So, I'm still working out the viability of this, but I'd like to build a Giant Flapjack at FliteFest this year. I'm thinking I'll scale up my current design by 240% (as that keeps all the parts on no more than 2 sheets of foamboard). That'l give me a wingspan of right around 60 inches, which should look pretty darned cool up in the air. Bomb drop could be interesting as well.

Now a 60" wingspan plane might not sound that big, but that's a pretty darned big flying circle. It's also got 39 sheets worth of parts, and a wing area of 3,110 square inches.

Now lets move on to preliminary weight calculations. 39 sheets of foamboard is right around 4,680grams. There's a lot of waste. I'm going to be conservative and only cut the weight by 1/3. So that's 3088 grams. Now, 60% of the remaining parts are going to have the paper removed from one side, which will drop the weight of those parts by 20%. That'l put the weight of the base airframe at 2700 grams, which is probably a bit high. Add about 1300 grams with of electronics, wiring, and batteries and you get a weight of 4000 grams. Pretty darned light. I can imagine that the weight could go up a bit once I factor in landing gear and some reinforcments, but even if I add another 1000 grams that's not an issue.

If the plane weighs in at 5000 grams, it's have a wing loading of 8.17 oz. sq/ft, or a wing cubic loading of 1.8. That's super light glider or indoor free flight territory lol.

The other big consideration here, is that at a 60" wingspan, scale prop size is 40 inches.

