You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ERC TimSav - Cheap DIY CNC Foamboard Cutter

- Thread starter Edwardchew

- Start date

Thanks!Noice!

skymaster

Elite member

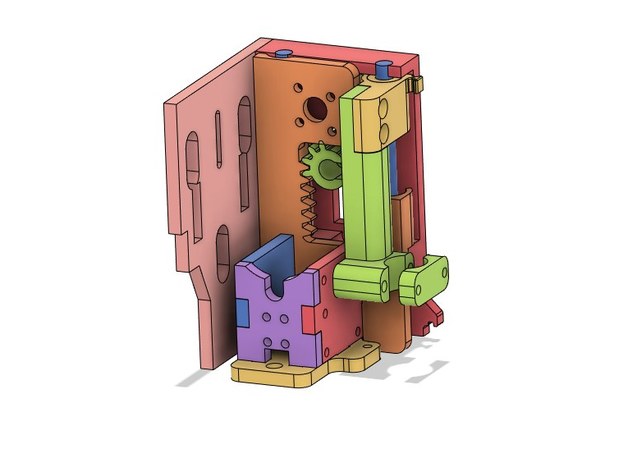

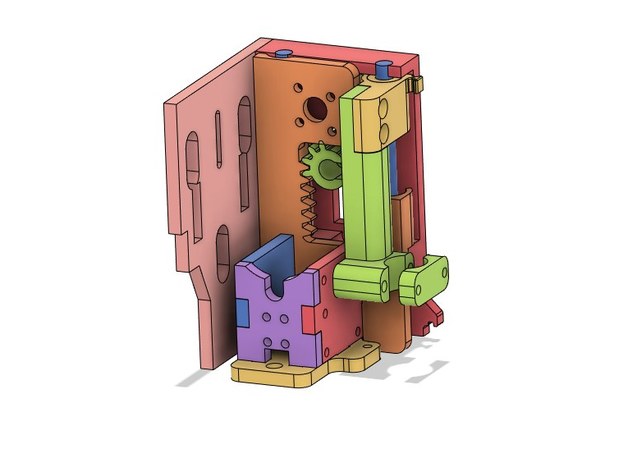

what is the range on this thingCan any of us leave well enough alone? With the extra parts (cheaper to order 5 than 3 of something) I added a second Y axis motor.

View attachment 243351 View attachment 243352 View attachment 243353

luvmy40

Elite member

If by range you mean work area, the original design works with 20"x 30" foam board with a little spare room on both the X and Y axis. As with any CNC system, you are limited only by the area available. this could easily be built to work in a much larger area, but you then be wanting to use a four sided frame and dual X(or Y depending on your orientation) steppers for sure.what is the range on this thing

skymaster

Elite member

can it be used with a pen instead of the needle cutter?If by range you mean work area, the original design works with 20"x 30" foam board with a little spare room on both the X and Y axis. As with any CNC system, you are limited only by the area available. this could easily be built to work in a much larger area, but you then be wanting to use a four sided frame and dual X(or Y depending on your orientation) steppers for sure.

Yes, there are a number of pen add-ons available. I'm using this one that can mark and cut.can it be used with a pen instead of the needle cutter?

ERC TimSav ball bearing head by zero_o

ERC TimSav ball bearing headThis a new head version for the ERC TimSav Foam board CNC cutter. It is based on linear rails and bearing and hence more sturdy. It also supports a drawing marker handling that can be operated with the same single servo. This way, cutting and drawing can be all done...

skymaster

Elite member

So let's say that i have an old set up from a laser engraver that i bought a long while a go you think i can use thatYes, there are a number of pen add-ons available. I'm using this one that can mark and cut.

ERC TimSav ball bearing head by zero_o

ERC TimSav ball bearing headThis a new head version for the ERC TimSav Foam board CNC cutter. It is based on linear rails and bearing and hence more sturdy. It also supports a drawing marker handling that can be operated with the same single servo. This way, cutting and drawing can be all done...www.thingiverse.com

Probably with some modifications for mounting it. The up and down motion to determine depth of cut is done with a 9g servo motor. How is your laser head moved up and down?So let's say that i have an old set up from a laser engraver that i bought a long while a go you think i can use that

I just finished cutting the first 3 sheets of the FT Sportster and averaged about 13 minutes per sheet with modest speed settings. WOW! This thing is worth the time. Thanks @Edwardchew for the great design.

I really really need to build mine.I just finished cutting the first 3 sheets of the FT Sportster and averaged about 13 minutes per sheet with modest speed settings. WOW! This thing is worth the time. Thanks @Edwardchew for the great design.

Flying Farm Kid

Active member

Does anyone have the dxf files for Ben Harbers Stearman? I don't want to hand cut it again lol.

Thank you!

Thank you!

Flying Farm Kid

Active member

Could you post the files that you used I would like to do that to mine.Can any of us leave well enough alone? With the extra parts (cheaper to order 5 than 3 of something) I added a second Y axis motor.

View attachment 243351 View attachment 243352 View attachment 243353

Looks great by the way!

Flying Farm Kid

Active member

On the Facebook group there were people that mounted lasers to theirs.So let's say that i have an old set up from a laser engraver that i bought a long while a go you think i can use that

Flying Farm Kid

Active member

What is the cutting rate for you. Mine is cutting at 700mm/s and travel is 1800mm/sI just finished cutting the first 3 sheets of the FT Sportster and averaged about 13 minutes per sheet with modest speed settings. WOW! This thing is worth the time. Thanks @Edwardchew for the great design.

Foamforce

Elite member

What is the cutting rate for you. Mine is cutting at 700mm/s and travel is 1800mm/s

I do 1500 and 3000 for travel. I found that too slow sometimes makes it cut worse. It might be because the end the needle doesn’t get over far enough to actually poke into the paper, so it’s just the tapered side of the needle doing the cutting. I have no idea if this is true, that’s just a guess.

Both tensioners are mash ups of the tensioner on thingiverse. I'll get them ready for release and post them here and on thingiverse. I got the biggest increase in speed by using laserweb to process the svg file, cut the time more than in half. I make 4 layers in inkscape - mark, score, internal cuts, cut out - and then have laserweb put them in that order.Could you post the files that you used I would like to do that to mine.

Looks great by the way!

Marking at 1400

Score at 1100

All cutting at 950

Cutting head ~ 10,000 rpm

I'm not an expert by any means. I've cut 6 successful sheets of production

Dudley1001

Member

Yes I have made a laser only version for my neighbour and mine can switch between laser and needle. Just got it running FluidNC rather than GRBL and I am using a MKS Tinybee 32bit ESP32 mainboard with wifi and a webpage to control it. Yes, going a little overboard but the board is about the same price as an uno/cnc shield. My mount is here but I am going to get rid of the v-rollers for the laser mount and just use hammer nuts. The reason for switching to the Tinybee was so my MPCNC and the Timsav will be both running fluidnc as well as my neighbours Root 3 CNCOn the Facebook group there were people that mounted lasers to theirs.

Attachments

Flying Farm Kid

Active member

Thanks That should make mine cut better when it is far away from home.Both tensioners are mash ups of the tensioner on thingiverse. I'll get them ready for release and post them here and on thingiverse. I got the biggest increase in speed by using laserweb to process the svg file, cut the time more than in half. I make 4 layers in inkscape - mark, score, internal cuts, cut out - and then have laserweb put them in that order.

Marking at 1400

Score at 1100

All cutting at 950

Cutting head ~ 10,000 rpm

I'm not an expert by any means. I've cut 6 successful sheets of production

, but that's what worked for me after calibration & test

Flying Farm Kid

Active member

Ok I will try to up mu cutting speed. I get decent quality cuts right now it is just the fine tuning that it needs.I do 1500 and 3000 for travel. I found that too slow sometimes makes it cut worse. It might be because the end the needle doesn’t get over far enough to actually poke into the paper, so it’s just the tapered side of the needle doing the cutting. I have no idea if this is true, that’s just a guess.

Similar threads

- Replies

- 3

- Views

- 120

- Replies

- 15

- Views

- 1K

- Replies

- 23

- Views

- 506

- Replies

- 266

- Views

- 10K