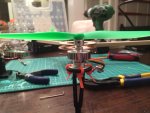

This is my first tri-copter and actually first anything RC related. I'm slowly piecing everything together and am enjoying the journey. I'm attaching the motors, props, etc and wanted to post a picture of the current state so I can confirm that I'm on the right path. I have two questions:

1. Should the motor mounts have gone on the bottom of the wood boom instead of the top...does it matter?

2. Should the prop savers lay flush with the motor or be slightly above it (not touching)?

Pictures attached

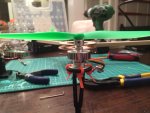

1. Should the motor mounts have gone on the bottom of the wood boom instead of the top...does it matter?

2. Should the prop savers lay flush with the motor or be slightly above it (not touching)?

Pictures attached