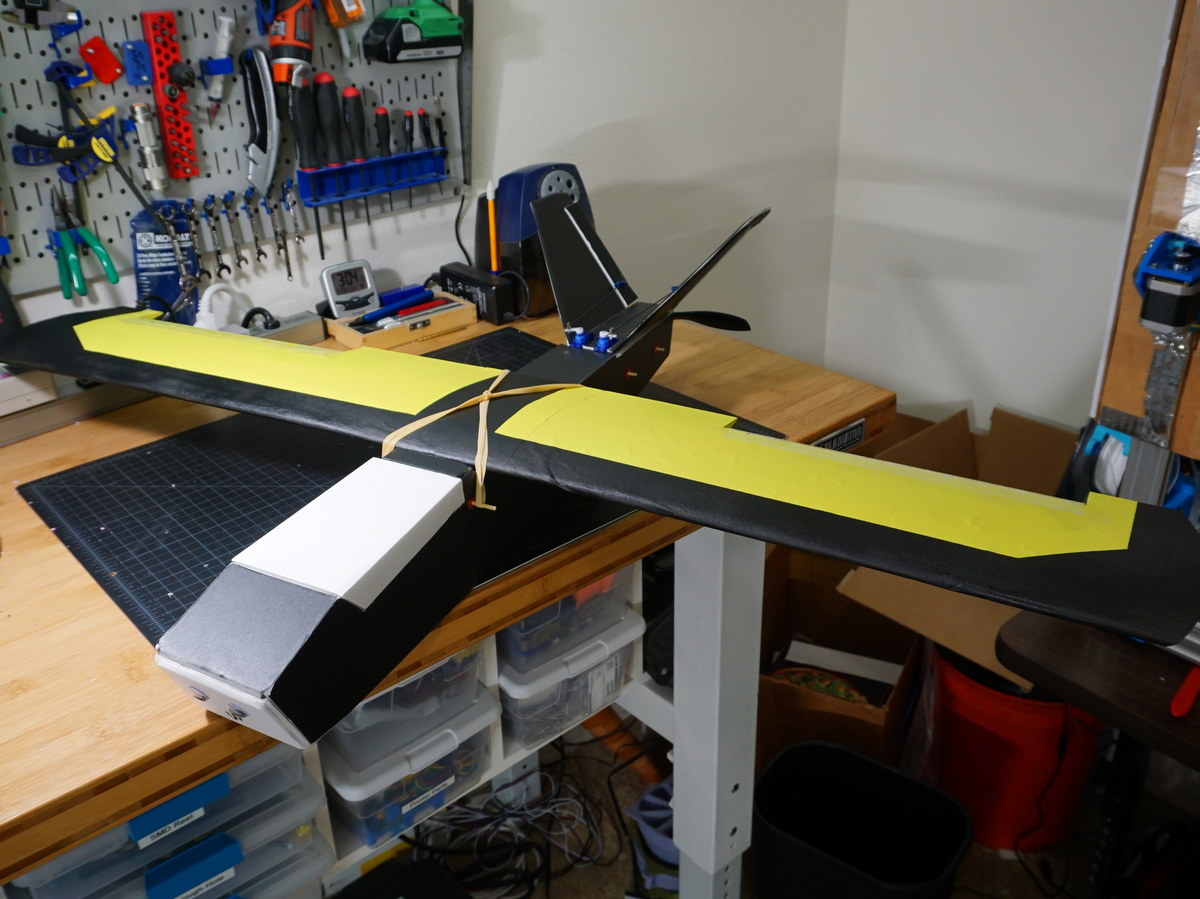

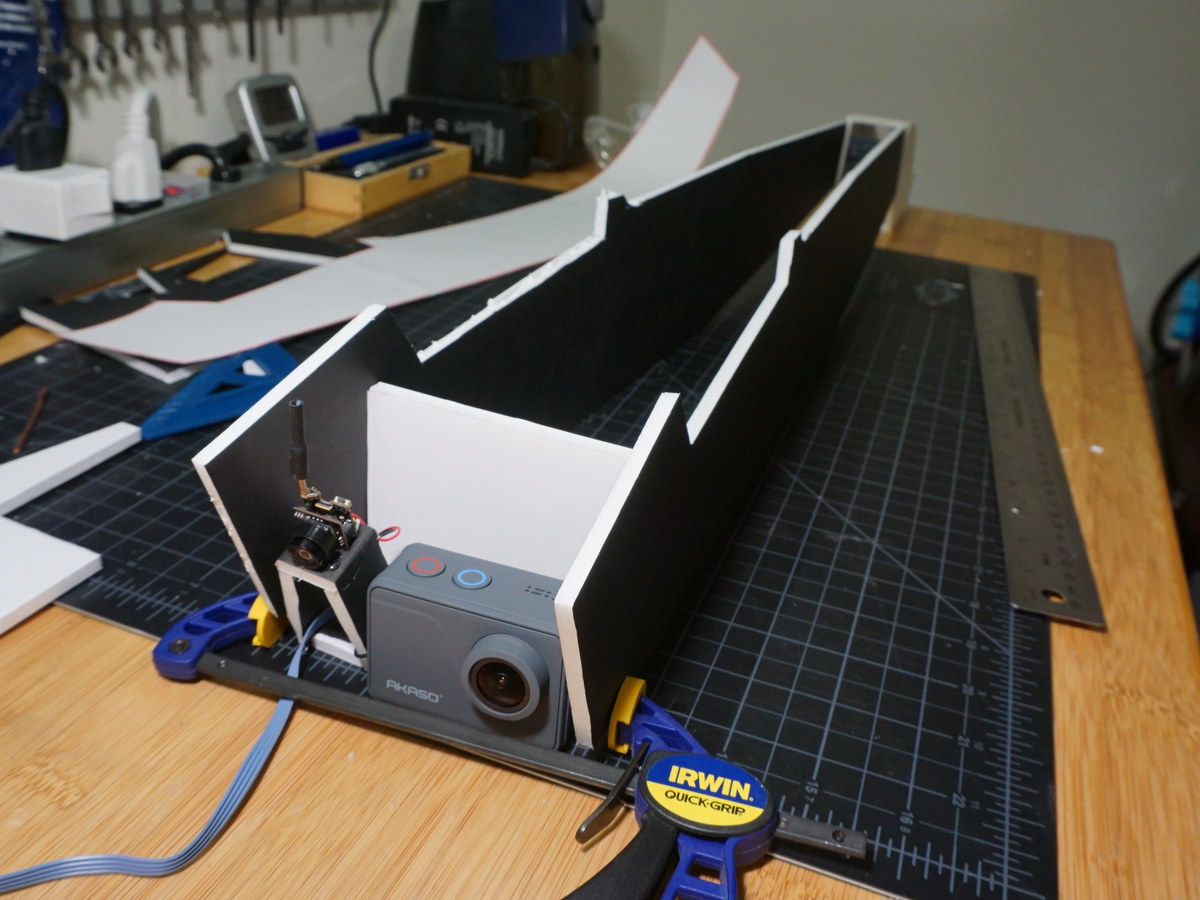

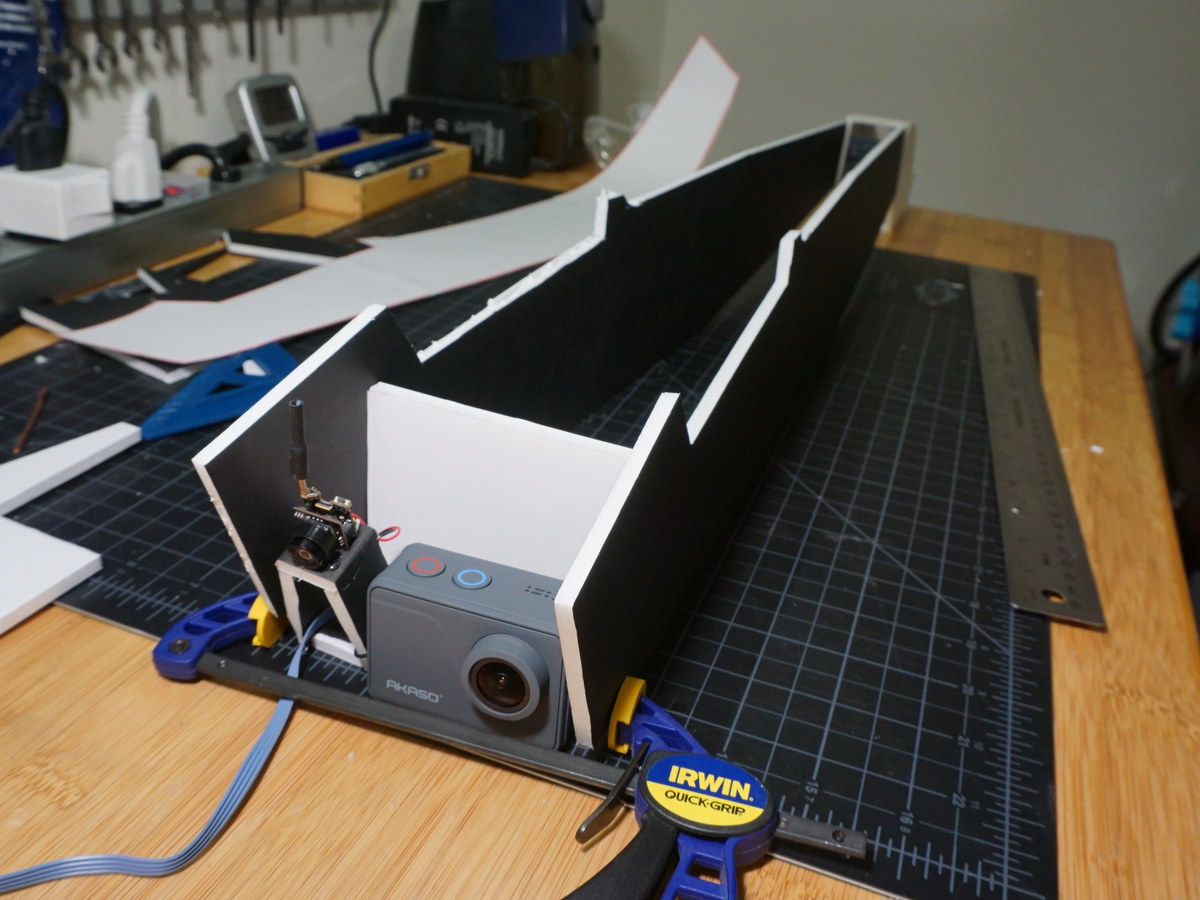

Been flying my motorized Ridge Runner glider quite a bit, but fitting everything inside such a puny thin fuselage is a real challenge. What is the exact opposite of a 26mm wide fuselage? The new ZOHD Talon Rebel GT. They really went all out with the name there, just keep adding words, guys. The boxy design almost begs to be made from DTFB so yesterday I sat down and started designing my first real new scratch build. Enter the CapnBry Galleon DTFB uhh Grand Tour?

