I was looking for an easier option to cut the planes of the foarmboards and I came accross this point. I guess I am just too lazy of looking though all the 129 pages in the hope of finding the list of materials that I would require to build one of these. Any suggestion where I should look into it?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting foam sheets... with a needle!

- Thread starter dkj4linux

- Start date

dkj4linux

Elite member

I was looking for an easier option to cut the planes of the foarmboards and I came accross this point. I guess I am just too lazy of looking though all the 129 pages in the hope of finding the list of materials that I would require to build one of these. Any suggestion where I should look into it?

No list of materials. It's strictly DIY and the idea is to use what you have on hand and/or can easily get... wood, metal, plastic, etc. Automated foam-cutting is indeed for "lazy" people... but some work and study is generally required to actually build and use a needle-cutter.

That said, there are a couple of 3d-printed versions of the needle cutter out on Thingiverse which might spell things out enough to satisfy your list of materials need. One of the most popular, and one I can highly recommend, is jhitesma's Improved Needle Cutter.

If you'll tell us a little about yourself, your capabilities, and your CNC foam-cutting plans, we'll do our best to help you build your own.

And welcome to the party. Should you decide you want to pursue it, just let us know.

-- David

I am pretty new to the hobby. So far I have built two airplanes from foamboards and I've printed them cut the prints out pined them to the foamboard, traced them then cut the foam board out. However this process took me about 3-5 days until I had everything cut out and was ready to glue the parts together. However cutting things manually does not makes sure that the cuts are straight and square therefore from time to time things get out of alignment. Like the ft spitfire had a tendency to roll(not sure if that was the reason for it). I was thinking to build a mpcnc and put a needle cutter on it. That should make the cutting process much faster and hopefully also fix the not square cuts issue. However I am living in eastern europe therefore not sure yet if I can get most of the parts from local shops. Fortunately I can 3d prints the parts pretty cheap as I do not own a 3D printer yet.

dkj4linux

Elite member

Zozo,I am pretty new to the hobby. So far I have built two airplanes from foamboards and I've printed them cut the prints out pined them to the foamboard, traced them then cut the foam board out. However this process took me about 3-5 days until I had everything cut out and was ready to glue the parts together. However cutting things manually does not makes sure that the cuts are straight and square therefore from time to time things get out of alignment. Like the ft spitfire had a tendency to roll(not sure if that was the reason for it). I was thinking to build a mpcnc and put a needle cutter on it. That should make the cutting process much faster and hopefully also fix the not square cuts issue. However I am living in eastern europe therefore not sure yet if I can get most of the parts from local shops. Fortunately I can 3d prints the parts pretty cheap as I do not own a 3D printer yet.

I quickly tired of hand-cutting planes... and, since I was already into CNC, the basic needle-cutter idea rapidly took shape.

MPCNC and the needle cutter are a great fit... I've built several of them. I also suggest you actively seek help over in the V1Engineering forum... there are many European MPCNC users and I suspect you'll get all the help you need to get the proper parts identified and ordered.

Good luck!

-- David

Keno

Well-known member

Ah, I have my MPCNC running and I should have built one a long time back. I am not using a needle cutter yet but I am working one. At present I am using a Dremel tool with a 0.8MM milling bit and pleased with its smooth cuts. The learning curve has proven to be well worth time spent. Thanks to you and others posts as they have contained a wealth of info. A lot of time spent on YouTube also.

David, (or anyone else who wants to chime in)

Couple of questions after doing much reading, both on this thread, and V1 Engineering, but I am looking for opinions,

1. When considering a CNC, is it best to build one to do all tools, or specific machines for specific jobs. I mean if a "foamripper" is my primary goal, but having a spindle is something for the future, are there other things to consider besides the time involved in configuration, and adjustments needed when switching the "tool"? Or is it easier than I think, unless dealing with a laser, to get things dial in. (Or am I wrong about the laser as well, and it's not as hard period.)

2. It appears foam rippers and other "light duty" things (to me) are using the "low rider" style more and more, and less of the traditional X, Y, Z-axis machine with square box like rails, instead of wheels for one of the axis. Again, are there things to consider, other than workspace needed to consider between the two? I believe I'm correct in thinking that things that don't touch the material, or touch lightly the material, don't need the old style, unless the tool is heavy. But I'm error checking my thought process here. Or have I not payed attention to detail, and the low rider style, can have, or does have another wheel on the underside to eliminate lift?

I was planing to do the old style, but here lately with more photos and pictures presented, as I neared the more recent posts, and finished reading this thread, everything I thought I was going to do/build, is now under scrutiny.

Thanks in advance,

Steve

Couple of questions after doing much reading, both on this thread, and V1 Engineering, but I am looking for opinions,

1. When considering a CNC, is it best to build one to do all tools, or specific machines for specific jobs. I mean if a "foamripper" is my primary goal, but having a spindle is something for the future, are there other things to consider besides the time involved in configuration, and adjustments needed when switching the "tool"? Or is it easier than I think, unless dealing with a laser, to get things dial in. (Or am I wrong about the laser as well, and it's not as hard period.)

