Minton

New member

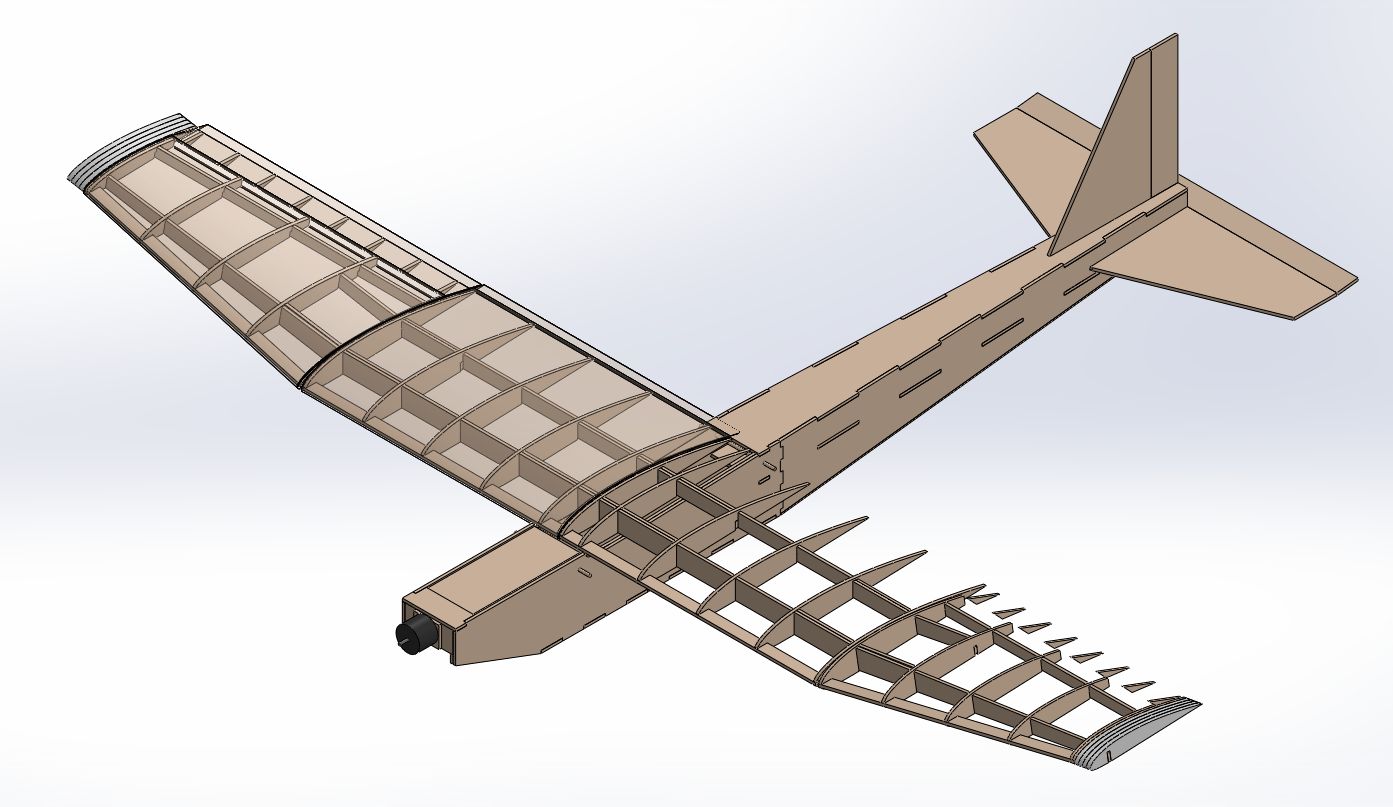

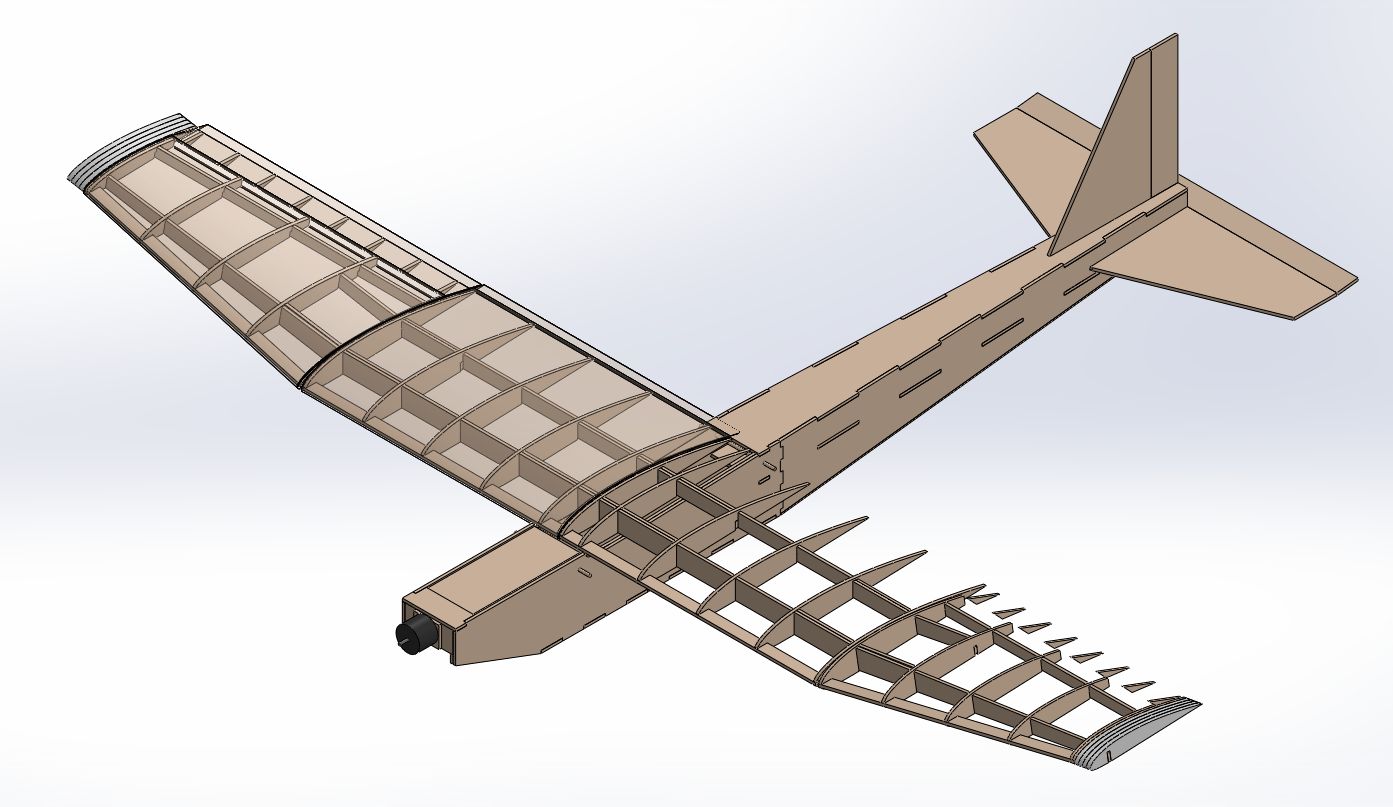

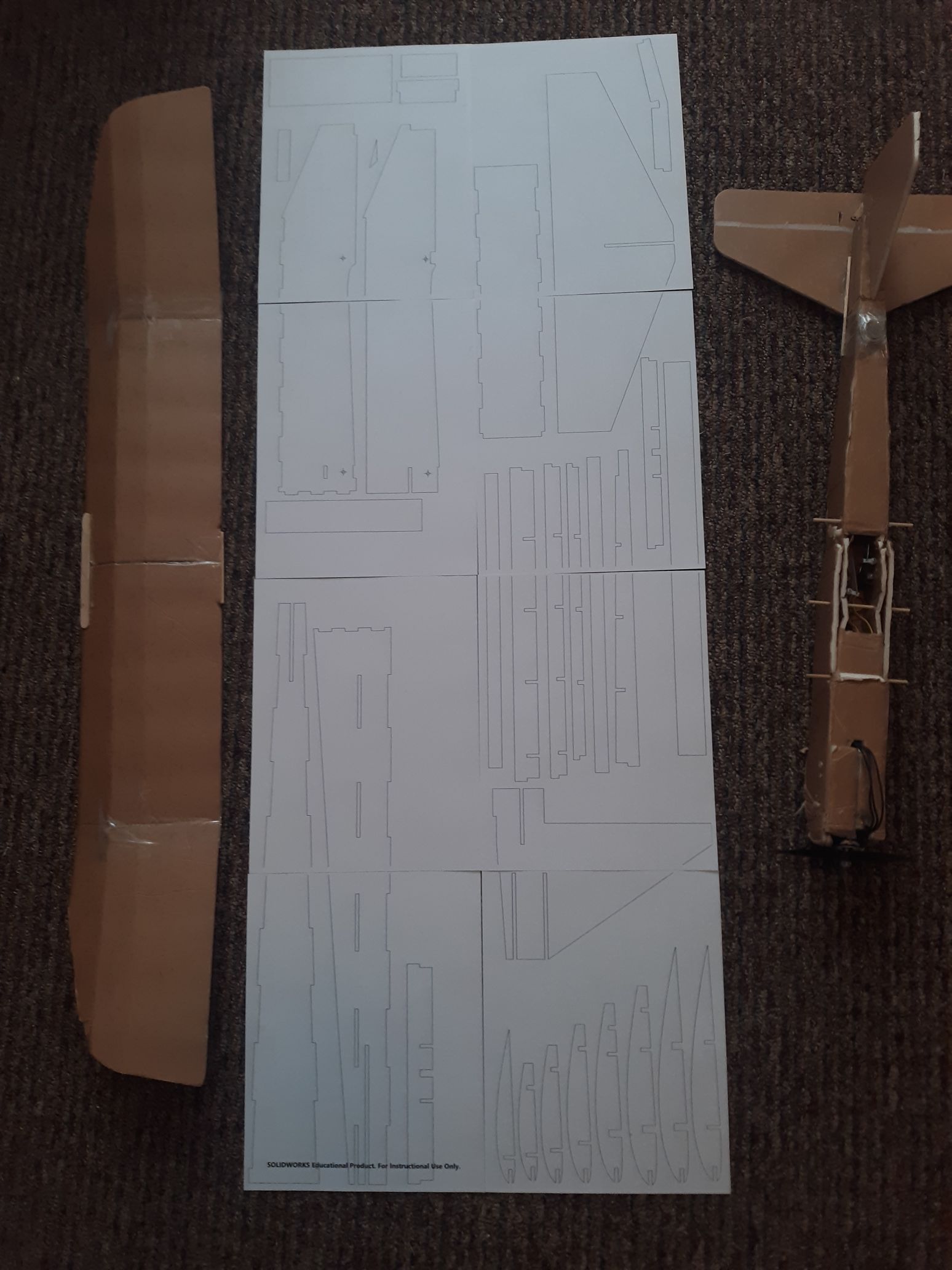

About a month and a half ago I ordered the FT Trainer kit along with everything else I needed to get started with RC aircraft. I had such a blast with it that I decided to try and design and build my very own plane. I'm new to flying planes but had previously modeled an RC plane for my school's Design Build Fly club, so I already had lots of experience with CAD software and the structural aspect of designing planes.

However, we ran out of time and never got to fly that one so I never really found out if I was capable of designing an airworthy plane. Compared to that 8-foot span, 20-pound monster, my little 4-foot trainer was pretty easy to design.

For the previous plane, I didn't have any part in the aerodynamic aspects of the design, so doing that for my own plane was a bit intimidating. I basically just designed the wing first, then figured out what the proportions of everything else had to be to match.

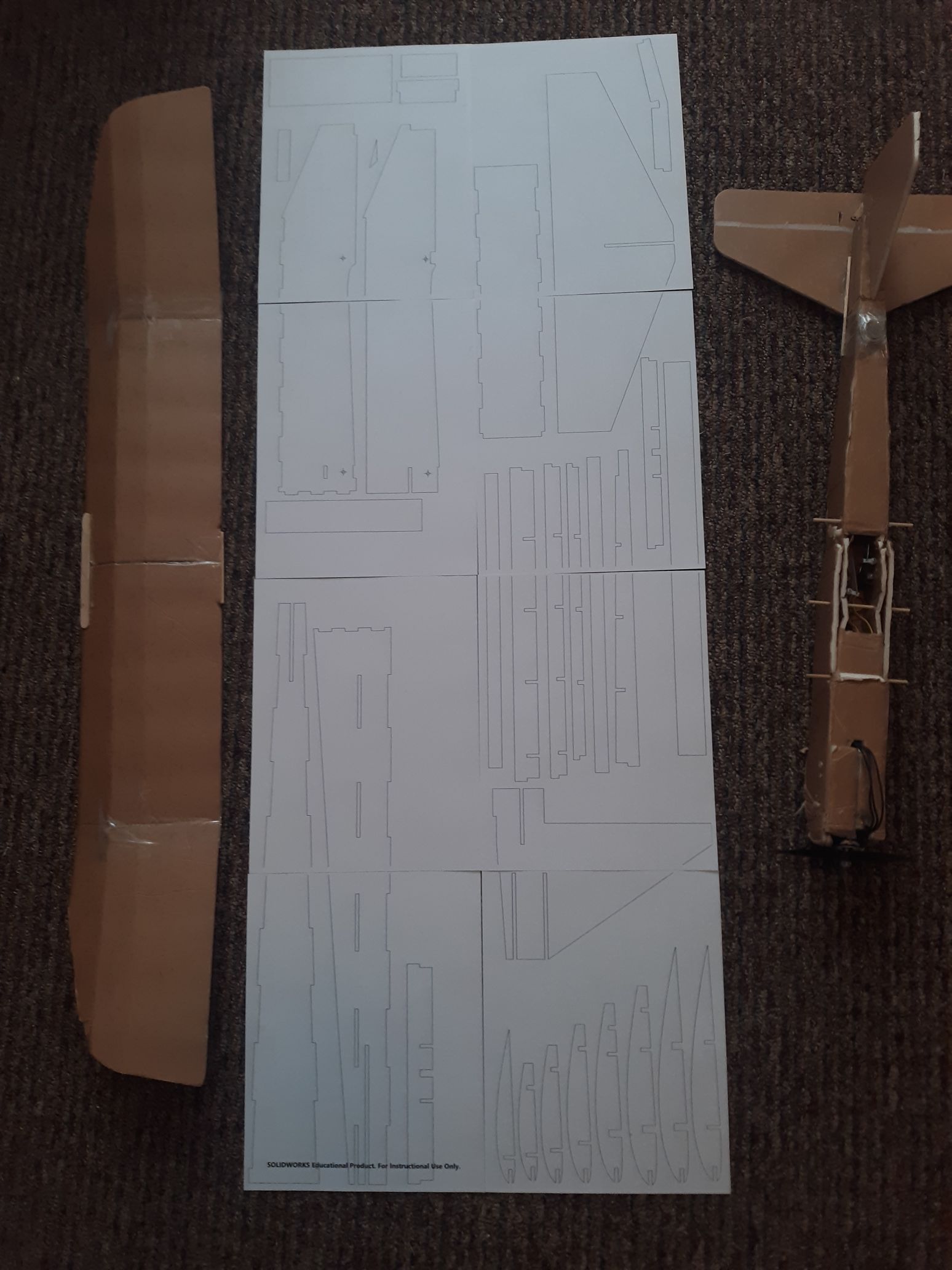

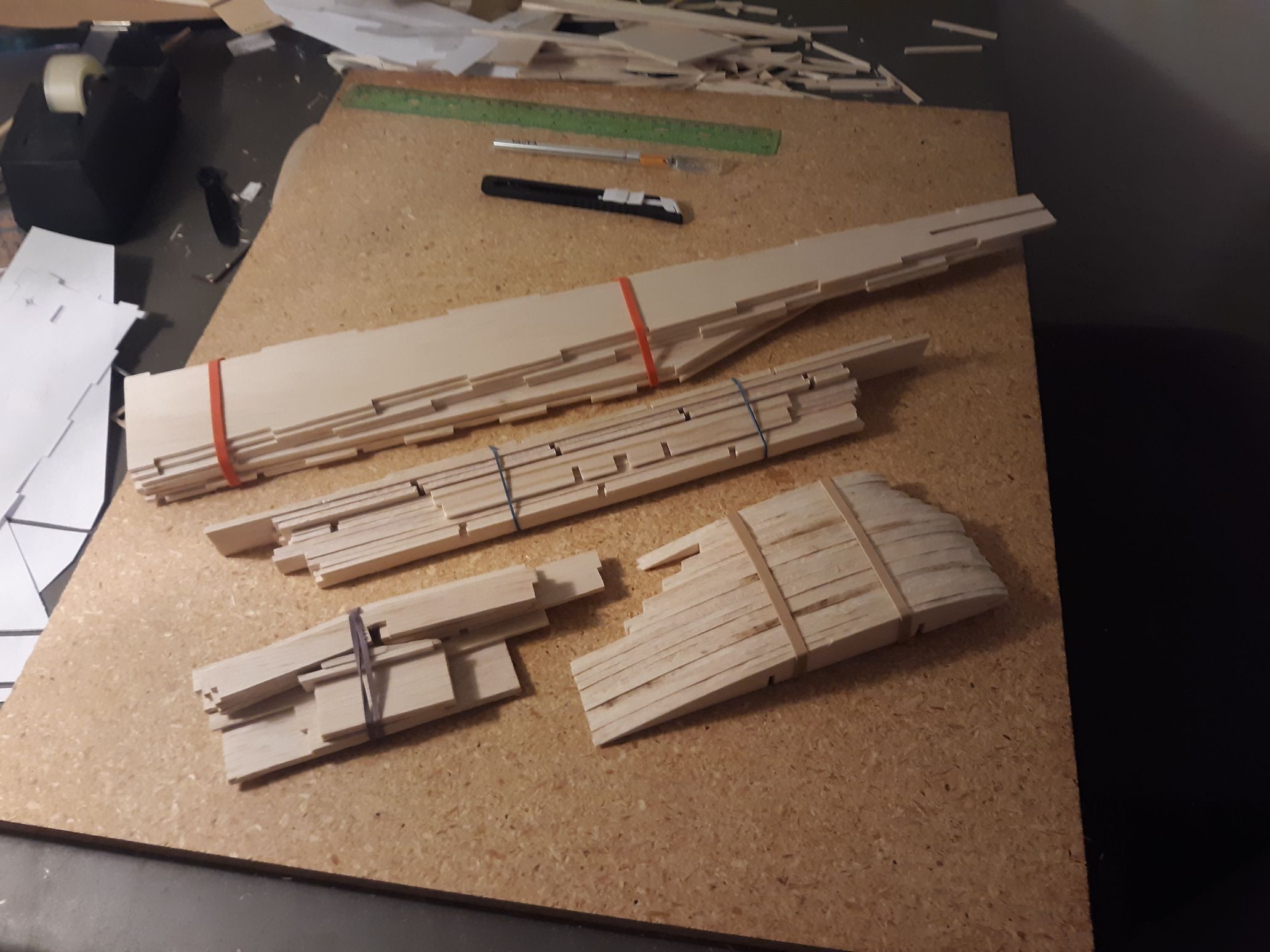

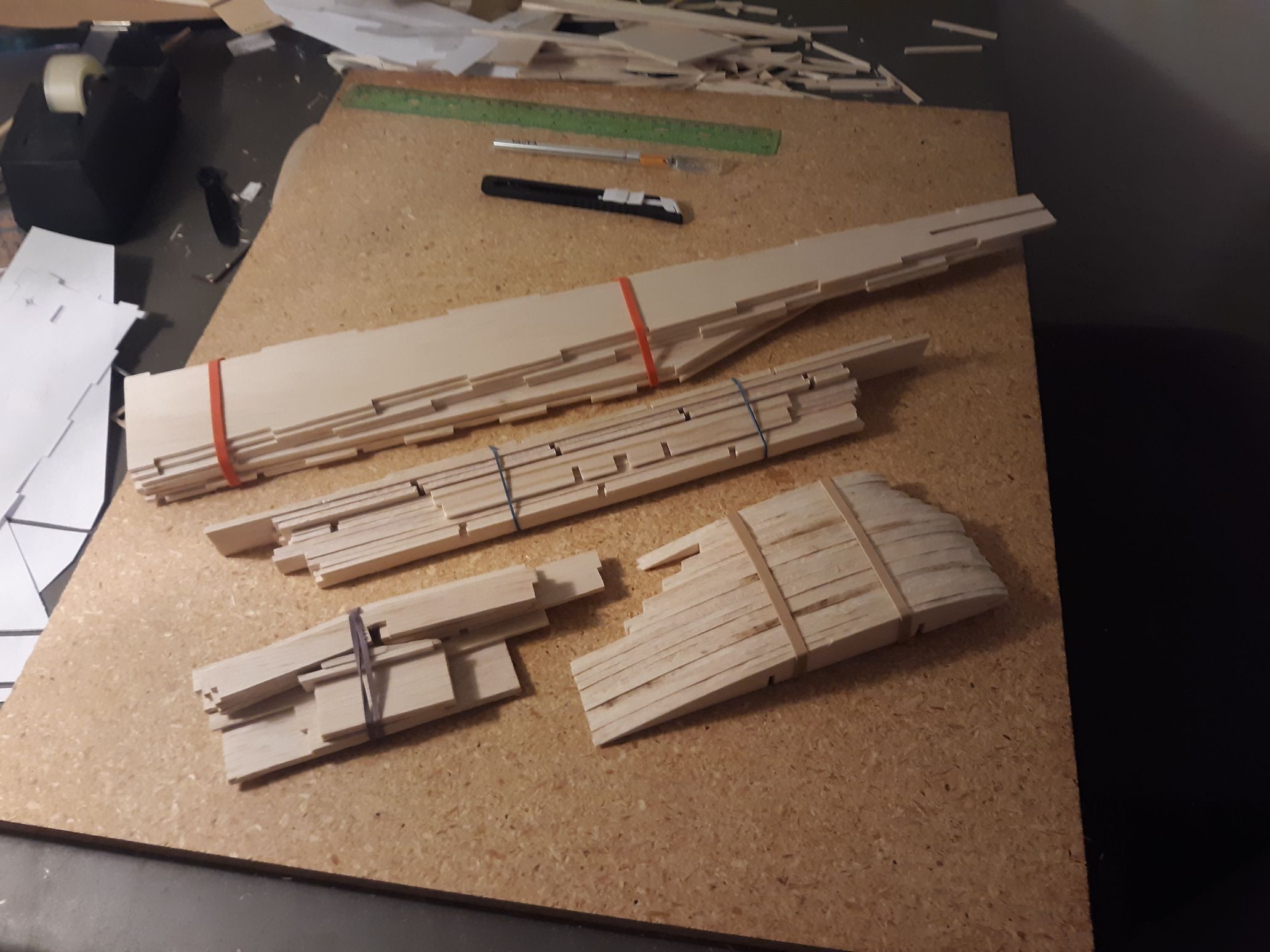

Since I don't own a laser cutter, I decided to hand cut all of the parts out of balsa with an Exacto knife. To ensure that I cut them accurately, I first made paper templates of all the parts and then used them as a guide when cutting the balsa. In case you were wondering, this process took about 2 weeks and was extremely tedious. I would not recommend doing this unless you have no other choice.

