bracesport

Legendary member

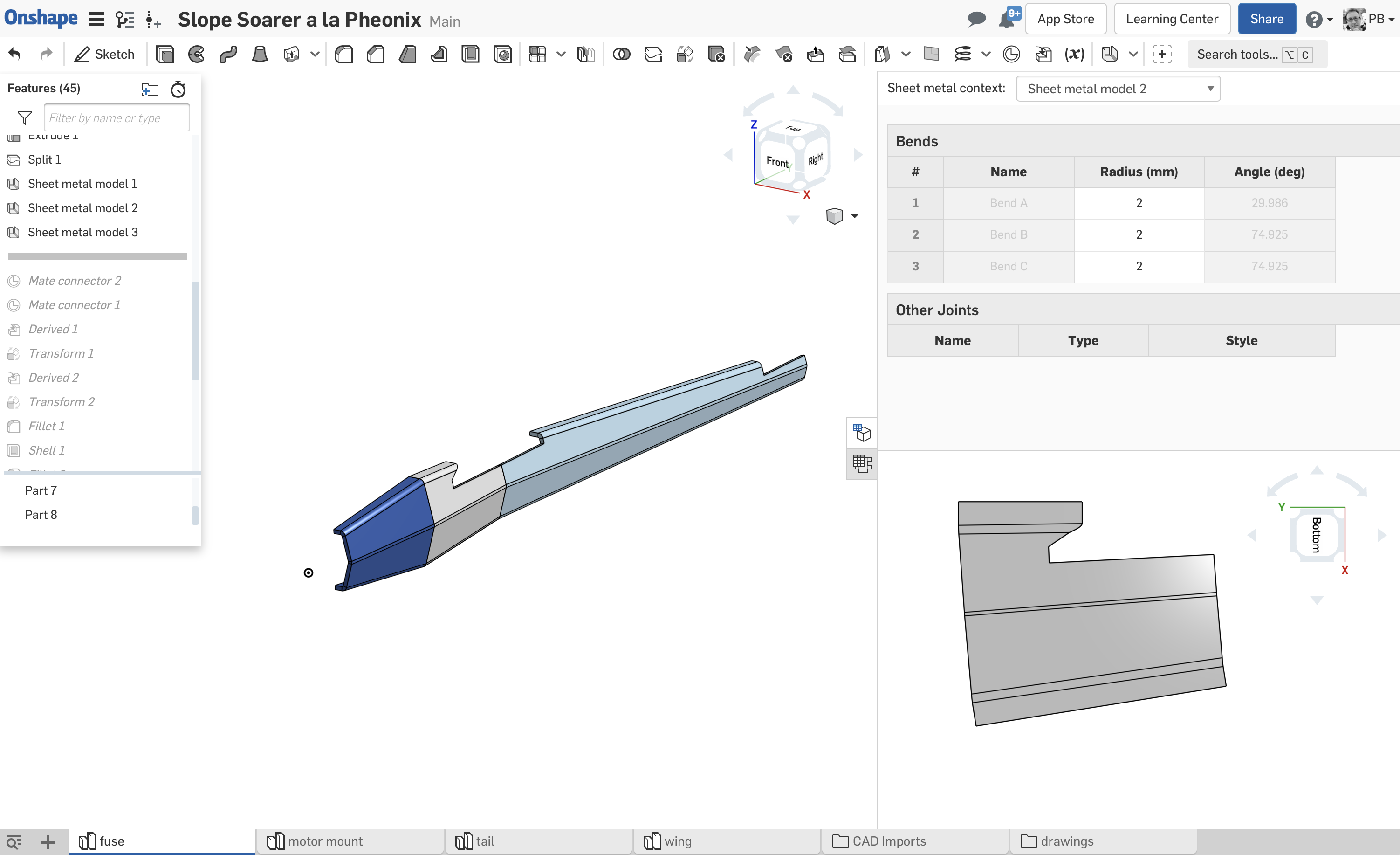

I have been contemplating my next build and given I am also assembling a Pheonix 1600 for my brother in law (and let's face it, he may not let me fly it) I thought I should build something complimentary.

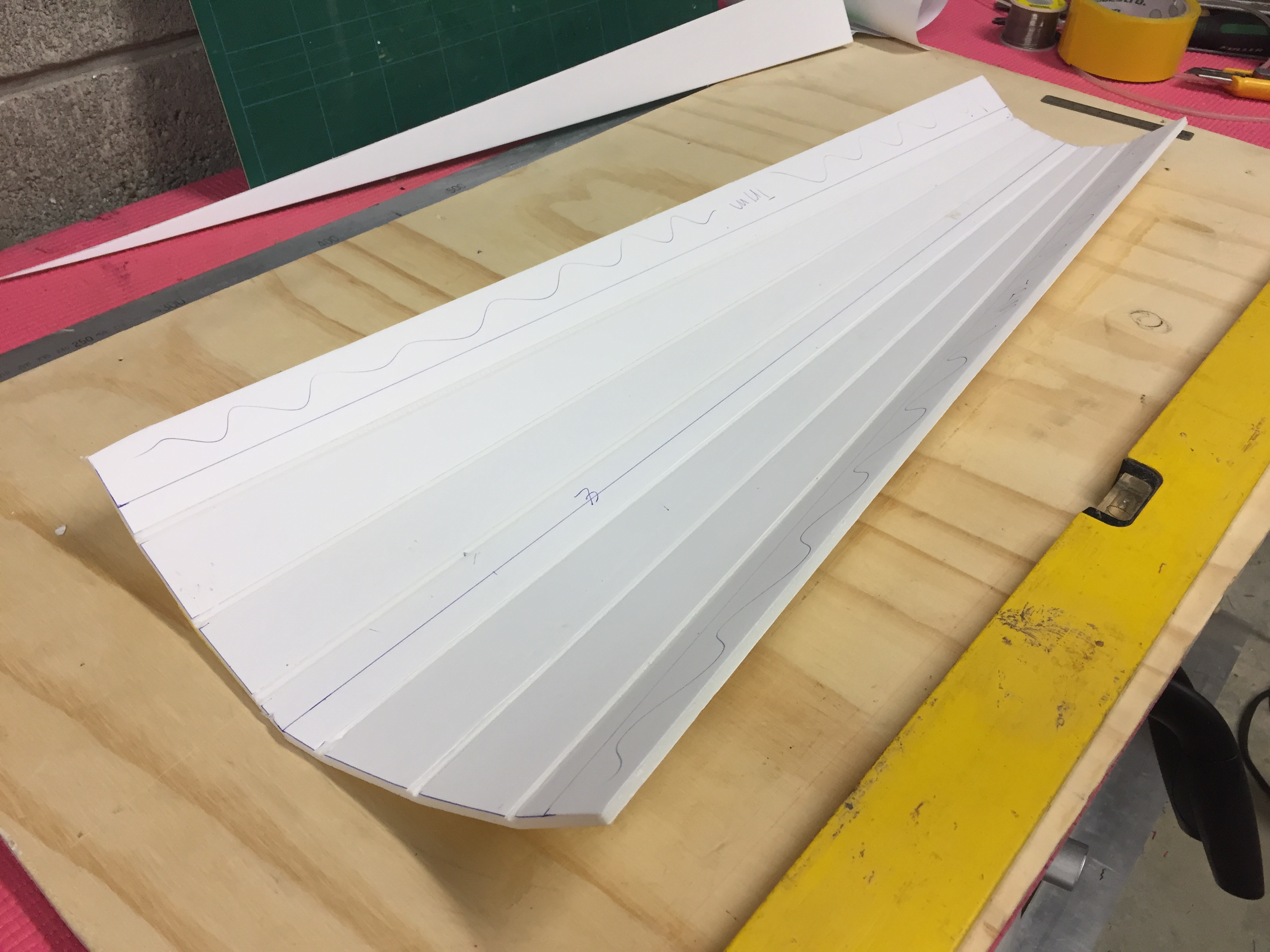

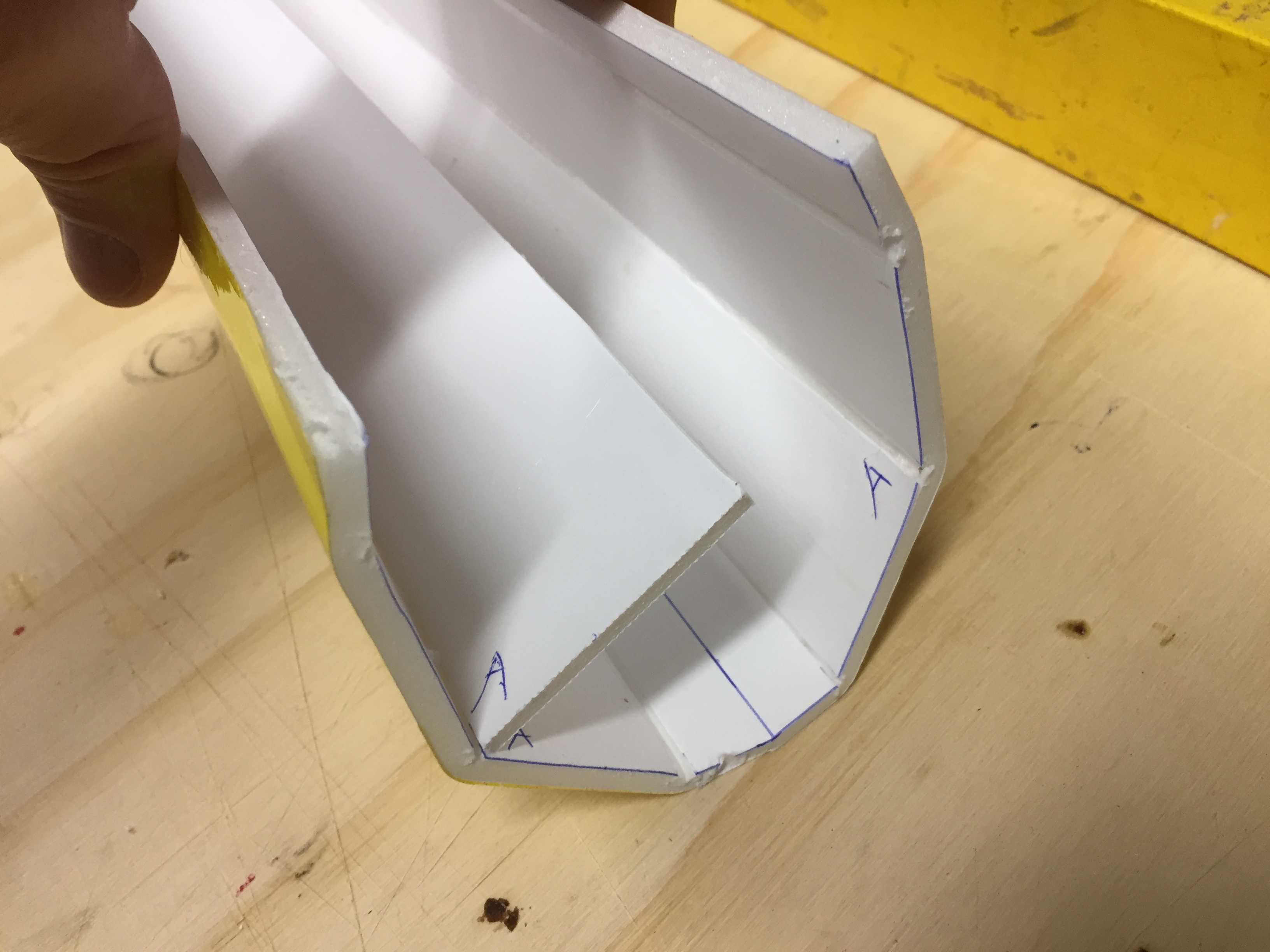

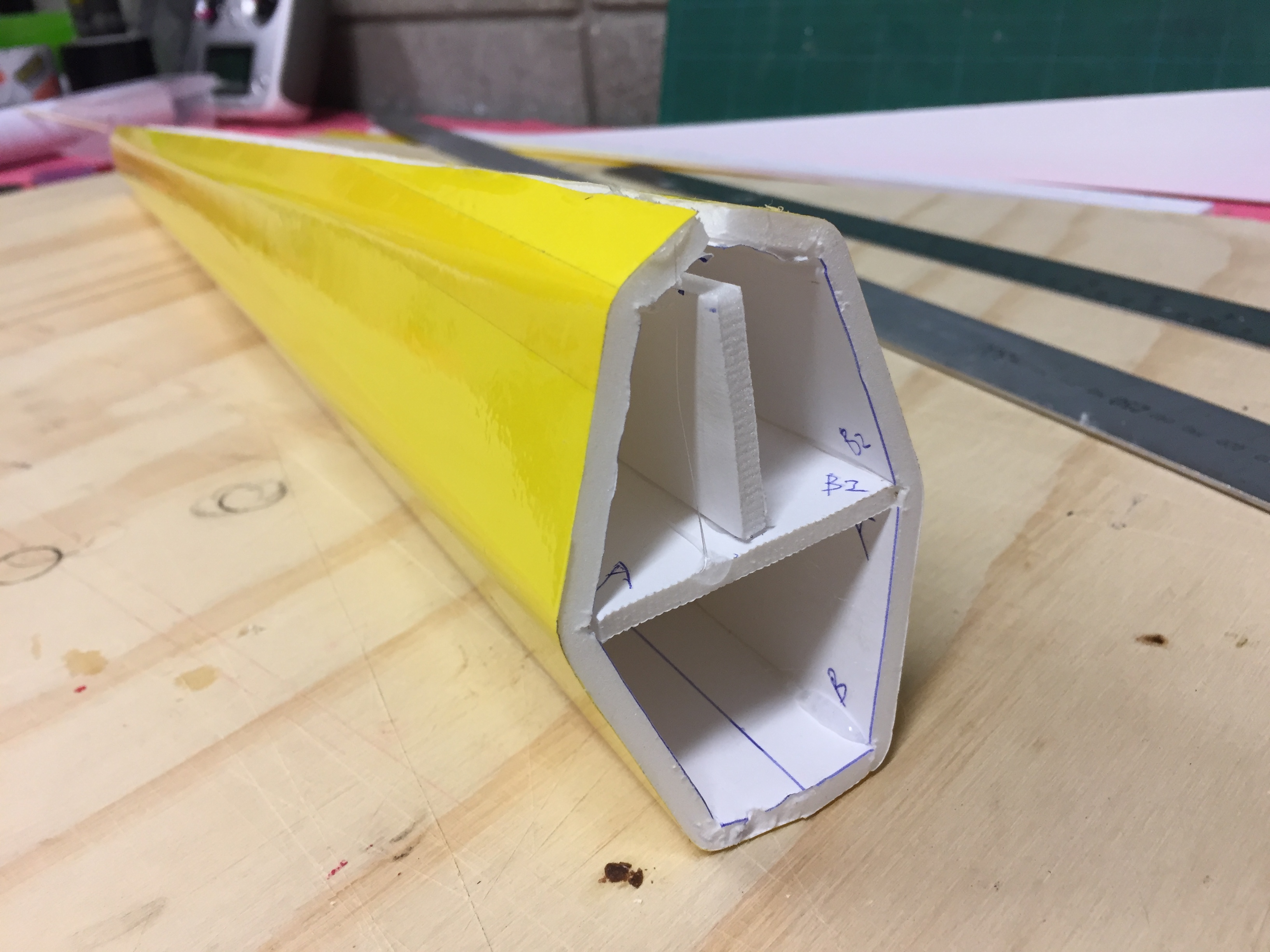

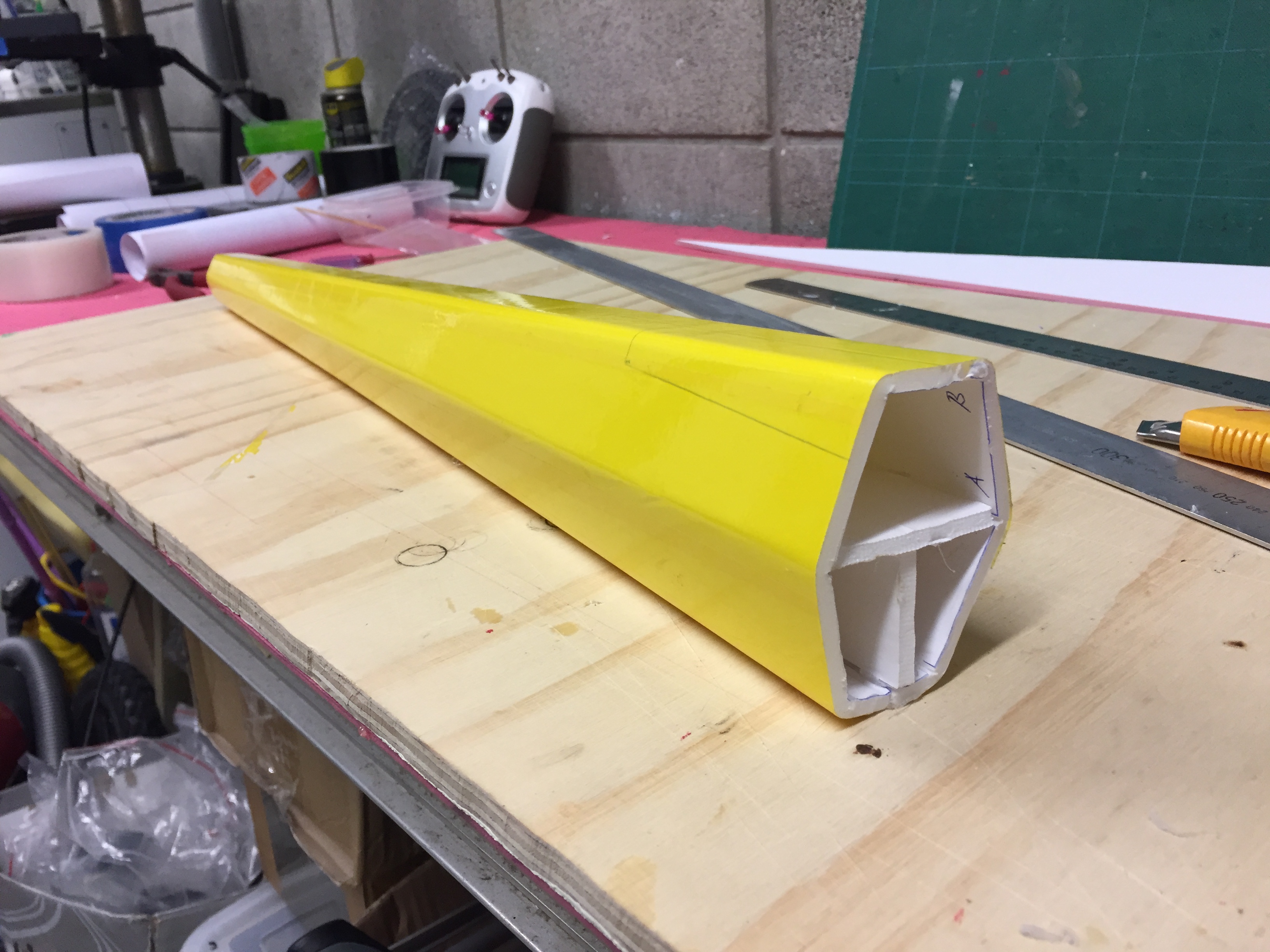

I have this Bixler 3 spare part wing under my bench that I bought a while back, a very nice Pheonix to measure, and about one and a half sheets of FB currently in stock - I am going to freestyle a fuse in FB to take the Bixler 3 wing (@1550mm) loosely based on the Pheonix design (@1600mm) - the Pheonix has quite a solid body so there should be enough mass to emulate it in FB.

Maybe it is time to use some of the 'Corsair' techniques, or find some way to make the fuse more organic than my usual box tube fuses - I will think about it!

I have this Bixler 3 spare part wing under my bench that I bought a while back, a very nice Pheonix to measure, and about one and a half sheets of FB currently in stock - I am going to freestyle a fuse in FB to take the Bixler 3 wing (@1550mm) loosely based on the Pheonix design (@1600mm) - the Pheonix has quite a solid body so there should be enough mass to emulate it in FB.

Maybe it is time to use some of the 'Corsair' techniques, or find some way to make the fuse more organic than my usual box tube fuses - I will think about it!

Last edited: