You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

nnP-38 - design, build, and review log

- Thread starter nerdnic

- Start date

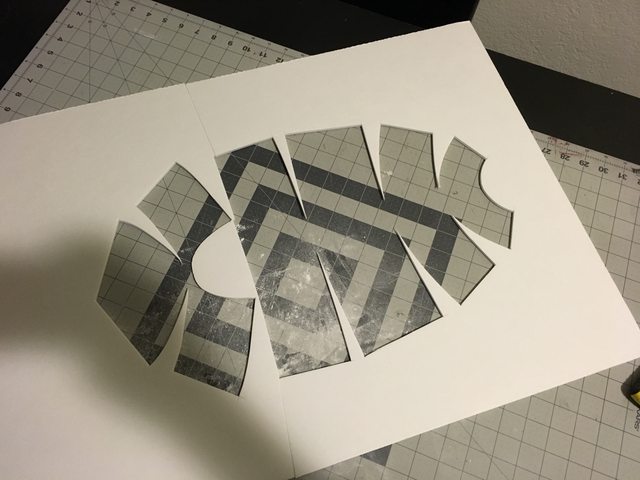

Working on a second nose design. The layered method I worked on first is very strong and has perfect shape but it's time consuming to build (4 hours or so). This method is a single sheet of foam and can be built in about an hour.

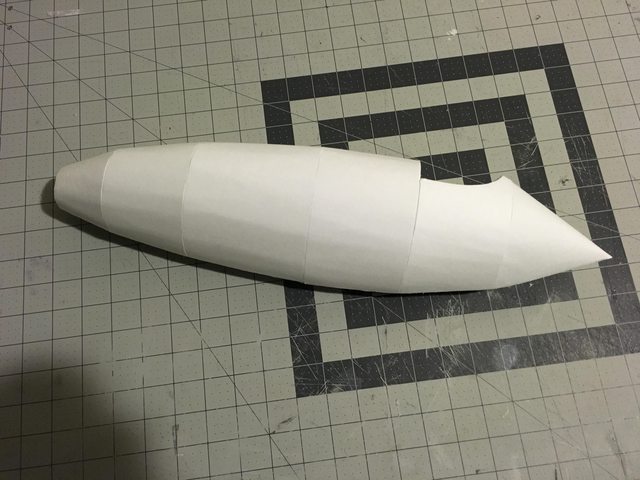

With the outside paper still on. You could leave it this way if you wanted.

Paper removed and light sanding.

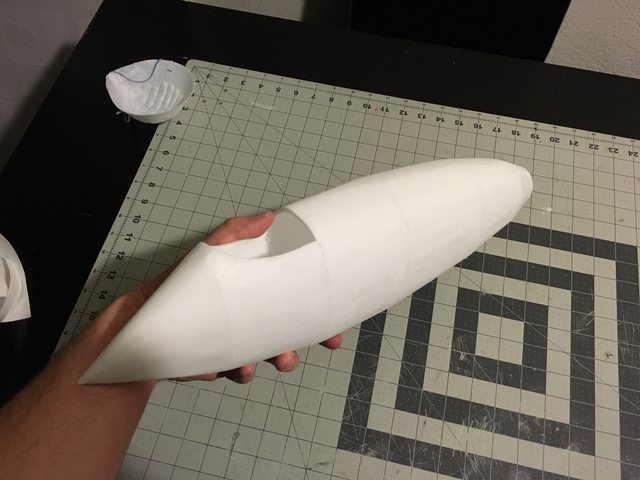

The single layer is very light weight and would work perfect for a slow fly nnP-38.

I like this method. I've been experimenting with round tapered fuselages for my Devastator build ever since the MM Corsair came out and settled on something similar. The ones I've been building have all been cut from separate pieces though, I like how you left yours joined.

I've been using former's on the inside for strength. Are you going to coat the sanded version for strength and finish?

Working on a second nose design. The layered method I worked on first is very strong and has perfect shape but it's time consuming to build (4 hours or so). This method is a single sheet of foam and can be built in about an hour.

The single layer is very light weight and would work perfect for a slow fly nnP-38.

Nic,

You continue to amaze! This is looks incredible. Did you ever get a chance to check out that thread I sent you?

Last edited:

TheRCNoobie

Member

Wow thats going to be a challenging one. SUBSCRIBE. I wanna see this thing happen.

TheRCNoobie

Member

Cool thanks!

That would probably work out well. You'd need to tweak the cockpit a bit to make it work. I'll keep this in mind to visit once everything is designed.

Good stuff. The P-38 is such a cool looking plane in the air.

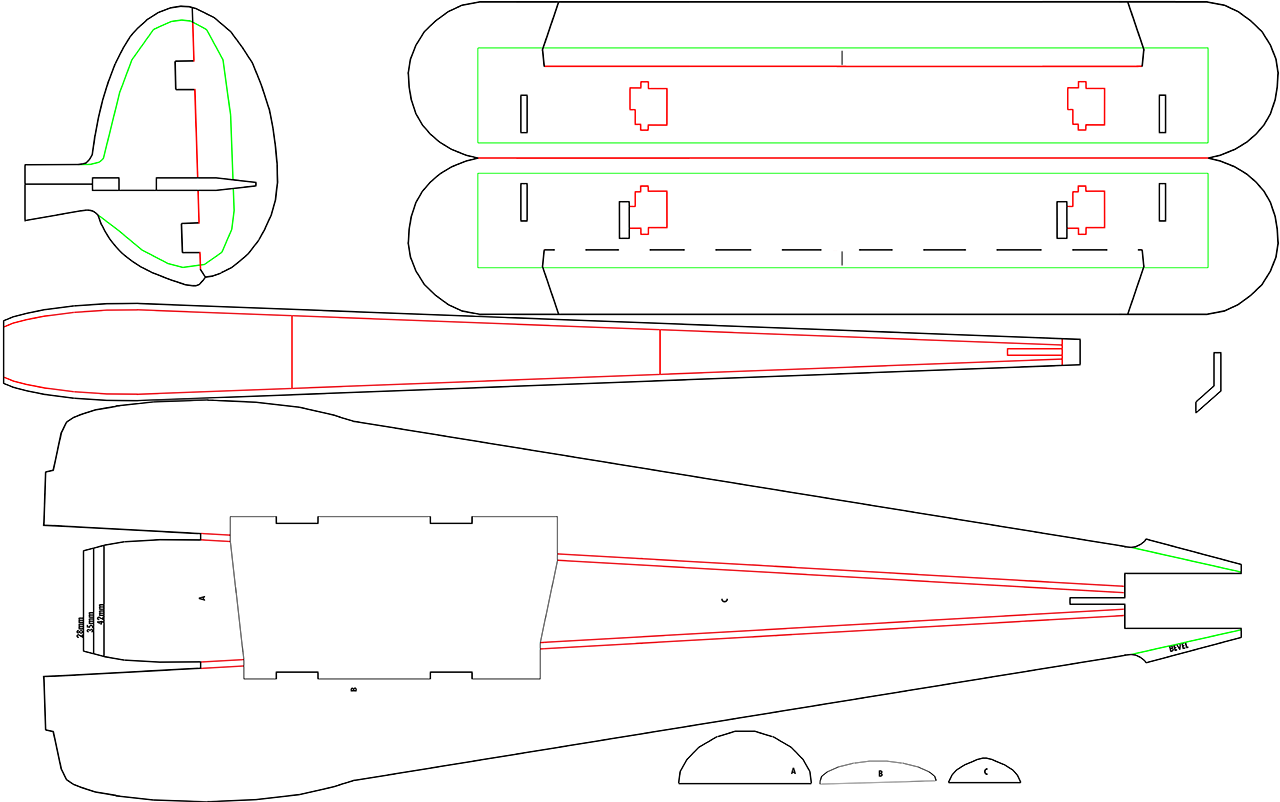

I made a little more progress on the plans tonight. The stabs will be two foam layers thick and beveled like the nnP-39. Right now the plan is to have two servos for the elevator connected on a Y. The elevator surface is 15 inches long and 1.3 inches wide. I think for slower flying a single standard 9g would be fine but I don't want to take any chances.

