Hai-Lee

Old and Bold RC PILOT

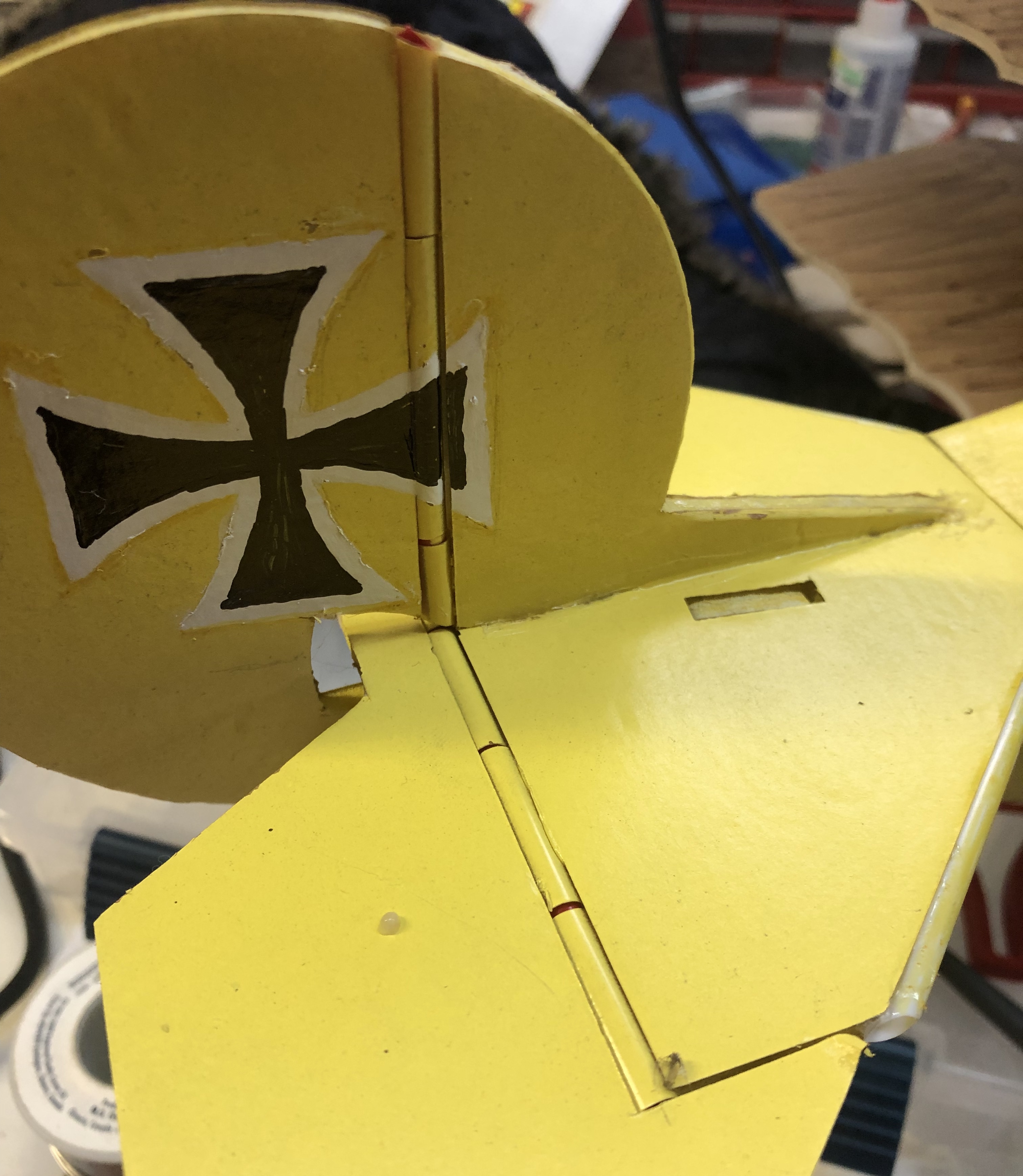

I have been building FB model aircraft for about 3 years and a member of this forum for about 2 years, (the times may be slightly erroneous because my watch battery has gone flat ). In that time I have been plagued with control surface hinge issues REGARDLESS of whatever I had done to lock them down and protect them from water and the like.

