You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project F-14 Tomcat

- Thread starter Flitedesign 3d

- Start date

Flitedesign 3d

Elite member

Thats the plan, after a few attempts I finally got a wingbox design Im satisfied with. Im going to start making it soon. Plenty of cnc cutting coming upDo you think you’ll get this finished before the cold weather comes again?

Oldrover TJ

Active member

That's beautiful

Captain Jay

Elite member

You're a heck of an engineer man!!! I sure hope you get into aerospace engineering or something like that...Thats the plan, after a few attempts I finally got a wingbox design Im satisfied with. Im going to start making it soon. Plenty of cnc cutting coming up View attachment 205444

Flitedesign 3d

Elite member

This is a long update post on the F-14 project, to make a long story short, the v2 is finished excluding some final paint and decals. I flew 3 flight with it yesterday. It flies extremely good, much better than the v1 which had a lot of backlash on the elevons, this one has barely any. The 2 first flight were just fiddling around trying to get all the flight modes trimmed. Although it has excellent flight characteristics its still the most stressful plane I have flown since my balsa model days because it has so many functions and different flight modes that I need to think about. I really need some time and many flights to get used to this before doing some knife edge sweeps. Here is a raw uncut video of the third flight.

Numbers:

Length: 1260 mm (scale 1:15)

Wingspan: on 20-68 deg. sweep: 820-1350 mm

Mass: 2000 g

Static thrust: 1900g at 90A

My stuff:

Receiver: Frsky X8R

Edf: 2x fms 11 blade 64mm 3150kv

ESC: 2x 60A skywalker

Batteries: 2x 4s 1400mah 45C

2x Emax ES09MD metal gear servo for the elevons

2x Corona DS-239MG metal gear servo for sweep

4x generic sg90 servo for the rudders and flapperons

In the rest of this post I will cover the wingbox design, the flight modes and some static stress simulations, if that sounds interesting keep reading.

Flight modes

Im using the frsky x9 lite transmitter and this is the first time Im using it on a plane. It was confusing at first but now when I got the hang of it I really like opentx firmware for the freedom it gives to make more complex planes. I made it so it has 3 flight modes, extended, half- and full sweep. Each flight mode has its own elevator trim, travel adjust and expo for the stabs. Flapperons work only with the extended mode. Flaps go up automatically if I sweep accidentally with flaps down. I noticed that the flaps makes the plane dive so I need to mix some elevator with them.

Wingbox design

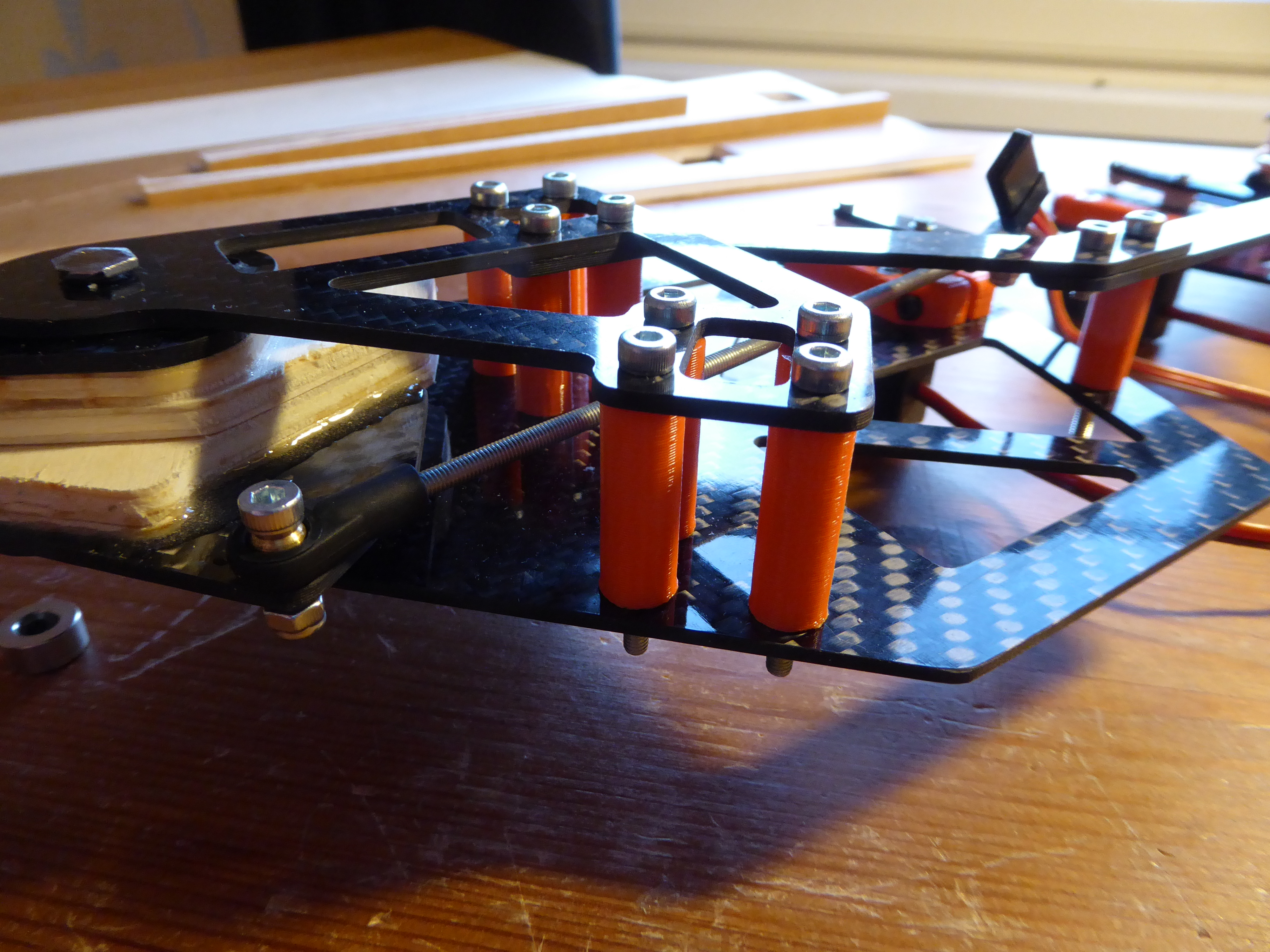

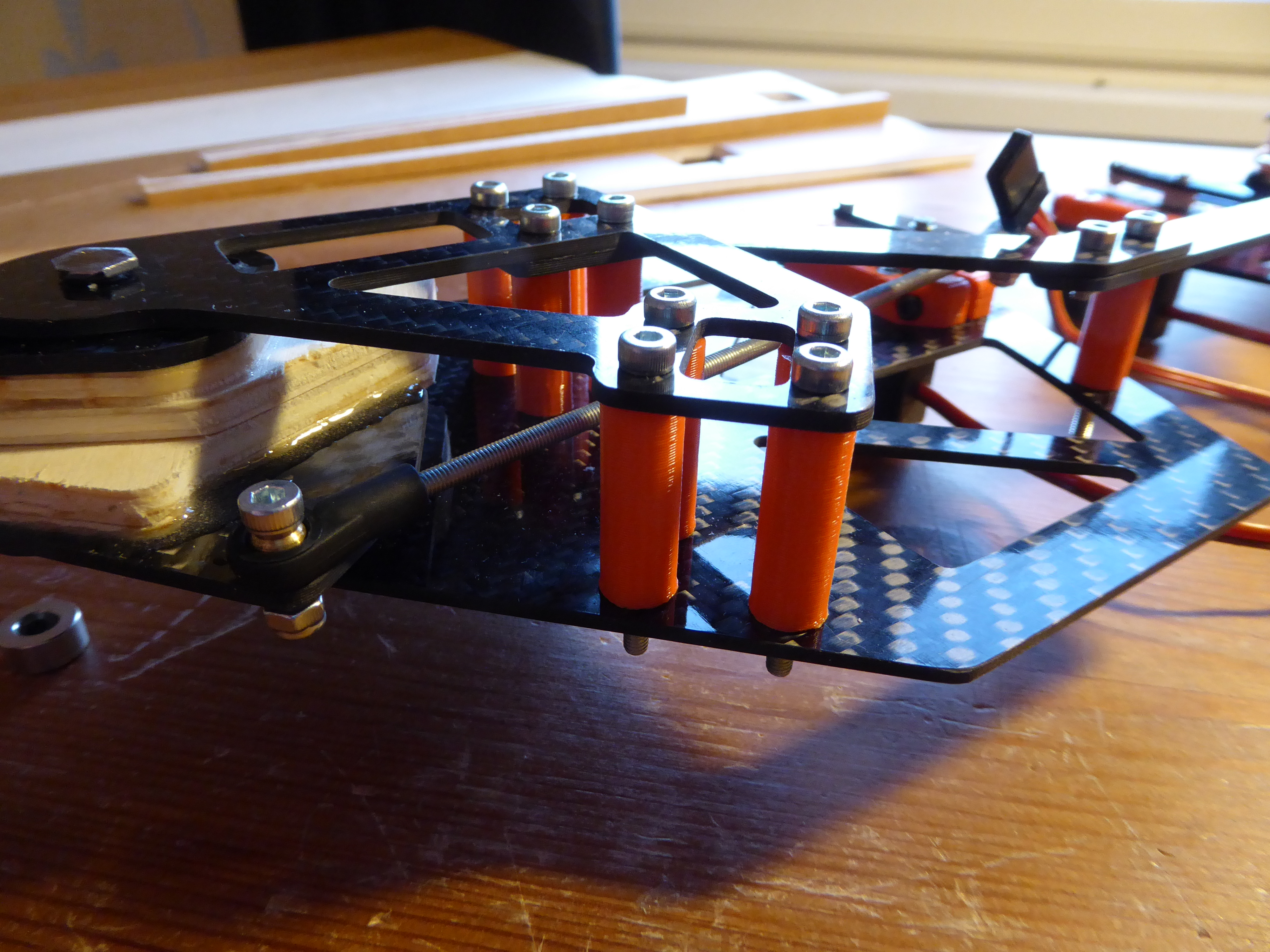

The geometry of the v1 wingbox had this design flaw that it could not handle any torsion around the traversal axis created by the center of lift behind the hinge, especially in the swept position. This is why the top carbon plate has also the diagonal support part. The neat thing about this wingbox is that only the main carbon plates are glued to the plane, everything else can be disassembled by unscrewing the m3 bolts. There are 3d printed m3 nut housings under the main plate so the bolts didn't get stuck in glue.

Static stress simulations

Just for the sake of learning and fun I ran some static stress simulations in fusion. This might look all fancy and complicated but its actually not any magic. The user just inputs various parameters and conditions such as constraints, forces and moments and the software creates the mesh and takes care of the calculations. Its called the finite element method (fem) (if you want to sound like you know what you're talking about) Now I need to mention that due to numerous factors like my lack of knowledge of aerodynamic forces, me not having the exact mechanical properties of the carbon fiber Im using, the fact that it is mounted on top of very non-rigit airframe etc. this is only a very rough estimation. I was mainly interested if there is any obvious stress concentrations or weak points.

I made some very rough and simplified calculations of forces that acts on the 5mm steel pin hinge on 5 G’s and the results show that the stress in the carbon parts stays quite low, partly because fusions default cf properties are overestimated I think but also because the carbon parts are not the weakest link of my wingbox. In the two pictures you can see two different kind of result plots, static stress and displacement. Static stress means the stress in the material and it can not surpass the yield strength of a material or in case of carbon fiber which does not really yield it can not surpass the ultimate tensile/compressive strength. The displacement plot shows how much the part has been displaced by the elastic deforming.

Numbers:

Length: 1260 mm (scale 1:15)

Wingspan: on 20-68 deg. sweep: 820-1350 mm

Mass: 2000 g

Static thrust: 1900g at 90A

My stuff:

Receiver: Frsky X8R

Edf: 2x fms 11 blade 64mm 3150kv

ESC: 2x 60A skywalker

Batteries: 2x 4s 1400mah 45C

2x Emax ES09MD metal gear servo for the elevons

2x Corona DS-239MG metal gear servo for sweep

4x generic sg90 servo for the rudders and flapperons

In the rest of this post I will cover the wingbox design, the flight modes and some static stress simulations, if that sounds interesting keep reading.

Flight modes

Im using the frsky x9 lite transmitter and this is the first time Im using it on a plane. It was confusing at first but now when I got the hang of it I really like opentx firmware for the freedom it gives to make more complex planes. I made it so it has 3 flight modes, extended, half- and full sweep. Each flight mode has its own elevator trim, travel adjust and expo for the stabs. Flapperons work only with the extended mode. Flaps go up automatically if I sweep accidentally with flaps down. I noticed that the flaps makes the plane dive so I need to mix some elevator with them.

Wingbox design

The geometry of the v1 wingbox had this design flaw that it could not handle any torsion around the traversal axis created by the center of lift behind the hinge, especially in the swept position. This is why the top carbon plate has also the diagonal support part. The neat thing about this wingbox is that only the main carbon plates are glued to the plane, everything else can be disassembled by unscrewing the m3 bolts. There are 3d printed m3 nut housings under the main plate so the bolts didn't get stuck in glue.

Static stress simulations

Just for the sake of learning and fun I ran some static stress simulations in fusion. This might look all fancy and complicated but its actually not any magic. The user just inputs various parameters and conditions such as constraints, forces and moments and the software creates the mesh and takes care of the calculations. Its called the finite element method (fem) (if you want to sound like you know what you're talking about) Now I need to mention that due to numerous factors like my lack of knowledge of aerodynamic forces, me not having the exact mechanical properties of the carbon fiber Im using, the fact that it is mounted on top of very non-rigit airframe etc. this is only a very rough estimation. I was mainly interested if there is any obvious stress concentrations or weak points.

I made some very rough and simplified calculations of forces that acts on the 5mm steel pin hinge on 5 G’s and the results show that the stress in the carbon parts stays quite low, partly because fusions default cf properties are overestimated I think but also because the carbon parts are not the weakest link of my wingbox. In the two pictures you can see two different kind of result plots, static stress and displacement. Static stress means the stress in the material and it can not surpass the yield strength of a material or in case of carbon fiber which does not really yield it can not surpass the ultimate tensile/compressive strength. The displacement plot shows how much the part has been displaced by the elastic deforming.

Last edited:

Oldrover TJ

Active member

The beauty of those carbon fiber parts.... I'd hang those on the wall and modern art!

This makes me even more excited to get my 3D printer and finish up the SU 27.

This makes me even more excited to get my 3D printer and finish up the SU 27.

cyclone3350

Master member

Looks like all kinds of nice flight characteristics. It looked like it went slow, and it went fast, and it accelerated from slow flight with ease. Very stable looking through out it's paces. Well done.

Flitedesign 3d

Elite member

Plans are now available here: https://forum.flitetest.com/index.php?resources/f-14-tomcat.249/

And build pictures here: https://forum.flitetest.com/index.php?threads/f-14-tomcat-build-guidance-pictures.68210/

Feels good to have this project finished, although a plane this complex is not very mature after only two iterations. This design could take some optimization in several aspects, but I think apart from flying it I'm done with it for now. Although I do have a tendency to always find my way back to F-14's...

And build pictures here: https://forum.flitetest.com/index.php?threads/f-14-tomcat-build-guidance-pictures.68210/

Feels good to have this project finished, although a plane this complex is not very mature after only two iterations. This design could take some optimization in several aspects, but I think apart from flying it I'm done with it for now. Although I do have a tendency to always find my way back to F-14's...

Roonie

New member

For the sweep Im using two ds-239hv servos one of which I have reversed.

Hi, great model you made

I know there are servo reverser but may by you did it an other way ??

thx.

Flitedesign 3d

Elite member

I reversed it by opening it and switching the motor wires and the outer wires of the potentiometer, you can find plenty of tutorials on youtube.Hi, great model you madeNow I`m trying to follow your plan a build me one. I also got the 2x 239 servo`s, but how did you reverse one ?

I know there are servo reverser but may by you did it an other way ??

thx.

I’m thinking of making one, though the carbon fibre parts would be hard to get. do you have any suggestions on where to get them?Thx, I'll give it a try... hopefully I won't break the servo.

Oh yeah........ anyone else making one ???

Roonie

New member

I ordered a carbon sheet from Aliexpress ... I will try to use a jigsaw to cut out the partsI’m thinking of making one, though the carbon fibre parts would be hard to get. do you have any suggestions on where to get them?

I must say I'm really impressed about the plans and ingeneering of this model.

My compliments to @Flitedesign 3d

I ordered a carbon sheet from Aliexpress ... I will try to use a jigsaw to cut out the parts.... I hope it wil work , it did with the plywood in the wings. The most important thing is that the holes for the m3 bolts and the wing line up.So I will drill the holes when top and bottom are firmly on top of one and other.....

I must say I'm really impressed about the plans and ingeneering of this model.

My compliments to @Flitedesign 3d

ah I see, I hope it works out for you! I have to agree, the engineering is insane for this F-14 and its really impressive!

Be sure to avoid inhaling the CF dust. Use a mask, and dust control on your machine. Be kind to your lungs.I ordered a carbon sheet from Aliexpress ... I will try to use a jigsaw to cut out the parts.... I hope it wil work , it did with the plywood in the wings. The most important thing is that the holes for the m3 bolts and the wing line up.So I will drill the holes when top and bottom are firmly on top of one and other.....

I must say I'm really impressed about the plans and ingeneering of this model.

My compliments to @Flitedesign 3d

Flitedesign 3d

Elite member

Woah that's quite a task you are about to take upon you. Just use a fine toothed blade, a coarse one can cause delamination on the cut edges. Also its highly recommended to use water while cutting to prevent dust from getting in the airI ordered a carbon sheet from Aliexpress ... I will try to use a jigsaw to cut out the parts

Roonie

New member

Oké, I haven't tried anything like that before..... But as I dont have a laser or cnc cutter.... Mayby I will first try to find a company with the right tools to do the job ...Woah that's quite a task you are about to take upon you. Just use a fine toothed blade, a coarse one can cause delamination on the cut edges. Also its highly recommended to use water while cutting to prevent dust from getting in the air

But mayby I could use some other materiaal ?? But dont think something is as light and strong as carbon.... I knew the making of the wingbox would be a challenge

The rest of the plane came together beautifully.

Last edited:

Similar threads

- Replies

- 8

- Views

- 3K

- Replies

- 6

- Views

- 1K