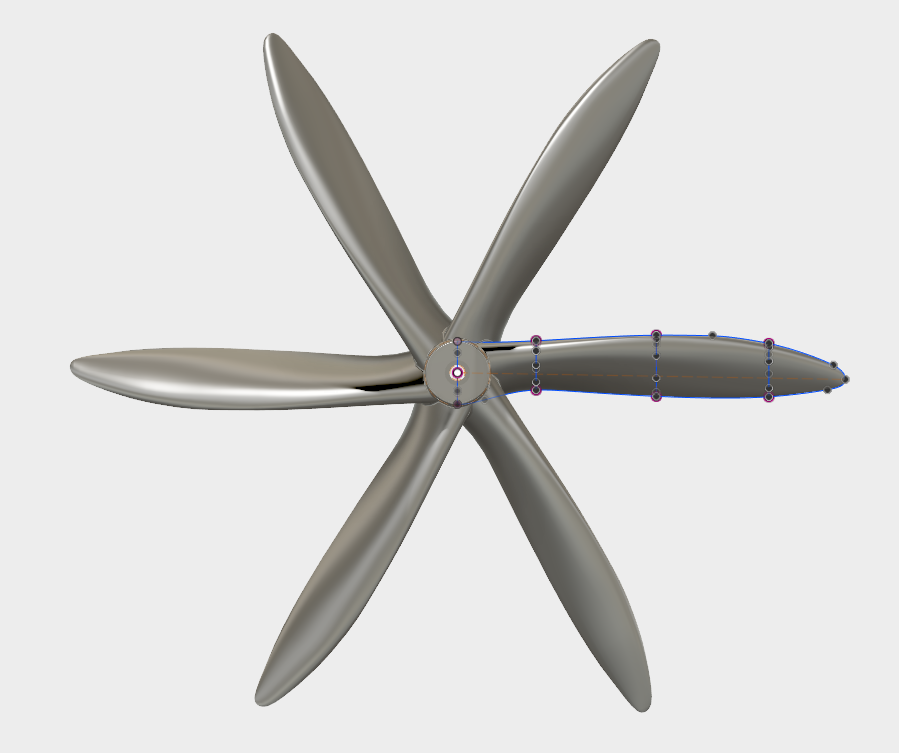

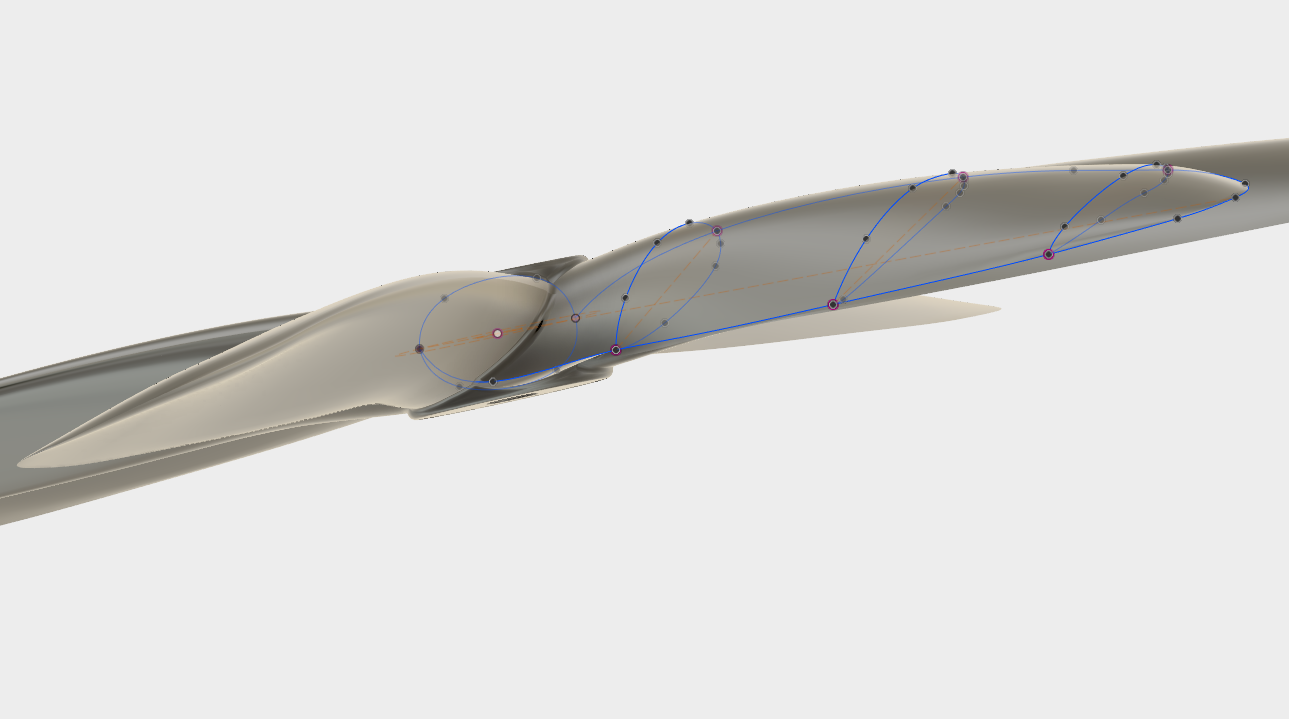

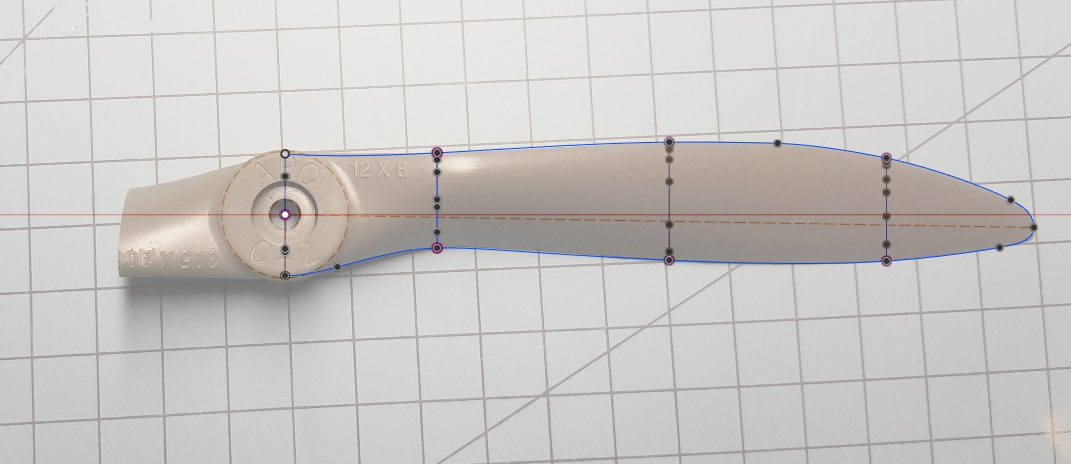

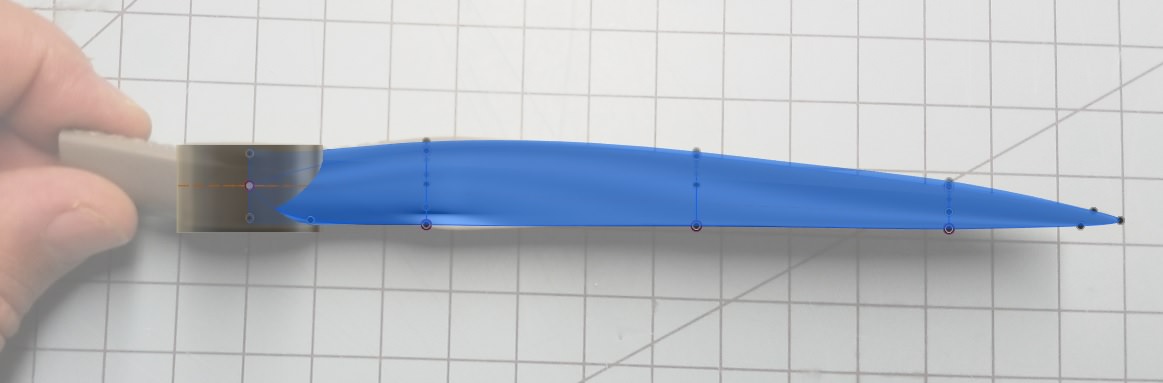

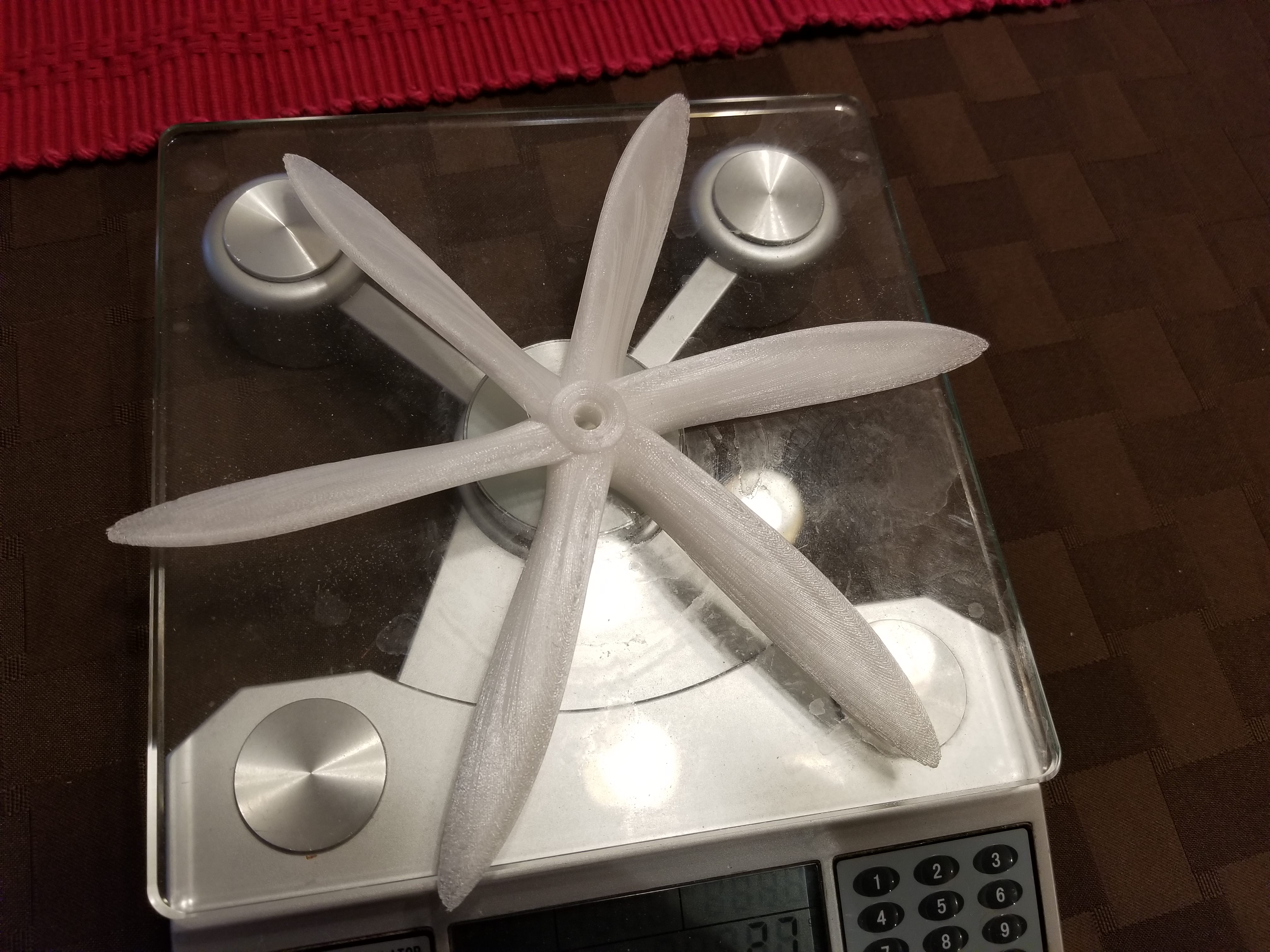

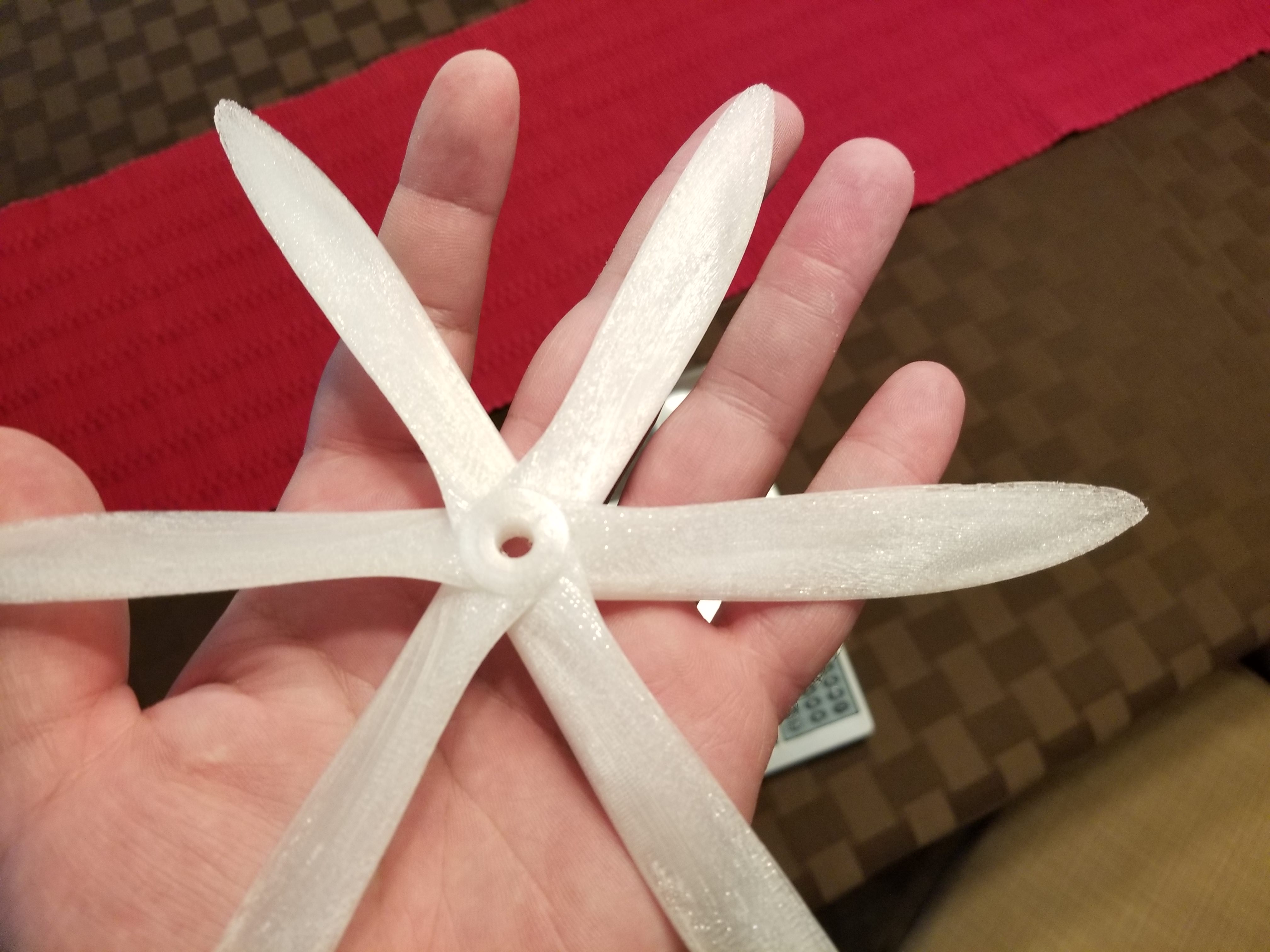

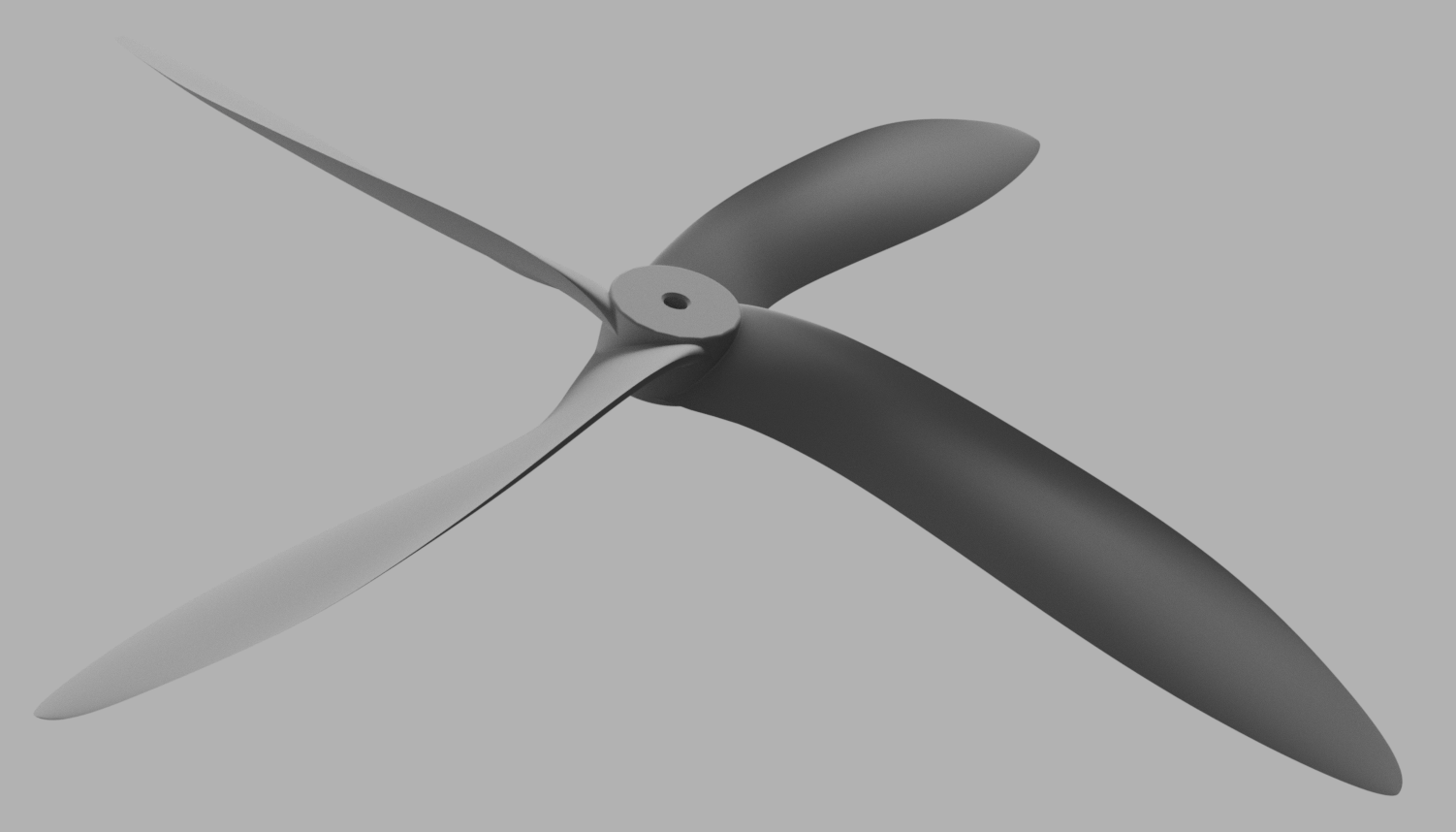

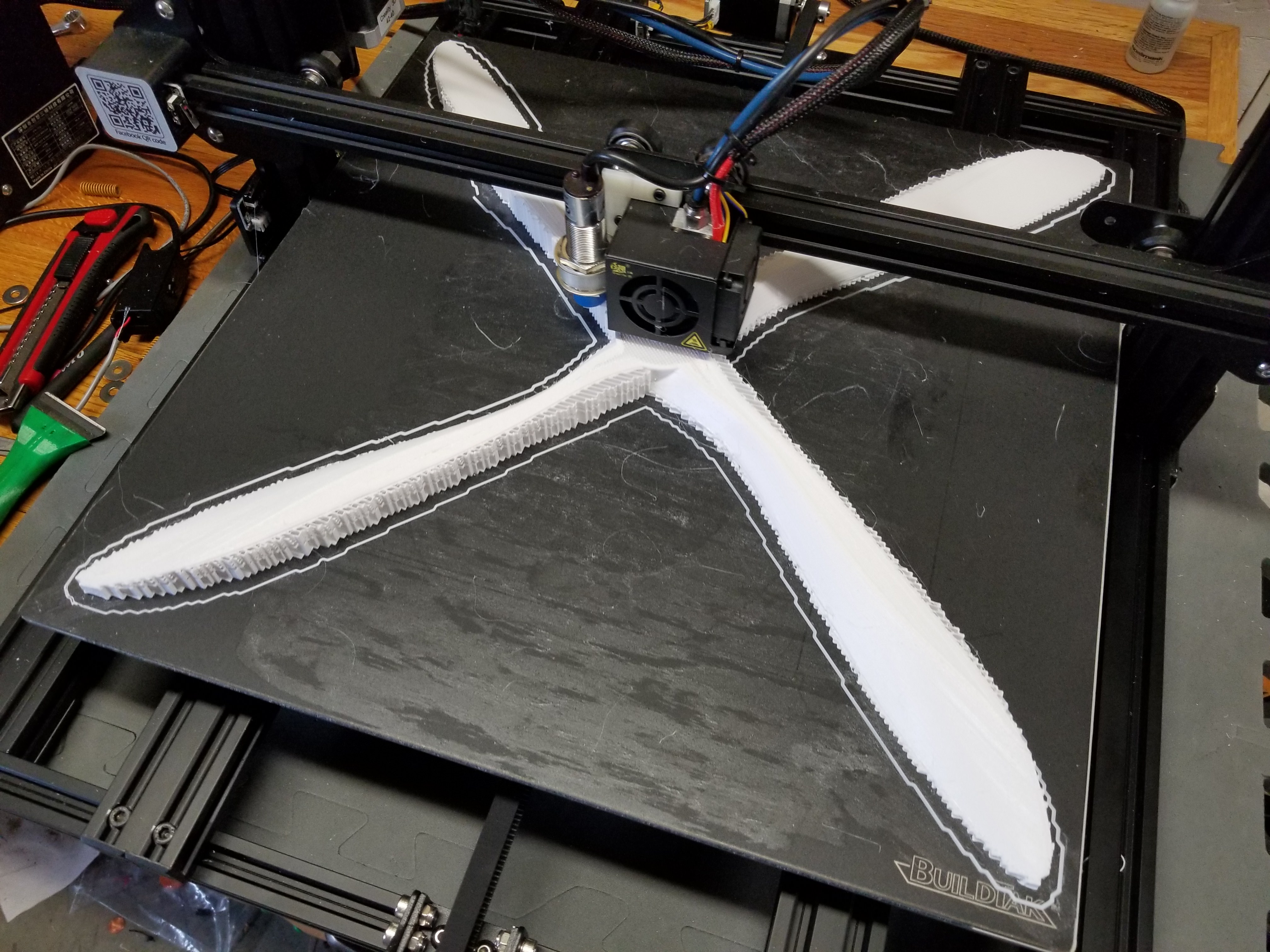

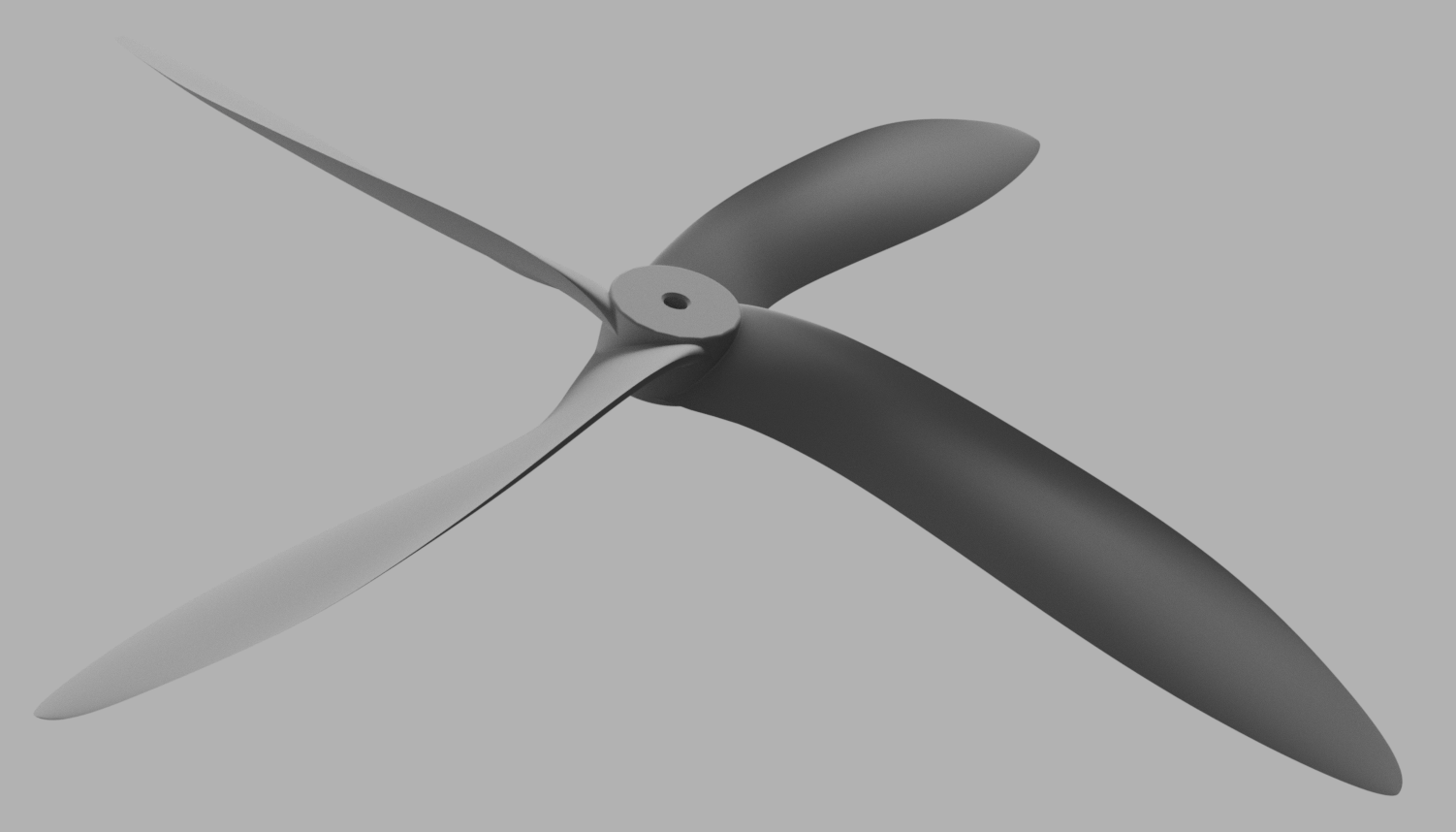

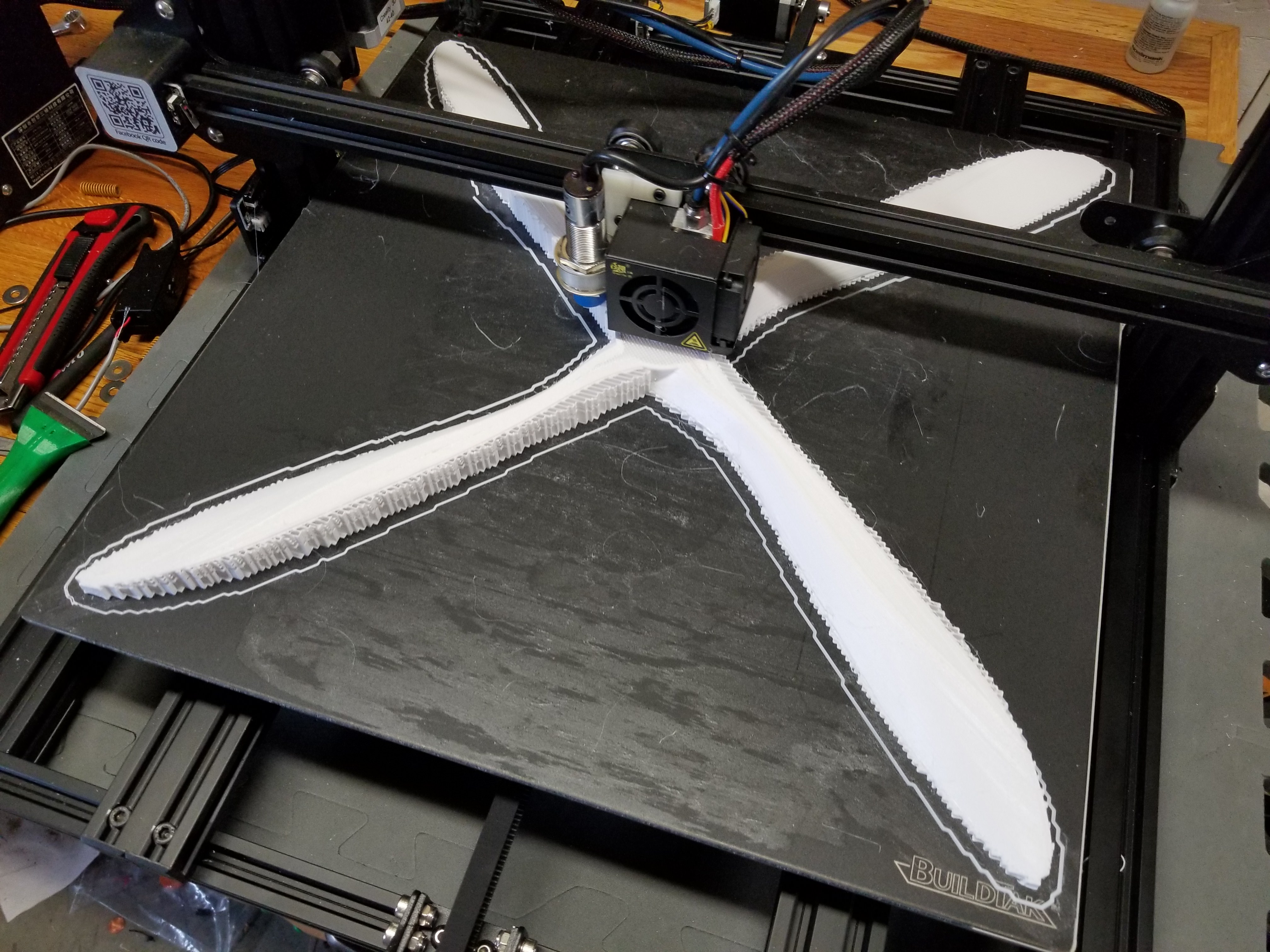

I don't have the electronics handy to drive a prop that size, but I can do 20 inches with 4 blades, or 26 inches with 2 after manufacturing a gearbox. The problem with these prop sizes, is that you need a lot of pitch to get any kind of airspeed at the RPM's I'll be able to drive props that size. Nobody makes big props with enough pitch, so right now I'm currently 3D printing a 20.5x20.5x4 blade prop with an APC E curve I designed in fusion360. It may end in an explosion, but it's worth doing if only for the laughs.

