bracesport

Legendary member

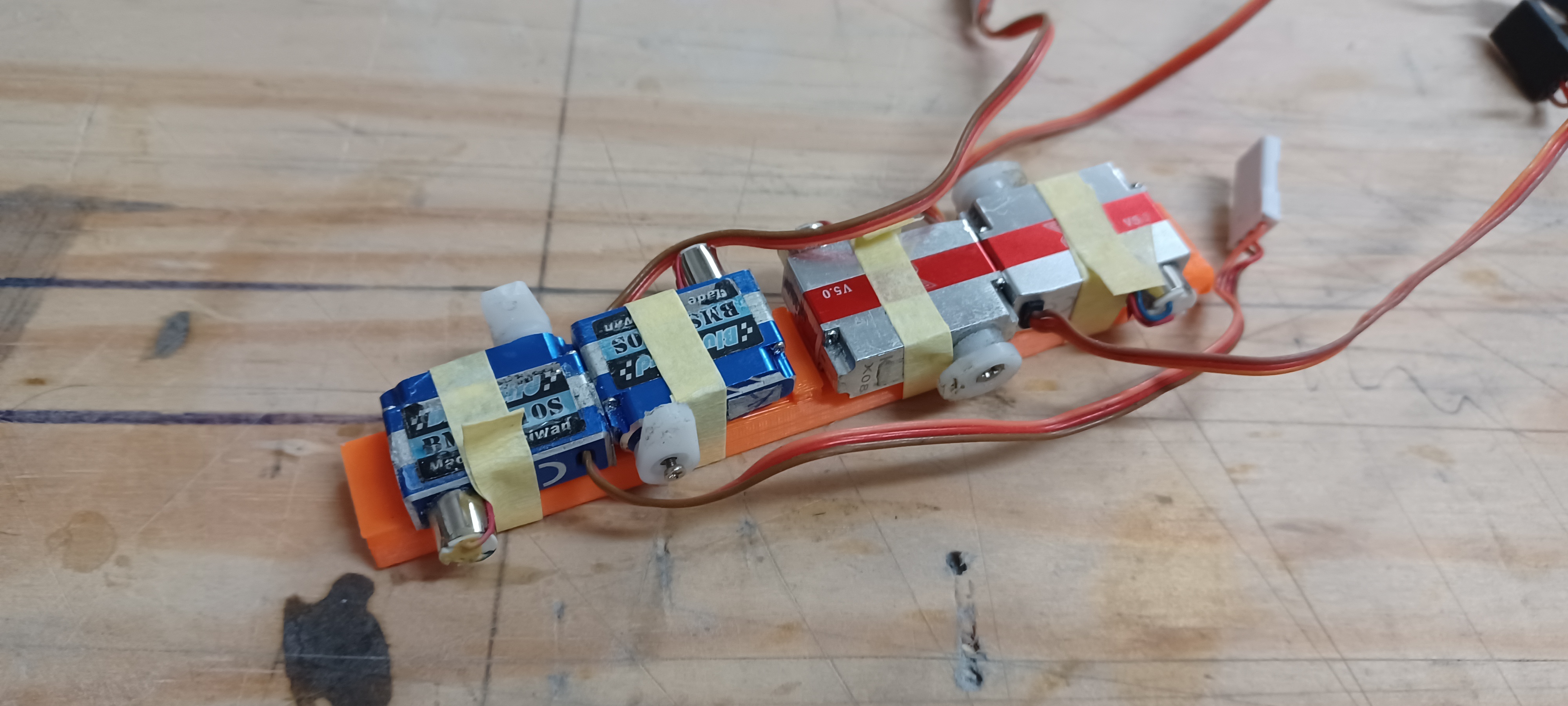

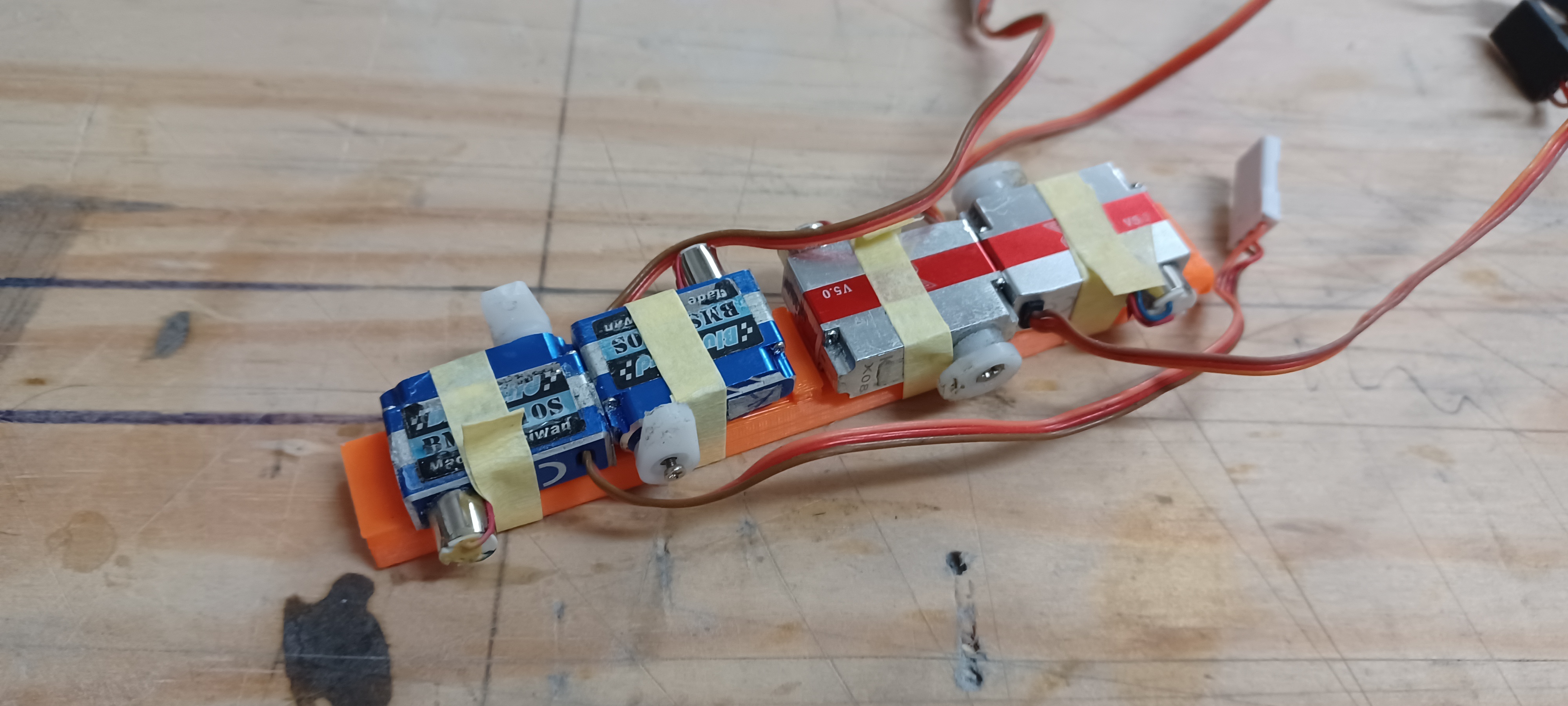

Here is the dry fit - the good, the bad, and ugly!

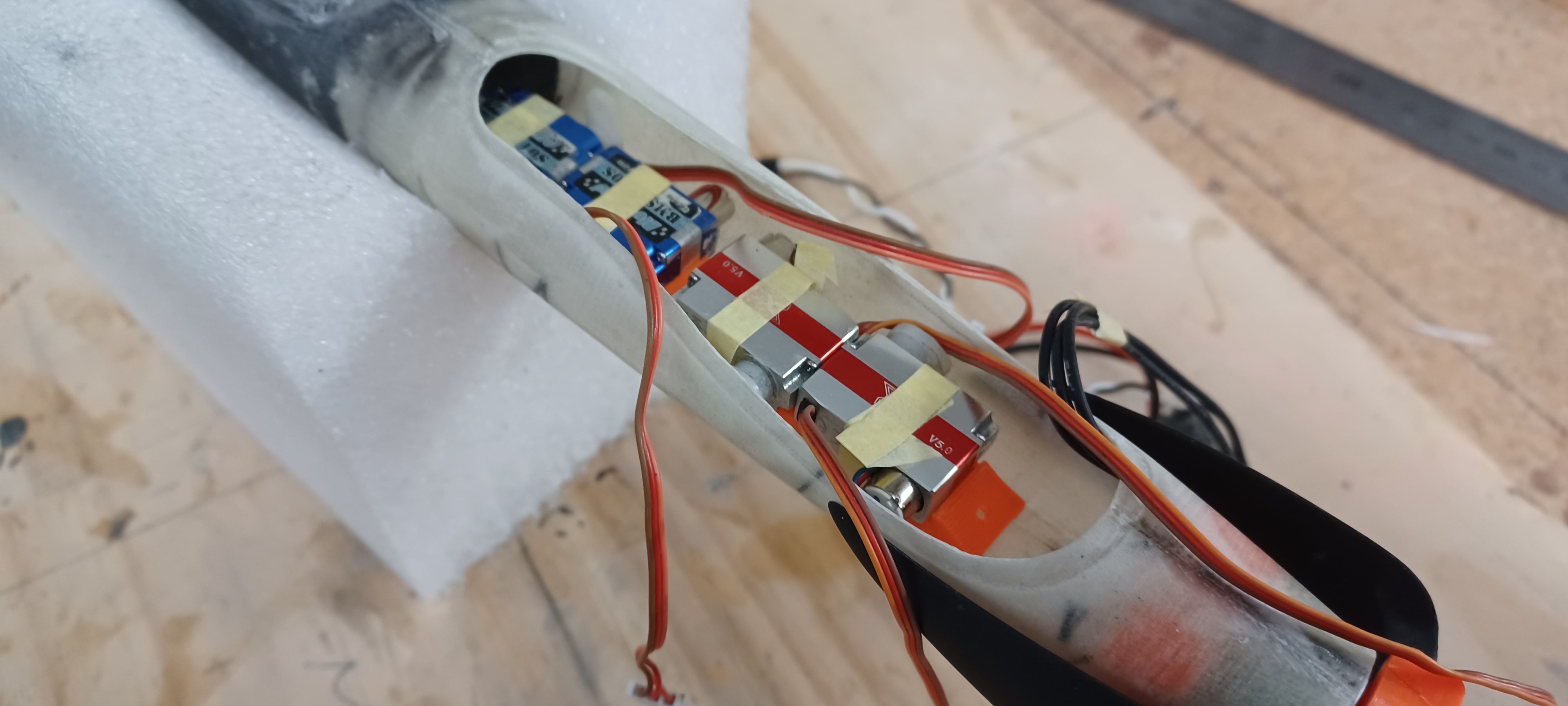

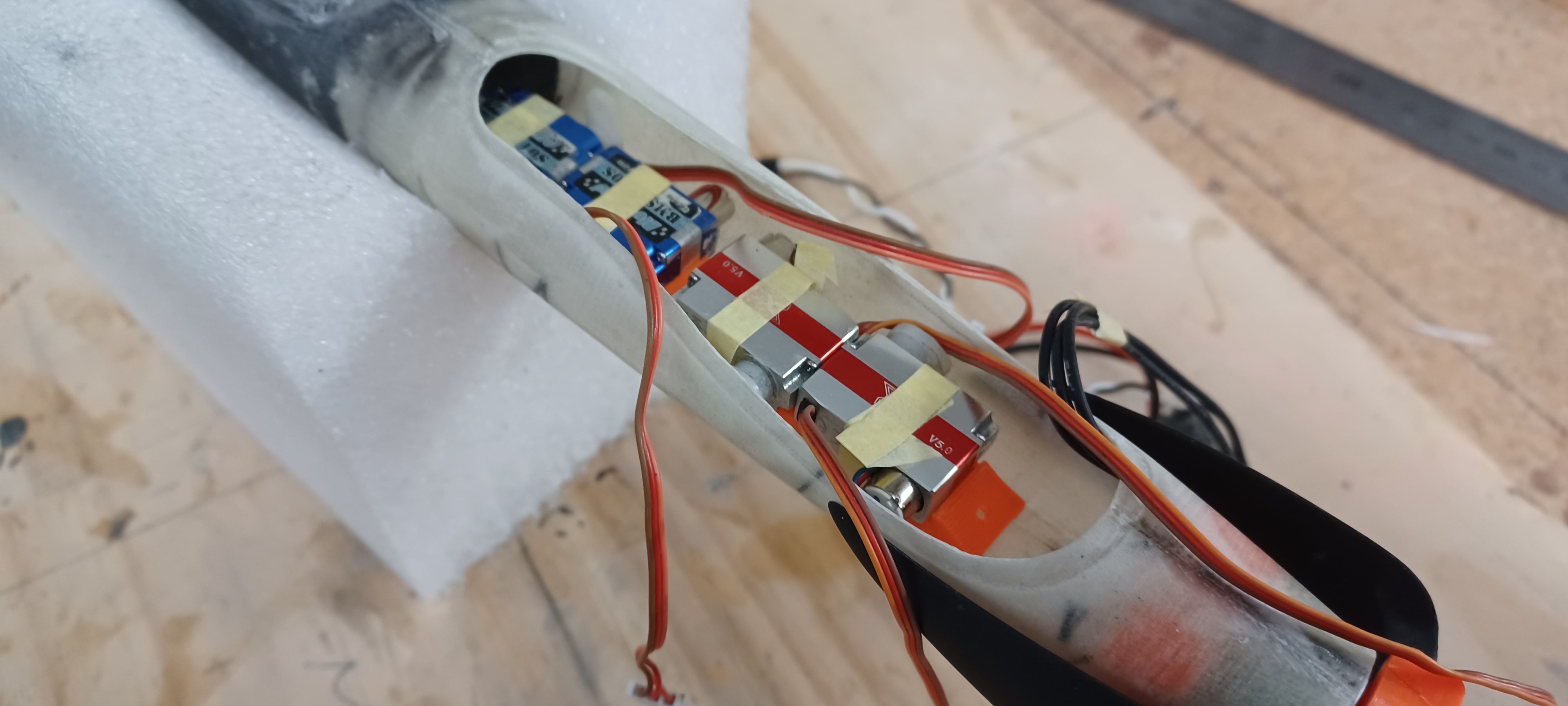

Actually, not so bad and not so ugly - the servo tray fits in through the fuse canopy and can slide back into position - it will be an interesting push rod install but as just mentioned by 'floatdog' I can consider a pre-built jig - my initial plan was to set my servos into the tray, fix the tray into the fuse, set my adjustable pushrods with a slow cure epoxy.

I am running two batteries - one for the motor and one for the Rx/servos - having the two batteries gives me the nose weight I need without just adding weight - the batteries and the servo tray weigh similarly but the batteries provide a more concentrated forward weight.

I will still try and remove a tad more tail weight - this is a 6 servo, motored, twin battery setup and compared to my old BAMFzilla at 275g I have currently added a further 75g with the added hardware - my fuse is 20g heavier than a factory fuse (not too bad) and my tail is a bit heavy so overall it is looking pretty good.

I have marked the balance point on the fuse with all the gear installed so I can see any improvements as I tweak the tail and add the hardware permanently.

Actually, not so bad and not so ugly - the servo tray fits in through the fuse canopy and can slide back into position - it will be an interesting push rod install but as just mentioned by 'floatdog' I can consider a pre-built jig - my initial plan was to set my servos into the tray, fix the tray into the fuse, set my adjustable pushrods with a slow cure epoxy.

I am running two batteries - one for the motor and one for the Rx/servos - having the two batteries gives me the nose weight I need without just adding weight - the batteries and the servo tray weigh similarly but the batteries provide a more concentrated forward weight.

I will still try and remove a tad more tail weight - this is a 6 servo, motored, twin battery setup and compared to my old BAMFzilla at 275g I have currently added a further 75g with the added hardware - my fuse is 20g heavier than a factory fuse (not too bad) and my tail is a bit heavy so overall it is looking pretty good.

I have marked the balance point on the fuse with all the gear installed so I can see any improvements as I tweak the tail and add the hardware permanently.