Hey Michael! Hope this finds you well.

Since you're runnng Grbl, I'd do the "$$" thing from the console and check out the $20 and $21 values first... soft limit enable and hard limit enable, resp. Then check $130, $131, and $132 to see that they match your machine's extents for X/Y/Z, resp. Then I suppose you'd need to check for your machine extent settings in Estlcam... don't remember off the top of my head where it's set but I'm pretty sure it's there someplace. Get them all matched up across you whole workflow and hopefully things will start working for you.

Good to hear from you. Let me know how it goes. -- David

Ha, David, you beat me to it I had to go downstairs to get my crib sheet of Grbl commands! Michael, it will be worth it to do the $$ command from the console in UGS, and print them out or write them down like I did (so low tech!). I had to increase the max travel $130 to 610 (mm), $131 to 1220, $132 to 50 for my unit.

First off, yes, I am well thank you for asking. I pray that you all are also doing well.

I did the $$ and lines $130-$132 looked good to me. Not sure about lines $20-$21.

Here is the dump I got from $$.

Current Arduino Settings

$0=10 (step pulse, usec)

$1=25 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=0 (dir port invert mask:00000000)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=3 (status report mask:00000011)

$11=0.010 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

$20=0 (soft limits, bool)

$21=0 (hard limits, bool)

$22=0 (homing cycle, bool)

$23=0 (homing dir invert mask:00000000)

$24=25.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

$26=250 (homing debounce, msec)

$27=1.000 (homing pull-off, mm)

$100=12.562 (x, step/mm)

$101=12.562 (y, step/mm)

$102=283.460 (z, step/mm)

$110=500.000 (x max rate, mm/min)

$111=500.000 (y max rate, mm/min)

$112=500.000 (z max rate, mm/min)

$120=10.000 (x accel, mm/sec^2)

$121=10.000 (y accel, mm/sec^2)

$122=10.000 (z accel, mm/sec^2)

$130=1219.000 (x max travel, mm)

$131=609.000 (y max travel, mm)

$132=50.000 (z max travel, mm)

FYI - when I try the visualize button in UGS I get this error.

WARNING: An illegal reflective access operation has occurred

WARNING: Illegal reflective access by com.jogamp.common.os.NativeLibrary$3 (file:/home/michael763/UniversalGcodeSender.jar) to method java.lang.ClassLoader.findLibrary(java.lang.String)

WARNING: Please consider reporting this to the maintainers of com.jogamp.common.os.NativeLibrary$3

WARNING: Use --illegal-access=warn to enable warnings of further illegal reflective access operations

WARNING: All illegal access operations will be denied in a future release

Inconsistency detected by ld.so: dl-lookup.c: 111: check_match: Assertion `version->filename == NULL || ! _dl_name_match_p (version->filename, map)' failed!

I am not sure if that means I have something not set correctly in Linux/UGS. Is it related or not, IDK. Too much of a NOOB to this side of it.

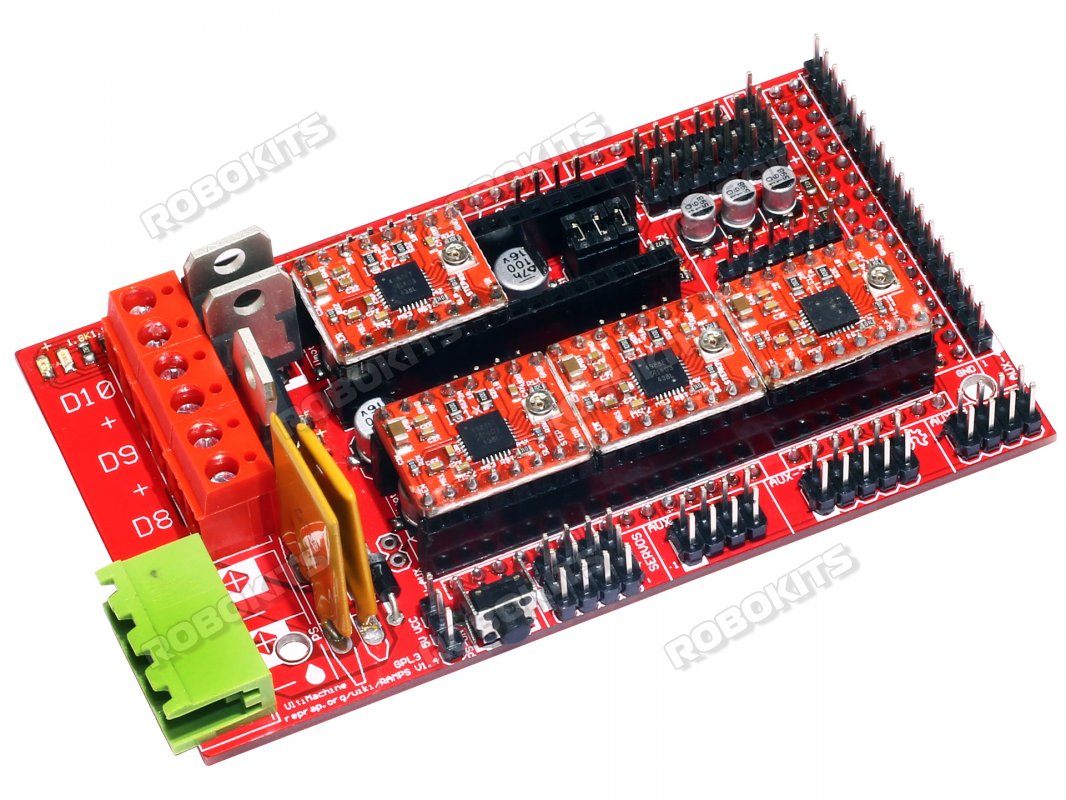

Back to the original issue. I cannot see in ESTCAM Gcode side where I would set the X,Y,Z limits. Here is some of the settings. The third and fourth photo show setting for ESTLCAM's cnc controller that I don't use.