kah00na

Senior Member

I have an FPV250 with the carbon fiber cage. How are people mounting the camera to the small piece of CF wedged between the upper and lower plates? I've seen some with nylon spacers and some with some anti-vibration connections. I've looked around and can't figure out what pieces they're actually using. I guess they are such simple parts that nobody thinks they are important to mention. I'd like to know the screw size or the nylon spacer size. Also, if anyone can point me to anti-vibration pieces that would work, I'd love it. I'm looking to use just a board camera with no case.

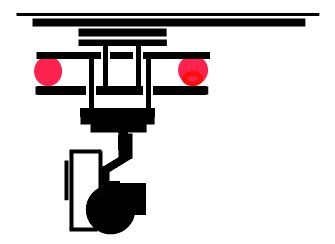

This is more what I'm looking to do:

This guy has the nylon spacers.

This is more what I'm looking to do:

This guy has the nylon spacers.

Last edited: