****I started this over in the alofthobbies.com forums, they are my local hobbyshop. So this is a copy paste from the discusions over their. Ill try and keep this place updated now too.

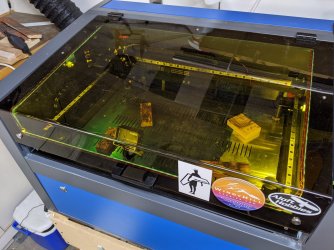

I finally cracked and ordered a Chinese laser cutter from omtechlaser.com. They are a company down in the LA area i think, they import them and make sure they are working, so you have a US based company for any problems. Its a 50w (probably 40w as most of the Chinese lasers are rated at peak and you got to keep it at 80% of that). 12x20 cutting area, same as glow forge, but has passthrough. After shipping tax it comes out about $1,300 less than a glow forge. If you have any interest in the experience let me know. Im sure at some point ill do a little video about how well/not well it goes. I made sure to get one with a Ruida controller so i can easily transition over using the same Lightburn software I'm already used to on my little 5.5 diode laser engraver.

Here's the specific model i ordered with a 10% off coupon. Being in California the shipping was free which is usually $250-300.

https://omtechlaser.com/collections/co2-cabinet-laser-engravers/products/50w-usb-5b3r-us

Starting this thread here to document the experience.

Here's some related videos if you interested:

https://www.youtube.com/c/LightBurnSoftware/videos

Made a base for the laser this weekend. The laser is 40" wide and 26x25 so it needs to be raised off the ground.

Here's some links to the additional stuff/upgrades i have ordered:

co2 rated safety goggles:

https://www.amazon.com/gp/product/B078HZZVZW/?tag=lstir-20

just a good idea. Plus i don't know that the viewing window is rated to stop any power from the laser.

Analog ammeter:

https://www.amazon.com/gp/product/B07F26M6M2/?tag=lstir-20

The reason for the above is that the laser i ordered has a digital ammeter which is harder to use, its not an instant read. The reason you need an ammeter is that there is no safety on the laser to stop you from damaging it by overdriving it. So with the ammeter you can find out what max power is (do a burn at 100%), note the amps used and than never go above 80% of that amps. Also the amps used and the speed used are the common "recipe" numbers people use to share cutting recipes online. Not percent of power which would be different on every machine.

Aquarium thermometer to monitor the temp of the cooling water system:

https://www.amazon.com/gp/product/B01A0TMS6Y/?tag=lstir-20

6" thru wall vent:

https://www.amazon.com/gp/product/B001AH5J8A/?tag=lstir-20

25" of 6" ducting

https://www.amazon.com/gp/product/B0791V19H7/?tag=lstir-20

390cfm 6" Hvac blower:

https://www.amazon.com/gp/product/B01DXYMJ94/?tag=lstir-20

These blowers are much quieter than the included "pc fan" setup most lasers come with.

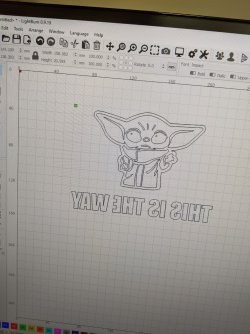

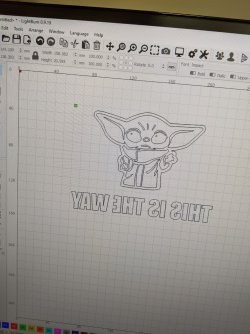

DSP version of lightburn software. I already had the lower version so it was only $40 to upgrade to dsp which is needed for these cabinet lasers (assuming you have the appropriate board in the laser).

Got my exhaust system up and running.

That was heavy

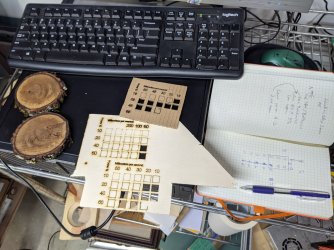

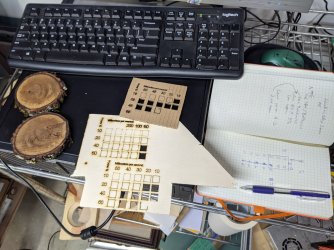

Working on recipes. 1/32 cuts very nice, seen in my hand below.

1/4 ACX construction ply is not going to cut thru, will grab some birch next time.

Mahogany 1/8 cuts nice.

Also engraved some glass which was really quick and easy.

Pretty much made for balsa and basswood. Cuts so nice.

This is 1/8 mahogany, one pass.

On my todo list is to figure out if there is a "materials" library in lightburn i can start setting up. That way i can just select "Birch 6mm From aloft" instead of referencing my notes to input it every time. Also need to get some better/more LEDS inside and externally on the back of the cart. I have a rule in my shop that anything that heats up has bright lights that are on if the machine has power. That way i can easily glance around when leaving the shop to see if anything is on. One time i left a laminating iron on all day on my workbench and it scared me pretty bad.

I finally cracked and ordered a Chinese laser cutter from omtechlaser.com. They are a company down in the LA area i think, they import them and make sure they are working, so you have a US based company for any problems. Its a 50w (probably 40w as most of the Chinese lasers are rated at peak and you got to keep it at 80% of that). 12x20 cutting area, same as glow forge, but has passthrough. After shipping tax it comes out about $1,300 less than a glow forge. If you have any interest in the experience let me know. Im sure at some point ill do a little video about how well/not well it goes. I made sure to get one with a Ruida controller so i can easily transition over using the same Lightburn software I'm already used to on my little 5.5 diode laser engraver.

Here's the specific model i ordered with a 10% off coupon. Being in California the shipping was free which is usually $250-300.

https://omtechlaser.com/collections/co2-cabinet-laser-engravers/products/50w-usb-5b3r-us

Starting this thread here to document the experience.

Here's some related videos if you interested:

https://www.youtube.com/c/LightBurnSoftware/videos

Made a base for the laser this weekend. The laser is 40" wide and 26x25 so it needs to be raised off the ground.

Here's some links to the additional stuff/upgrades i have ordered:

co2 rated safety goggles:

https://www.amazon.com/gp/product/B078HZZVZW/?tag=lstir-20

just a good idea. Plus i don't know that the viewing window is rated to stop any power from the laser.

Analog ammeter:

https://www.amazon.com/gp/product/B07F26M6M2/?tag=lstir-20

The reason for the above is that the laser i ordered has a digital ammeter which is harder to use, its not an instant read. The reason you need an ammeter is that there is no safety on the laser to stop you from damaging it by overdriving it. So with the ammeter you can find out what max power is (do a burn at 100%), note the amps used and than never go above 80% of that amps. Also the amps used and the speed used are the common "recipe" numbers people use to share cutting recipes online. Not percent of power which would be different on every machine.

Aquarium thermometer to monitor the temp of the cooling water system:

https://www.amazon.com/gp/product/B01A0TMS6Y/?tag=lstir-20

6" thru wall vent:

https://www.amazon.com/gp/product/B001AH5J8A/?tag=lstir-20

25" of 6" ducting

https://www.amazon.com/gp/product/B0791V19H7/?tag=lstir-20

390cfm 6" Hvac blower:

https://www.amazon.com/gp/product/B01DXYMJ94/?tag=lstir-20

These blowers are much quieter than the included "pc fan" setup most lasers come with.

DSP version of lightburn software. I already had the lower version so it was only $40 to upgrade to dsp which is needed for these cabinet lasers (assuming you have the appropriate board in the laser).

Got my exhaust system up and running.

That was heavy

Working on recipes. 1/32 cuts very nice, seen in my hand below.

1/4 ACX construction ply is not going to cut thru, will grab some birch next time.

Mahogany 1/8 cuts nice.

Also engraved some glass which was really quick and easy.

Pretty much made for balsa and basswood. Cuts so nice.

This is 1/8 mahogany, one pass.

On my todo list is to figure out if there is a "materials" library in lightburn i can start setting up. That way i can just select "Birch 6mm From aloft" instead of referencing my notes to input it every time. Also need to get some better/more LEDS inside and externally on the back of the cart. I have a rule in my shop that anything that heats up has bright lights that are on if the machine has power. That way i can easily glance around when leaving the shop to see if anything is on. One time i left a laminating iron on all day on my workbench and it scared me pretty bad.