You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

nnCorsair - 2200mm BUILD

- Thread starter nerdnic

- Start date

If I have to use lead (which I try to always avoid), I use lead shot from a gun store. I figure out how much I need using ziploc baggies. Then I empty the shot into a small paper cup and squirt in some gorilla glue. Mix it all around with a BBQ skewer and grab a glove. You can then use this stuff like a putty and conform the ballast into corners and such. Inside front lip of a cowl is the perfect place to use as little ballast as possible.

I would definitely look at willsonman's approach for securing the weight. TBH I know there are some folks who use weighted spinners but I would shy away from that myself. You're increasing the rotational resistance on the motor and the P-factor by increasing the rotational mass. This thing is stupid lightweight as it is and even if Nic crams in 2-3lbs of lead shot in the nose it will still be a featherweight. Just make sure the weight is somewhere secure and cannot fall off/shift.

I'm gonna try to make it balance with just battery weight. I'll soon know if that is possible..

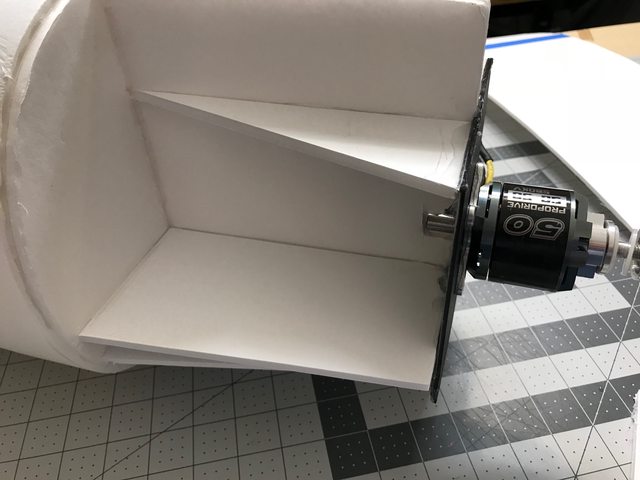

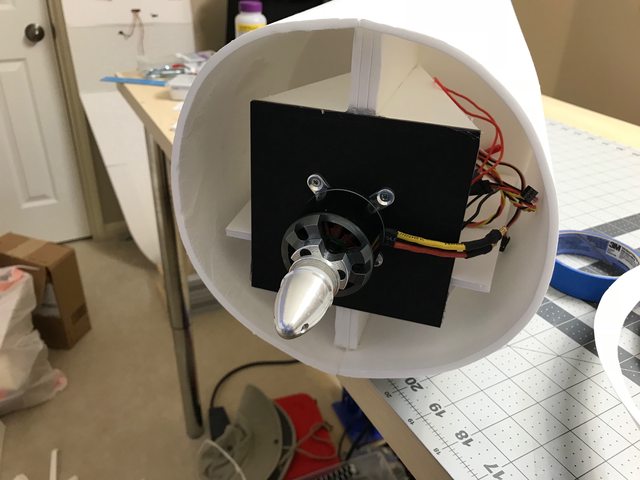

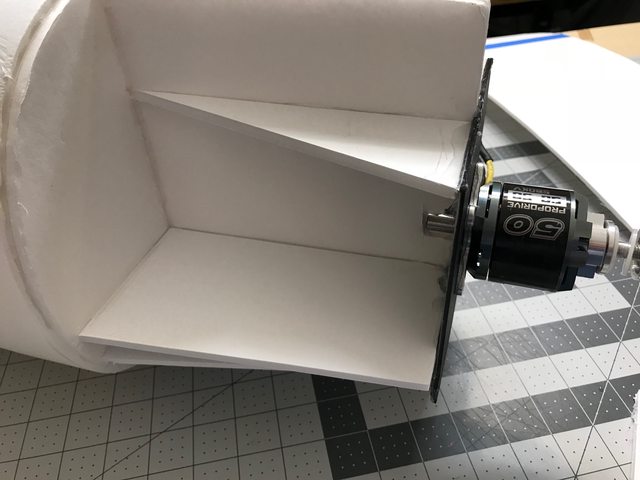

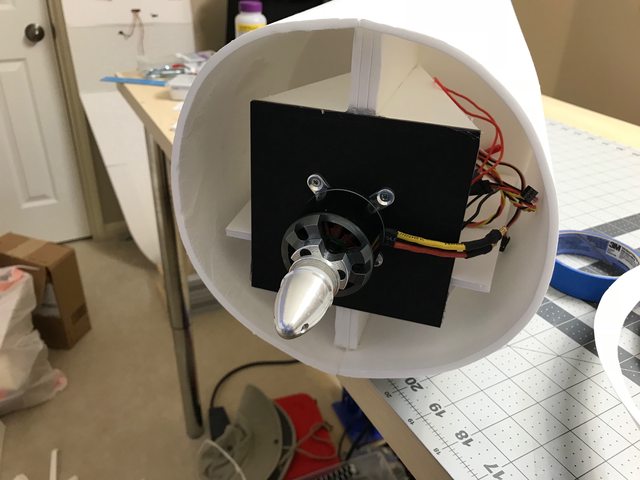

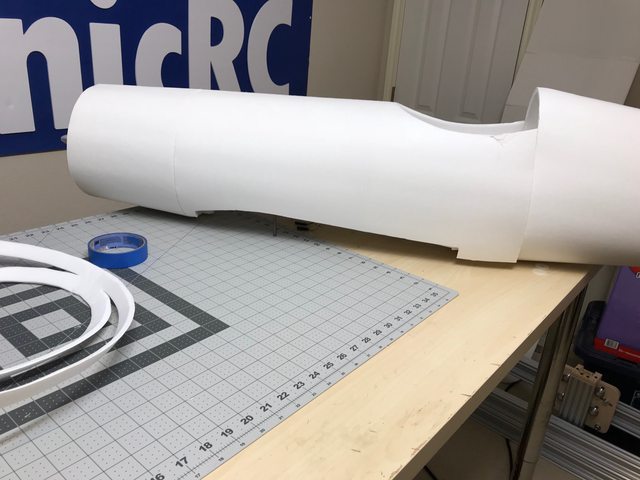

Added 1 more layer of bracing to the motor mount. This piece will also act as the battery shelf.

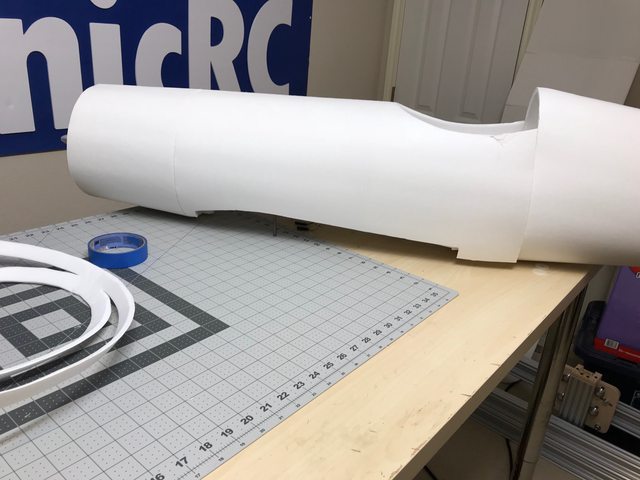

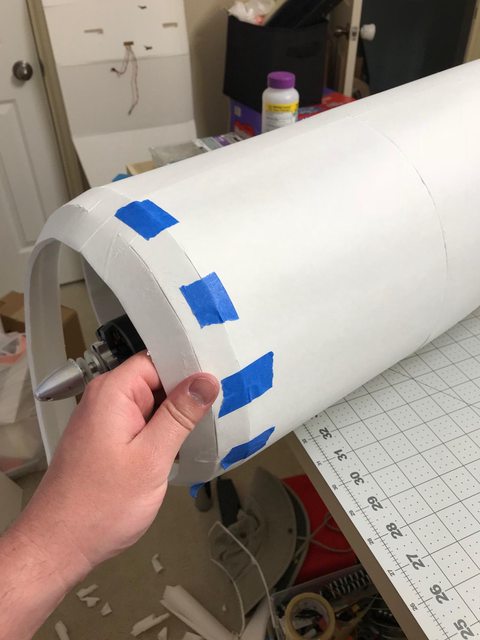

Wrapped the next layer of the nose.

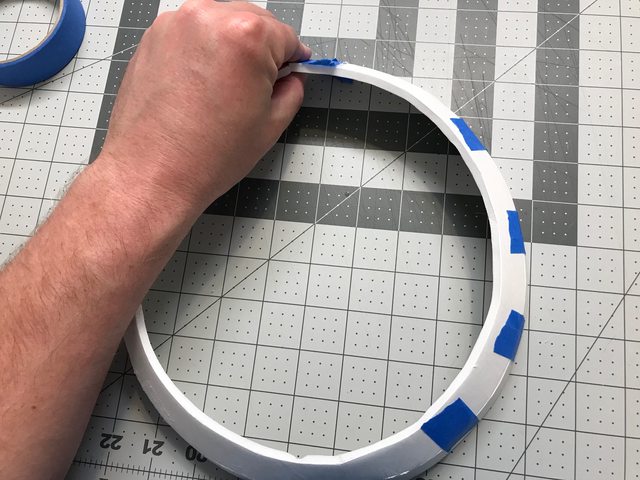

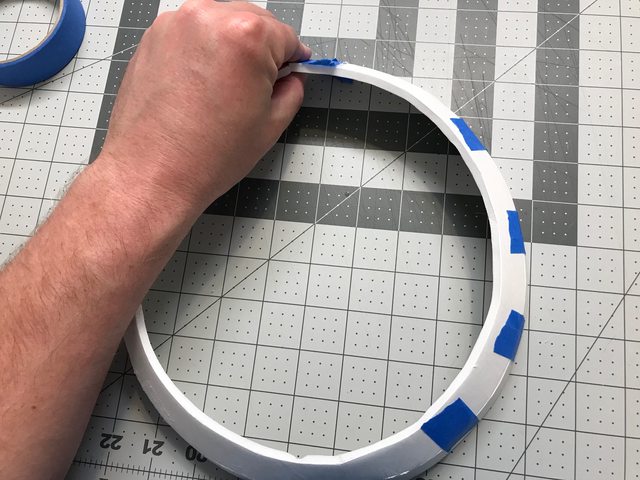

For the last bit of the nose I need to make it look as rounded as possible. I'm using some thin strips of foam with some bevels on the inside.

The pieces get bent and taped together to make a slight curve.

The tape holds the shape so I can lay down some hot glue.

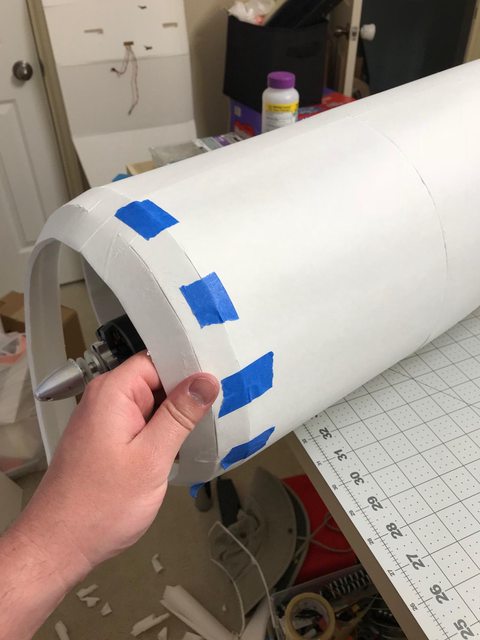

Once the curved piece dried I attached it to the fuse using the same tape method.

Was a little tricky to attach, but it came out really good I think.