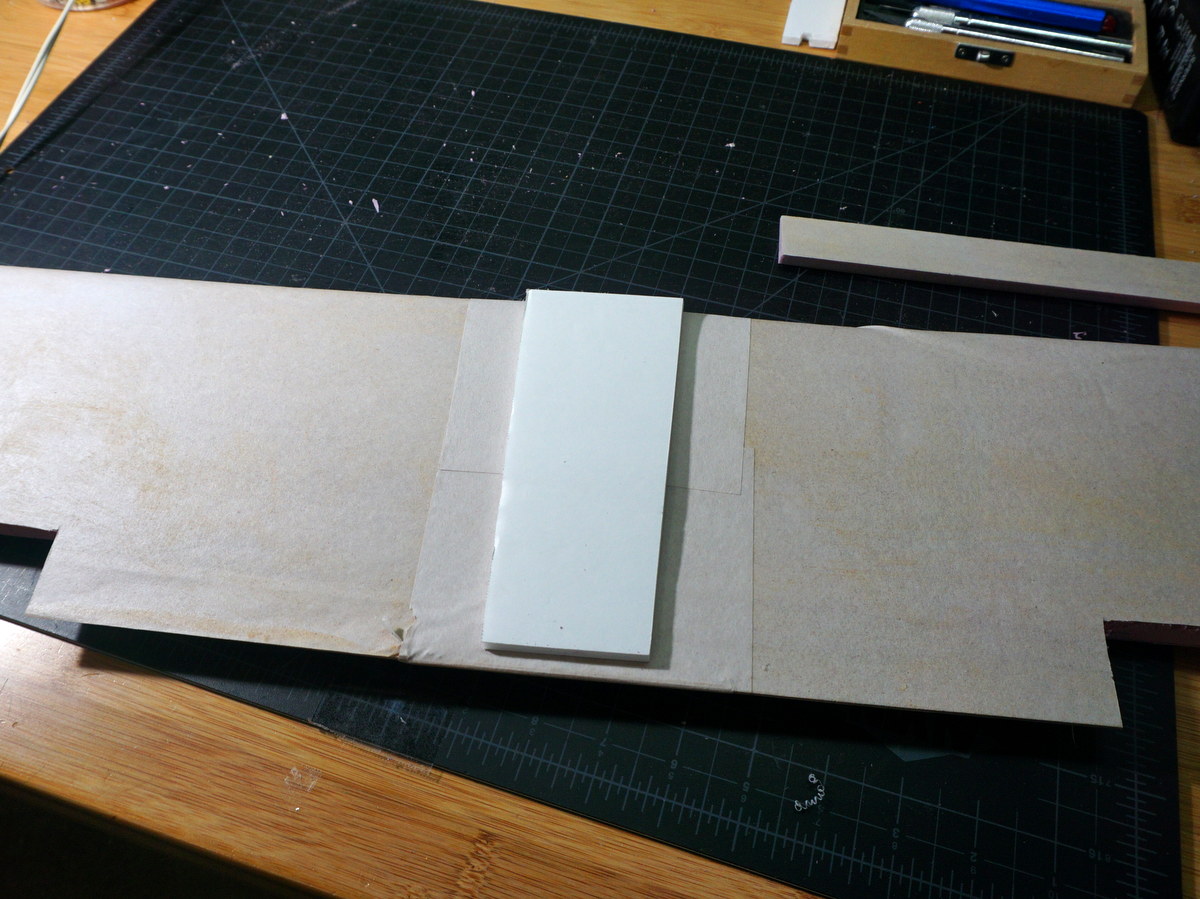

Wide enough at the nose to hold a GOPRO style camera and an FPV camera at the same time. Smashing ideas about aerodynamics and instead putting the biggest, fattest part right up front. The overall width of the front is 100mm or ~91mm after foam and tapers down to 1.5" in the back, which could hold a FliteTest power pod I think? I spent most of the day yesterday trying to figure out how to make the fuselage all one cut piece that has nice B folds but golly if I can't figure out how to make parallel lines that are the same length as each other. I got antsy by the end of the afternoon and just cut the sides and will connect them after the fact. The profile is spot on.

The ZOHD has nice carbon fiber to reinforce the nose so I decided to embed some bamboo skewers in the sides as well, to be mas fuerte. I'm not sure if these will make a difference, but I always welcome the opportunity to make something more complicated and have a chance of cutting clear through to the exterior so why not.

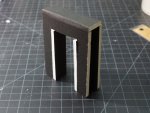

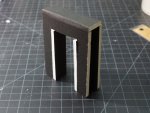

The bottom is just a trapezoidal strip. The big sides felt like an opportunity for everything to be all loosey goosey so I made a nice 3D reinforcement in front of the wing (also where the skewer to hold the wing will go through).

