You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

800 Series | nnSpitfire

- Thread starter nerdnic

- Start date

jpot1

Elite member

Thanks for the picture. I took a couple of liberties with the build as I was concerned about my build abilities. I have not gotten a dual pushrod elevator working 100% so I modified by cutting out a notch in the rudder and spanning the two halves of the elevator. It's not ideal and weak at the rudder hinge line so I reinforced with a bit of carbon fiber.

Ended up putting the servos down lower and routing through the side of the fuse.

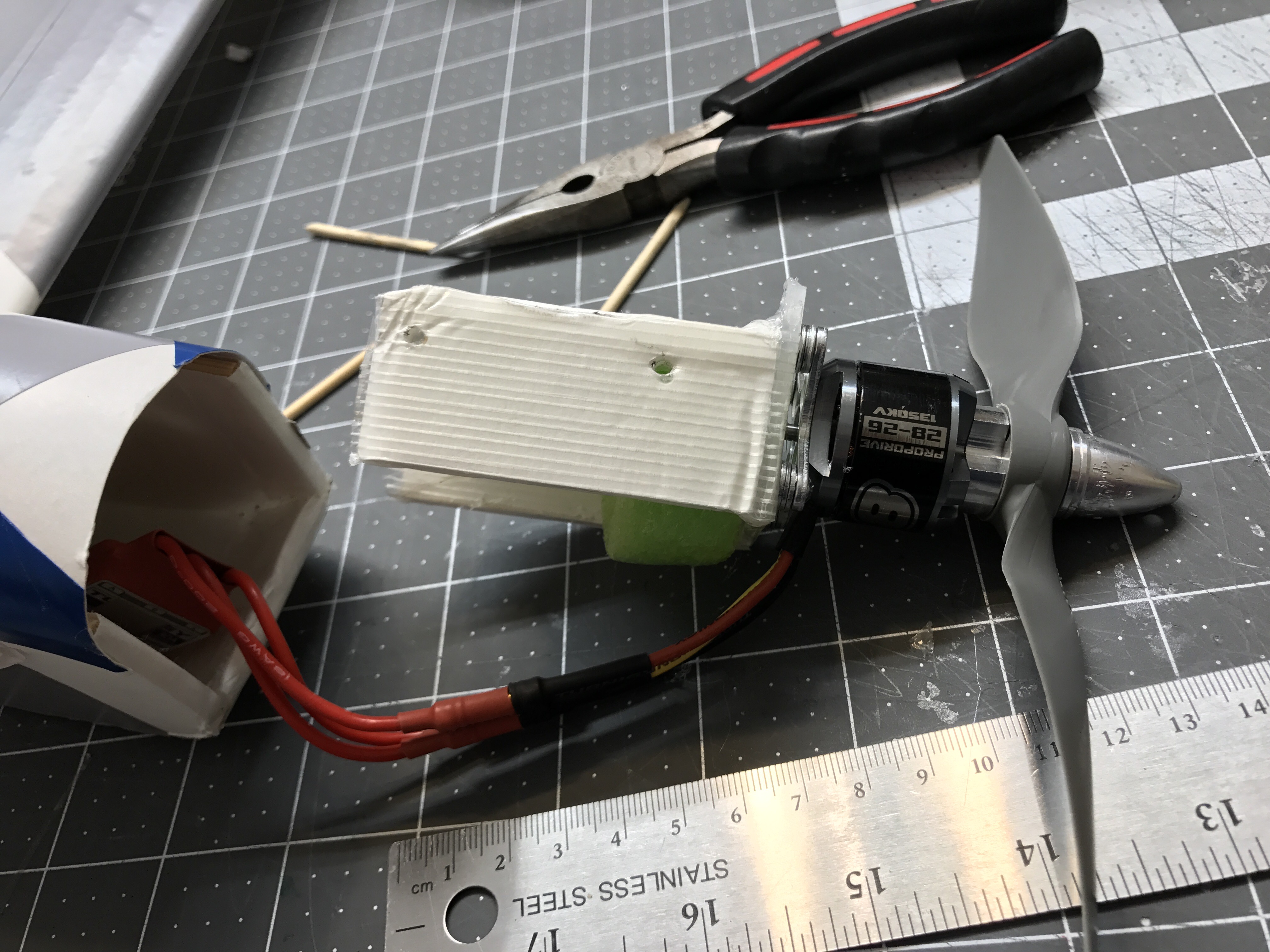

Used the smaller pod from the nnChipmunk, that I reduced the length on and set it up in regular FT style with the dual BBQ skewers in the front and one going through the side.

I spent a little time trying to build the speedwing and had some challenges. My wife wouldn't let me use one of the kitchen knives so I tried with a razor blade and some sandpaper but was just not happy with the result. I am planning to build more of the standard FT wing to keep things simpler. I will use undercamber wing tips but keep the multiple 50% score cuts and use the line on the wings where the paper would be removed for the speedwing as my cut line. This mimics the way the nnMig3 was built which flies beautifully for me. I'm not looking for speed so hopefully this will be fine.

so I tried with a razor blade and some sandpaper but was just not happy with the result. I am planning to build more of the standard FT wing to keep things simpler. I will use undercamber wing tips but keep the multiple 50% score cuts and use the line on the wings where the paper would be removed for the speedwing as my cut line. This mimics the way the nnMig3 was built which flies beautifully for me. I'm not looking for speed so hopefully this will be fine.

Ended up putting the servos down lower and routing through the side of the fuse.

Used the smaller pod from the nnChipmunk, that I reduced the length on and set it up in regular FT style with the dual BBQ skewers in the front and one going through the side.

I spent a little time trying to build the speedwing and had some challenges. My wife wouldn't let me use one of the kitchen knives

Love it Nic! Can't wait to build this one! Maybe I'll actually take my time and give this one a good paint job this time. Nice flying in the video too!

I would love to see a P-40 Warhawk in this size, or even the Sonic series size. Nobody does a foamboard Warhawk, and they're just such an iconic aircraft...

I would love to see a P-40 Warhawk in this size, or even the Sonic series size. Nobody does a foamboard Warhawk, and they're just such an iconic aircraft...

Thanks for the picture. I took a couple of liberties with the build as I was concerned about my build abilities. I have not gotten a dual pushrod elevator working 100% so I modified by cutting out a notch in the rudder and spanning the two halves of the elevator. It's not ideal and weak at the rudder hinge line so I reinforced with a bit of carbon fiber.

View attachment 79475

Ended up putting the servos down lower and routing through the side of the fuse.

View attachment 79476

View attachment 79477

Used the smaller pod from the nnChipmunk, that I reduced the length on and set it up in regular FT style with the dual BBQ skewers in the front and one going through the side.

View attachment 79478

I spent a little time trying to build the speedwing and had some challenges. My wife wouldn't let me use one of the kitchen knivesso I tried with a razor blade and some sandpaper but was just not happy with the result. I am planning to build more of the standard FT wing to keep things simpler. I will use undercamber wing tips but keep the multiple 50% score cuts and use the line on the wings where the paper would be removed for the speedwing as my cut line. This mimics the way the nnMig3 was built which flies beautifully for me. I'm not looking for speed so hopefully this will be fine.

The changes you made will work just fine. For the wing it would be worth it to just buy a 5$ knife, definitely makes a huge difference. But doing a basic wing will work too. Make sure to reinforce the wing tip (see my chip build).

Keep me posted!

Love it Nic! Can't wait to build this one! Maybe I'll actually take my time and give this one a good paint job this time. Nice flying in the video too!

I would love to see a P-40 Warhawk in this size, or even the Sonic series size. Nobody does a foamboard Warhawk, and they're just such an iconic aircraft...

Thanks! Let me know if you build one, would love to see a clean paint job. You're in luck because I'm actually working on a p40 already. No eta yet though

Mile Hy warbirdz

New member

nn spitfire 800mm

View attachment 79510 View attachment 79511 View attachment 79512

Here is my version I put the servo's through the top of the wing to protect them from my less than stellar landings. Also used an aluminum spar for those speed runs. Now just have to maiden before the paint dries! thanks Nic !

View attachment 79510 View attachment 79511 View attachment 79512

Here is my version I put the servo's through the top of the wing to protect them from my less than stellar landings. Also used an aluminum spar for those speed runs. Now just have to maiden before the paint dries! thanks Nic !

Today I nosedived my FT Arrow into the ground at 61 miles per hour (measured via my FrSky airspeed sensor) and cracked the airframe in half on both sides of the paint stirring stick I was using to reinforce the airframe  All the electronics are fine, and smashing stuff is actually kinda fun, so overall it was a good outing. I like the Arrow, but the tiny electronics compartment leaves a lot to be desired, and it's a pretty drag-heavy airframe. So I'm using this opportunity to transfer the electronics over to the nnSpitfire 800 that I've been eyeing ever since Nic released it.

All the electronics are fine, and smashing stuff is actually kinda fun, so overall it was a good outing. I like the Arrow, but the tiny electronics compartment leaves a lot to be desired, and it's a pretty drag-heavy airframe. So I'm using this opportunity to transfer the electronics over to the nnSpitfire 800 that I've been eyeing ever since Nic released it.

I'm taking some vacation time over the next few days, so prepare to be barraged with questions!

I've never built a single-servo dual-pushrod setup before, but I'm interested in trying it that way for this build. Does anybody have any tips for that? I've seen some interesting designs where there's a "T" right after the servo connection (for example https://static.rcgroups.net/forums/attachments/9/6/3/8/ai11582262-141-thumb-ch49.jpg?d=1195677774), but the plans make it sound like both pushrods are just inserted into the same servo hole. I don't see how that would work without destroying the servo arm. Am I overthinking this? Should I just solder a second pushrod to the first right by the servo Z bend?

Thanks for the plans Nic! You've really taken DTFB to a completely different level.

I'm taking some vacation time over the next few days, so prepare to be barraged with questions!

I've never built a single-servo dual-pushrod setup before, but I'm interested in trying it that way for this build. Does anybody have any tips for that? I've seen some interesting designs where there's a "T" right after the servo connection (for example https://static.rcgroups.net/forums/attachments/9/6/3/8/ai11582262-141-thumb-ch49.jpg?d=1195677774), but the plans make it sound like both pushrods are just inserted into the same servo hole. I don't see how that would work without destroying the servo arm. Am I overthinking this? Should I just solder a second pushrod to the first right by the servo Z bend?

Thanks for the plans Nic! You've really taken DTFB to a completely different level.

Last edited:

View attachment 79510 View attachment 79511 View attachment 79512

Here is my version I put the servo's through the top of the wing to protect them from my less than stellar landings. Also used an aluminum spar for those speed runs. Now just have to maiden before the paint dries! thanks Nic !

Love it! You did a great job on the paint.

Looks great Mile Hy! I was able to finish my version of the standard wing today. Very pleased with how it came out. I love these planes because the planes are basically balanced on the CG before adding the battery.

View attachment 79517

View attachment 79518

Very nice! I might add some dotted 'basic wing' lines to the plans for others that want to build a similar wing. As for CG, I wish I could say I plan that, but it's just luck

This looks great, Nic! I love Spitfires, so this is a must-build for me. It will get serial number 6.

And that's a beautiful example you have there, Mile Hy!

I can't wait to see it!

Today I nosedived my FT Arrow into the ground at 61 miles per hour (measured via my FrSky airspeed sensor) and cracked the airframe in half on both sides of the paint stirring stick I was using to reinforce the airframeAll the electronics are fine, and smashing stuff is actually kinda fun, so overall it was a good outing. I like the Arrow, but the tiny electronics compartment leaves a lot to be desired, and it's a pretty drag-heavy airframe. So I'm using this opportunity to transfer the electronics over to the nnSpitfire 800 that I've been eyeing ever since Nic released it.