To my surprise, the parts came out rather nicely and required minimal sanding to fit together. The biggest issue that I encountered during this process was that I discovered part way through that the 4"x36" sheets of balsa that I bought from Hobby Lobby were rather inconsistent. Some were extremely dense and felt almost like plywood, while others felt more like foam. Knowing this, I tried to cut any load-bearing parts from the harder balsa, and use the softer stuff for wing ribs and whatnot.

After all the parts were made, the plane came together in about a week. I decided to use 1/16" balsa sheets for the wing surface instead of Monokote because I don't have an iron and thought it would be easier. It turned out to be rather tedious but it gave the wing an incredible amount of strength. The wingtips are rather delicate due to how I designed the dihedral, but the straight part of the wing is so sturdy that you could probably beat somebody to death with it.

Unfortunately, I discovered that the CG was very far back, nearly at the trailing edge of the wing. I could have avoided this by checking the CG in Solidworks before finalizing the design but as you'll come to see, I'm a bit impatient when it comes to double-checking things. I tried to counteract this by adding about a half pound of random stuff into the nose, which was a lot considering that the plane only weighed about 1.5 pounds prior. The CG moved to the front half of the wing which I deemed to be good enough, thinking that even if it was a little far back I could counteract it easily enough. As it turns out, it wasn't good enough. The plane took off and immediately nosed up. I tried to push it back down which caused it to start turning. At that point, I decided to try and land it as quickly as possible. I throttled down and tried to set it down but it was flying too slow and it rolled over and nosedived into the ground from about 4 feet up.

Luckily, the only things that were damaged were the left wingtip and the nose. The ribs in the wingtip were all completely destroyed, but all the spars and the root of the wing were completely fine. All the panels on the nose were gone, and the nose itself was a bit mangled, but nothing too serious. A week later, I had everything repaired and ready to fly again.

This time I took the extra 2 minutes to google where the CG should be, and then mark it on the wing. I ended up having to move the wing back about 2.5 inches to get the CG in the right place, but that's just the price for not planning thoroughly.

For the first flight, I attempted to fly on the golf course that is right behind my house. It's quite long but a bit narrow and has trees and houses lining either side. Following the pattern of doing the bare minimum, I found a nice big park on google maps to fly at for my second flight. However, once I showed up I realized that there were power lines going over one-half of the field, and huge light poles all over the other half. I found an area that seemed big enough to fly and went for it.

This time it flew wonderfully! However, I quickly realized that it flew rather fast and I didn't really feel comfortable flying it with the space I had so I turned around and came in for a landing. Unfortunately, the grass was a bit long and the approach was a bit steep so I ended up ripping the landing gear off and destroying the bottom panel of the fuselage.

That last flight was yesterday, and I plan on repairing and flying it again but I'm going to wait until I'm back at school first. My college is located in Middle of Nowhere, California, and has a huge open area perfect for flying right next to it.

Overall, despite having about 20 seconds of total flight time between 2 test flites that both ended in crashes, I'm incredibly happy with how it came out and I certainly don't regret doing it. In the future, unless I can get my hands on a laser cutter or cnc machine, I'm definitely going to stick to foamboard because I do not have the mental strength to go through that cutting process all over again. I hope that this encourages anyone that might have been on the fence about trying to scratch build a plane to go for it. If I, someone with very little designing and flying experience, basically no power tools, and a bedroom closet for a workshop can build a working balsa plane, I'm certain that you can too. I would love to answer any and all questions that anyone has so feel free to ask away.

However, we ran out of time and never got to fly that one so I never really found out if I was capable of designing an airworthy plane. Compared to that 8-foot span, 20-pound monster, my little 4-foot trainer was pretty easy to design.