2. It appears foam rippers and other "light duty" things (to me) are using the "low rider" style more and more, and less of the traditional X, Y, Z-axis machine with square box like rails, instead of wheels for one of the axis. Again, are there things to consider, other than workspace needed to consider between the two? I believe I'm correct in thinking that things that don't touch the material, or touch lightly the material, don't need the old style, unless the tool is heavy. But I'm error checking my thought process here. Or have I not payed attention to detail, and the low rider style, can have, or does have another wheel on the underside to eliminate lift?

I was planing to do the old style, but here lately with more photos and pictures presented, as I neared the more recent posts, and finished reading this thread, everything I thought I was going to do/build, is now under scrutiny.

Thanks in advance,

Steve

dkj4linux

Elite member

Welcome, Steve. Good questions...

I personally think it best to build a machine for a primary/specific tool/task... and accept the fact that it's suitability to other tasks will be limited. If tasks not suitable are eventually planned I'd think in terms of building a separate machine.

In general... smaller footprint machines can be more rigid and heavier-duty ... larger footprint machines are less rigid and lighter duty.

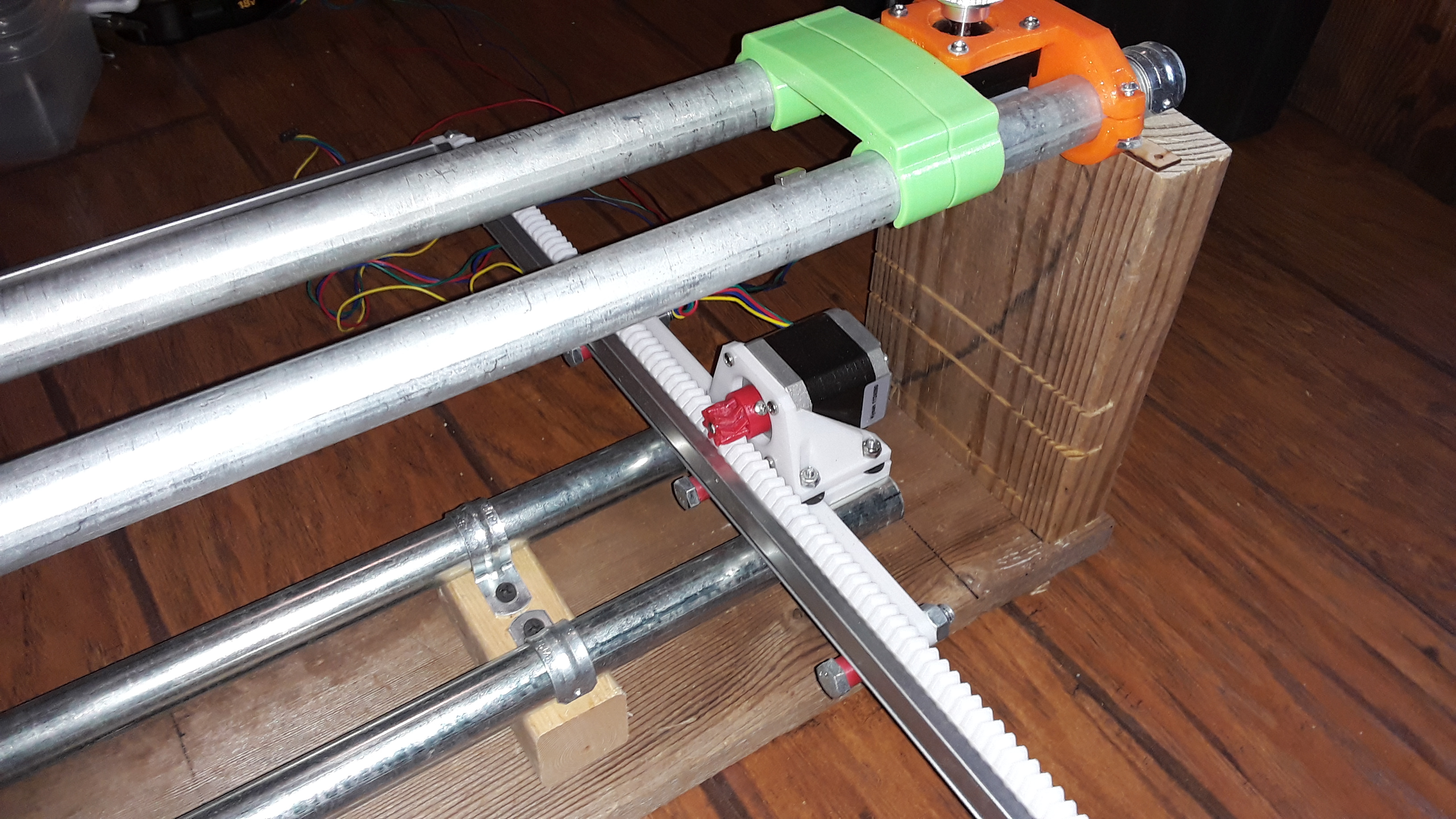

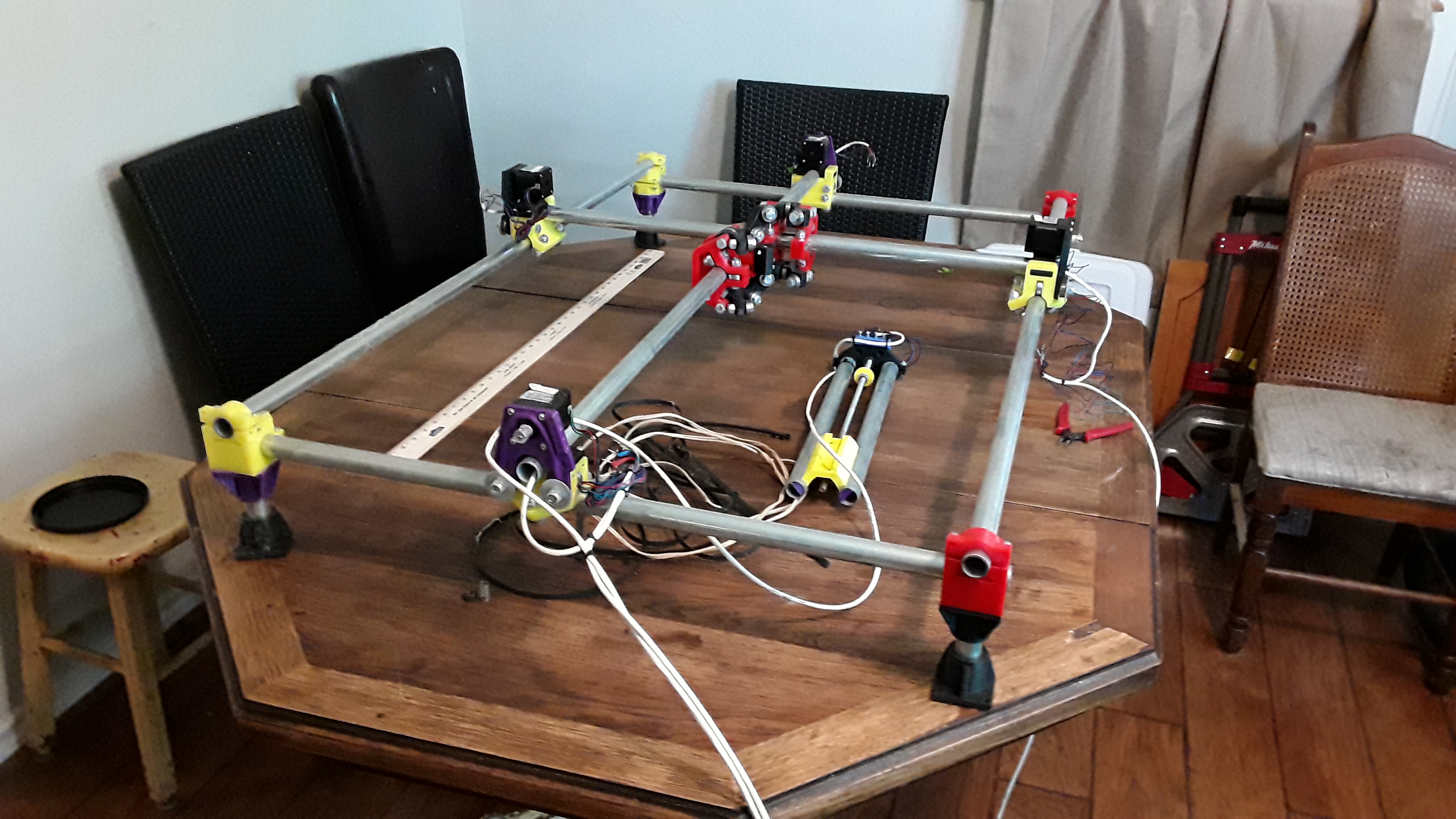

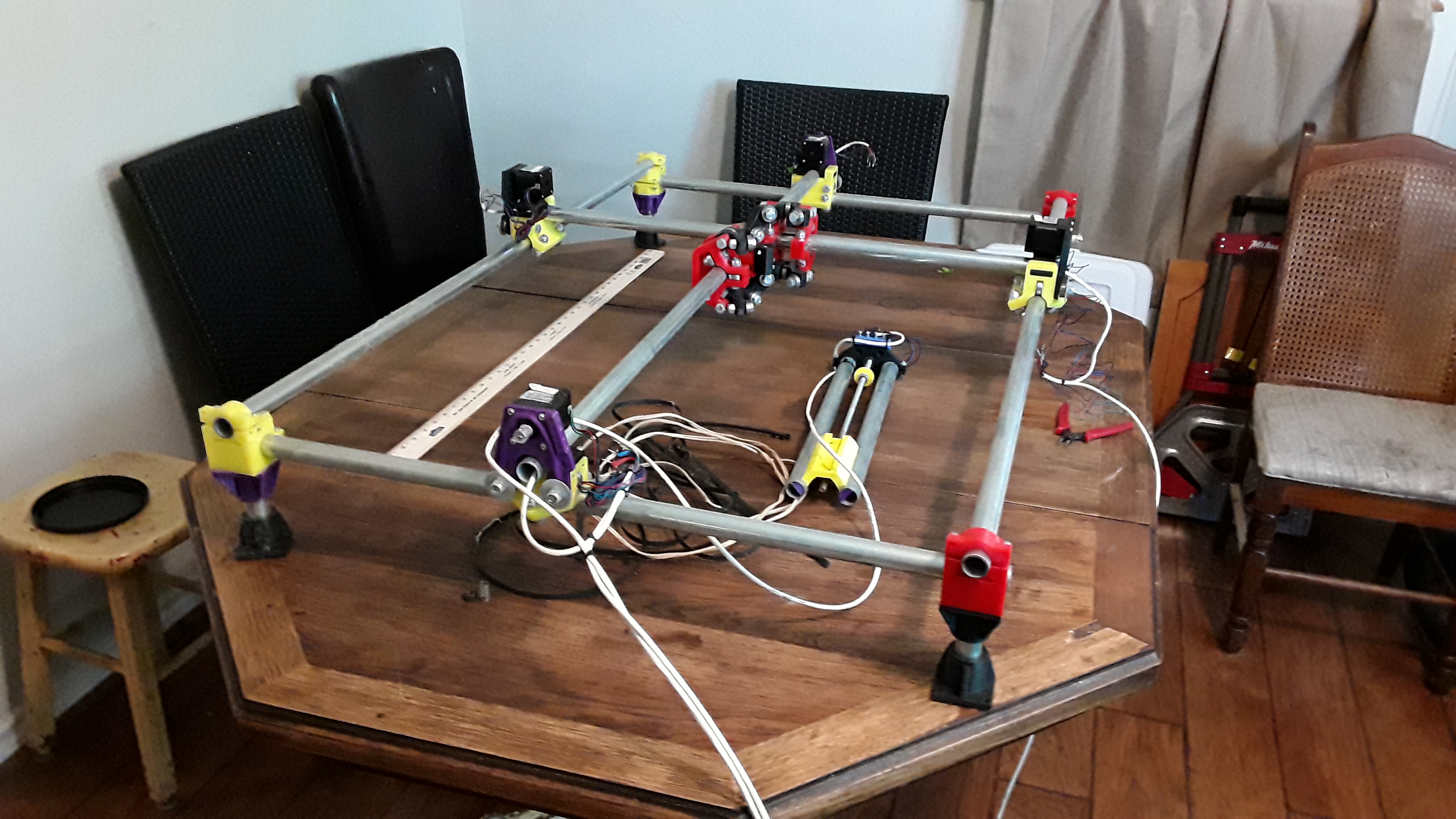

I've built several larger MPCNC's (4' x 4' and 4' x 3') for needle-cutting foam. They worked fine for that task... and were also suitable for pen/marker, drag-knife, and laser duty; i.e. light-duty use. These machines were rather bulky (taking up a lot of shop space) and this was also before the LowRider machine had come on the scene.

I've also built several smaller foot-print MPCNC's (2' x 2') for light-milling with a Dewalt palm router over a limited work-area. Certainly capable of lighter-duty use as well... the limited work area will then most likely be the greatest restriction.

The original LowRider was a heavier duty machine than MPCNC... carrying a larger router and capable of handling full-sheets of plywood. It was far more rigid than MPCNC and covered a far-larger work-area. Other tasks/tools are possible, or course, but the tool mount plate's proximity to the material surface makes it somewhat more difficult to align and see what's going on with the tool's business end.

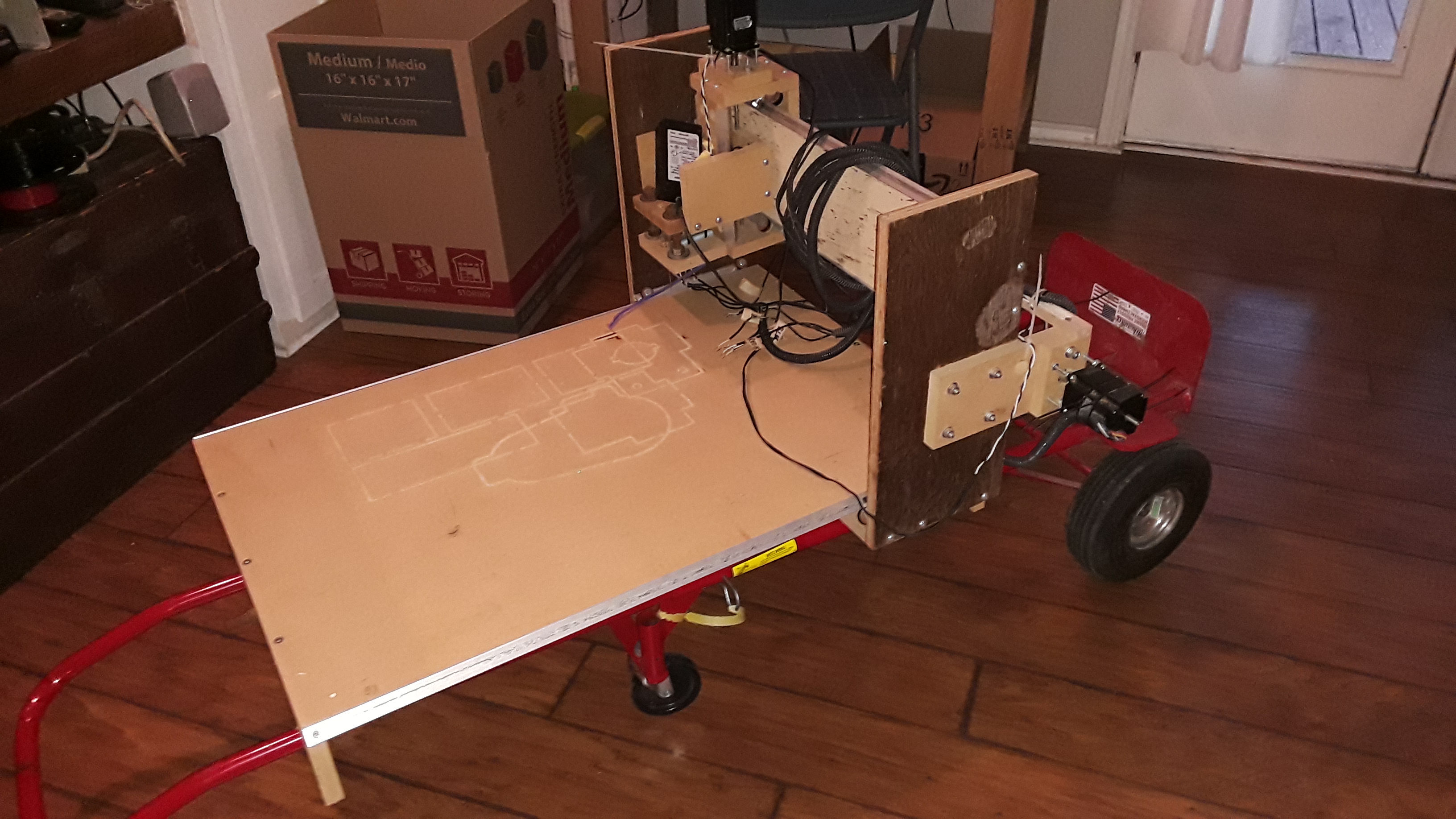

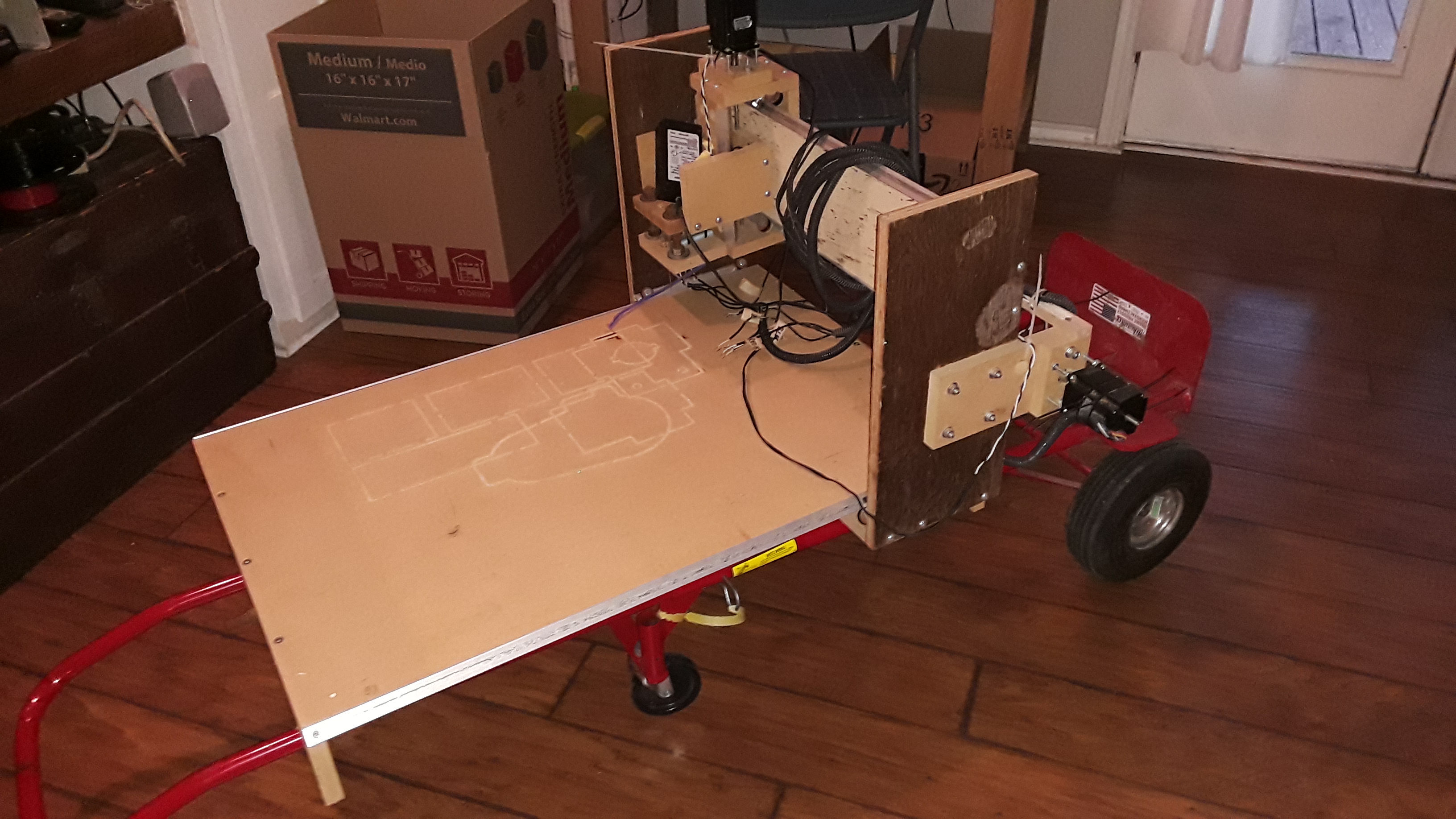

Then Moebeast came up with his LowRider-inspired Foam Ripper... a simpler, lighter, cheaper machine, specifically designed to cut foam, that is also somewhat portable. This is the machine I eventually built and adapted to the uses i've documented in this thread and elsewhere. This machine more resembles the moving, overhead gantry style machine I started with. It's actually my favorite machine for lighter-duty tasks as, for off-duty tasks, the gantry can be moved to one end and a generous portion of the work surface made available for other tasks; i.e. something not possible with the MPCNC.

I hope this addressed your questions. If foam-cutting was my primary goal, I'd be thinking FoamRipper. If making furniture, go with LowRider. If versatility, go with MPCNC... smaller foot-print for heavier duty tasks and larger footprint for light-duty tasks only. Also, given the differing and sometimes conflicting requirements, I'd recommend separate machines to address a range of tasks rather than trying to build one multi-purpose, do-all machine.

-- David

I personally think it best to build a machine for a primary/specific tool/task... and accept the fact that it's suitability to other tasks will be limited. If tasks not suitable are eventually planned I'd think in terms of building a separate machine.

In general... smaller footprint machines can be more rigid and heavier-duty ... larger footprint machines are less rigid and lighter duty.

I've built several larger MPCNC's (4' x 4' and 4' x 3') for needle-cutting foam. They worked fine for that task... and were also suitable for pen/marker, drag-knife, and laser duty; i.e. light-duty use. These machines were rather bulky (taking up a lot of shop space) and this was also before the LowRider machine had come on the scene.

I've also built several smaller foot-print MPCNC's (2' x 2') for light-milling with a Dewalt palm router over a limited work-area. Certainly capable of lighter-duty use as well... the limited work area will then most likely be the greatest restriction.

The original LowRider was a heavier duty machine than MPCNC... carrying a larger router and capable of handling full-sheets of plywood. It was far more rigid than MPCNC and covered a far-larger work-area. Other tasks/tools are possible, or course, but the tool mount plate's proximity to the material surface makes it somewhat more difficult to align and see what's going on with the tool's business end.

Then Moebeast came up with his LowRider-inspired Foam Ripper... a simpler, lighter, cheaper machine, specifically designed to cut foam, that is also somewhat portable. This is the machine I eventually built and adapted to the uses i've documented in this thread and elsewhere. This machine more resembles the moving, overhead gantry style machine I started with. It's actually my favorite machine for lighter-duty tasks as, for off-duty tasks, the gantry can be moved to one end and a generous portion of the work surface made available for other tasks; i.e. something not possible with the MPCNC.

I hope this addressed your questions. If foam-cutting was my primary goal, I'd be thinking FoamRipper. If making furniture, go with LowRider. If versatility, go with MPCNC... smaller foot-print for heavier duty tasks and larger footprint for light-duty tasks only. Also, given the differing and sometimes conflicting requirements, I'd recommend separate machines to address a range of tasks rather than trying to build one multi-purpose, do-all machine.

-- David

Last edited:

dkj4linux

Elite member

Hey, Streff... welcome to the party.

