Piotrsko

Legendary member

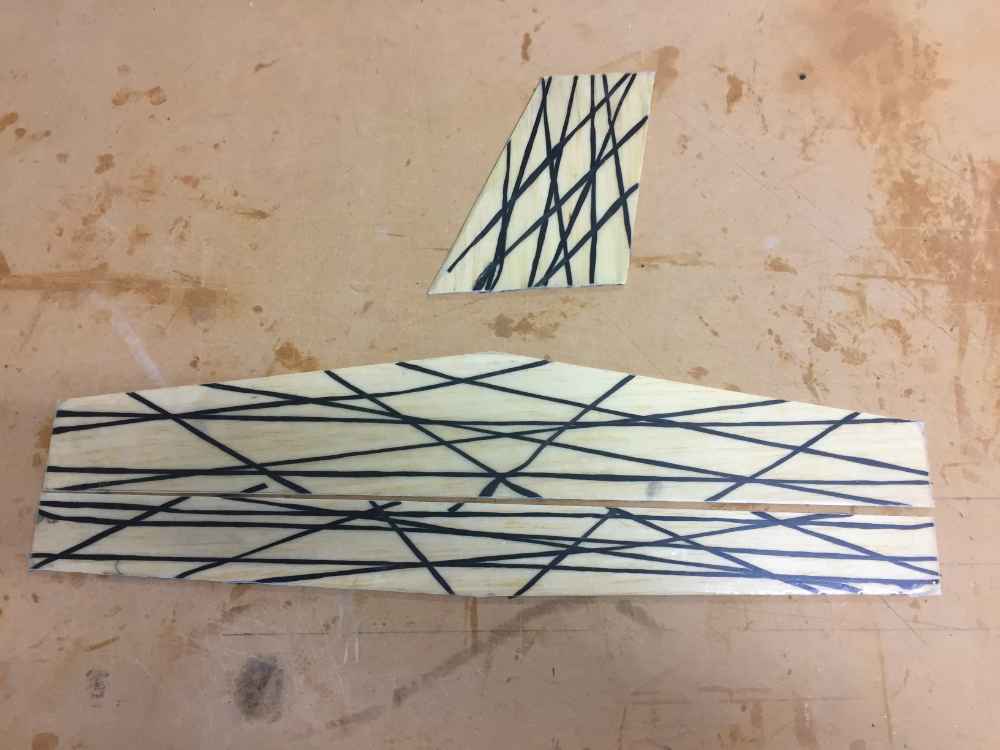

There are low temp versions of covering, much more inexpensive than moneycoat, suitable for direct covering of expanded polystyrene (aka "Styrofoam") there are also mylars and other polymer makeup materials that do not shrink as aggressive. The colored tapes used on DTFB also work well for this as does common kitchen cling wrap.