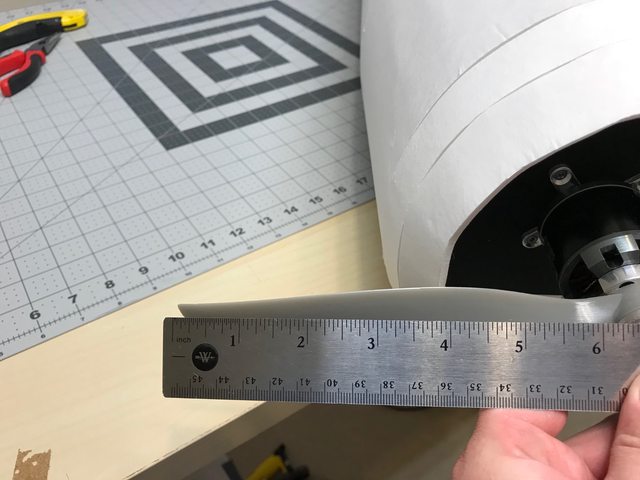

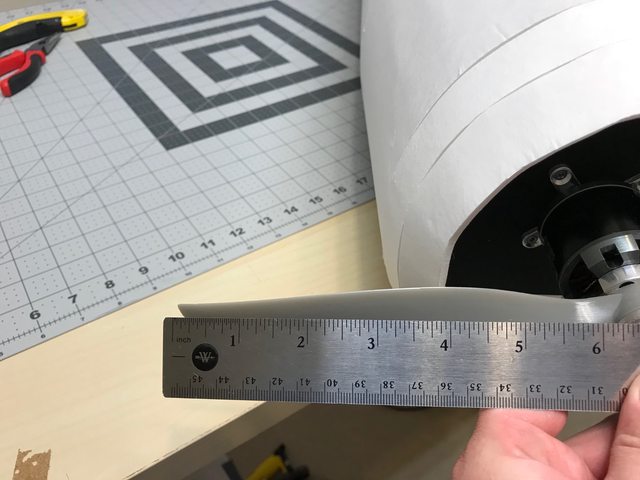

Prop clearance came out PERFECT.

Next up is the last bit of fuse skin on the tail.

Added 1 more layer of bracing to the motor mount. This piece will also act as the battery shelf.

Wrapped the next layer of the nose.

For the last bit of the nose I need to make it look as rounded as possible. I'm using some thin strips of foam with some bevels on the inside.

The pieces get bent and taped together to make a slight curve.

The tape holds the shape so I can lay down some hot glue.

Once the curved piece dried I attached it to the fuse using the same tape method.

Was a little tricky to attach, but it came out really good I think.

Prop clearance came out PERFECT.

Next up is the last bit of fuse skin on the tail.

TurtlesThatFly

Member

I’m gonna give it the ol hand launch heave-ho and hope for the best

The most epic hand launch (at your field) ever!

Christopher14

Driftin' with the wind...

Subscribed.

This is gonna be epic! I love big planes.

This is gonna be epic! I love big planes.