I'm taking some vacation time over the next few days, so prepare to be barraged with questions!

I've never built a single-servo dual-pushrod setup before, but I'm interested in trying it that way for this build. Does anybody have any tips for that? I've seen some interesting designs where there's a "T" right after the servo connection (for example https://static.rcgroups.net/forums/attachments/9/6/3/8/ai11582262-141-thumb-ch49.jpg?d=1195677774), but the plans make it sound like both pushrods are just inserted into the same servo hole. I don't see how that would work without destroying the servo arm. Am I overthinking this? Should I just solder a second pushrod to the first right by the servo Z bend?

Thanks for the plans Nic! You've really taken DTFB to a completely different level.

The 2204 FT electronics will work great in this plane. For the dual push rod setup check out my nnChipmunk build video, it uses the same thing.

The only tricky part is getting each elevator surface the same when you secure the rod on the control horn. If you're using linkage stoppers then this is very easy, though.

Thanks Nic! I looked through designs that had build videos and just assumed the Chipmunk had a single elevator pushrod since each side looked connected from a glance. I'll check it out! I just ordered some linkage stoppers from Heads Up Hobby the other day so that was perfect timing.

I actually got a hold of the brand new Emax RS2205S 2600KV motor, and that thing screams for the size and was what I was using for the Arrow. I was able to spin an APC 4.75x5.5 at 20374 RPM (106 MPH theoretical pitch speed) using 28.6 amps on a 3S 1300 mah 75C lipo. This 29 gram 2205 motor actually outperforms my Suppo 2208 42 gram motor of the same KV. So that's the power system plan for now, but my ultimate plan with this spitfire is to have a kilowatt that I can fit in my passenger seat. Can't wait!

I actually got a hold of the brand new Emax RS2205S 2600KV motor, and that thing screams for the size and was what I was using for the Arrow. I was able to spin an APC 4.75x5.5 at 20374 RPM (106 MPH theoretical pitch speed) using 28.6 amps on a 3S 1300 mah 75C lipo. This 29 gram 2205 motor actually outperforms my Suppo 2208 42 gram motor of the same KV. So that's the power system plan for now, but my ultimate plan with this spitfire is to have a kilowatt that I can fit in my passenger seat. Can't wait!

Last edited:

Thanks! Let me know if you build one, would love to see a clean paint job. You're in luck because I'm actually working on a p40 already. No eta yet though

Awesome!! Can't wait for that P-40!! I'm going to do an inventory of parts and electronics today, and probably place an order so I can start building the Spitfire and have reserves for the next one. Thanks Nerdnic!

Nice one Nerdnic. Thanks for the plans. This will be my next build. I hope I can use my Turnigy D2826-6 2200kv, as I crashed my Sparrow and have it spare now.

Btw, my Chipmunk has broken into pieces many times, but it still flies very well after repairs. Thanks for that one also!

Btw, my Chipmunk has broken into pieces many times, but it still flies very well after repairs. Thanks for that one also!

Nice one Nerdnic. Thanks for the plans. This will be my next build. I hope I can use my Turnigy D2826-6 2200kv, as I crashed my Sparrow and have it spare now.

Btw, my Chipmunk has broken into pieces many times, but it still flies very well after repairs. Thanks for that one also!

That motor with a 7x6 on 3s 2200 40c is one of my favorite setups! Good thrust and about 80mph top speed.

jpot1

Elite member

That motor with a 7x6 on 3s 2200 40c is one of my favorite setups! Good thrust and about 80mph top speed.

7x6 on that motor is not too much? I had thought the specs called for a 6x4 max.

Similar threads

- Replies

- 62

- Views

- 3K

- Replies

- 145

- Views

- 11K