For the previous plane, I didn't have any part in the aerodynamic aspects of the design, so doing that for my own plane was a bit intimidating. I basically just designed the wing first, then figured out what the proportions of everything else had to be to match.

Since I don't own a laser cutter, I decided to hand cut all of the parts out of balsa with an Exacto knife. To ensure that I cut them accurately, I first made paper templates of all the parts and then used them as a guide when cutting the balsa. In case you were wondering, this process took about 2 weeks and was extremely tedious. I would not recommend doing this unless you have no other choice.

To my surprise, the parts came out rather nicely and required minimal sanding to fit together. The biggest issue that I encountered during this process was that I discovered part way through that the 4"x36" sheets of balsa that I bought from Hobby Lobby were rather inconsistent. Some were extremely dense and felt almost like plywood, while others felt more like foam. Knowing this, I tried to cut any load-bearing parts from the harder balsa, and use the softer stuff for wing ribs and whatnot.

After all the parts were made, the plane came together in about a week. I decided to use 1/16" balsa sheets for the wing surface instead of Monokote because I don't have an iron and thought it would be easier. It turned out to be rather tedious but it gave the wing an incredible amount of strength. The wingtips are rather delicate due to how I designed the dihedral, but the straight part of the wing is so sturdy that you could probably beat somebody to death with it.

Unfortunately, I discovered that the CG was very far back, nearly at the trailing edge of the wing. I could have avoided this by checking the CG in Solidworks before finalizing the design but as you'll come to see, I'm a bit impatient when it comes to double-checking things. I tried to counteract this by adding about a half pound of random stuff into the nose, which was a lot considering that the plane only weighed about 1.5 pounds prior. The CG moved to the front half of the wing which I deemed to be good enough, thinking that even if it was a little far back I could counteract it easily enough. As it turns out, it wasn't good enough. The plane took off and immediately nosed up. I tried to push it back down which caused it to start turning. At that point, I decided to try and land it as quickly as possible. I throttled down and tried to set it down but it was flying too slow and it rolled over and nosedived into the ground from about 4 feet up.

Luckily, the only things that were damaged were the left wingtip and the nose. The ribs in the wingtip were all completely destroyed, but all the spars and the root of the wing were completely fine. All the panels on the nose were gone, and the nose itself was a bit mangled, but nothing too serious. A week later, I had everything repaired and ready to fly again.

This time I took the extra 2 minutes to google where the CG should be, and then mark it on the wing. I ended up having to move the wing back about 2.5 inches to get the CG in the right place, but that's just the price for not planning thoroughly.

For the first flight, I attempted to fly on the golf course that is right behind my house. It's quite long but a bit narrow and has trees and houses lining either side. Following the pattern of doing the bare minimum, I found a nice big park on google maps to fly at for my second flight. However, once I showed up I realized that there were power lines going over one-half of the field, and huge light poles all over the other half. I found an area that seemed big enough to fly and went for it.

This time it flew wonderfully! However, I quickly realized that it flew rather fast and I didn't really feel comfortable flying it with the space I had so I turned around and came in for a landing. Unfortunately, the grass was a bit long and the approach was a bit steep so I ended up ripping the landing gear off and destroying the bottom panel of the fuselage.

That last flight was yesterday, and I plan on repairing and flying it again but I'm going to wait until I'm back at school first. My college is located in Middle of Nowhere, California, and has a huge open area perfect for flying right next to it.

Overall, despite having about 20 seconds of total flight time between 2 test flites that both ended in crashes, I'm incredibly happy with how it came out and I certainly don't regret doing it. In the future, unless I can get my hands on a laser cutter or cnc machine, I'm definitely going to stick to foamboard because I do not have the mental strength to go through that cutting process all over again. I hope that this encourages anyone that might have been on the fence about trying to scratch build a plane to go for it. If I, someone with very little designing and flying experience, basically no power tools, and a bedroom closet for a workshop can build a working balsa plane, I'm certain that you can too. I would love to answer any and all questions that anyone has so feel free to ask away.