The presser foot idea has certainly been brought up before and several folks are using it IIRC. Another hold-down method that a number of us are using is a vacuum pad... consisting of three sheets of DTFB -- two slotted sheets with slots at right angles and a top sheet, doubling as spoilboard, with holes at all the slot intersections. Workpiece goes on top, of course, and the entire stack sucks down to both the machine work surface below and the workpiece on top. Works well as the needle kerf is quite narrow and suction is usually still maintained even after cutting is complete.

Please let us know how we can help.

-- David

The presser foot idea has certainly been brought up before and several folks are using it IIRC. Another hold-down method that a number of us are using is a vacuum pad... consisting of three sheets of DTFB -- two slotted sheets with slots at right angles and a top sheet, doubling as spoilboard, with holes at all the slot intersections. Workpiece goes on top, of course, and the entire stack sucks down to both the machine work surface below and the workpiece on top. Works well as the needle kerf is quite narrow and suction is usually still maintained even after cutting is complete.

Please let us know how we can help.

-- David

Headbang

Master member

The vacuum pad is the best solution I have used. I still put pins in 2 corners just in case something goes wrong. It is cheap, you can use your cutter to make it, can replace it whenever needed for $3.75. I have cut over 100 sheets without needing to replace, also have used it for ply with a router.Been reading through this thread as I have been using a router to cut depron and this could be a useful conversion.

Just a thought how about fitting a sprung shoe to the needle cutter similar to a sewing machine to hold the board down?

Btw over 100 sheets with old style wire crank, only replaced my needle once. I have everything to build an upgrade, just no need.

dkj4linux

Elite member

Noiseless, no. But you can get one of those inexpensive router speed controls and get adequate vacuum at the lowest, quietest setting. Here's a job setup video I did (turn down the sound)... everything shown can be done in less than a minute but I was also trying to demonstrate the vacuum noise from speed control MIN to MAX, setting the needle cutter speed with the tach, and adjusting/zeroing the Z height...

-- David

-- David

Last edited:

dkj4linux

Elite member

Since everything is moving very slowly here now, I'll take this opportunity to give a status update...

Something I never thought I'd do, I'm selling my place and moving to the San Antonio area. I'd originally intended to spend the remainder of my days here on my family's plot of land in East Texas and, for now, I'm in reasonably good health and sound mind and can live alone and pretty independently. But, at 73 years old and with a family history of heart/dementia/Alzheimer's issues, I can't realistically expect that to continue for too many more years. It is inevitable that I'll eventually need the increasing help/support of my kids... but jobs and family will never allow any of them to come and settle in rural East Texas, so I need to go to them. And, as It happens, there's a perfect place available, right next door to my loving daughter and her family, that will allow me all the independence I still want/need now... but without the burden of owning/maintaining a place that's gotten to be too much for me to handle alone. So NOW seems the perfect time to make the move and "down-size"... and not leave the burden of dealing with this place, and a lifetime's accumulation of "junk", after I'm gone.

Thankfully, I'm fortunate enough to be in a position to "play" more than I "work" in my retirement... but, right now, I'm fighting a losing battle trying to "organize" [some of] my junk in preparation for my upcoming move/life-change. This is WORK! I do just a little at a time -- until I'm sweating profusely and my heart is pounding and I'm huffing/puffing heavily -- and then have to go sit down. What a mess!

Normally, messing with my machines is PLAY... doing to them what I want, when I want to do it. But, to stay OT (too late!) and with time starting to run short, I've dismantled two of my earlier ***NEEDLE-CUTTING*** machines (a 4'x3' MPCNC and a BuildYourCNC-inspired machine) so that I can pack the hardware and electrics. I can't stand the thought of just trashing them...

So, that's the latest with me... more WORK at the moment than PLAY. I am still online during my rest breaks, however, and keeping up with the several forums in which I participate, so I'll chime in if/when the spirit moves.

Later.

-- David

Something I never thought I'd do, I'm selling my place and moving to the San Antonio area. I'd originally intended to spend the remainder of my days here on my family's plot of land in East Texas and, for now, I'm in reasonably good health and sound mind and can live alone and pretty independently. But, at 73 years old and with a family history of heart/dementia/Alzheimer's issues, I can't realistically expect that to continue for too many more years. It is inevitable that I'll eventually need the increasing help/support of my kids... but jobs and family will never allow any of them to come and settle in rural East Texas, so I need to go to them. And, as It happens, there's a perfect place available, right next door to my loving daughter and her family, that will allow me all the independence I still want/need now... but without the burden of owning/maintaining a place that's gotten to be too much for me to handle alone. So NOW seems the perfect time to make the move and "down-size"... and not leave the burden of dealing with this place, and a lifetime's accumulation of "junk", after I'm gone.

Thankfully, I'm fortunate enough to be in a position to "play" more than I "work" in my retirement... but, right now, I'm fighting a losing battle trying to "organize" [some of] my junk in preparation for my upcoming move/life-change. This is WORK! I do just a little at a time -- until I'm sweating profusely and my heart is pounding and I'm huffing/puffing heavily -- and then have to go sit down. What a mess!

Normally, messing with my machines is PLAY... doing to them what I want, when I want to do it. But, to stay OT (too late!) and with time starting to run short, I've dismantled two of my earlier ***NEEDLE-CUTTING*** machines (a 4'x3' MPCNC and a BuildYourCNC-inspired machine) so that I can pack the hardware and electrics. I can't stand the thought of just trashing them...

So, that's the latest with me... more WORK at the moment than PLAY. I am still online during my rest breaks, however, and keeping up with the several forums in which I participate, so I'll chime in if/when the spirit moves.

Later.

-- David

Getting ready for FliteFest. Still can't bring myself to go back to the needle cutter after trying these .8mm bits on the spindle. Cutting at 40mm/sec and getting super crisp edges. The vacuum table is working amazingly, I get perfect suction down to even 30% power. I did have to move it from my basement to the guest room after some flooding and the following crew adding a french drain last week, but aside from my wife's complaints, no problems!

View attachment 134886

View attachment 134887 View attachment 134888

Verris

Can you provide the details for the bit you are using, (is that a DW660?) I tried one in the past but had lots of issues with the foam building up on it that it stopped cutting.

I have used a needle cutter for quite awhile, but am suddenly having significant needle failures. Not sure what changed, but I am looking for alternatives.

Last edited:

So....

I've been mulling over this concept for quite some time, Monitoring both V1-engineering forum and here. I've finally decided to jump in head first, and build a machine. Dave, thanks for answering my questions in the past. Although I feel more at home in the FT forum, I know V1 forum is also full of helpful people as well. I'm going to apologize in advance, for my question, as I feel as much time as I have spent in the forums I should know the answers already, and yet I'm only looking for confirmation that I'm on the right track, and I didn't want to make a bad name for myself in the V1 Engineering forum.

My needs are building a "foam ripper", to be able to handle 20x30 sheets. And yet I'm seeing value (from the forums) at not building the first machine this large to handle this right out of the gate. I would like to some day be milling material (wood, MDPE, others). Dual end stops seem to be highly recommended, but not for the beginner. So I wanted to make sure I had the parts, and capability, but don't plan on this being used on the initial build. Although with my anal tendencies, would like SS rails, I believe I'm starting with conduit. So currently my shopping cart appears like this:

MPCNC Printed Parts - 23.5mm -Burly

Mount_Option: Dewalt DW660 Mount

Mount_Nut_Size: #6-32

GT2 6mm Belt GT2 6mm Belt

Mostly Printed CNC Parts Bundle - 6A / RAMBo Dual Firmware & Wire kit Mostly Printed CNC Parts Bundle

6A / RAMBo Dual Firmware & Wire kit

I have everything needed (except conduit, and maybe some nuts and bolts) as long as I have a way to have a friend print out some of the missing pieces on a 3D printer, correct? Or is it desired to add the LCD screen, to print from SD, instead of host computer?

Sorry to ask this here, I know the V1 forum is probably the more accurate place. Again, just feel more at home here.

I've been mulling over this concept for quite some time, Monitoring both V1-engineering forum and here. I've finally decided to jump in head first, and build a machine. Dave, thanks for answering my questions in the past. Although I feel more at home in the FT forum, I know V1 forum is also full of helpful people as well. I'm going to apologize in advance, for my question, as I feel as much time as I have spent in the forums I should know the answers already, and yet I'm only looking for confirmation that I'm on the right track, and I didn't want to make a bad name for myself in the V1 Engineering forum.

My needs are building a "foam ripper", to be able to handle 20x30 sheets. And yet I'm seeing value (from the forums) at not building the first machine this large to handle this right out of the gate. I would like to some day be milling material (wood, MDPE, others). Dual end stops seem to be highly recommended, but not for the beginner. So I wanted to make sure I had the parts, and capability, but don't plan on this being used on the initial build. Although with my anal tendencies, would like SS rails, I believe I'm starting with conduit. So currently my shopping cart appears like this:

MPCNC Printed Parts - 23.5mm -Burly

Mount_Option: Dewalt DW660 Mount

Mount_Nut_Size: #6-32

GT2 6mm Belt GT2 6mm Belt

Mostly Printed CNC Parts Bundle - 6A / RAMBo Dual Firmware & Wire kit Mostly Printed CNC Parts Bundle

6A / RAMBo Dual Firmware & Wire kit

I have everything needed (except conduit, and maybe some nuts and bolts) as long as I have a way to have a friend print out some of the missing pieces on a 3D printer, correct? Or is it desired to add the LCD screen, to print from SD, instead of host computer?

Sorry to ask this here, I know the V1 forum is probably the more accurate place. Again, just feel more at home here.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 8

- Views

- 1K

- Replies

- 6

- Views

- 734

- Replies

- 0

- Views

- 305