nebraskatrevor

Member

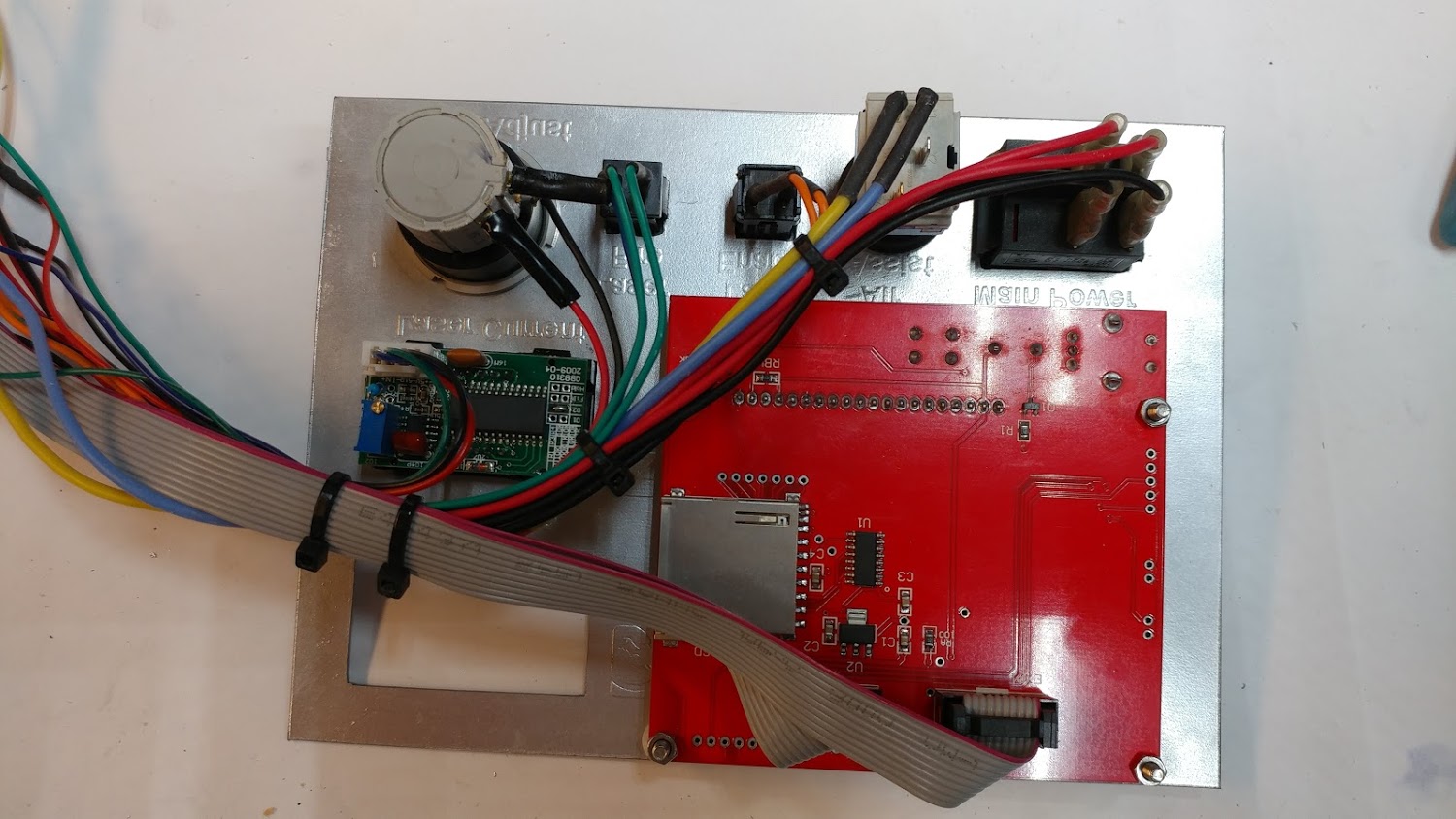

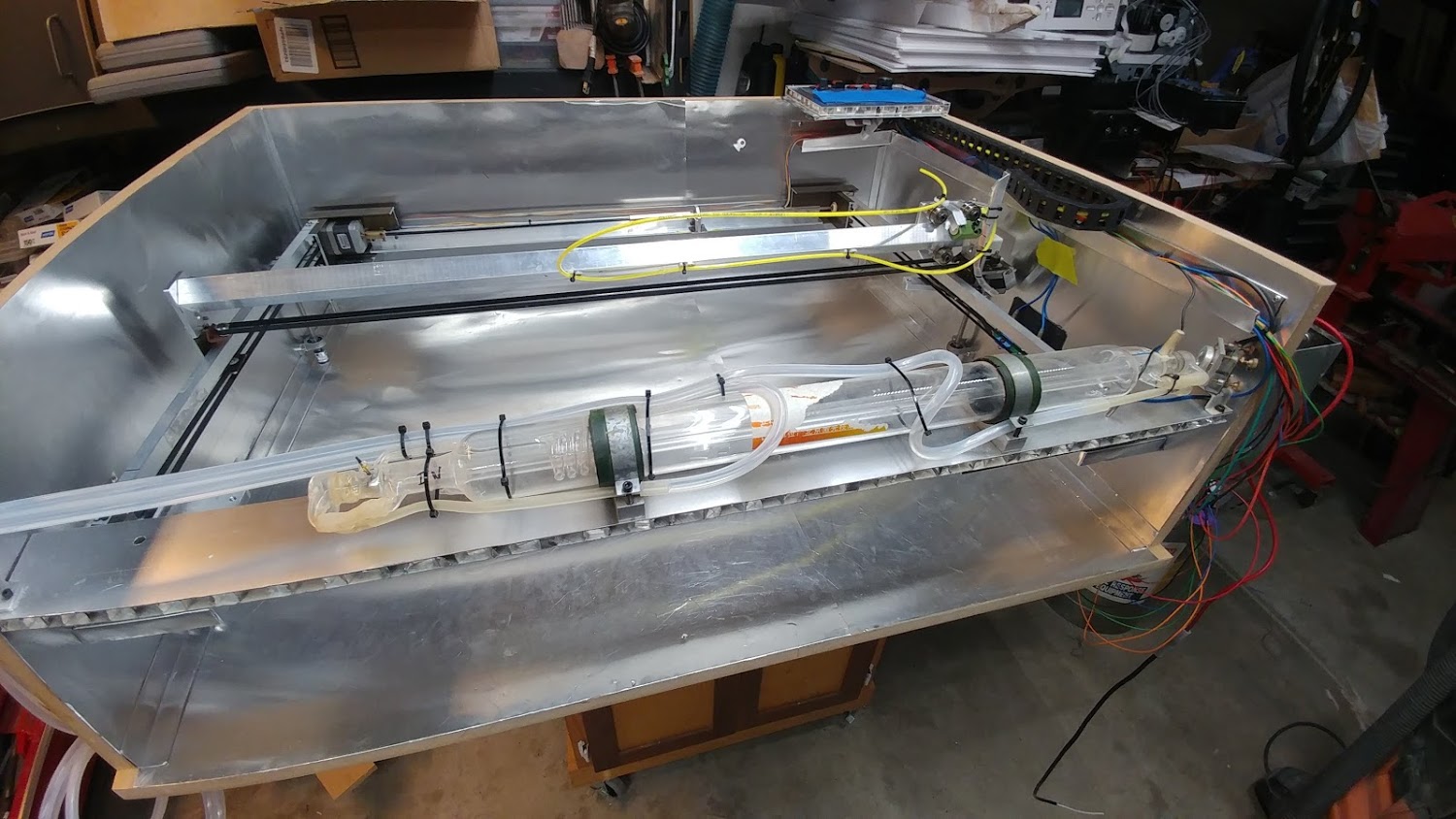

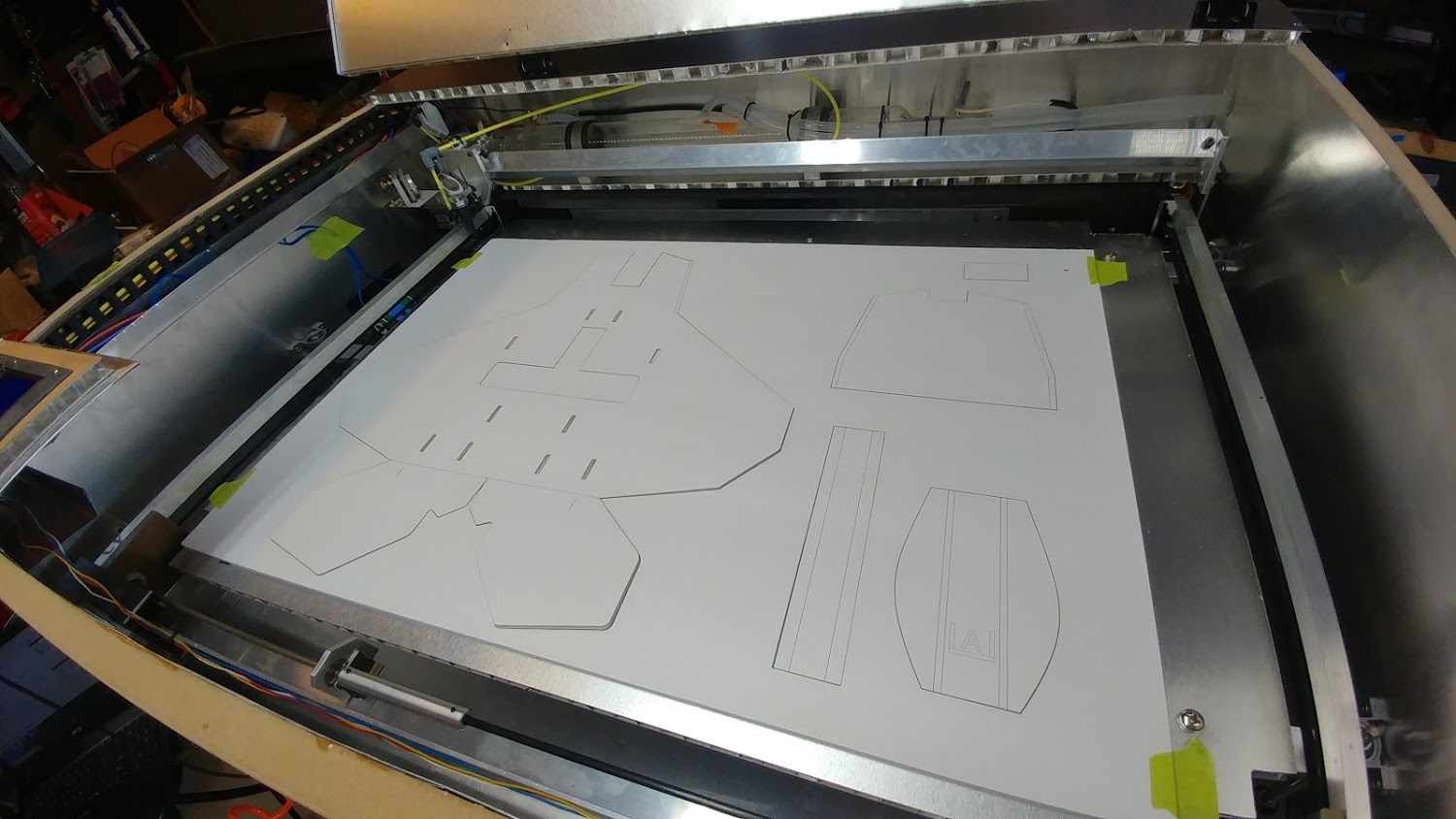

I thought I would share a few pictures of the laser build that I completed recently. When I began with flite test planes only a few months ago I knew quickly that I wanted a way to cut out my own planes from the plans that they so generously provide for each of their new releases. I have a CNC router that cuts the foam nicely with a little tiny bit, but it can only cut out a sheet up to 24x24 so the DTFB at 20x30 was a no go. I had been modifying the layout of the plans within auto-cad and Corel to get them to fit the working area of the router but it was a pain. I had a little old lightly used Asian K40 laser laying around so I decided to gut it as a donor for a much larger laser that could cut a full sheet of DTFB. I ended up with a little over 31x21" of travel so I can comfortably fit a full sheet of the foam and use every square inch of it now. I did not have any plans I just designed it in my head as I went. Most of the mechanics are from the original K40, they have just been cut apart and extended quite a bit to get the desired travel. The electronics are from Cohesion3D (amazing improvement over stock) and the software that I use to control it is called LightBurn, again a quantum leap over the corel plugin that the stock K40 relied upon. Now I have full control of laser speed and power on the fly and I can assign different cut or score or engrave strategies to each layer as I see fit. Below are about 35 pics of the build process up to the laser as it sits today. It is all done with the exception of the lifting bed that I need to get finalized, for right now it is just set for the thickness of DTFB but as I want to be able to cut other things or engrave on thicker objects it will ultimately be able to move up and down about 4 or 5 inches. Thanks for looking.