You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody else scratch building tonight?

- Thread starter K3V0

- Start date

MaxTheFliteFreak

Active member

Great idea, I didn't think of that...That is what all these skins are for that are available on this forum. Check in the Resources. I watched a video on it and they take off the DTFB paper on one side and REPLACE with the printed skin. It even suggested using the better grade 24# paper and using 3M 77 spray glue. It probably doesn't add any significant weight... certainly less than putting poly and painting! That adds a lot of weight!

shadeyB

Legendary member

Yeah I have bought from balsa cabin before or https://stevewebb.co.uk/index.php?srch=DepronHey @shadeyB where do you get your Depron? I seem to have to look in a hundred places whenever I want to restock. Had a look on Jetworks online but their sold out of the white sheets.

I finally found a source on an Essex based site called the Balsa cabin. The weird part is you order it without entering payment details then they say they'll contact you to sort payment. So I'm half ready to be told it's out of stock afterall.

Or if there is a few builders it’s good to buy in bulk https://www.rcleo.com/construct/depron

but it seems to go as soon as it arrives these days

shadeyB

Legendary member

fresh of the table and out the paint shop

Jetworks SU-27 finished in Ukrainian Livery

6mm Depron with some 3D printed parts for scale look that I couldn’t carve from foam

Absolutely love it 😍

FMS Twin 64 running 4s

and 1 crazy little pilot inside praying for better weather soon

Jetworks SU-27 finished in Ukrainian Livery

6mm Depron with some 3D printed parts for scale look that I couldn’t carve from foam

Absolutely love it 😍

FMS Twin 64 running 4s

and 1 crazy little pilot inside praying for better weather soon

Last edited:

mastermalpass

Master member

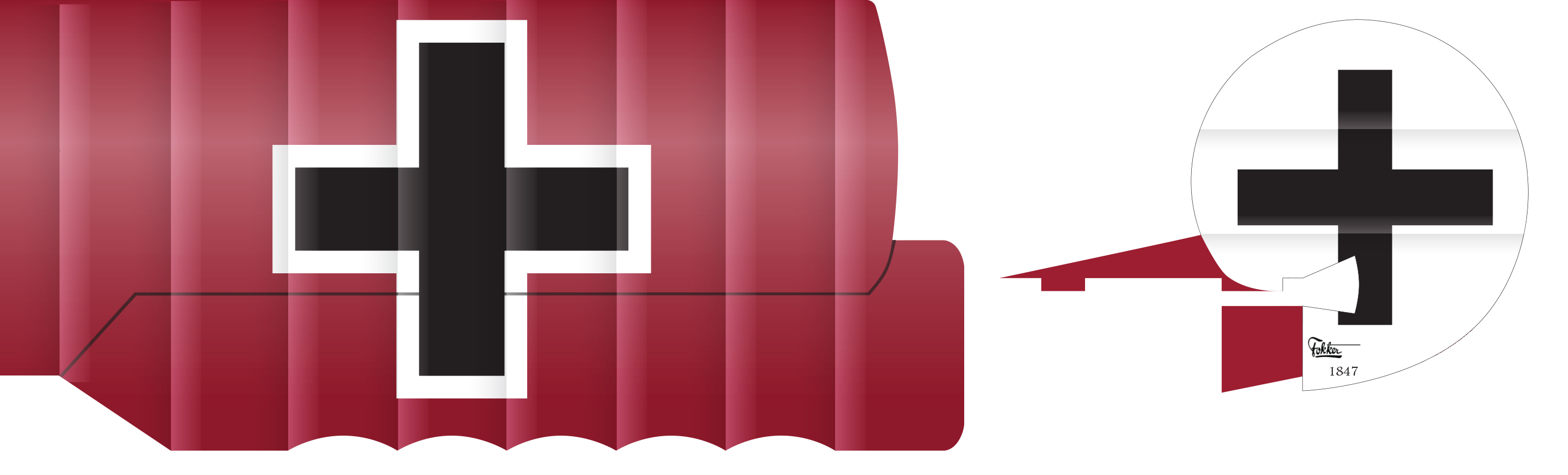

Exactly, why my question to people that have done it. It sounds like you might not know what I'm talking about... Can't do these with colored paper or with paint (at least not me). Wondering would you have anything left after doing the Spitfire or Fokker DR-1.

F-18 Super Hornet - This is more like decals - https://forum.flitetest.com/index.p...f-18-super-hornet-decal-placement-sheets.318/

Spitfire - Note panels seems and lettering, and camo blending instead of sharp lines between.

FT MM DR-1 Triplane -

Yes, I see why you want to print now. Not an easy job with paint or coloured paper. But if @Mr NCT drained his cartridge on 1 and 1/5 mini planes, the next best option is to ask your boss if you can use the office laserjet.

Failing that, considering inkjet cartridges can cost $30 on a good day, it may be cheaper to pay those with more industrial printers to print it for you. Google "printing service" and there's no end to the companies both online and local who want to print your stuff for a few bob.

When I was worried that tiling my shoddy plans risked introducing one imperfection too far, I was happy to pay PlanPrint-it £20 to print out sheets as big as my foamboard. They're UK based, but I'm sure you can find the equivalent in your state.

cyclone3350

Master member

fresh of the table and out the paint shop

Jetworks SU-27 finished in Ukrainian Livery

6mm Depron with some 3D printed parts for scale look that I couldn’t carve from foam

Absolutely love it 😍

FMS Twin 64 running 4s

and 1 crazy little pilot inside praying for better weather soon

View attachment 234515 View attachment 234516 View attachment 234517 View attachment 234518

Totally awesome! Been along since I've used depron, but I just might have to buy a box from RCDepron while it is available.

mastermalpass

Master member

fresh of the table and out the paint shop

Jetworks SU-27 finished in Ukrainian Livery

6mm Depron with some 3D printed parts for scale look that I couldn’t carve from foam

Absolutely love it 😍

FMS Twin 64 running 4s

and 1 crazy little pilot inside praying for better weather soon

View attachment 234515 View attachment 234516 View attachment 234517 View attachment 234518

Once again, absolutely gorgeous. Looking forward to hearing those engines blasting by!

mastermalpass

Master member

Question for 3D flyers: how do we mitigate torque roll?

I'm working on an Su-26, which will have a 65cm wingspan and an 8x5 three-blade prop; that will no doubt give a lot of torque to manage. Now, with a 3D plane having giant control surfaces, I have a few options to counter the torque and I'm wondering which approach is best. Do I...

A) Off-set the angle of thrust like I normally do?

B) Counter it with Rudder Trim?

C) Counter it with Aileron Trim?

D) Mix Aileron with Throttle?

E) Use a bit of two or more of the above options?

I'm working on an Su-26, which will have a 65cm wingspan and an 8x5 three-blade prop; that will no doubt give a lot of torque to manage. Now, with a 3D plane having giant control surfaces, I have a few options to counter the torque and I'm wondering which approach is best. Do I...

A) Off-set the angle of thrust like I normally do?

B) Counter it with Rudder Trim?

C) Counter it with Aileron Trim?

D) Mix Aileron with Throttle?

E) Use a bit of two or more of the above options?

danskis

Master member

In my city copy shops like kinkos vary from store to store including price and expertise. They are expensive. Try to find a shop that prints architecture or construction plans. They will be cheaper and higher quality. Plus they can print it full size. Even so color printing is pricey.Thank you... that was the confirmation that I was expecting, but didn't know. I've never had good luck with InkJets. I buy one... use ten sheets out of it and when I go to use it next time, it's all dried up.

I switched to a Laser, but I don't want to use toner in those rates either!

I think I heard/read that copy shops like Kinkos can do them... and even if its $5/page it sounds like a better deal than on my own printer at $100+ for a toner color.

shadeyB

Legendary member

Question for 3D flyers: how do we mitigate torque roll?

I'm working on an Su-26, which will have a 65cm wingspan and an 8x5 three-blade prop; that will no doubt give a lot of torque to manage. Now, with a 3D plane having giant control surfaces, I have a few options to counter the torque and I'm wondering which approach is best. Do I...

A) Off-set the angle of thrust like I normally do?

danskis

Master member

@mastermalpass - not an expert here but I've asked a few about setting up 3D planes. There answer has universally been no offset - no up down right or left. My mini pattern ship flys great with no offset. Which has got me to wondering why I've been putting so much offset in on some of my planes.

luvmy40

Elite member

Jut a WAG, but it seems to me, the shorter the wing span and the lighter the air frame(less inertial/centrifugal mass), the more prop/motor torque will effect the roll.@mastermalpass - not an expert here but I've asked a few about setting up 3D planes. There answer has universally been no offset - no up down right or left. My mini pattern ship flys great with no offset. Which has got me to wondering why I've been putting so much offset in on some of my planes.

danskis

Master member

@SquirrelTail - Hey squirreltail we've got a question about 3D and acrobatic planes. How do you determine the motor/engine angle offset and what is common or a good setting to start.

rkcharles12

New member

Because my grandfather restores and flies real Stearmans, I've always been around them. I decided to build the Stearman because I had a balsa wood kit for a rubber band powered model lying around. I took the plans to Staples and had them scaled up to a 40-inch wingspan before constructing it. To create a beautiful (completely foam board) fuselage, a box is surrounded by formers and an outer skin. The wings feature a new wingtip technique for more realistic wingtips, as well as a box spar inside the wing.

Inq

Elite member

Because my grandfather restores and flies real Stearmans, I've always been around them. I decided to build the Stearman because I had a balsa wood kit for a rubber band powered model lying around. I took the plans to Staples and had them scaled up to a 40-inch wingspan before constructing it. To create a beautiful (completely foam board) fuselage, a box is surrounded by formers and an outer skin. The wings feature a new wingtip technique for more realistic wingtips, as well as a box spar inside the wing.

There's a saying on the forum, "It didn't happen (doesn't exist) if there aren't pictures and a video."

Hmmm... now that things like that can be deep faked, I wonder what is going to be necessary for proof now.

BTW... Welcome to the forum!

Bo123

Elite member

I would leave everything straight, and counteract the torque roll with manual ailerons.Question for 3D flyers: how do we mitigate torque roll?

I'm working on an Su-26, which will have a 65cm wingspan and an 8x5 three-blade prop; that will no doubt give a lot of torque to manage. Now, with a 3D plane having giant control surfaces, I have a few options to counter the torque and I'm wondering which approach is best. Do I...

A) Off-set the angle of thrust like I normally do?

B) Counter it with Rudder Trim?

C) Counter it with Aileron Trim?

D) Mix Aileron with Throttle?

E) Use a bit of two or more of the above options?

Taildragger

Legendary member

mastermalpass

Master member

@mastermalpassWhich has got me to wondering why I've been putting so much offset in on some of my planes.

For me, off-setting the thrust angle has been a must on most of my models, because with the prop on straight, I would be spending nearly all my aileron throw on countering the torque.

A 3D plane has much, much more aileron to give though. Enough that @Bo123 is happy to work it with it all manually. I might try that myself; I often do find it easier to lean on the stick rather than go fumbling for the trim buttons.

MaxTheFliteFreak

Active member

Banana cub. Love it.

Similar threads

- Replies

- 5

- Views

- 264

- Replies

- 0

- Views

- 802

- Replies

- 2

- Views

- 314