Things that flashed through my head through the build video:

- (has been mentioned

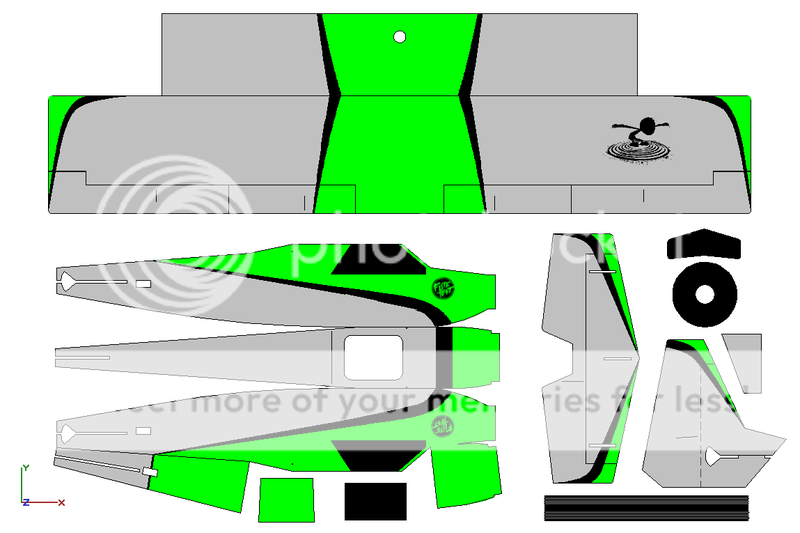

) No glue between the two wing parts?

) No glue between the two wing parts?

- Isn't that part Peter called "Top" a C-Fold?

- I migh have tried and install the landing gear thingies first to hold the gear at about 90°?

- Why did he made the small spars on the wing extra and not just part of the wing that can be folded over (had to be cut from the other side probably?)

I kinda had the same thought about the wing, but since he eliminated most of the gap in the foam by going inbetween the paper and with the box spar being glued full surface for the whole top surface of the wing I think the strength added by that one central bead of glue is pretty much negligible.

On the other hand if that bead of glue gives you peace of mind the added weight probably wouldn't matter, either.

Yep, I think that's been called a c-fold at times

I was kinda wary of the whole landing gear anyway, since it didn't seem to have much support laterally but it seemed to hold up fine in the review vid. Also,It's proably better to have the gear rip off cleanly if you hook it into something rate than ruining your fuse.

It might help during assembly, though if you hinge the foam struts onto the fuselage right after you dig out the channel in the fuselage. After that these flaps can be used to align the wire while gluing. (I think that's what you were describing...) The only disadvantage I see in that is that, at this point you will have a lot of hot glue floating around.

If there's room on the foam sheet I'd probably leave the trailing edge spacers attached to the wing as well. You would have to score cut them from the other side, though and the laser can't do that. (My good... Our robot overlords aren't without weaknesses after all... Prepare for the revolution!)