). In that time I have been plagued with control surface hinge issues REGARDLESS of whatever I had done to lock them down and protect them from water and the like.

Well today I was working on an FT Mini Scout courtesy of a buzzbomb challenge, (Thanks for that @buzzbomb ). When I decided it was time to investigate the hinge issue once and for all. It has been driving me crazy for years. I do like puzzles but really hate those puzzles that are far too simple. The hinge issue was one of those far too simple puzzles . The way the brain works sometimes is frustrating!

. The way the brain works sometimes is frustrating!

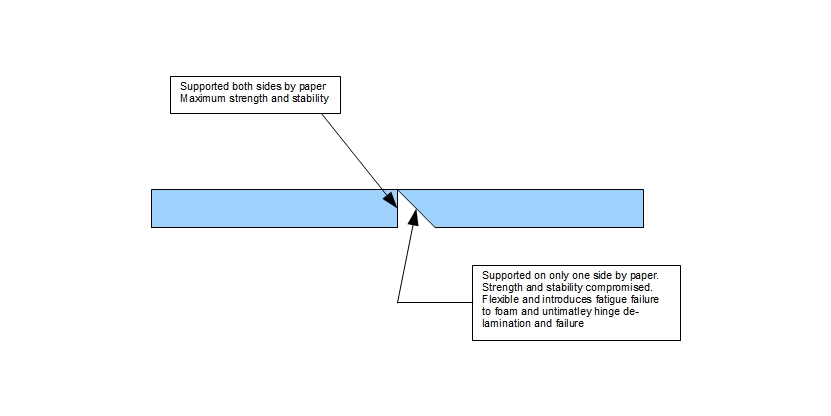

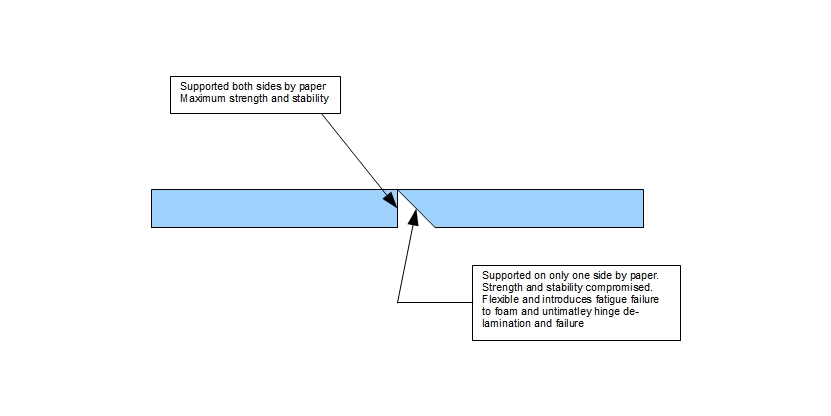

The problem was/is simply one of fatigue! Simply put a simple bevel hinge is flexible even if sealed with glue, tape, or even ironed. Control surfaces generate forces that move the aircraft, (remember for every action there is an equal and opposite reaction), and so these forces are also trying to separate the control surface from the structure. Well consider that at the hinge line the bevel supporting foam decreases from maximum FB foam thickness, (5mm) down to zero at the actual hinge line. Now add to this that the bevel itself is single sided with respect to the supporting paper laminate. The foam, (the only support for the connection of the control surface to the Wing or Fin), is not only somewhat flexible but also compressible. Any glue you apply to seal the hinge, (due to the applied forces), will eventually fail or crack.

