L Edge

Master member

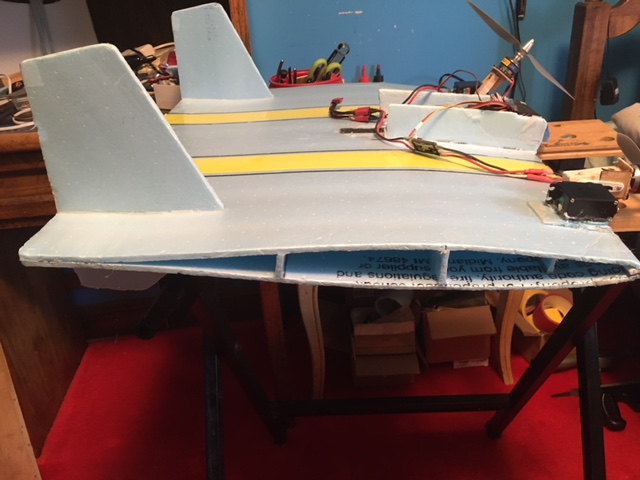

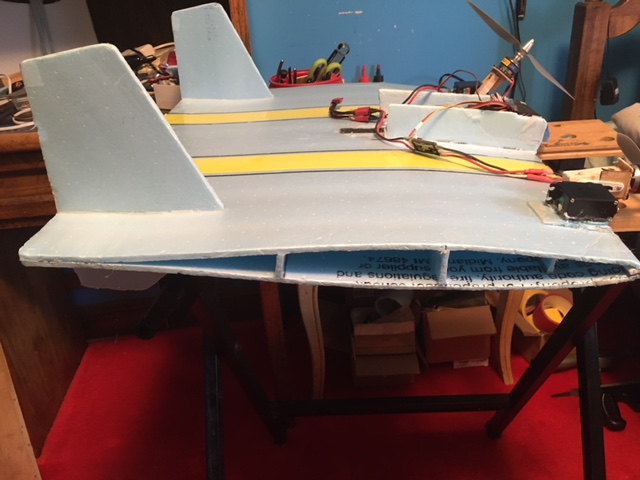

About 10 years ago, drone companies started to fabricate different designs for all kinds of "Eye in the SKY". So I decided to duplicate this one for RC'ers.

The Unique features:

1) Plane has no moving surfaces controlling roll, pitch or yaw.

2) Can take off vertically or launched by hand.

3) All directional changes take place in front of the leading edge.

4) The drone when landing, has no landing gear, so motor/prop are held to frame by magnets and when it hits ground, pop off.

Can it be adapted for us?

Still have it and you will see it in 2 different applications. This will show you how I got it to work as such and the next thread will show how it can be used as a bi-copter VTOL.

Materials-- foam sheets, carbon rod, large digital servos , HH E-Flite Park 370 1360 kv motors, and 9 x 4/7 APC props.

Design:

Since blue foam is a continuous sheet, I used the fold point and glued the carbon rod to make a symmetric wing (just eyeballed it) that had a 19" chord and a width of 2 ft. Cross spars are at 3", 6", 11" from LE, and glue together from 16" to 19" . Height's are 7/8", "1 1/4", "3/4"

The two large rudders are hand fitted 3" in from edge with a 5 3/4" base of fixed rudder with a front edge height of 5 1/2". The under rudders are 2 1/" high and 2 1/2" in length from rear to form the taper. If you are going to launch vertically, stand the plane up and cut the back surface of the rudder(both sides) so it sits perpendicular to the motors/prop!!!!!

Concept of Yaw, Roll and Pitch: (Standing behind plane)

To control Yaw, a transmitter mix is needed to give you a right turn where the left motor is speeded up and the right motor is reduced. Opposite for a left turn.

To control pitch, both servos move up (say to do a loop) and to pitch down points the nose down.

To control roll, (say to do a right roll) the left servo moves up and the right servo moves down

More tomorrow.

The Unique features:

1) Plane has no moving surfaces controlling roll, pitch or yaw.

2) Can take off vertically or launched by hand.

3) All directional changes take place in front of the leading edge.

4) The drone when landing, has no landing gear, so motor/prop are held to frame by magnets and when it hits ground, pop off.

Can it be adapted for us?

Still have it and you will see it in 2 different applications. This will show you how I got it to work as such and the next thread will show how it can be used as a bi-copter VTOL.

Materials-- foam sheets, carbon rod, large digital servos , HH E-Flite Park 370 1360 kv motors, and 9 x 4/7 APC props.

Design:

Since blue foam is a continuous sheet, I used the fold point and glued the carbon rod to make a symmetric wing (just eyeballed it) that had a 19" chord and a width of 2 ft. Cross spars are at 3", 6", 11" from LE, and glue together from 16" to 19" . Height's are 7/8", "1 1/4", "3/4"

The two large rudders are hand fitted 3" in from edge with a 5 3/4" base of fixed rudder with a front edge height of 5 1/2". The under rudders are 2 1/" high and 2 1/2" in length from rear to form the taper. If you are going to launch vertically, stand the plane up and cut the back surface of the rudder(both sides) so it sits perpendicular to the motors/prop!!!!!

Concept of Yaw, Roll and Pitch: (Standing behind plane)

To control Yaw, a transmitter mix is needed to give you a right turn where the left motor is speeded up and the right motor is reduced. Opposite for a left turn.

To control pitch, both servos move up (say to do a loop) and to pitch down points the nose down.

To control roll, (say to do a right roll) the left servo moves up and the right servo moves down

More tomorrow.