Mr Man

Mr SPEED!

Yes you can do a bit of 2d, but it can only export in svg and dxf, which is why I use Inkscape alongside it.I think I will give it a try. can you do 2D in it too?

Yes you can do a bit of 2d, but it can only export in svg and dxf, which is why I use Inkscape alongside it.I think I will give it a try. can you do 2D in it too?

I can also use FreeCAD for that because I already know how to do 2D pretty well in it.Yes you can do a bit of 2d, but it can only export in svg and dxf, which is why I use Inkscape alongside it.

Onshape is the way to go for master Series imoI can also use FreeCAD for that because I already know how to do 2D pretty well in it.

My tailless plane designs are on hold for the moment, but I eventually want to get back into them. My investigation of wing apex flaps in this F-106 project would possibly explain some of my control issues though. The spoiler may have actually resulted in an increase in lift on that wing, therefore counteracting some of the roll due to the yaw it generates. It would explain some of the control difficulties I've been running into. But for the moment, my stable of planes is getting a bit low since I've been working on projects without wrapping them up, so I need to finish building a few things before I get too experimental again.To get back on subject of rudderless planes, getting antsy, added a gyro to all three axis, did a quick test run in the industrial park (33 degrees) and lifted off(gyro on) and it flew about 20 ft. I pulsed the rudder (inside the EDF) and it it yawed and drop back down. Next week, 40+ degrees and I can't wait if I can wean the roll and pitch off the gyro. Soon as snow is off in park parking lot, will try flight for single EDF.

I mentioned to you the second method I was exploring was to have dual edf's using a pair of drag brakes. Solved the problems on how I should program it and just purchased 2 sets of drag brakes(making them sucks for repeatability) and hopefully, I can cut them down to use next to the ailerons. Bought 2 sets, so I can try both ways, on trailing edge and imbedded in the wings, so you could make different styles of planes use 1 or 2 EDF's. If it does, the NYGAD problems is solved.

Any flights or data info yet on your models ready to go? Hope other FT pilots are interested in your data so they understand what is going on.

To keep busy in the house, made a EZ 2 FSW plane and thought of you when I tested in the cellar. Having a real high AOA, every time when I was exploring the CG and it was aft, pull back power, it stalls beautifully and lands tail heavy, with no damage. Same as my morphing plane.

By the way, the drag brakes are from China, if you want more info or where to buy, (only a few left- 5 for right, 8 for left), PM me. I have been waiting 4 months for this shipment to come in.

WOW man! I am impressed with this!The final version of the wings is finally finished.

View attachment 248679

There are a couple of things to note.

First, the gear now has a wheel with a tire. I'd be curious to know if anyone has printed PLA wheels. I have questions about how the wheel will wear against the axle and I suspect I may need to replace them with PETG wheels after a few flights. The tire is 85A durometer TPU printed with 3 walls and 50% infill. It feels like about the right level of flexible and doesn't seem to deform too much in tests where I press down on a scale with half the weight of the plane. The grip is also much better than previous TPU wheels where I used 98A durometer filament and I think the ground handling should be fine. They also didn't permanently deform when I tried pressing them against a 100 C 3D printer build plate, likely due to the higher infill, so I think they should be able to survive Florida asphalt ok.

View attachment 248681

Next, the wing now bulges out by 3mm to fit the gear and gear door. The gear door couldn't quite fit flush with the gear due to the rubber bands, so that extra space means everything can fit.

View attachment 248682

Finally, the servo trays are now printed and integrated into the wing. The elevons are driven by FT99R servos which are probably far overkill for the application, but in a plane this big that might be able to hit 130 mph, and for control surfaces that size I would far rather be safe than sorry. Once I get a better sense of how fast this plane actually is (I think 130 mph is pretty optimistic and I suspect the real number will be closer to 100 mph), I may be able to go down a size or two and save about 70 or 80 grams.

Apart from the design of the wings, I decided that the wings being an inch too far back was bothering me too much, so I'm in the process of redesigning the core fuselage to move the wing forward to where it should be. Since I have to print all the other little bits, it's not really delaying the maiden flight, and even without everything modeled right, it already looks so much better. The directional stability should also be a little better, but if I'm being honest, I'm doing this for the looks.

View attachment 248684

Its looking great!WOW man! I am impressed with this!

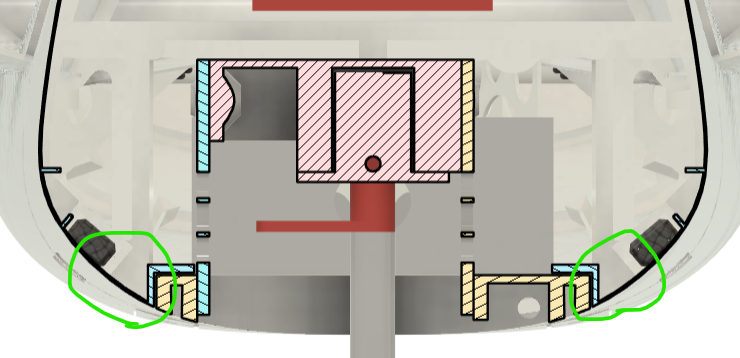

Looks good!The airbrake system is now designed. It makes use of SLA printed gears to allow it to fit into the very narrow tail fin. It will probably take a couple of tries to get the tolerances perfect and the print dialed in, but even on the first try, the gears seem to mesh correctly and resist skipping somewhat well.

View attachment 249386

One gear fits onto the servo splines, and the other is held in place with a clamp which supports the other side of an axle made of a paper clip. This clamp also retains the pushrods in the arm on the gear which means I don't need to worry about fitting a Z bend in such a tight space.

View attachment 249387

The push rods are linked to fairly conventional control horns on the airbrakes. View attachment 249388

This should give the airbrakes 60 degrees of travel while being a bit easier to assemble than the system on the smaller F-106.

View attachment 249389

The airbrake system went together remarkably easily. I need to wait until I have the receiver installed to connect the airbrakes themselves to the pushrods, but the servo and gears all seem to work quite well. Contrary to my expectations, the second version of the gears seem to work perfectly.

View attachment 249425

It's a bit challenging to get good pictures of the system assembled since the retaining clip blocks the gears from most angles, but it all fits together very neatly. The assembly is very simple and doesn't require glue or a ton of fiddling around with getting everything to fit into place. View attachment 249421

View attachment 249420

Probably the part I'm most proud of is the gears. They are absolutely tiny and even smaller than I expected despite knowing their size from the CAD model. The gear that goes on the servo has 3D printed splines that are only 0.1 mm in size and they interface perfectly with the splines on the servo.

View attachment 249423

If anyone is interested, I can post an STL or Fusion 360 file with the spline pattern since it seems like it could be useful for other custom servo arms, gears, or other servo hardware.

These airbrakes are a bit different from split rudder air brakes in that they only deflect outwards at the same time. I'm planning on using ball links for the majority of my control surfaces, but for the airbrakes there isn't really enough space. On the smaller F-106 a similar setup seemed to work without problems, so I'm hopeful that the airbrakes on the big F-106 will be ok tooFor your hookup, you might want to make sure that there is very little slop when you open/close the airbrakes. I found that heli parts work real well. I explored dual air rudder brakes many years ago and the slop was terrible causing yaw problems both at open/close position. Especially if they aren't closed properly in flight. Caused yaw moments in flight.

One way to resolve the slop issue is to use helicopter parts of ball joints at either end and threaded rods. Or use a ball joint and other setup as pic shows. For my servo and drag rudders, since both rudders need to be closed or at the same open angle in flight, I used ball/socket for no slop at all.

@telnar1236

Since you are in a club, find the guys who fly heli's. With crashes, comes extra spare parts, so ask some one if they have different lengths of very thin high strength light threaded rods and some ball/socket joints they will give or that you can buy. Since heli's come in all sizes, get the smallest setup you can to keep weight down. Notice the ball on the drag rudder.

If you ever get bored with planes, try helis and that will keep your heart rate up.

View attachment 249448

"small"😂These airbrakes are a bit different from split rudder air brakes in that they only deflect outwards at the same time. I'm planning on using ball links for the majority of my control surfaces, but for the airbrakes there isn't really enough space. On the smaller F-106 a similar setup seemed to work without problems, so I'm hopeful that the airbrakes on the big F-106 will be ok too