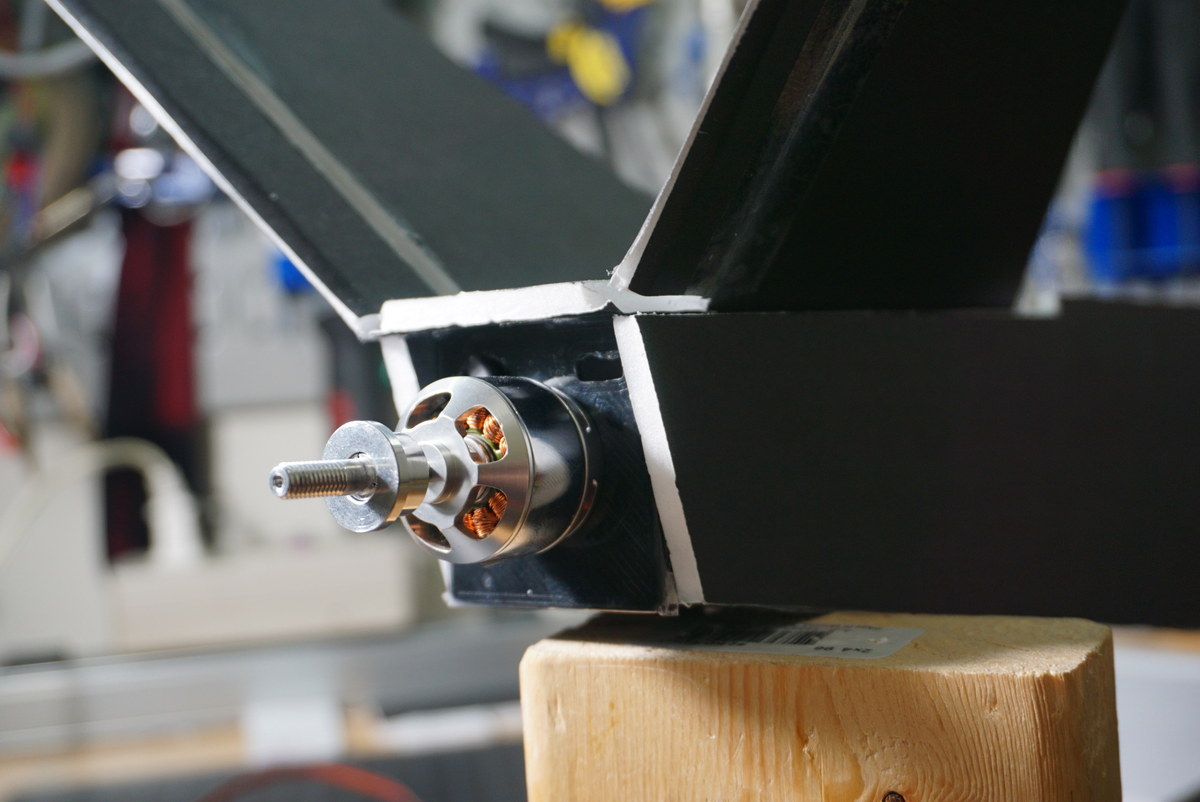

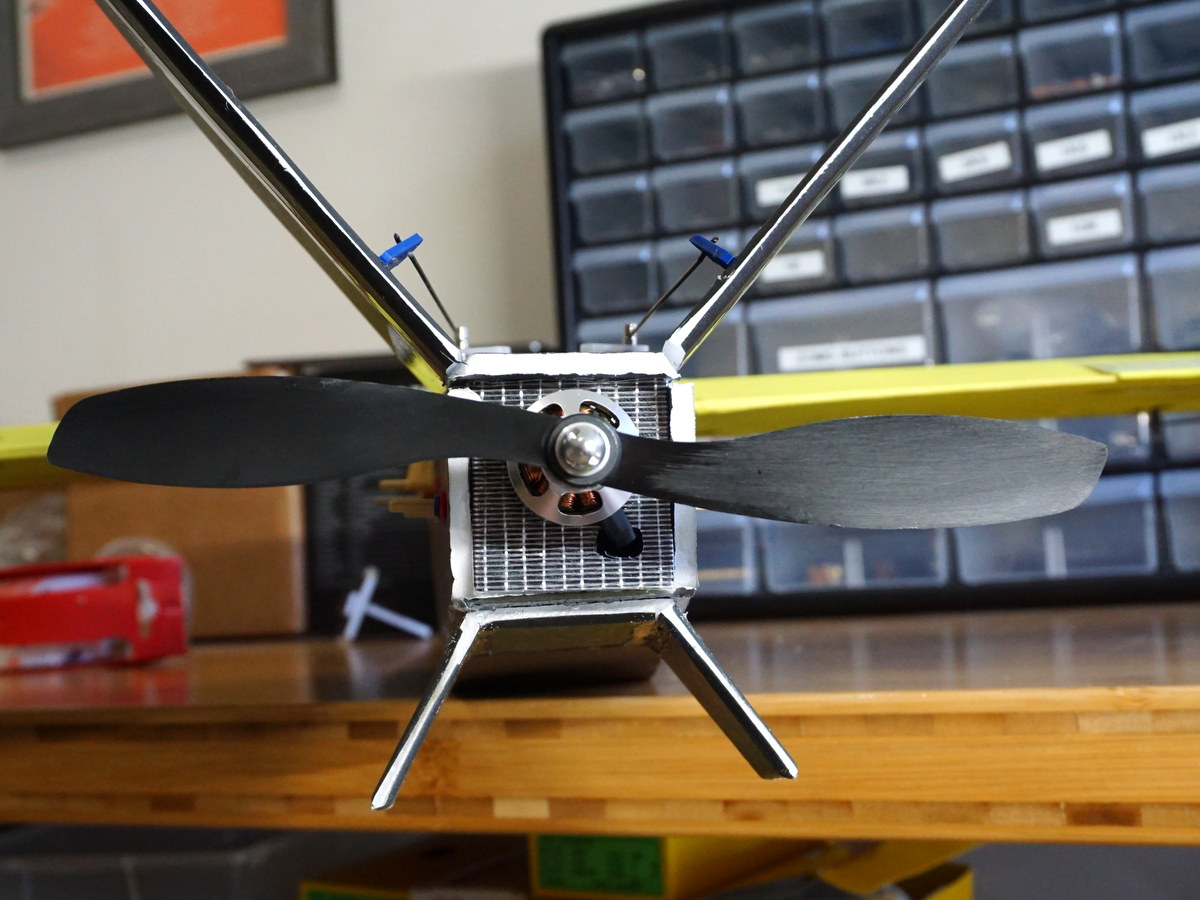

Now we'll start work on the tail. I'm shooting for this to be powered with a B power pack size motor with an 8" or 9" prop, but there's only around 3" of clearance between where I think the motor will go and the ground. A 6" prop with a higher KV motor might be better for preventing ground strikes, but it is easy enough to just spin the motor when I'm landing to move the prop horizontal. The wing I'm going to try hot wire cut foam with a ~1000mm wingspan, 175mm chord, but any of the FliteTest 4ch wings with about 6-6.75" chord will work.

Oh for those unfamiliar, here is what we're going for.

EDIT: v1.0 plans are attached in the SVG file

EDIT a year later: v1.1 plans are attached in the SVG files

Wide enough at the nose to hold a GOPRO style camera and an FPV camera at the same time. Smashing ideas about aerodynamics and instead putting the biggest, fattest part right up front. The overall width of the front is 100mm or ~91mm after foam and tapers down to 1.5" in the back, which could hold a FliteTest power pod I think? I spent most of the day yesterday trying to figure out how to make the fuselage all one cut piece that has nice B folds but golly if I can't figure out how to make parallel lines that are the same length as each other. I got antsy by the end of the afternoon and just cut the sides and will connect them after the fact. The profile is spot on.

The ZOHD has nice carbon fiber to reinforce the nose so I decided to embed some bamboo skewers in the sides as well, to be mas fuerte. I'm not sure if these will make a difference, but I always welcome the opportunity to make something more complicated and have a chance of cutting clear through to the exterior so why not.

The bottom is just a trapezoidal strip. The big sides felt like an opportunity for everything to be all loosey goosey so I made a nice 3D reinforcement in front of the wing (also where the skewer to hold the wing will go through).

Now we'll start work on the tail. I'm shooting for this to be powered with a B power pack size motor with an 8" or 9" prop, but there's only around 3" of clearance between where I think the motor will go and the ground. A 6" prop with a higher KV motor might be better for preventing ground strikes, but it is easy enough to just spin the motor when I'm landing to move the prop horizontal. The wing I'm going to try hot wire cut foam with a ~1000mm wingspan, 175mm chord, but any of the FliteTest 4ch wings with about 6-6.75" chord will work.

Oh for those unfamiliar, here is what we're going for.

EDIT a year later: v1.1 plans are attached in the SVG files

Attachments

Last edited: