ScottyWarpNine

Mostly Harmless

I've aquire these plans second hand in a lot of balsa building stuff that came with my 1/4 scale Sig Cub kit. They have been sitting in my basement for about a year and that's just sad. They need to be used, and someday I will build the most beautiful Ziroli DC3 out there, but until I can afford to spend the money I need to and would want to on a plane of this caliber, I have another idea.

My intention is to build this plane out of foam, using traditional balsa building techniques. I'm thinking two 5065 motors on 6S delivering 2000W each should pull this thing airborne.

Can I get this thing flying by Flight Fest? Can it survive on my roof at highway speeds? Will it hover?

We are going to answer all of these questions and more in the epic thread that is sure to follow.

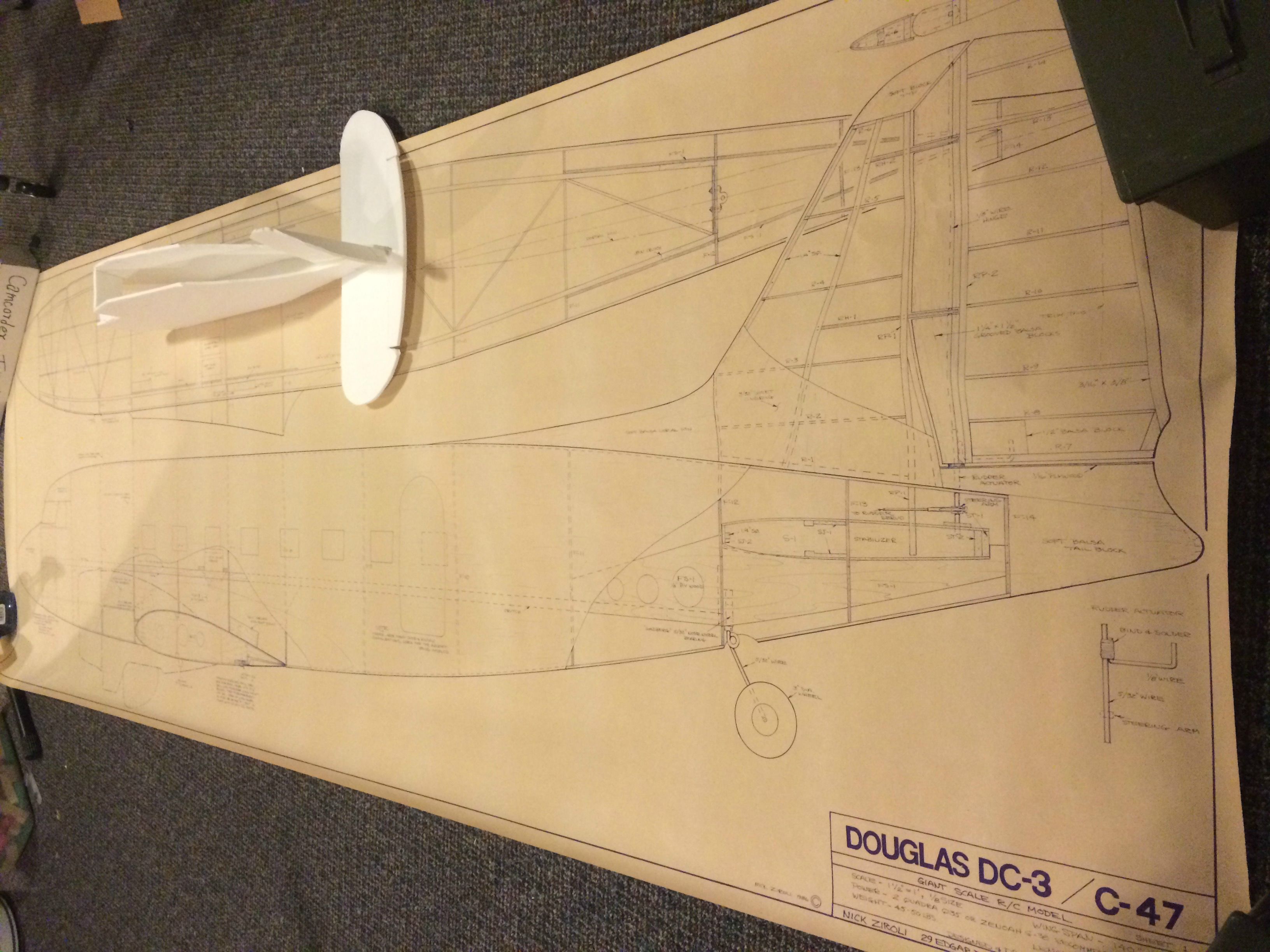

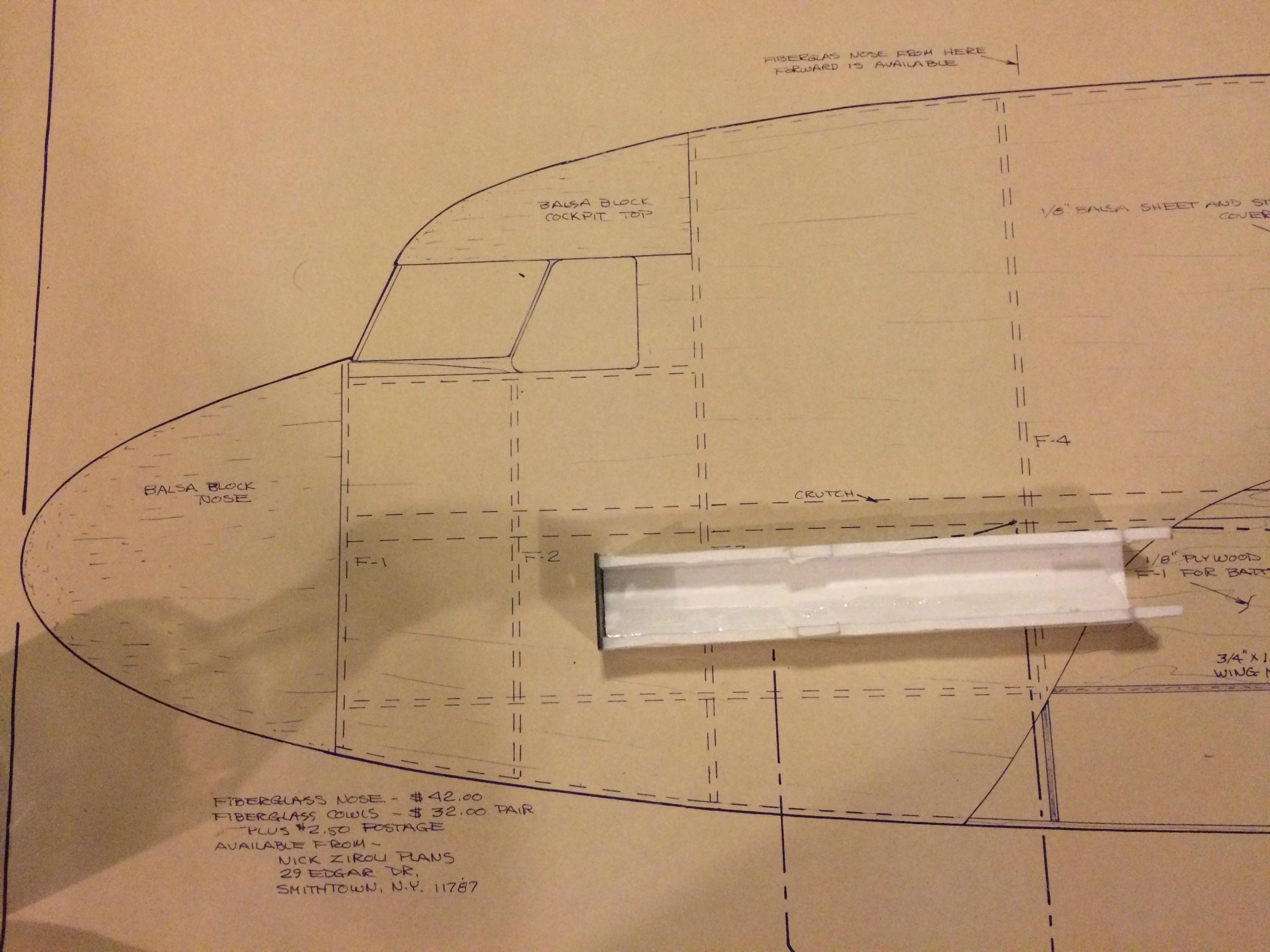

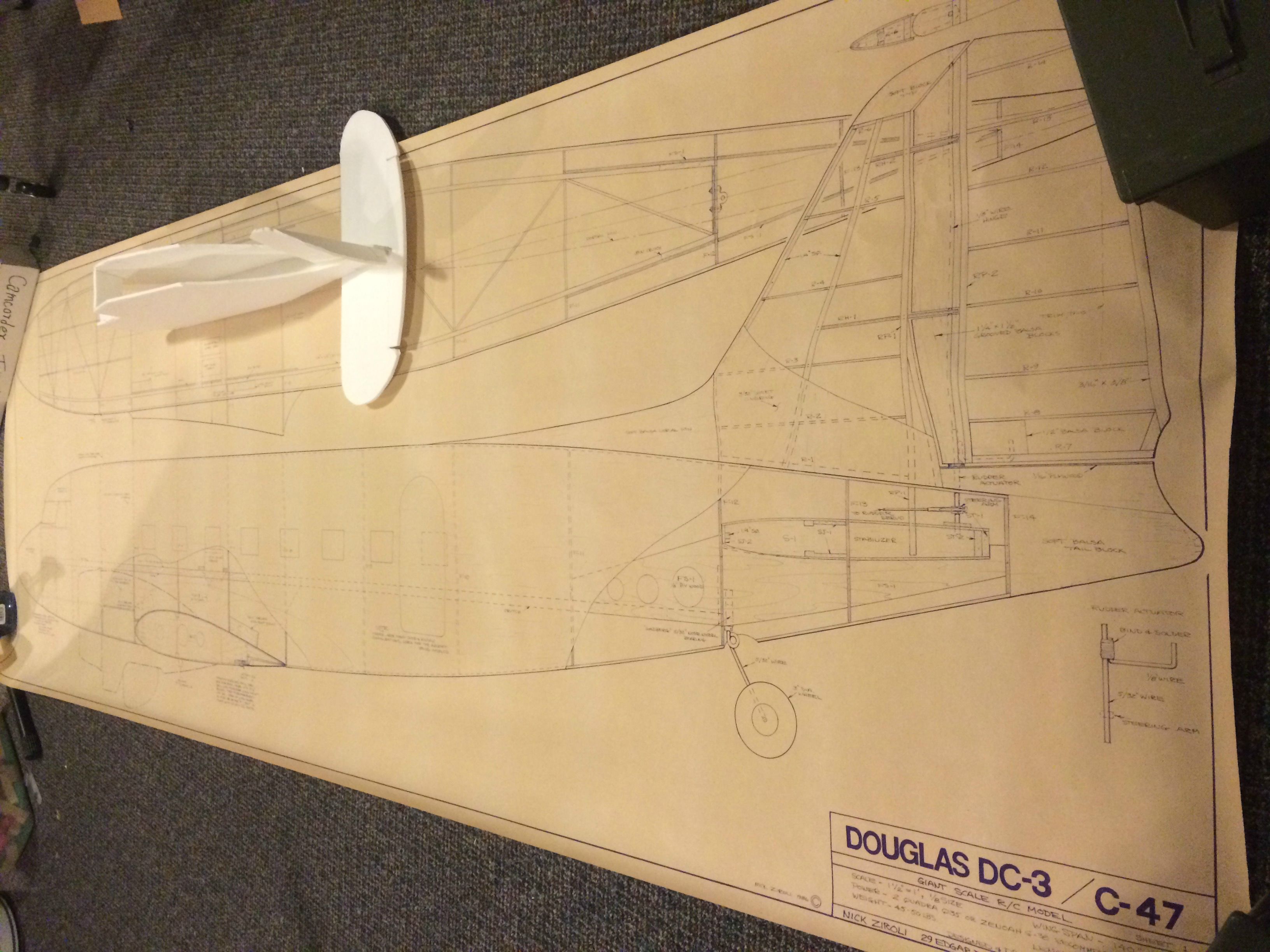

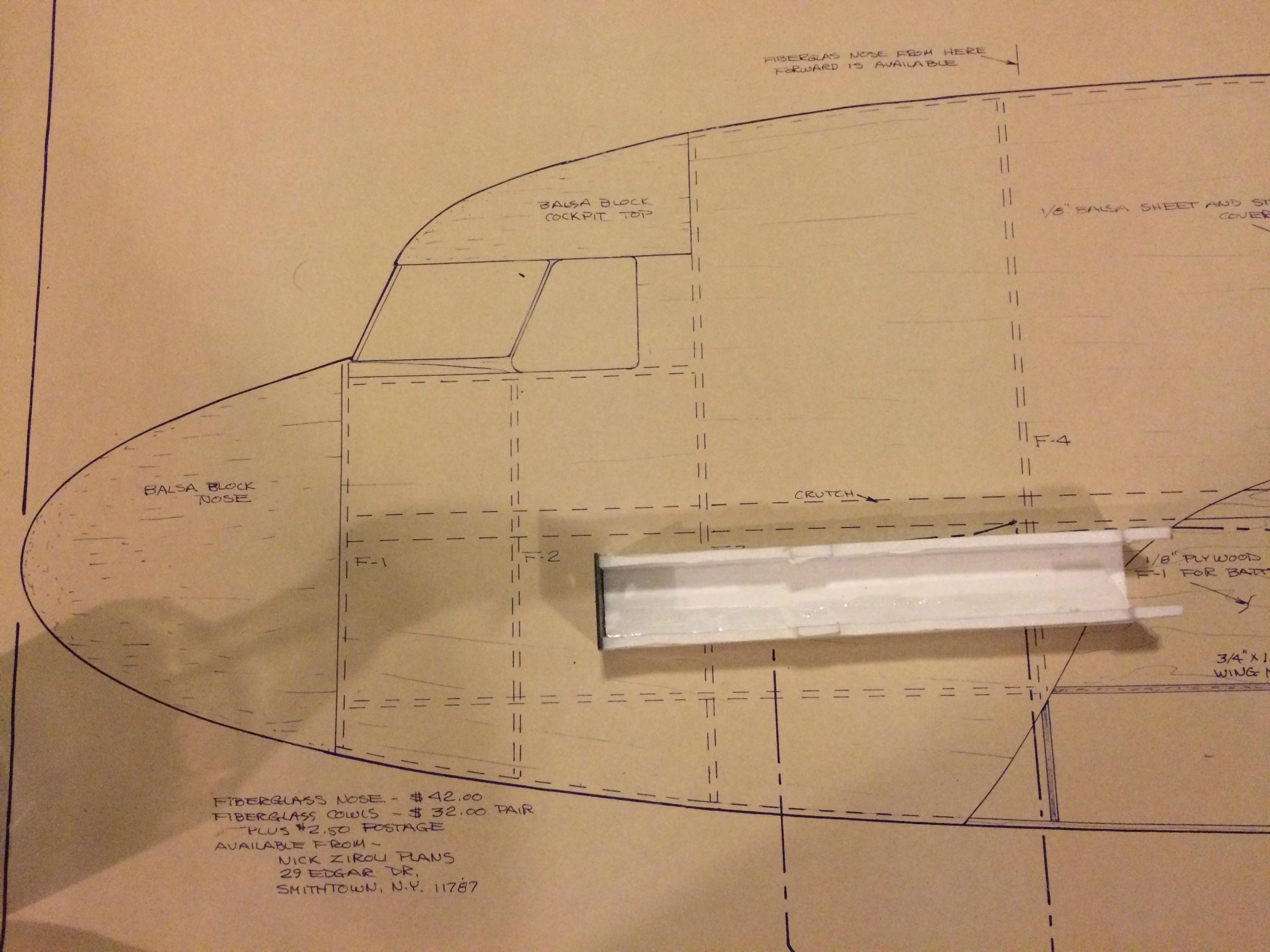

Here are some pictures to help you get a rough idea for size of this monster.

Time to start cutting!

My intention is to build this plane out of foam, using traditional balsa building techniques. I'm thinking two 5065 motors on 6S delivering 2000W each should pull this thing airborne.

Can I get this thing flying by Flight Fest? Can it survive on my roof at highway speeds? Will it hover?

We are going to answer all of these questions and more in the epic thread that is sure to follow.

Here are some pictures to help you get a rough idea for size of this monster.

Time to start cutting!

Last edited: