at most 10K.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale Build-Off - Dare FW-190

- Thread starter willsonman

- Start date

ok, Ill give it a go this weekend with a 2300KV motor that can handle 4S; assuming it survives, you would know you a fair safety margin. Id be a little surprised if it disintegrates, I have a FMS FW190 with a molded spinner like that, and it feels a lot more fragile. But we'll see.

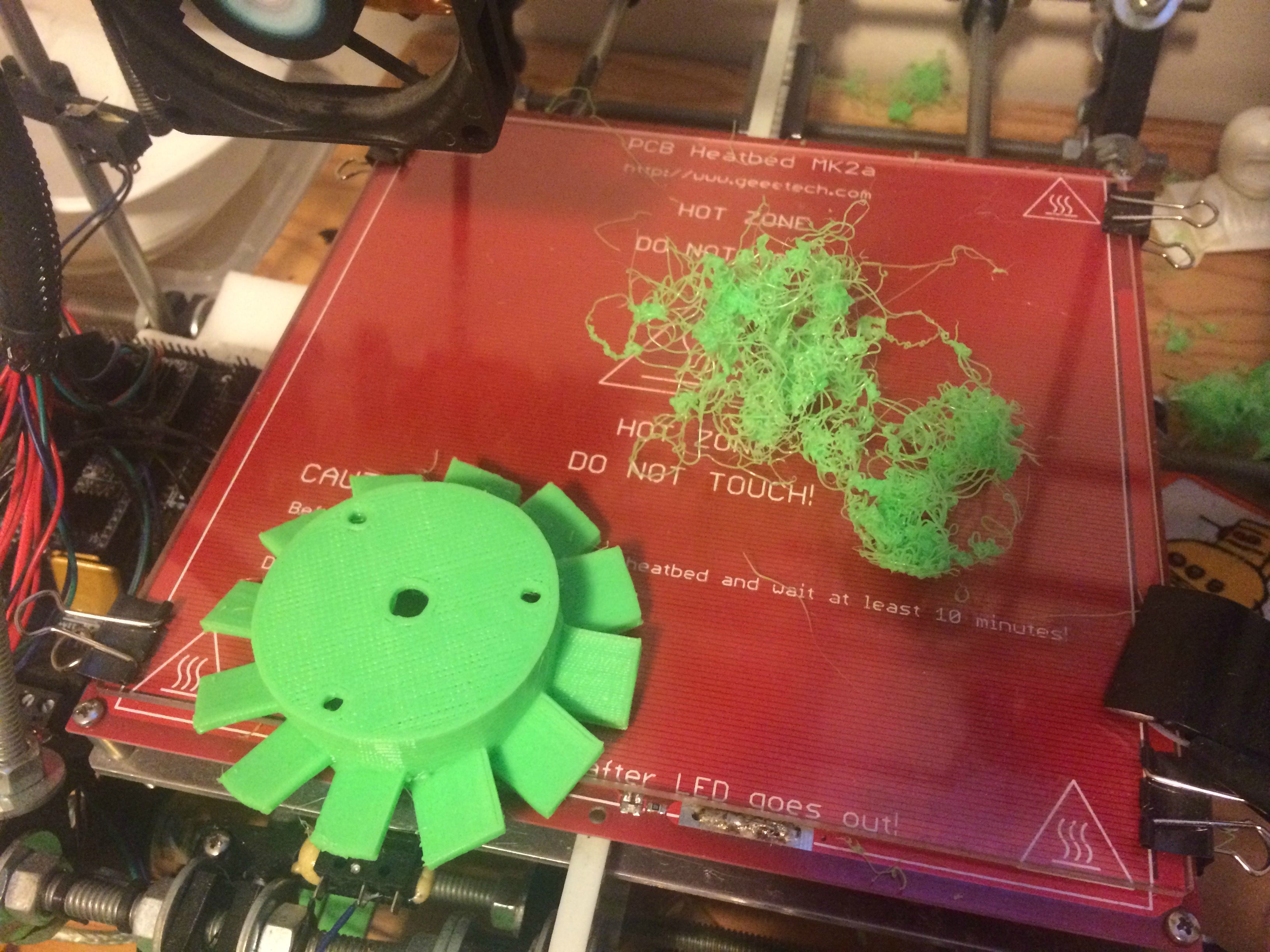

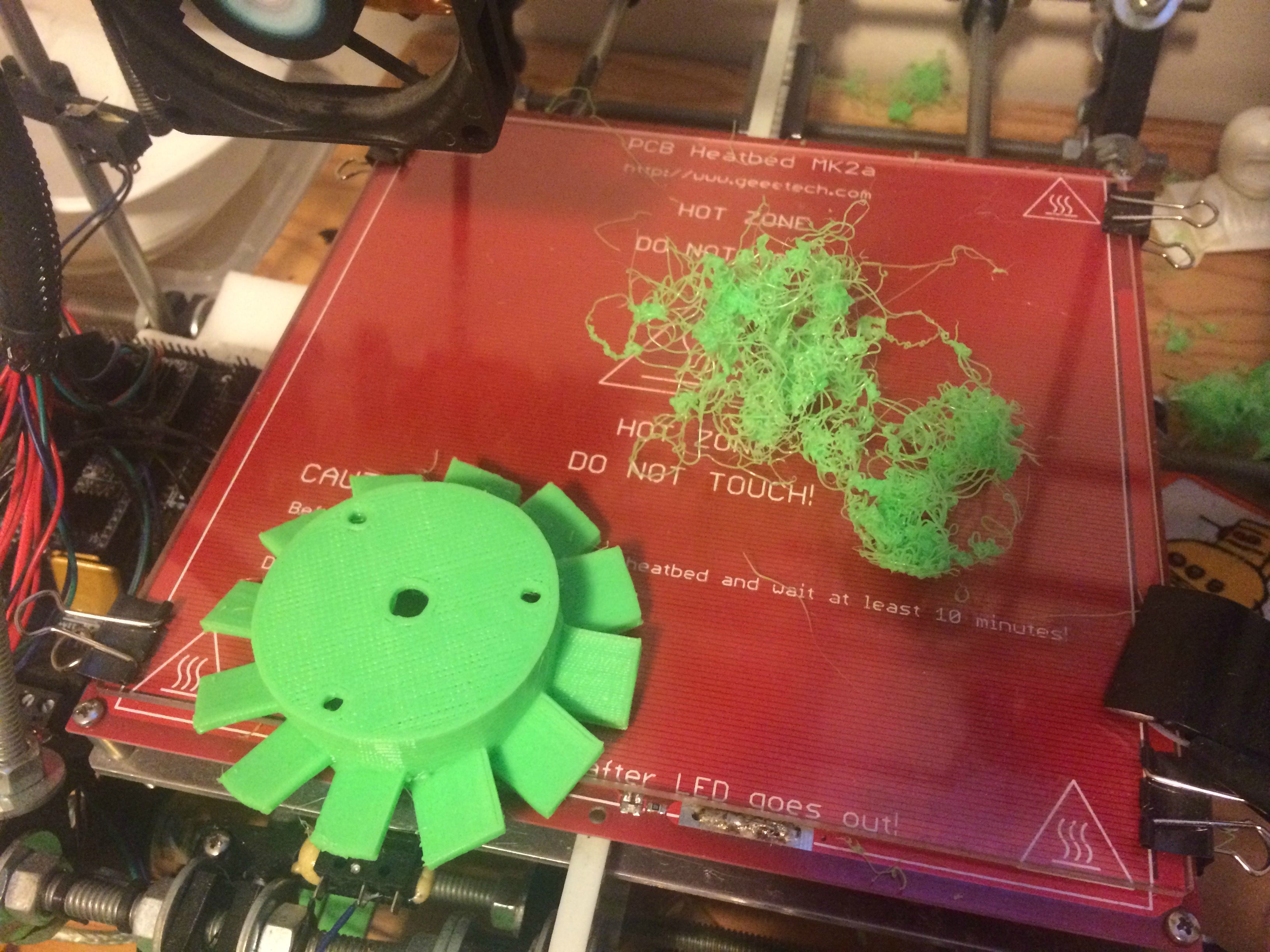

Meanwhile the print finished. Small remark, the 'pins' dont fit, I dont think you left any margin in your design. You can sand it off to make it fit, but they are already relatively thin too. In your next revision, I would make them a bit thicker, longer and allow some margin. Id also consider making the spinner shell a bit thicker in case you overtighten the screw. FYI, the bottom part weighs ~28 gr (some support material to be removed yet) the spinner 12 gr.

Meanwhile the print finished. Small remark, the 'pins' dont fit, I dont think you left any margin in your design. You can sand it off to make it fit, but they are already relatively thin too. In your next revision, I would make them a bit thicker, longer and allow some margin. Id also consider making the spinner shell a bit thicker in case you overtighten the screw. FYI, the bottom part weighs ~28 gr (some support material to be removed yet) the spinner 12 gr.

Yeah, I figured I would have to sand that bit. Good to know on the dome. Making it thicker is not an issue.

ScottyWarpNine

Mostly Harmless

I did a test print of the lower part at .1mm layer height. Detail is great, strength of the fins is fantastic. I printed with no infill and everything seems to have turned out alright. I'll try the dome now. I'm gonna try printing it right side up with infill

Just tested the bottom fan part on a 1100KV motor and 4S battery, theoretically good for ~15K rpm. I didnt balance it (at all) and I didnt properly remove all the support material near the axe mount, so it wasnt even mounted straight. As a result, it shook like crazy, like a hammering drill, but it stayed intact (and produced a fair amount of airflow).

Thats great news! Sounds like I don't need to re-work the fins then?

Well, if the cone is balanced I'm not afraid of that.

ScottyWarpNine

Mostly Harmless

Printing the cone part right side up obviously didn't work.

Any more info on the spinner Scotty? I'b be happy to shoot you a couple $ to cover some shipping if you think you have a print that is worth using.

ScottyWarpNine

Mostly Harmless

Any more info on the spinner Scotty? I'b be happy to shoot you a couple $ to cover some shipping if you think you have a print that is worth using.

Sorry for the delay, tonight I'll finally have time to try printing the spinner cone upside down, which should work much better. I'll let you know how it goes.

My main laptop has died so I've had to commandeer my 10 year old dell laptop which is usually relegated to 3D printing duty, so that makes multitasking much harder...

ScottyWarpNine

Mostly Harmless

I've been having the worst luck with this part. I've attempted it 4 times and every single time the part pops off the bed half way through and ruins the print. The tip of the cone just doesn't have a wide enough base to remain stable.

Maybe ZoomNBoom can chime in with what slicer program he was using. I'll try a couple other things tonight.

Maybe ZoomNBoom can chime in with what slicer program he was using. I'll try a couple other things tonight.

wilsonb

New member

Looks like Repetier Host running Slic3r (maybe Cura).

Have you tried printing it with a brim? He already said he is going to sand/finish the part, so the extra lip on the tip of the cone shouldn't be a problem. Are you getting only 1 or 2 perimeters on the base?

When I slice it up in Slic3r, I only get 1 perimeter. It is quite the accomplishment to print the thing upside down without it knocking off the bed. Bonus points for ZnB for completing one!

Have you tried printing it with a brim? He already said he is going to sand/finish the part, so the extra lip on the tip of the cone shouldn't be a problem. Are you getting only 1 or 2 perimeters on the base?

When I slice it up in Slic3r, I only get 1 perimeter. It is quite the accomplishment to print the thing upside down without it knocking off the bed. Bonus points for ZnB for completing one!

ScottyWarpNine

Mostly Harmless

I'm using a brim, but the problem is it keeps putting a gap between the brim and the part, so the brim is really kind of useless. I tried using a couple raft layers too, but it still won't make a larger base to make it stable. I'll try using repetier, it may have some extra features to play with or something.

wilsonb

New member

I'm using a brim, but the problem is it keeps putting a gap between the brim and the part, so the brim is really kind of useless. I tried using a couple raft layers too, but it still won't make a larger base to make it stable. I'll try using repetier, it may have some extra features to play with or something.

Maybe add a couple concentric cylinders that are 1 perimeter thick as support? I don't know...

ScottyWarpNine

Mostly Harmless

Success!

I used Cura to slice the model into Gcode and I was able to configure it to make support material around the base that Slic3r deemed unnecessary.

Wilsonman, if you PM me your address I'll get it shipped out right away.

You're definitely going to want to brush on a few coats of thinned epoxy, or the print smoother stuff to make the bond between layers stronger and to fill in the valleys. The lower portion with the fins is quite strong, the cone, not so much. It would probably be worthwhile to coat the inside of the cone as well even though it won't be seen, just for some extra strength.

I used Cura to slice the model into Gcode and I was able to configure it to make support material around the base that Slic3r deemed unnecessary.

Wilsonman, if you PM me your address I'll get it shipped out right away.

You're definitely going to want to brush on a few coats of thinned epoxy, or the print smoother stuff to make the bond between layers stronger and to fill in the valleys. The lower portion with the fins is quite strong, the cone, not so much. It would probably be worthwhile to coat the inside of the cone as well even though it won't be seen, just for some extra strength.

Easy peasy. Might make the sanding less work too.

Received the parts from Scotty yesterday. I did some initial sanding and bored out the locator rods for the cone to slip in. Overall, its ok. I think I can make this work with some 5 min epoxy slathered around. It will take some work to get everything smooth with the dremel but not impossible.

Attachments

Looks spectacular! Can't wait to see is all painted up.

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 10

- Views

- 704

- Replies

- 0

- Views

- 486

- Replies

- 8

- Views

- 823