RyanAlexander

New member

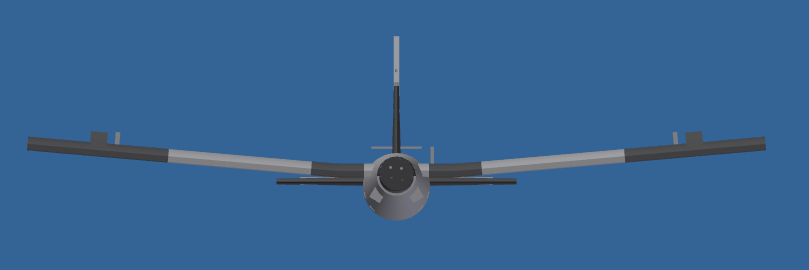

Hi all, Im new here, and ive been designing a plane and 3D Printing it. I've been working at this well over 4 months, as im on Version 14 haha (originally was a glider that slowly morphed into a full powered airplane). But im looking for outside help. The plane is just about 20 inches long, with a 33 inch wingspan. It has a 5 degree dihedral, and the normal control surfaces. For electronics, im using everything from the Power Pack B, small fixed wing aircraft with the 10 inch propeller. With previous versions, Ive made the wings out of 1/4 inch balsa shafts and ive wrapped them in plastic wrap and shrunk them. The plane would taxi great, as it was light(er) than now, with a 200 ft hallway. With previous versions, it would take off from the ground, but would always roll left or right, and crash (the hallways at my school at 10ft or so wide) But ive come to the conclusion that as my first plane, i should have ailerons. Making wings the same old way wont work, as you cant really mount servos on plastic wrap and I started to print wing segments. Each completed wing is 15 inches. Now, with the added weight, the motor cant simply pull up the weight. As a test, i held the plane vertically and put full throttle, and it came clear that it was too heavy. At the moment of this post, I have (hopefully) a lighter wing segment printing, as the infill density has been decreased dramatically. If there is nothing that can be done about the weight of the plane, what motor and esc can i upgrade to? As being new to this hobby, i know very little about matching ESC's, Motors, and batteries. The electronics im using are all in the Power Pack B. I know that the ailerons are on the smaller side, and in the future I will make them bigger, but Im more concerned about getting off the ground that anything else haha

Any help or input would be amazing!

Any help or input would be amazing!