See the pic below:

OK! After identifying the issue what is the simplest solution. Sure I could add different hinges which would be more long lived but then that is not what FT is all about! The solution was just to look at what other hinges look like. I tried to distribute the weakness, (it must hinge after all), to both sides of the hinge joint and provide the maximum support to the control surface that I could. Basically I just cut the hinge, or made the bevel/s differently.

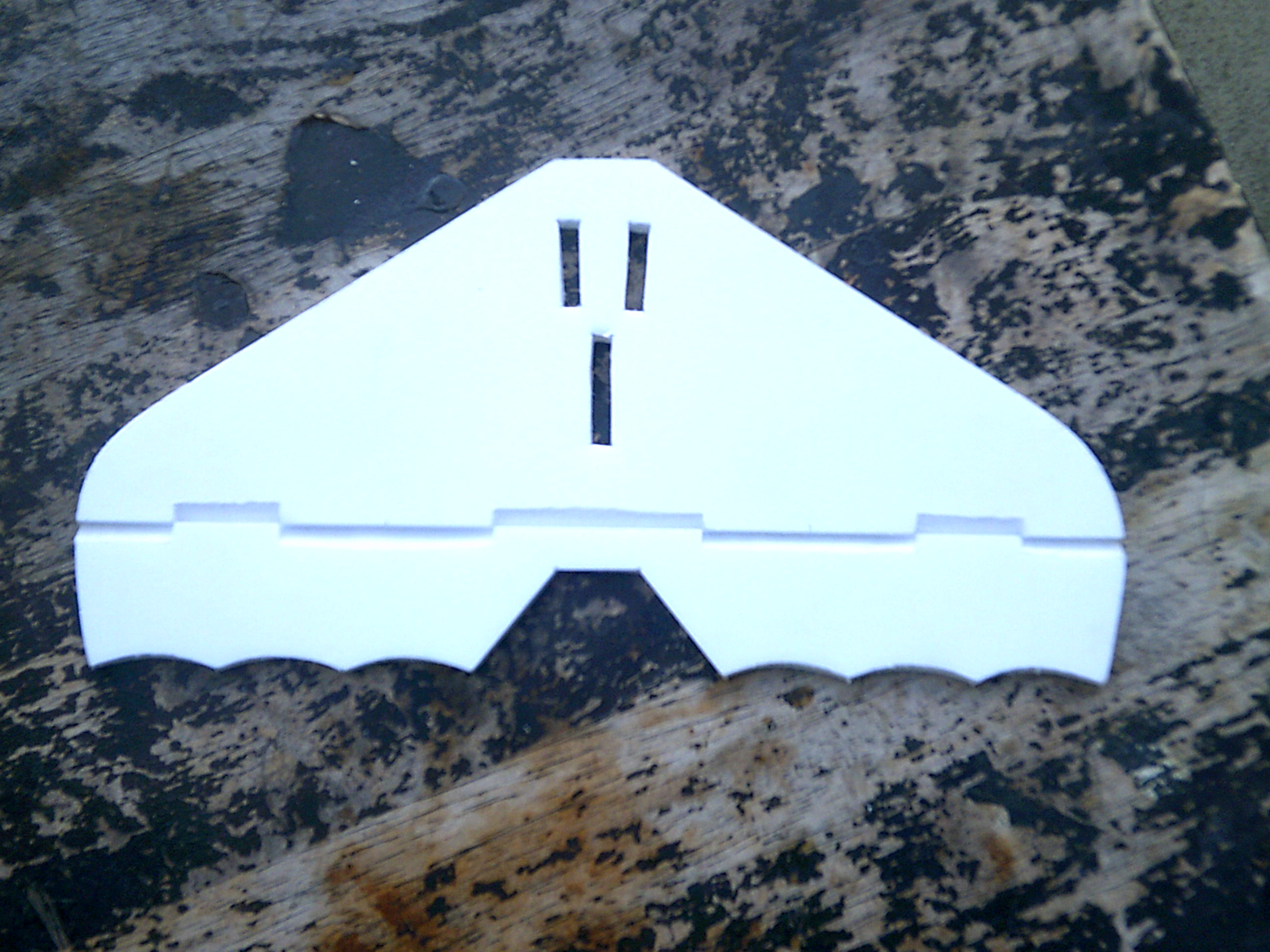

Standard Mini Scout Horizontal tail:

The different hinge bevels now!