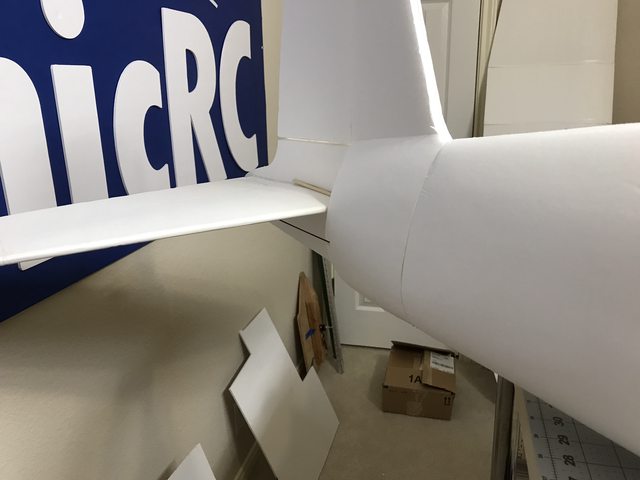

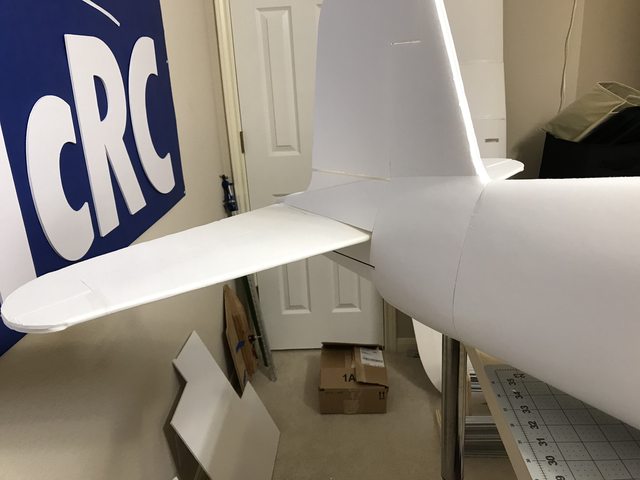

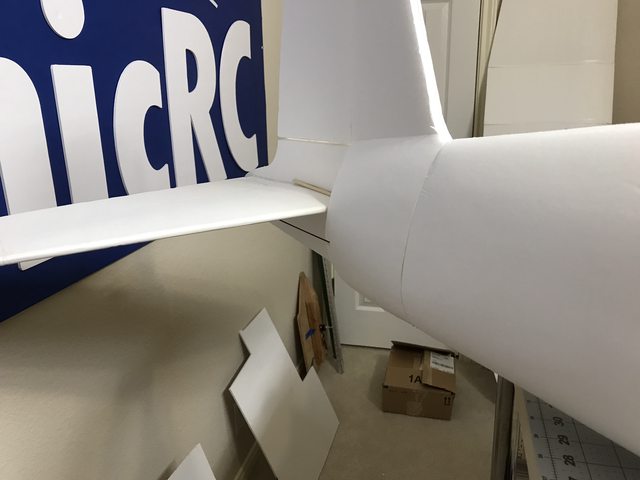

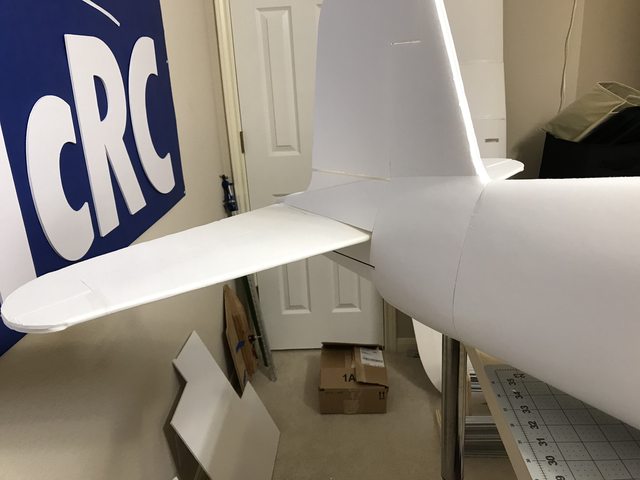

My son got a little too excited and knocked over the fuse. The hstab hit the ground and tweaked the fuse right under the rudder hinge line.

I added some BBQ skewers to stiffen it up and that worked really well. You can see it here along with the next tail panel installed. I cut a little notch to allow the push rode to glide smoothly.

The last top piece had to be adjusted quite a bit, but it went on clean.

I added some BBQ skewers to stiffen it up and that worked really well. You can see it here along with the next tail panel installed. I cut a little notch to allow the push rode to glide smoothly.

The last top piece had to be adjusted quite a bit, but it went on clean.

ClearSkiesCalmWinds

Active member

Looking good!!!

Kunphushun

Member

Nicely done!

Similar threads

- Replies

- 0

- Views

- 148

- Replies

- 0

- Views

- 598

- Replies

- 11

- Views

- 470