I am still reading through all the posts, but am I seeing that you laid your servos down on their sides and used the servo arm as the control horn? Wait, control horn would be on the aileron, is the servo mounted inside the wing?

I am still reading through all the posts, but am I seeing that you laid your servos down on their sides and used the servo arm as the control horn? Wait, control horn would be on the aileron, is the servo mounted inside the wing?

Servo mounted inside wing/horizontal stab with the arm extending below the surface. Control horn attached to the flight surface (aileron/elevator) and connected to servo arm with pushrod.

Cool, glad you guys like it!

Yes, you'll need to add some protection to the bare foam. I'll be using polycrylic.

I like this method. I've been experimenting with round tapered fuselages for my Devastator build ever since the MM Corsair came out and settled on something similar. The ones I've been building have all been cut from separate pieces though, I like how you left yours joined.

I've been using former's on the inside for strength. Are you going to coat the sanded version for strength and finish?

Yes, you'll need to add some protection to the bare foam. I'll be using polycrylic.

shitabrick

Member

Hi Nick

Thanks for the great work it helps when you are learning to fly

Im intrested in the build log for the nnP-38

Have you done it and where can i view it if you have

Thanks keep up the good work

Regards

Edwin

Thanks for the great work it helps when you are learning to fly

Im intrested in the build log for the nnP-38

Have you done it and where can i view it if you have

Thanks keep up the good work

Regards

Edwin

Hi Nick

Thanks for the great work it helps when you are learning to fly

Im intrested in the build log for the nnP-38

Have you done it and where can i view it if you have

Thanks keep up the good work

Regards

Edwin

Hey there,

No build log yet, but the build video is almost done.

Plans updated - http://www.nerdnic.com/beta

RC1 02.23.2016 @ 1:00 PM PST

Plans

-All plans redrawn in vector format

-Various changes to all pieces

-Wrap nose added

RC1 02.23.2016 @ 1:00 PM PST

Plans

-All plans redrawn in vector format

-Various changes to all pieces

-Wrap nose added

Started the build today, Cant wait to see this come together!

Using hobbyking foam for this one, without the paper backing im not sure how to create the folds and 50% cut area's. Hopefully ill figure it out.

All other parts are bought so should be no delays in the build. Photo's coming soon.

Using hobbyking foam for this one, without the paper backing im not sure how to create the folds and 50% cut area's. Hopefully ill figure it out.

All other parts are bought so should be no delays in the build. Photo's coming soon.

Last edited:

Yea, so for the 90 and 180* folds (fusalage and leading wing edge) i was thinking to use packing tape to replace the paper.

Or an alternative to the fusalage butt joint i could use a 45 angle joint. I may do some sample tests to see how well the hold and how easy they are to build.

Progress is a little slow, usually cutting a2 plan an evening, so far the tail and one tail fusalage has been cut, ill get some pics once they are all cut out.

Or an alternative to the fusalage butt joint i could use a 45 angle joint. I may do some sample tests to see how well the hold and how easy they are to build.

Progress is a little slow, usually cutting a2 plan an evening, so far the tail and one tail fusalage has been cut, ill get some pics once they are all cut out.

For the HK foam, use wing tape (or packing tape) to do the folds. The tape adds a LOT of strength and durability. For ease of applicability you'll want to add it before building, to the flat foam, anyway.

If you use wing tape (Hobby King sells a bunch of different colors), you get the added benefit of immediately having a good-looking color on there.

If you use wing tape (Hobby King sells a bunch of different colors), you get the added benefit of immediately having a good-looking color on there.

Similar threads

- Replies

- 11

- Views

- 449

- Replies

- 15

- Views

- 775

- Replies

- 0

- Views

- 327

- Replies

- 12

- Views

- 674

- Replies

- 13

- Views

- 428