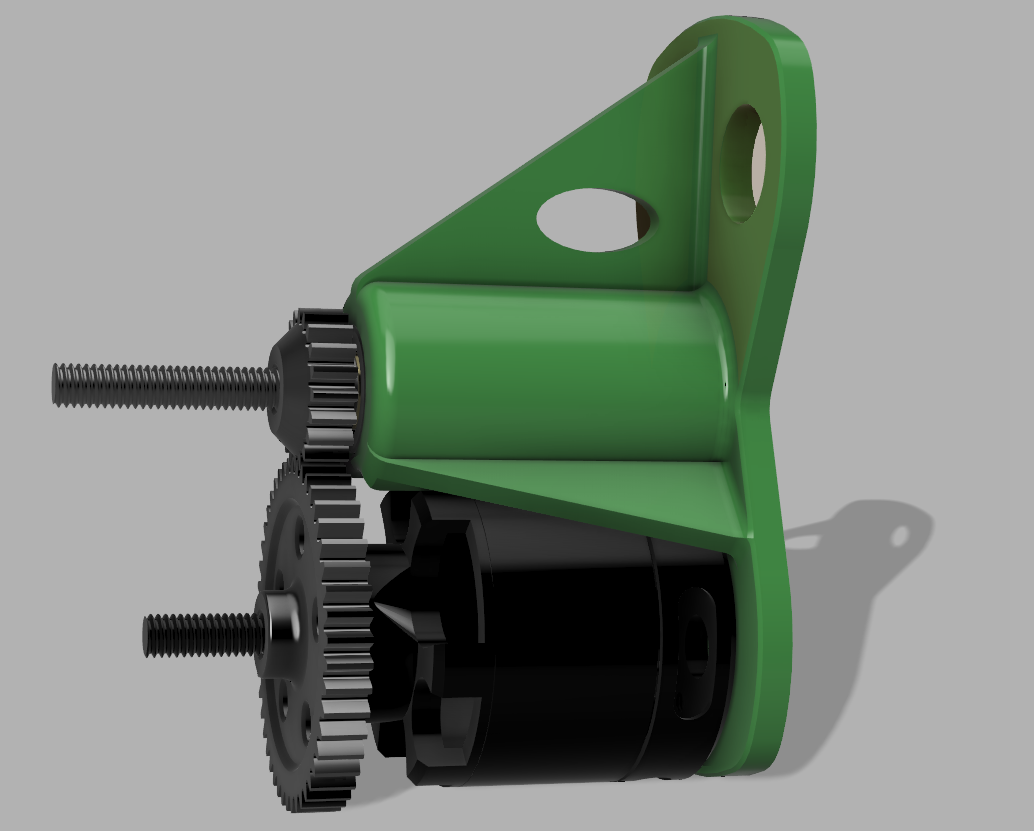

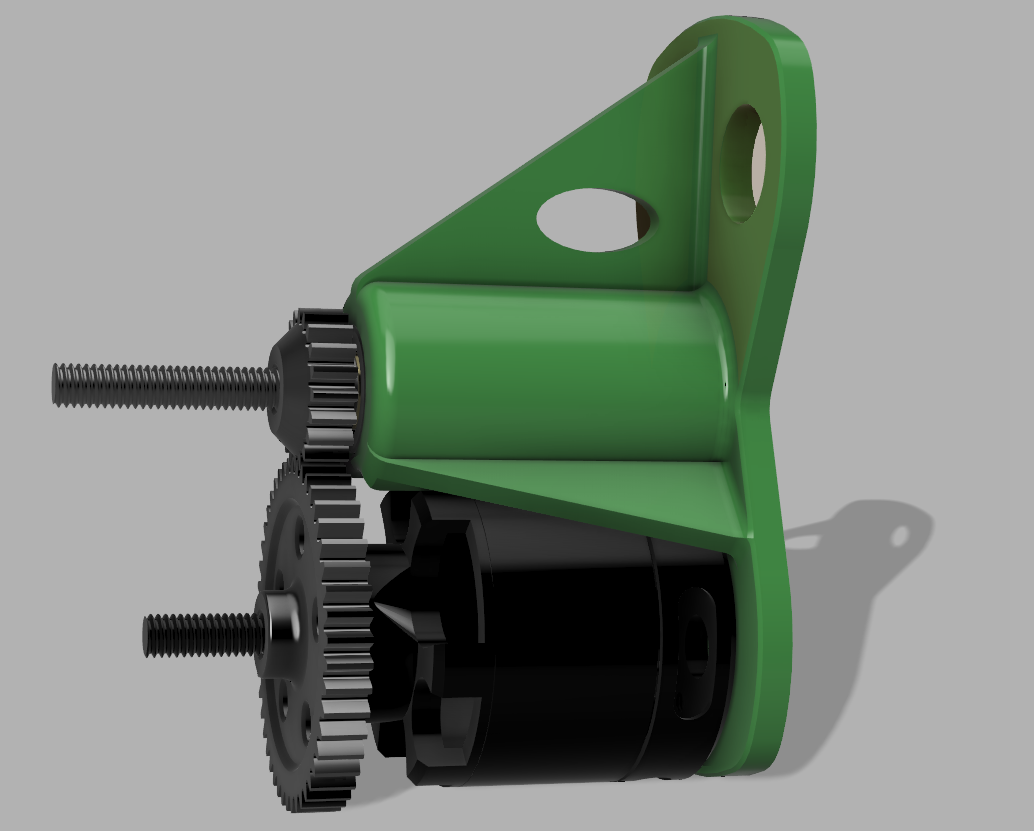

In order to to be able to spin props above 16 inches with the motors I have (Sunnysky x3520-6 720kv), I'll be needing a gearbox. I've also got something I think might work drawn up, and am going to start 3D printing it in polycarbonate as soon as my printer with an enclosure is done printing other stuff. The current gearset gives me 2.3 to 1 reduction.

Now a 60" wingspan plane might not sound that big, but that's a pretty darned big flying circle. It's also got 39 sheets worth of parts, and a wing area of 3,110 square inches.

Now lets move on to preliminary weight calculations. 39 sheets of foamboard is right around 4,680grams. There's a lot of waste. I'm going to be conservative and only cut the weight by 1/3. So that's 3088 grams. Now, 60% of the remaining parts are going to have the paper removed from one side, which will drop the weight of those parts by 20%. That'l put the weight of the base airframe at 2700 grams, which is probably a bit high. Add about 1300 grams with of electronics, wiring, and batteries and you get a weight of 4000 grams. Pretty darned light. I can imagine that the weight could go up a bit once I factor in landing gear and some reinforcments, but even if I add another 1000 grams that's not an issue.

If the plane weighs in at 5000 grams, it's have a wing loading of 8.17 oz. sq/ft, or a wing cubic loading of 1.8. That's super light glider or indoor free flight territory lol.

The other big consideration here, is that at a 60" wingspan, scale prop size is 40 inches.

I don't have the electronics handy to drive a prop that size, but I can do 20 inches with 4 blades, or 26 inches with 2 after manufacturing a gearbox. The problem with these prop sizes, is that you need a lot of pitch to get any kind of airspeed at the RPM's I'll be able to drive props that size. Nobody makes big props with enough pitch, so right now I'm currently 3D printing a 20.5x20.5x4 blade prop with an APC E curve I designed in fusion360. It may end in an explosion, but it's worth doing if only for the laughs.

In order to to be able to spin props above 16 inches with the motors I have (Sunnysky x3520-6 720kv), I'll be needing a gearbox. I've also got something I think might work drawn up, and am going to start 3D printing it in polycarbonate as soon as my printer with an enclosure is done printing other stuff. The current gearset gives me 2.3 to 1 reduction.