It might look like a lot of additional work but it only took me around 3 minutes to complete and that is nothing compared to the time it took to cut out, check, and clean up the fin before being satisfied that it the best I can make it. Instead of a long unsupported hinge line that is subject to fatigue failure and even to the control surface curling up at the ends I now have a hinge line that has a maximum unsupported length of 25mm. I also checked the whole tail for flexibility from side to side and it flexes up and down less than a standard bevel hinged tail.

More support, Less flex, less fatigue, Longer life, and less flutter if the bird ever moved fast enough, I think it is worth the extra effort ESPECIALLY if the hinge line is quite long!

It takes a little more time and effort but I intend to recover that time by not having to rebuild the bird in a year or two because the elevator is falling off! You still apply the tape to the top of the hinge and still seal it of course. A photo of my actual tail can be supplied for the next day or two if required, After that it will be consumed in a Mini Scout.

Have fun!

Well today I was working on an FT Mini Scout courtesy of a buzzbomb challenge, (Thanks for that @buzzbomb ). When I decided it was time to investigate the hinge issue once and for all. It has been driving me crazy for years. I do like puzzles but really hate those puzzles that are far too simple. The hinge issue was one of those far too simple puzzles

The problem was/is simply one of fatigue! Simply put a simple bevel hinge is flexible even if sealed with glue, tape, or even ironed. Control surfaces generate forces that move the aircraft, (remember for every action there is an equal and opposite reaction), and so these forces are also trying to separate the control surface from the structure. Well consider that at the hinge line the bevel supporting foam decreases from maximum FB foam thickness, (5mm) down to zero at the actual hinge line. Now add to this that the bevel itself is single sided with respect to the supporting paper laminate. The foam, (the only support for the connection of the control surface to the Wing or Fin), is not only somewhat flexible but also compressible. Any glue you apply to seal the hinge, (due to the applied forces), will eventually fail or crack.

See the pic below:

OK! After identifying the issue what is the simplest solution. Sure I could add different hinges which would be more long lived but then that is not what FT is all about! The solution was just to look at what other hinges look like. I tried to distribute the weakness, (it must hinge after all), to both sides of the hinge joint and provide the maximum support to the control surface that I could. Basically I just cut the hinge, or made the bevel/s differently.

Standard Mini Scout Horizontal tail:

The different hinge bevels now!

It might look like a lot of additional work but it only took me around 3 minutes to complete and that is nothing compared to the time it took to cut out, check, and clean up the fin before being satisfied that it the best I can make it. Instead of a long unsupported hinge line that is subject to fatigue failure and even to the control surface curling up at the ends I now have a hinge line that has a maximum unsupported length of 25mm. I also checked the whole tail for flexibility from side to side and it flexes up and down less than a standard bevel hinged tail.

More support, Less flex, less fatigue, Longer life, and less flutter if the bird ever moved fast enough, I think it is worth the extra effort ESPECIALLY if the hinge line is quite long!

It takes a little more time and effort but I intend to recover that time by not having to rebuild the bird in a year or two because the elevator is falling off! You still apply the tape to the top of the hinge and still seal it of course. A photo of my actual tail can be supplied for the next day or two if required, After that it will be consumed in a Mini Scout.

Have fun!

![IMG_8361[1].JPG IMG_8361[1].JPG](https://ftforumx2.s3.amazonaws.com/2019/03/218049_e1c5dfb46a70894194f9a59c2b2fb3d6_thumb.jpg)