Apis

Member

Well, this looks like the solution for the glycerin based system. I tried finding updates on this but i couldn't.This may be a good way to go.

Well, this looks like the solution for the glycerin based system. I tried finding updates on this but i couldn't.This may be a good way to go.

I posted something like this here: https://forum.flitetest.com/index.p...-rc-electric-planes.69530/page-12#post-735797cdfigueredo, have you ever considered using an Auger? Augers are how particle solids are transported thru pipes. See picture below.

The advantage of an auger is the tight control of releasing powder can be as simple as turning a motor on and off and due to the screw, when it's off, nothing leaks.

I am imagining the same shape pod but with a channel at the bottom where the auger screw turns and pushes the powder to the outlet. The pod could be designed to catch air from the front and concentrate this high speed air to aerosolize the outgoing powder.

Edit: since high torque and low speed would be preferred, modified 9 g servo that has the 360° modification could easily be the motor for the auger.

I like the idea of a fan at the output, that may help to get some smoke at slow speeds. But i am not sure about feeding the auger screw by gravity because planes are not always at normal position. that's why i thougth to use the screw as container. This would possibly decrease the pwder capability but I think it would work no matter what position the aircraft is in.This is what I had in mind. A triangular trough with an open top channel for the auger screw leading the output with the air catching device. The screw goes a bit past the opening so it stays out in the channel under load.

View attachment 241028

The air catcher could also be replaced by a small fan of you want ideal dispersal. Maybe mounted 90 to the screw output with the output like in the picture link I shared with you a couple posts above.

The only issue with the screw as the container is the limited volume of powder and the binding of too much powder causing screw to break. You need to give the powder room to get out of the way. Industrial augers are never more than half full so they don't bind up since solids don't flow nice like liquids.I like the idea of a fan at the output, that may help to get some smoke at slow speeds. But i am not sure about feeding the auger screw by gravity because planes are not always at normal position. that's why i thougth to use the screw as container. This would possibly decrease the pwder capability but I think it would work no matter what position the aircraft is in.

I agree. It's probably a limitation that can't be easily worked around due to the nature of powders (ie: a solid, not liquid).Flying inverted, spins, or negative Gs might not be great for powder.....

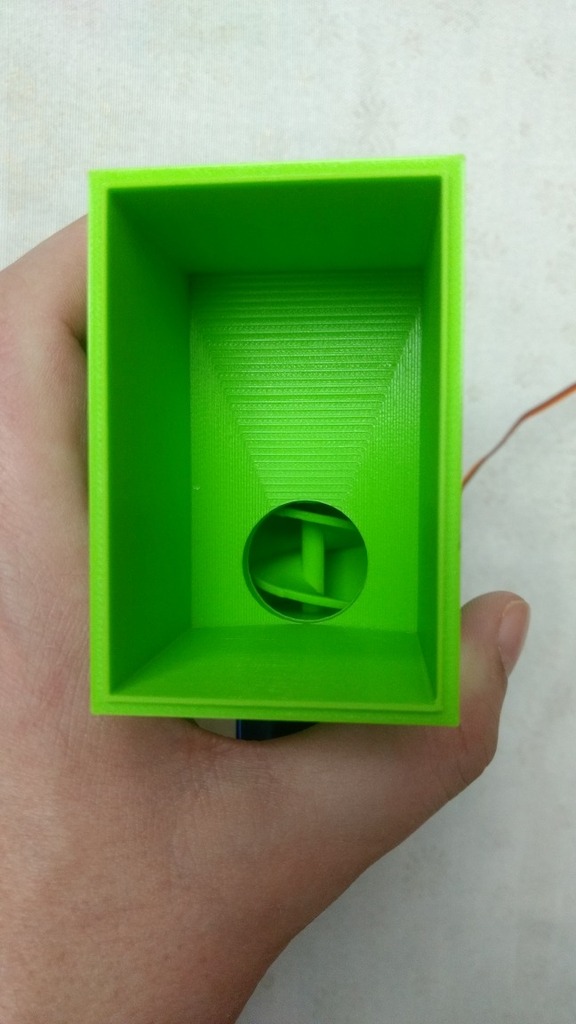

Ohhh, I understand what you are saying about not being able to fill the whole auger, I hadn't thought of that, it makes sense. But I still don't see how the gravity tank can work when the plane is flying inverted.Fan version

The only issue with the screw as the container is the limited volume of powder and the binding of too much powder causing screw to break. You need to give the powder room to get out of the way. Industrial augers are never more than half full so they don't bind up since solids don't flow nice like liquids.

Rough drawing of fan plus angled bits to help keep the screw well guided added. Angled bits would be nice for above design too.

I'm leaning towards the fan version even though it'll be more complicated to wire.

BTW, I have a 3D printer and I'd be willing to print and build this design.

This could perhaps be solved with several powder tanks, but it would be a waste if it is not flown inverted, as it would leave one tank full.I agree. It's probably a limitation that can't be easily worked around due to the nature of powders (ie: a solid, not liquid).

This could perhaps be solved with several powder tanks, but it would be a waste if it is not flown inverted, as it would leave one tank full.

I agree. It's probably a limitation that can't be easily worked around due to the nature of powders (ie: a solid, not liquid).

You're right, we often tend to overthink things when sometimes we don't even need to. On the other hand the amount of inverted flight time would cause "loads" to be lost in the auger, causing intermittency in the smoke. However, this may not even be noticeable.With the channeled screw, I'm thinking (would have to test this theory), that if you are not inverted for too long (ei: for a second or two), and the screw turns slowly enough then powder trapped in the channel would still be able to output during the temperary inversion, so still "smoke". And when the plane returns to upright, the powder can flow back into the depleting screw channel and the system would keep "smoking" like the inversion didn't happen.

Longer and slower the channeled screw turns, the more resistant it should be to temporary inversion.

But I think this theory would need real world testing to suss out.

So you suggest using the red helix instead of the blue one?Based on your above design, I suggest a thin narrow and closely spaces blades. Make the servo turn very slow. Also, since you don't have a reservoir to load new material, you could probably fill it 80-90% full and not expect binding or bogging.

Yes, for sure.So you suggest using the red helix instead of the blue one?

View attachment 241034